The interaction between wear

and polish on Swedish roads ?

Paper prepared for presentation at the lst World Conference

on Highway Surfacing, May 11-13, 1998, Budapest, Hungary

Peet Höbeda and Torbjörn Jacobson

Swedish National Road and

'Transport Research Institute

VTI särtryck 284 - 1998

The interaction between wear

and polish on Swedish roads

Paper prepared for presentation at the lst World Conference

on Highway Surfacing, May 11 13, 1998, Budapest, Hungary

Peet Höbeda and Torbjörn Jacobson

Swedisiä

Mä

The interaction between wear and polish on Swedish roads

Peet Höbeda and Torbjörn Jacobson, Sweden, Swedish National Road and

Transport Institute, Linköping

Abstract

The polishing properties of aggregate have until now not been considered in

Sweden, as in the rest of the Nordic countries. In the wintertime wear of studded

tyres has roughened up the aggregate surfaces and thus provided the microtexture

necessary. Also, the most polish susceptible aggregates as limestones etc. have not

been used.

However, in the last few years, the wear of studs on road surfacings has been

reduced because very hard aggregates as porphyry and quartzite have come in use,

most often also in stone mastic asphalt that has a high amount of coarse aggregate.

Another development has been that at present only light weight studs, with a

reduced wearing action, are allowed to be marketed.

The reduced wear has in recent time resulted in poor skid resistance, in wet

conditions especially in locations as sharp bends, round abouts, etc. The

microtexture of the aggregate surfaces is poor and this is especially the case with

porphyry which is extremely hard.

The special Swedish conditions, with wear of studs wintertime, hinders experience

from other countries to be utilised in a full extent. Investigations have recently

begun at VTI, both laboratory work, experiments in road simulator and skid

resistance measurements on experimental sections. Preliminary results are

presented and means to improve the skid resistance to an acceptable level and

especially avoiding dangerous black spots are discussed.

1(10)

The interaction between wear and polish on Swedish roads

_

P. Höbeda and T. Jacobson, Swedish Road and Transport Research Institute (VTI)

IntroductionThe wearing of road surfaces, especially by studded tyres, means loss of material, primarily mineral fragments. Polishing, however, can in principle occur without any material loss because of surficial micro-plastic deformation when a more or less amorphous Beilby layer (Beilby 1921) is formed on polishable mineral surfaces. Variable traffic stresses on roads mean that there is always an interaction between wear and polishing.

The polishing of road surfacing aggregates has until now not been considered a problem in Sweden because the roughening effect of studded tyres in winter has provided both the macro- and microtexture necessary for good skid resistance in wet conditions. Moreover the varying mineral compositions of the eruptive and metamorphic aggregates used has meant that they have not been very susceptible to polishing.

According to the Swedish Road Administration (SRA 1994), the skid-resistance value for a newly laid road surfacing must not been less than 0.5, when measured at 70 km/h and using an optimum slip of 17% as an average value of 20 m. The SAAB Friction Tester used to assess skid resistance is equipped with a specified treaded tyre and the thickness of the water film during measurement is 0.5 mm (SRA 1990). No specification exists for macrotexture because of the wearing off of the bituminous mortar by studded tyres in the winter.

For natural aggregates such as those used in Sweden, a high resistance to polishing also means a lower resistance to wear (Höbeda 1997). Consequently the wearing of road surfacings by studded tyres has been the major concern and research on bituminous mixes has focused much on wear resistance. Aggregates have been tested for their wear resistance and not for their polishing properties. In Sweden, premium wear resistant coarse aggregates such as porphyries and quartzites are transported hundreds of kilometres for use in surfacings on major roads and streets. By contrast, in the UK premium or high specification aggregates are considered to be those with a PSV (Polished Stone Value) of at least 58 (Thompson 1993) and wear resistance is not the favoured property.

The introduction of stone mastic asphalt (SMA, with 16 mm or later mostly l 1 mm maximum aggregate size) has permitted the use of surfacings with a high content of wear-resistant aggregates. This has become the most favoured type of bituminous mix on major roads and streets. It provides a good macrotexture, especially in combination with studded tyre wear, but the microtexture of the surfacing depends on the state of the aggregate surfaces. As studded tyres ef ciently remove the mortar between the coarse aggregate particles, the fine aggregate in the bituminous mortar has little or no effect on skid resistance. Over the past few years, only tyres with light weight studs with a reduced wearing action (Gustafson 1992) have been allowed on the Swedish market. The combined effect of all these developments has been to decrease the wear caused by studded tyres by almost an order of magnitude (Jacobson 1997).

Measurements of skid resistance

Attention was drawn to possible problems with poor skid resistance ascribable to polishing by several accidents that occurred in the Eugenia road tunnel in Stockholm in the late autumn of 1996. This tunnel, which forms part of road E4 (the major north south artery in Sweden) runs in a bend and vehicles often brake before entering it.

The Road Administration, Region Stockholm, commissioned VTI to investigate skid resistance properties in the Eugenia tunnel and some other possible black-spots in Stockholm. The SAAB Friction Tester was used for this investigation (Jacobson and Höbeda 1997). The bituminous mix in the tunnel was an SMA 16 with porphyry aggregate. The first measurement showed lower skid resistance than is permitted for new surfacings (Figure la). The surface was then cleaned using pressurised water, and the skid resistance declined still further, possibly because of a wetting action.

The surfacing in the tunnel was then mildly milled and soon after that (from lst November) studded tyres were permitted. Figure la and especially lb show that milling gives higher, skid resistance. Figure lb shows that the polishing occurs just outside the tunnel where the vehicles brake. (It would have been interesting to have taken

measurements using a locked wheel, to better simulate the effect of sudden braking).

It was found that in Stockholm surfacings with porphyry tended to have lower skid resistance than those with quartzite because of petrological differences that can be seen in a scanning electronic microscope (Höbeda 1997). Quartzite wears to a better microtexture than porphyry, because the latter is dominated by an extremely fine mineral

1(10)

The interaction between wear and polish on Swedish roads

P. Höbeda and T. Jacobson, Swedish National Road and Transport Research Institute (VTI)

IntroductionThe wearing of road surfaces, especially by studded tyres, means loss of material, primarily mineral fragments. Polishing, however, can in principle occur without any material loss because of surficial micro-plastic deformation when a more or less amorphous Beilby layer (Beilby 1921) is formed on polishable mineral surfaces. Variable traffic stresses on roads mean that there is always an interaction between wear and polishing.

The polishing of road surfacing aggregates has until now not been considered a problem in Sweden because the roughening effect of studded tyres in winter has provided both the macro- and microtexture necessary for good skid resistance in wet conditions. Moreover the varying mineral compositions of the eruptive and metamorphic aggregates used has meant that they have not been very susceptible to polishing.

According to the Swedish National Road Administration (SNRA 1994), the skid-resistance value for a newly laid road surfacing must not be less than 0.5, when measured at 70 km/h and using an optimum slip of 17% as an average value of 20 m. The SAAB Friction Tester used to assess skid resistance is equipped with a specified treaded tyre and the thickness of the water film during measurement is 0.5 mm (SNRA 1990). No specification exists for macrotexture because of the wearing off of the bituminous mortar by studded tyres in the winter.

For natural aggregates such as those used in Sweden, a high resistance to polishing also means a lower resistance to wear (Höbeda 1997). Consequently the wearing of road surfacings by studded tyres has been the major concern and research on bituminous mixes has focused much on wear resistance. Aggregates have been tested for their wear resistance and not for their polishing properties. In Sweden, premium wear resistant coarse aggregates such as porphyries and quartzites are transported hundreds of kilometres for use in surfacings on major roads and streets. By contrast, in the UK premium or high specification aggregates are considered to be those with a PSV (Polished Stone Value) of at least 58 (Thompson 1993) and wear resistance is not the favoured property.

The introduction of stone mastic asphalt (SMA, with 16 mm or later mostly 11 mm maximum aggregate size) has permitted the use of surfacings with a high content of wear resistant aggregates. This has become the most favoured type of bituminous mix on major roads and streets. It provides a good macrotexture, especially in combination with studded tyre wear, but the microtexture of the surfacing depends on the state of the aggregate surfaces. As studded tyres efficiently remove the mortar between the coarse aggregate particles, the fine aggregate in the bituminous mortar has little or no effect on skid resistance. Over the past few years, only tyres with light weight studs with a reduced wearing

action (Gustafson 1992) have been allowed on the Swedish market. The combined effect of all these developments has

been to decrease the wear caused by studded tyres by almost an order of magnitude (Jacobson 1997).

Measurements of skid resistance

Attention was drawn to possible problems with poor skid resistance ascribable to polishing by several accidents that

occurred in the Eugenia road tunnel in Stockholm in the late autumn of 1996. This tunnel, which forms part of road E4

(the major north south artery in Sweden) runs in a bend and vehicles often brake before entering it.

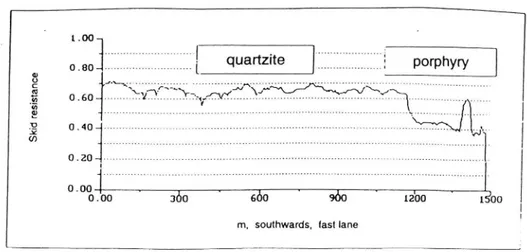

The Road Administration, Region Stockholm, commissioned VTI to investigate skid resistance properties in the Eugenia tunnel and some other possible black-spots in Stockholm. The SAAB Friction Tester was used for this investigation (Jacobson and Hobeda 1997). The bituminous mix in the tunnel was an SMA 16 with porphyry aggregate. The first measurement showed lower skid resistance than is permitted for new surfacings (Figure la). The surface was then cleaned using pressurised water, and the skid resistance declined still further, possibly because of a wetting action.

The surfacing in the tunnel was then mildly milled and soon after that (from lst November) studded tyres were permitted. Figure la and especially lb show that milling gives higher, skid resistance. Figure lb shows that the polishing occurs just outside the tunnel where the vehicles brake. (It would have been interesting to have taken

measurements using a locked wheel, to better simulate the effect of sudden braking).

It was found that in Stockholm surfacings with porphyry tended to have lower skid resistance than those with quartzite because of petrological differences that can be seen in a scanning electronic microscope (Höbeda 1997). Quartzite wears to a better microtexture than porphyry, because the latter is dominated by an extremely fine mineral size. Differences in skid resistance can be seen in another road tunnel in Stockholm (the Sodertunneln) where both

'2(10)

porphyry short section and quartzite are found in SMA surfacings (Figure 2a). However, because the tunnel runs straight, no black-spot is formed. Conditions in bends, where polishing is most intense, are especially critical (Hosking and Tubey 1974). In Göteborg, only quartzite aggregate is used and skid resistance in general was found to be somewhat higher than in Stockholm, where porphyry is favoured (Jacobson and Höbeda 1997).The results from measurements made in Stockholm in 1997 are shown in Figure 2b. It can be seen that the surface

was quite skid resistant during the winter, but that polishing obviously occurs in summer. It is also apparent that surfacings with porphyry aggregate tend to be less skid resistant. Measurements were also made later in autumn 1997 on

rural stretches of road E4 from Linköping north to Härnösand, a distance of about 600 km. Only SMAs with porphyry

and quartzite were found, and the skid resistance was at a suf ciently high level despite traf c polishing in summer (friction values O.6 O.8). It is dif cult to see the difference between surfacings with porphyry and quartzite observed inStockholm.

The results of the eld measurements of skid resistance prompted the Swedish Road Administration to commission further investigations in the laboratory and using VTI s road simulator.

i

l

. . Before and In tunnel fter

Before msrde In tunnel In tunnel a ' - ft sh' ft mlll' after tunnel. milling and

0's after tunnel a erwa mg a er mg stud studgramc

Oct-96 Oct-96 Oct-96 Nov-96 Nov-96 77 7 % 30,6 %%% %%% %%

&,

.,,

,,

%%%%

%%%%

%%%%

%%%%

%%

%%

z

x0.4

%%

%%%

%%

% %%%% %%%% %%

%%%%

%%%%

%%

co

%%%

%%%

%%%%

%%%%

%%

,%%

%%%

%%c%f%

%%%%

%%

%%%

%%%

%%%%

%%%%

%%

%%%

%%%

%%%%

%%%

%%

%%%

%%%

%%%%

%%%%

%%

%%% %%%/% %%% %,%%%% %% %%%/% %%% %%% %%%/% %% Km K2n Kts Kin K2n K1: K2: Ktn K2n Kl: KZs Ktn Kln Kls Kts Kin Ktslane, K1=slow, K2=fast, s=south, n=north

Results (mean values) from skid-resistance measurements in the Eugenia road tunnel, October and Figur la November 1996. d) 0 C £9 .9(I) 93 9 x (1) 0.00 . . _ . . 0.00 150 230 aéo 450 260 m. northwards . . . . , . . I

Ftgure 1b Effect of mzllmg on the sktd reszstance measurements (mean values) Ul the Eugenia road tunnel (29 November 1996).

X 1.00

0.302ffffffff f f fff!

quartzite Jfffffffff f ff?

porphyry

|

Sk id re si stan cem, southwards, fast lane

Skid resistance in the Söder road tunnel on SMA, surfacing with porphyry and quartzite aggregate, Figur 2a 29th November 1996. 0.90 ' 0 ' mmm +$6d. KI:.kv 0.85 °*'°86d.K .po - -x - warm. 0.80 . _K mxzxoo 0.75 _ _l ... . - _ _ % > _ +mmm 8 0-70 , _ Q quartzite & xxx .; _ . _ \ Q ä ). 5 0.65 - - _..xxx _ . __..R i _ . _ xx ... E \\:~ __ . _ .

cf) 0.60 -

_ x_n..-

__

ä: E

0.55 "' A \\:\ . . ~ \ 0,50 '_ A c . . x ' ' 1... 0,45 _, - -- * 0.40 . o så _ $ 8: _ 4 ti _ : ' g , .. .. g&

s

s

å

s

%

&

s

é

&:

a

§

s

é

&

s

&

$

$

E

&

& J

$

Figure 2b Development of skid resistance during the year I 997 showing effects ofpolishing and wear. Polished Stone Values (PSVs) for selected Swedish aggregates

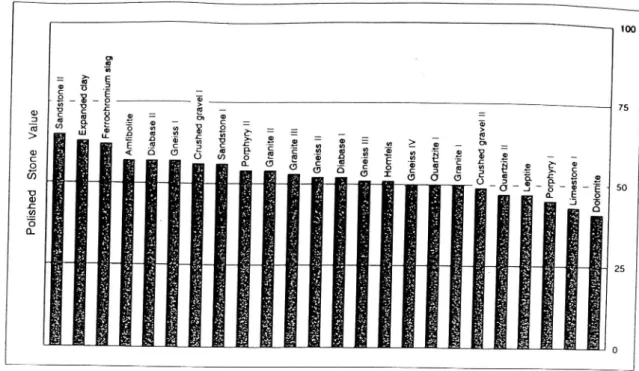

The microtexture of aggregate surfaces has to be measured indirectly, most commonly using the PSV, prEN 1097 8. In this test, the polishing action of traf c on aggregate is simulated in a laboratory. A UK laboratory has extensive experience with such tests, and so samples of Swedish aggregates already available at VTI were sent there. Besides natural premium , some local aggregates with rather poor wear resistance were also tested. For comparative purposes, the test samples also included two carbonate aggregates, used in some Baltic states though not in Sweden; a poorly cemented sandstone; a ferrochromium slag, at present not used for road surfacings in Sweden; and an expanded clay, sometimes used abroad in skid resistant surfacings (Thessoneau and Serfass 1996).

The results are presented in Figure 3. As expected, the two carbonate aggregates have low PSV results, but the homogenous, wear-resistant porphyries and quartzites also have rather low values. Porphyry rich crushed gravel gives a better result than crushed rock porphyry aggregate. However, as the particles are measured on their attest surfaces, the test does not take the sharpness of the edges of hard particles into account. Lower PSVs than expected were obtained for a few local materials that are quite heterogeneous and sometimes rich in mica.

4r|m

_. > E 0 _ 3 C 0 - _ .. Q _. 8 _ o 0.) v) 0 t- > X Q) UC C(6 £8 0 __ 9c» 0 _ 75 _3. U)(U aK t =__ 0 Oc: _ d)

(6

... .. s :e s 8 » b = _:

%

> '.'4. .: (L -- ._ C 0) > m __ _ ___ _ *-;>. .. »- D t» q) U c :. q; 0 _. ,, > 0. ., .»..., . e».».-,. . .,,.>.* E -m c 8 a:c e- "E '_'C.- «n _ -- 2 _ __ 0 "_ a» q) __ _,. . .. -.. ._ ( O (9 m ... 'o- 07 ... O _ _ c . _» m=- _ . o . | .. 7 -.- _ 0 ' ° * 8 ° a: a E '9 t? - c '' O ;>? \,;,~ "3; __:f ,-;,. .; ., _ . , __ O.. (9 0 C - C 0 0 G % q) g 0 a" 8 H .. -. _.g' .... j ___ f. h; .b ( :., _ . ( (9 O 0 I C 3 __ a .: >= I : .*v =- :» ». . . .: w _. c .- .: 0 o .. .. .. .-. . . - ,, . . . o 3 & ;;, .. _,,. ». __. _ _. ,' : '. .." .. '.' *-I :.,, .._. ..,._ ..,__ ,.__ _ ._., .;. _ .., __, ;.2-. .»_... ;,»_.9 ,_,_.>., - ' ,._= ..,..,. . -.__ W,.. . ,, O -_JQ O O _ _ 50 - ___ .. 0 .., _ .. . 1 , , .,. _, ...g __ ., . Uw .'..,? . _»: . ____, .._'.',.' , '_: _ )f)._ . -.-... . .._' " '.,.- ' .. '_'", ,»..,. J:'12 ",;&.., ._)»'.! __' 'n'».* ' .: .- c ..,;' \-u. "V3.:.. __;_v4 )::. ; ft'W 0. ._ öO .:. '.. '.'. ' ,. ._ - : .: .._ .- . ., . .. _. 3°.- . -, '... - w "C( ____..,&. ;.- -'__, . .,._ ..)_' -. c ..;.' - .,:?-. . ._...,.u '_, ,",:s ',.-- I >j,.n _ .'3-., ,', x»._ . u..-'-\. .-.q,-. . .»,- '. &; ... )-n,_ , f,.,;.,- ";-.,.,,. ._å'_'(.., »,"*" !_* -;';,. '. O

.. 9. , .» ;? ; x ,» . " .*' v "v ,. ' - " - .. : r. >:- *:; '~'-." I? .:;

_, .;_ o,: . ,, __ -__ ._ __, . . _ . »; .» - .. _ . .- ,'

; a; . __ 't a, .. in, i. . "V : . . - . -.* f." ") .: . -, *": ?.; ;" x'."

0 .. ; . _, r" "J, -- --; '» '. vs We .c 3g, .'> '$ . =.

0. *.:_ _ ..; ;;_ .c.,." _.&. gr. » xr A:.."~. 51. _ fl.-.. _)".u . .;._ -. ; .., .,1ll: ...7,,» ...E': _- i:,_ ::..z. k. vv; o ;,3.. . ..?. s," ; * f. "z f 5," .-._v- f.- " 73 ' . f..! ...". 3" »":- . m" c : v J -' 53 ""$" ' !.

v.-, .-. ,' .! ,.» m » __ -. . .); , . a . ..- --. '_'-' 'i' - ,./ =( -- '# "'

$". ." a;" wi *, "__,:.; 't",- ._'.': " f..). .-7.'-\ .,'-_ - ."" a. '%:! _..» => *,»;. . .,_.»: ."_. _. _'2- . .'-*.--, .. '_'"i .' ', .;" :.o "

v:;-38.. >,_f., 4.3,. ,,;.- _...x; g,"_ ,_..... _4'-_(_. ,. ;:lt , _ '.";&_ y_. . ___::; _:_ .a.... ~ 1.»...» :.,2-x. 'x*; ':';;. ..,»._-,'& _?k.a:- » v.as, »»~.: s..:» _

v . I " fl; ' AV, '.? '_' ."- " ' _ " y, x 'å' . -.' a t , "* .! '.'l ...,-' -0 ',." ' '

:::1' ; .:,y'»; I."a _, ,n;- ...?I; s?,,;9 =...*,; of;g, "m;,i"; .' _*:.-»? ="»..; , mv>.; ;. :=; ::..e :* b! ;>; _- ( f.»; f», ' ?g . > « 2 ; n , '.u L'- Ägs "uf. if." 25

:. . : . -; =.". 0. J; "* - M = **. e ': ' =*- -'~"- "3 ' » if N

av,. __... ',. . '_;e ..a t' ';"v .Q'. - '\_ O'0 'v no' ..a 'F. -4 y'' us.,' ;.A ",..: l h.' "*. ,- "I.. . :.»,, .y ?".-.33_ _Ni" "»? ?":~ .wa ' _-' ;n'- s ."*"'_': ".) fs.s J,... :* ;?.h '.' 'j_.<2 "q .?_ 7i; ,,-Å '1:" ":.;_.___4. ..,**.? '! .a. ' .:;» **fs.". ;. .?. =' >' :?:t', ,"' *; A.:i .'Ö' _a);x., ,: ).g;' ' .:;' x'Åh ;>?ac-_, «a"w';; .,?» ;).? : ::, x" A . :x". -9. ..!!-1.16; 'f' ;" .!_ . _. (.; .- fw x.-_ _.A, _. : ".: ; , t; ia.

_ ._ f, _ _ ~ . _., . _ . . . _ _ ,. __, . ,_ >, »" . ' ,

i ?"w :*.i' T';?u &' ':*""-3 "'""2-5 'ås'x' 75~' . ; :**: a»at. "=i" -'> 4..:: Ah ** '='...»-" .! 'i'.»-: ;;.'».å C;"3 ; ' 3"Jré ::.,y. Öl 'få; '..:.. » få- o .»

's .'.'6, v,,-!'f ,; 'a (,, *. r -_* "1 .. v,,. j: (N .N'." w1,-0 -'4.. .; .- a.'~'.! _ -!~ '. »"" t -; _ '.."i ' -".9' » f):. ""'P " o'!"få. '* ""':'-' " \N I;"3 -'- *?

".. _.x." H» . :* ':. ~5\ ':». = ! . 4- . . 3 ~ . w. w.- "- M. - . = -- sf. "0 -.-' 't" ~~ *"

HZ-;q, .;3, "4 s ;;» _- ,,_ ;>? "_.r. a; ._A_ us 3»; _._ , '_'; s; i _ &, :::; .- ! -':.; '.!; . != ,-,-_c'. *.»! :::

x.".a. ',.» v:. :w, m 9.».; as, v»'.' t :» » . .'.'»; a; ".:-?' * .- »»: :* 'a'..= &;r *;s' «z*" :.). &?_. :$;'#'. '?2w .-.ew "i ..,y: a * »?

.» -, '. '.. . . .- ... .. w ». =. .* .. r ; ,. ' - ! : . ~*- fw ,, "'» '.'".

___ '.. «an _'__ ___ S - . __», . K y '. z [**- S. nu. _äq .!) _ ? bh: _\..

ar; ?..g : , t a .». 't". :a. 4 . v " *:.": .- x"!. ..:3. :P.? .:» .. '_' i ' '&_ . få? . -.- o- ' "'x ..te rm

g- w. V- . .f' '!"- "**; V \ S ~ "? t' ' 3. _ N' '5 . xx -x' . .-:'. _|, .., JK. . 9

:.. t ?,.- so it»: n; vi; . :. : ?. 's: _a; ':. !. »» .» f *. :.: gs e:» s;? .. "> "= ». "r.? e.. ??:

..» -..». .. ., _._,_» m as ::.; *:; i;: t... " * s : : ;.- set ..:v ;; .';- : 9.32- - .-.. .. ... :?»;. O

Figure 3 Polished Stone Values obtained for selected Swedish natural aggregates and two synthetic aggregates.

A granite aggregate was also tested, using samples obtained before and after final processing in a vertical shaft impact mill. Such processing is often used in order to improve the wear resistance of surfacing aggregates. It can be seen that this treatment reduces the PSV a few points by rounding off particles, having a smoothing effect. This has also been shown by Bean and Pidwerebsky (1995).

The testing done so far clearly indicates that in Sweden it is very dif cult to obtain aggregates in the categories PSV68, and PSVGZ and also to some extent PSVSÖ in the prEN 13043, Aggregates for Bituminous Mixtures. If the UK high speci cation aggregate criteria (PSV>58) is applied to Swedish conditions, only some aggregates that are heterogeneous or have poor interlocking of mineral grains fulfil this criteria or are near it, besides the slag and expanded clay aggregates.

Testing in the VTI road simulator

In the past, this circular, horizontal, road simulator with a diameter of5 in has been successfully used to predict the wear of road surfacings by studded tyres. A high correlation with wear in road conditions has been obtained (Jacobson 1997). In order to gain a better understanding of the polishing process, a special investigation was carried out using standard car summer tyres. The road simulator was equipped with 4 tyres, loaded with 4.5 kN and each having an eccentric movement in the test track.

A literature survey of this type of testing of bituminous mixes revealed that many different procedures have been used in different countries. Sometimes the polishing has been carried out using only a rubber tyre or other type of rubber element. In most cases some abrasive or polishing powder has been used. Road dirt would be preferable, but is unrealistic. Skid resistance has been often measured using the British Pendulum Tester. braking the tyre in tracks specially built for skid resistance experiments, etc.

In the VTI road simulator, roller compacted test slabs (75 x 47.5 x 4 cm) are used. Because of lack of time and funding, no new bituminous mixes were manufactured for this polishing experiment but spare slabs, made for wear testing, were used. There was variation both of aggregates and of their maximum sizes in the mixes. The mix types and

aggregates used are given in table 2. Of the 25 mixes selected, 23 were of the SMA type (some of them prOprietary

mixes) and only 2 were dense asphalt concrete (AC) mixes. Many of the coarse aggregates in the mixes were wear-resistant premium porphyries or quartzites. Some less wear wear-resistant local aggregates and an electric arc furnace steel

slag (a different type of slag to that used in the PSV investigation) were also tested in SMA mixes. All test slabs were

5(10)

Consideration was given to using the British pendulum to measure skid resistance, but the instrument s lack of precision on road surfacings (also referred to in The British Pendulum Tester 1997) and the time such tests would take led to the VTI Portable Friction Tester (PFT) being used instead. It was mounted on the road simulator when measurements were performed. This instrument has mostly been used for road markings. The skid resistance is measured at slip in a similar manner to the SAAB Friction Tester, but at walking speed. A good correlation has been obtained with the British pendulum test on road markings. However, the skid resistance values obtained cannot be compared with the values before, using the special SAAB vehicle.

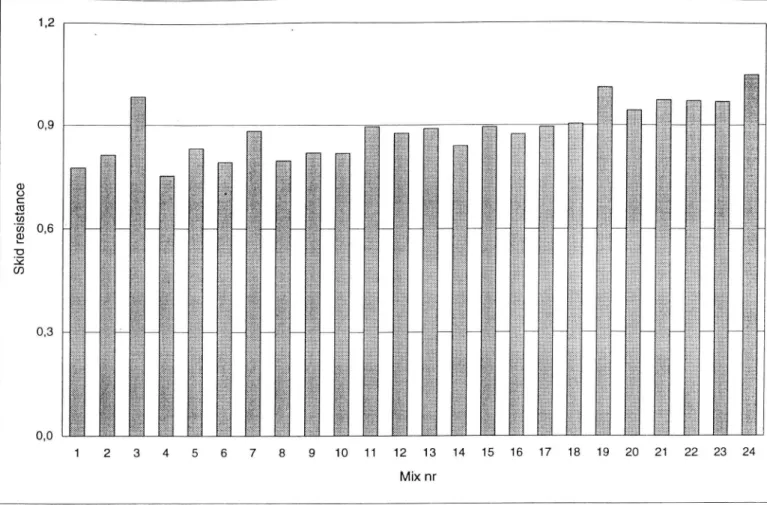

Because of a lack of experience with this type of test, the test programme was not fixed from the beginning. The nal test conditions are given in Table 1 and the results achieved (the mean values for skid resistance) in Table 2 and Figure 4. All testing was done at room temperature in wet conditions in order to prevent dusting and the build up of rubber deposits formed by the frictional heat generated. The low speed of 7 km/h was used to prevent the different sizes of polishing powders from being blown off the test track surface.

The rst skid-resistance measurement was performed on unworn surfacings and the second one after wearing off the sur cial bituminous mortar, using studded tyres for 10 000 passes (cycles 1 and 2 respectively). The level of skid resistance was high, and in most cases improved after stud wear. The only exceptions were SMAs with porphyry aggregates.

Then the polishing cycles began, first using only summer tyres at 70 km/h. The greatest decrease in skid resistance occurred during the rst 100 000 passes. Only a very small decrease is noticed between 200 000 and 300 000 passes. The nal results from polishing, using a summer tyre only, are illustrated in Figure Sa. An AC with porphyry aggregate and two SMA:s with steel slag and hornfels are the least affected mixes.

The following polishing cycle used emery grit no. 280, similar to that used in the PSV test (cycle 5-7). The skid resistance dropped and had not quite stabilized at constant levels when ner emery flour no. 400, also similar to that used in the PSV test, was introduced (cycle 8). In order to speed up the experiment, emery our no. 600 was then used with a further drop in skid resistance (cycle 9). The skid resistance measured after using these emery powders is given in Figure 5b. There is a tendency for those aggregates that performed best when using the summer tyre only to also resist later polishing with emery powders best. The development of skid resistance in relation to the number of revolutions during the whole experiment for SMAs with porphyry and steel slag aggregate is given in Figures 6a and b.

Table I Overview of the testing parameters in. the road simulator.

l i

l Cycle l Number of revolutions Type of tyre Emery powder nr ] Speed km/h J

- i - unworn surface [ 1 10 000 studded tyre x) ' 70 2 100 000 summer tyre xx) ' 70 3 100 000 summer tyre - 70 4 100 000 summer tyre - 70 5 ; 10 000 summer tyre 280 7 6 l 60 000 summer tyre 280 7 ; 7 60 000 summer tyre 280 7 l 8 i 60 000 summer tyre 400 7 ' : 9 i 60 000 summer tyre 600 7

10

f

30 ooo

studded tyre

_

ÄLJ

" Gislaved 185 ' 65 15' studded winter tyre, 1.8 g studs

u) Michelin 185 ' 65 15 summer tyre

The road simulator exerted a very efficient polishing action because of the intense lateral force exerted in the circular test track. Especially when using emery powders, there is a rapid loss of microtexture and formation of a Beilby layer on hard polish-susceptible aggregates. The level of skid resistance is lower than is the case under road conditions with much more variable stressings of the bitumen-bound surface. In fact, earlier laboratory experiments when modifying the rst-generation BS 812 PSV test, using an inclined wheel as well as a more ef cient abrasive, displayed a considerably

6(lO)

more intense polishing action than the original apparatus (Höbeda l970). The correlation between the test results was rather poor because of the great differences in microtexture obtained with some aggregates.The investigation in the road simulator had to be terminated before a final polish (a constant level of skid-resistance) has been obtained. However, it was found that the skid resistance values for most surfacings is surprisingly low. Some cores have been obtained for further studies.

Finally, the surfacings were subjected to 30 OOO passes with studded tyres. The roughening up effect of the studs is very clear (cycle lO), for the skid resistance increased to a level not far from the initial values, possibly except for the most wear resistant surfacings.

Comparing the different surfacings, the most surprising result was obtained with the steel slag (not the same type of slag as in the PSV investigation) SMA mix (no. 24), which so clearly resisted polishing action. This was already evident in the cycle using only the rubber tyre (Figures 4 and 6b) but is the only material that later shows an increase in skid resistance. It has been known that the surface of steel slag aggregate is chemically reactive and can rejuvenate itself (Emery 1983) and thus resists polishing by traffic. Zieger (l99()) has shown an increase in the PSV value when storing a polished steel slag specimen in wet conditions. In the road simulator, the surficial, fine reaction products formed in moist conditions are obviously worn away in the second polishing cycle, using the rather coarse corn emery. When a

ner emery powder was introduced, the skid resistance increased.

Steel slags are already in use as skid-resistant surfacings in some countries (Stock et al. 1997). Unfortunately, at the time of writing, the PSV of the slag is not available, but it seems likely that this laboratory test is too rapid to allow the bene cial, sur cial chemical reactions to take place. The test in road simulator has been run during a considerable long time (Table 2). Previous wear studies of the same slag mix in the road simulator have shown that it had a rather poor resistance to studded tyre wear.

There is also a risk with certain steel slags, especially of the basic oxygen furnace type, that expansion and deterioration of bituminous mixes may occur (Coomarasmy and Walzak 1995). The prEN l744 therefore contains special tests for the volume stability of steel slags.

Turning to the other aggregates, the differences in skid resistance are not great. The different mix compositions hinder direct comparisons. The best results are obtained from a comparison of a fine grained hornfels. a rather heterogeneous ne-grained rock, with the porphyries and quartzites studied. lt is difficult to nd evidence of the difference noticed between the two premium aggregates in skid-resistance tests in Stockholm (Figure 2b), There is a only a slight tendency for the few local aggregates, with rather poor wear resistance, to have a better resistance to polishing than the premium aggregates . This indicates that mixing premium and local Swedish coarse aggregates in bituminous mixes will not gain much in skid resistance.

Most of the mixes studied were SMAs. There were, however, also two ACs (no. 3 and 7) and there is a tendency for

the skid resistance of these surfacings to be somewhat better than that of stone-richer SMA surfacings using the same aggregate but the difference is quite small. No conclusions can be drawn regarding the effect of maximum particle size in the mixes (which varied from I 1 to l6 mm) as the differences are minor.

Conclusions and recommendations

Recently Sweden has experienced some local problems with poor skid resistance because of polishing of road surfacing

aggregates. Because these problems have been concentrated in locations such as sharp bends, roundabouts, etc. where

there are speed limitations, there have been no serious or fatal accidents, and therefore the polishing problem has, until now, received little attention. The skid-resistance measurements made recently, however, show that possible black spot locations must be monitored, and when necessary, surfacings with a better microtexture must be provided.

The wet skid resistance on Swedish roads in general seems to be at a satisfactorily high level and the very beneficial effect of studded tyre wear on skid resistance is clear from the study. But more studies need to be done in the future. when only light-weight studs are in use.

It is very difficult to optimise a road surface for both wear and skid resistance and compromises must therefore be found. With a highly wear-resistant surfacing, it is dif cult to provide the microtexture necessary for critical driving conditions on a wet road surface. Microtexture is particularly important at low speeds and in critical conditions (Hoskings and Tubey l974) and it is important to sometimes sacrifice wear for wet skid resistance.

7(10)

Table 2 Skid resistance during test cycles, for the different surfacings tested.

After cycle nr

Br 1 Mix type J Aggregate unwom I 1 l 2 I 3 I 4 I 5 ] 6 I 7 I 8 9 10

1 Viaootop porphyry 1,19 1,13 0,83 0,77 0,78 0,72 0,51 0,45 0,29 0,21 1,08 2 ABS 18 porphyry 1,23 1,15 0,85 0,82 0,81 0,73 0,52 0,45 0,28 0,22 1,11 3 HAB 181 22232 1,28 1,30 1,07 0,98 0,98 0,87 0,55 0,50 0,33 0,28 1,21 4 MABS 18 porphyryÄ 1,30 1,11 0,81 0,76 0,75 0,85 0,46 0,4? 0,29 0,24 1,08 5 ABS 18 333333- 1,08 1,21 0,90 0,84 0,83 0,74 0,52 0,46 0,30 0,23 1,18 8 ABS 18 $$$/522232 ' 1,09 1,18 0,85 0,77 0,79 0,70 0,48 0,44 0,28 0,21 1,14 7 MAB 121 porphyry Ä 1,01 1,27 0,95 0,88 0,88 0,81 0,58 0,49 0,32 0,25 1,18 8 HABS 11 porphyry Ä 0,95 1,19 0,85 0,78 0,80 0,89 0,51 0,48 0,30 0,22 1,29 9 HABS 11 porphyryÄ 1,02 1,22 0,87 0,81 0,82 0,72 0,51 0,45 0,30 0,22 T 10 HABS 8 porphyry Ä 1,05 1,28 0,89 0,81 0,82 0,72 0,47 0,43 0,29 0,5 1,20 11 HABS 8 quartzite K 0,98 1,29 0,98 0,91 0,90 0,77 0,48 0,44 0,28 0,20 1,29 12 HABS 11 quartzite K 1,01 1,27 0,95 0,89 0,88 0,75 0,47 0,43 0,28 0,20 1,08 13 HABS 18 quartzite K 0,95 1,28 0,97 0,90 0,89 0,77 0,48 0,48 0,28 0,21 1,19 14 HABS 18 quartzite J 1,12 1,21 0,90 0,88 0,84 0,74 0,50 0,46 0,28 0,21 1,17 15 HABS 11 quartziteJ 1,13 1,27 0,98 0,90 0,89 0,84 0,52 0,50 0,30 0,26 1,28 18 3 Viacotop quartzite 0 1,14 1,22 0,92 0,89 0,87 0,74 0,51 0,46 0,28 0,24 1,23 17 Duratop 18 quartzite 1,11 1,25 0,98 0,91 0,90 0,78 0,53 0,48 0,29 0,23 1,25 18 HABS 18 hornfels 1,10 1,22 0,97 0,90 0,90 0,82 0,83 0,55 0,40 0,38 1,24 19 HABS 8 horntets 1,20 1,32 1,10 1,02 1,01 0,93 0,85 0,81 0,44 0,41 1,34 20 HABS 18 diabase 1,17 1,28 1,04 0,94 0,94 0,85 0,82 0,57 0,41 0,38 1,28 21 HABS 18 granite 1,01 1,28 1,07 0,99 0,97 0,90 0,82 0,58 0,38 0,33 1,30 22 Stabinor 11 1 gnet'ss 1,13 1,30 1,08 0,98 0,97 0,87 0,57 0,54 0,35 0,27 1,27 23 Viaeotop11 7 gneiss 1,18 1,29 1,09 1,00 0,97 0,90 0,59 0,54 0,38 0,29 1,31 24 1 HABS 11 steel slag 1,10 1,18 1,08 1,00 1,05 0,76 0,59 0,55 0,73 0,82 1,20

Date: 22-apr 22-apr 29-apr 28-may 13-jun 01-jul 22 sep 23-sep 13-0kt 20-n0v O1-dec

1,5

_

_

_ __

_

1,2

l

| | | .

.

. | |

| |

8 0,9 __ __ _ __ __ __ __ __ __ _ __ __ __ __ __ C £9 .98

_ Eå, 0,8

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

0,3

a

_

a

-

1-0,0 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 Aggregate _ ________ __ __ _______ _#__ _ _ _ "___,9Figure 4 Skid resistance results for bituminous mixes with different aggregates, obtained in road

simulator after dt erent wear and polish cycles (parameters given in table I).

8(10)

1,2 _ 0,9 m 0 C S 32ca 0,6 Q E x (1) 0,3 0,0 | 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 ?Mix nr

:

Figure 5 a Skid resistance in the roaa simulator after polishing performed with summer tyre only.

0,9 ,, .___-,,___,___ 0,6 m O C E QU) 9 "O E (1) 0,3 0,0 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 Mix nr

Figure 5b Skid resistance in the road simulator after using emery powders no. 280, 400 and 600 in combination

#

'

9(10)

0 stud wear '

1.2

h.

_\

[

F ÅY summer tyre only ___ >

8

N

X C 0,8 ' _. o __ __s

£0.(I)x.

5;

E _CUa

\

s

å

%

'D E __ - _ U _ (% \ \x. m ;a) «3 E 0.4 \ m (_ emery __, \ nr 280 ox 0 0,0 0 100 000 200 000 300 000 400 000 500 000 600 000 Revolutions 0/0 \ *. \ \ 0 _. v l4 summer tyre only _____._>\ | . o 0 C 0,8 4a __ _ cu (75 0/ å <7) o 9 \ / 8 5

9

'~\,/

E " ' '

ac)<- 9 W "'

' me>

8sr

gE

0.4 280 ___ _ E __ 0 ,,,,,,__ 2 G) E 0) 0,0 0 100000 200000 300000 400000 500000 600000 RevolutionsFigure 6 Development of skid resistance, obtained after different cycles in. road simulator as afunction of number of revolutionsfor mixes a) SMA [() wit/1 porp/tyry and b) SMA II with steel slag aggregate.

A survey of the PSVs of some typical and some rather special aggregates has shown that it is difficult to find

aggregates with high values that at the same time have reasonable wear resistance. It is also doubtful if a PSV

characterisation is appropriate for Sweden, because of the studded tyre wear. Moreover, it is uncertain whether surfacings such as SMA, with stone to-stone contaCt, can be made from high PSV aggregates that have rather poor characteristics in other respects (Woodside and Woodward l99 l ).

At present, there seems to be no need to introduce a PSV characterisation of aggregates in Sweden. In fact, the most promising aggregate in this investigation (steel slag) probably cannot be adequately classi ed according to the PSV test.

Ibberson et al (1996) have in fact shown that steel slag can have a rather variable PSV but its performance in road

surfacing is better than indicted by their laboratory test. More investigations are needed.

The testing done in the VTI road simulator has shown that it is possible when conditions are favourable to obtain a very high degree of polish and thus poor skid resistance with typical Swedish aggregates, both in SMA and AC surfacings. Excluding the steel slag, however, the differences between mixes with different Swedish aggregates are less

10(10)

than expected. Basic aggregates tend to polish less readily, probably because they are often altered more than acid ones. Mixes of different natural aggregates in a bituminous mix obviously offer limited benefits.The polishing action in the simulator is greater than under road conditions, especially when using polishing agents such as emery powders. Studded tyres have demonstrated their efficient roughening up effect, resulting in a much better microtexture. Differences between mix types (SMA and AC) and the effect of maximum aggregate sizes are hard to find

because of the minor differences.

Acknowledgement

The authors acknowledge the funding achieved from Swedish Road Administration, Central Office in Borlänge and the Region Stockholm, specially Svante Johansson and Sven Eliasson.

References

The British Pendulum Tester. New Zealand Transit no. 27, June 1997.

Bean, D., Pidwerebsky, B; Does the polished stone value test assure skid resistance? Roads and Transport Research, vol. 3, 1995.

Beilby, G. T; Aggregation andflow ofsolids, London, Macmillan, 1921.

Coomarasmy, A, Walzak. T. L; E fects of moisture on surface chemistry of steel slag asphalt paving mixtures. Transportation Research Record 1492, 1995 .

Emery, J. J; Skid resistance requirements and predictive models for asphaltic concrete surface courses. RTAC Forum, vol. 5, no. 3, 1983.

Gustafson, K; Tests with light-weight studs in a road simulator (in Swedish with an English summary). VTI Rapport 377, 1992.

Hosking, J. R, Tubey, L. W; E ect of turning and braking on the polishing of roadstone by traf c. TRRL Suppl. Report 103UC, 1974.

Höbeda, P; The polishing and wear characteristics ofsurfacing aggregate (in Swedish), Swedish Road Institute Report 101, 1970.

Höbeda, P; Polishing of aggregates in road surfacings and the in uence on. skid resistance: a state of the art report considering Swedish conditions (in Swedish, with an English summary). VTI notat 18 1997.

Ibberson, C. M. et al.; The performance of steel slag aggregates: Skidding resistance. The Asphalt Yearbook 1996. Jacobson, T; The wear resistance of bituminous mixes to studded tyres: Swedish experience (in English), VTI Notat no.

30 1997.

Jacobson, T, Höbeda, P; Polishing of road surfacing: skid resistance measurements in autumn 1996 (in Swedish). VTI Notat no. 11 1997.

PrEN 1097 8. Determination of the polished stone value. Draft December 1997.

prEN 1744. Tests for chemical properties of aggregates Part I . Chemical analysis. Final Draft October 1997.

prEN 13043. Aggregates for bituminous mixtures and surface dressings for roads, airfields and other tra/ficated areas. Draft September 1997.

Stock, A. F. M ; Skidding characteristics of pavement surfaces incorporating steel slag aggregates. Transportation Research Record 1545, 1997.

Swedish Road Administration. Functional properties. Measurement of skid resistance on road surfacing (in Swedish). Method no. 10: 1990.

Swedish Road Administration, VÄG 94 (Technical guidelines for road construction. In Swedish), 1994.

Thessoneau, H., Serfass, J.-P.; Light aggregate asphalt concrete for improved skid resistance. Eurasphalt & Eurobitume Congress, Paper 7.183 (in French with an English summary), 1996.

Thompson, A. F. et. al. High specification aggregatesfor Britain s roads. Highways and Transportation, October 1993.

Woodside, A. R. , Woodward, W. D. H. Deteroration of road surfacings. PTRC 19th Summer Annual Meeting,

University of Sussex, Sept. 1991.

Zieger, M; Application of Austrian slag material to road construction (in German with an English summary). Proceedings of the East West European Road Conference, Vol. 2. Warshaw 1990.