Managerial Challenges of

Implementing Industry 4.0

MASTER THESIS WITHIN: General Management NUMBER OF CREDITS: 15 ECTS

PROGRAMME OF STUDY: Engineering Management AUTHOR: Jennifer Lucke, Jonas Stegmüller

Master Thesis in General Management

Title: Managerial Challenges of Implementing Industry 4.0 Authors: Jennifer Lucke, Jonas StegmüllerSupervisor: Jonas Dahlqvist

Date: 2020-05-18

Key terms: Industry 4.0, Implementation, Managerial Challenges, Organisational Framework

Abstract

Background: Advances in new technologies like the Internet of Things, Big Data, and Cloud Computing are opening up new possibilities for manufacturing firms. The extent of these changes is expected to be far-reaching leading researchers to proclaim the fourth industrial revolution a priori. Within this development, Industry 4.0 presents the concept of how manufacturing firms want to meet these changes and benefit from newly created possibilities. However, while the technological aspects leading the introduction of Industry 4.0 have been subject to many studies, the managerial aspects on how to lead such an implementation have so far mostly been neglected.

Purpose: The purpose of this paper is to investigate the managerial challenges that companies might face when implementing Industry 4.0 and to draw conclusions on how they could be met. Method: Our empirical study included a range of qualitative methods. After following a sampling strategy, semi-structured interviews were conducted with researchers, consultants, and plant managers located in Western countries. All collected data were transcribed, open coded and analysed using grounded analysis.

Conclusions: While managing people to welcome and embrace new processes as well as leading projects in general has been described in the literature concerning change and project management to some extent, we broaden this knowledge by providing a new Industry 4.0 related perspective and describe possible adaptations to meet the special characteristics of the concept. Further, we elaborated on how the right mindset of top management can influence implementation efforts. On top of the managerial issues described, we added an organisational perspective to the knowledge in the field, making first attempts at describing how a structural framework supporting the implementation could look like. Finally, we investigate how current ways of working might be affected by the implementation of Industry 4.0 and how these might change.

Table of Contents

1 Introduction ... 1

1.1 Background – The Path Towards the Fourth Industrial Revolution ... 1

1.2 Problem ... 3

1.3 Purpose... 3

2 Theoretical Frame of Reference ... 5

2.1 Explanation of the Literature Review Process ... 5

2.2 The Concept “Industry 4.0” ... 6

2.3 Technologies Enabling Industry 4.0 ... 8

2.4 Previous Studies of Industry 4.0 With a Non-technical Focus ... 10

2.5 Change Management at the Intersection of Industry 4.0 ... 11

2.6 Research Model ... 12

3 Method ... 14

3.1 Philosophical Assumptions ... 14

3.2 Research Approach ... 15

3.3 Research Strategy and Methodology ... 15

3.4 Sampling Strategy ... 15

3.5 Data Collection Technique ... 16

3.6 Data Analysis ... 17

3.7 Trustworthiness ... 18

3.8 Ethical Considerations ... 20

4 Empirical Results ... 22

4.1 Interviews With Researchers ... 22

4.2 Interviews With Consultants ... 25

4.3 Interviews With Plant Managers ... 28

5 Analysis ... 31

5.1 Managing People to Welcome Industry 4.0 ... 31

5.2 Adapting Project Management to Industry 4.0 ... 33

5.3 Inheriting the Right Mindset ... 34

5.4 Defining an Organisational Framework ... 35

5.5 Defining New Ways of Working ... 36

6 Conclusions ... 38

7 Discussion ... 40

7.1 Contribution ... 40

7.2 Managerial Implications... 41

7.3 Limitations ... 41

7.4 Suggestions for Future Research ... 43

8 References ... 44

Table of figures

Figure 2.1: Research model... 12

Figure 3.1: Sampling strategy acc. to Robinson (2014) ... 16

Figure 3.2: Interview schedule ... 17

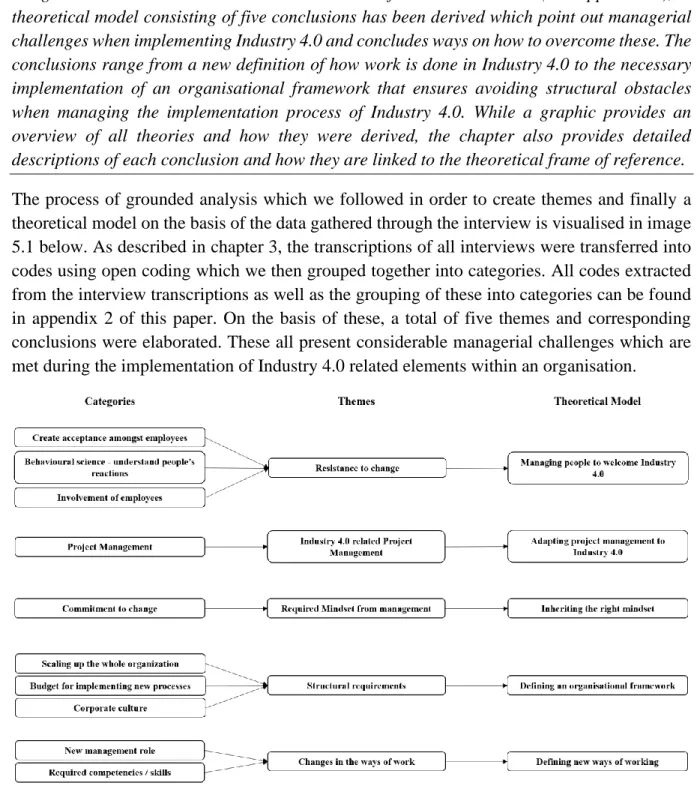

Figure 5.1: Categories, themes, and theories built through grounded analysis ... 31

Table of tables

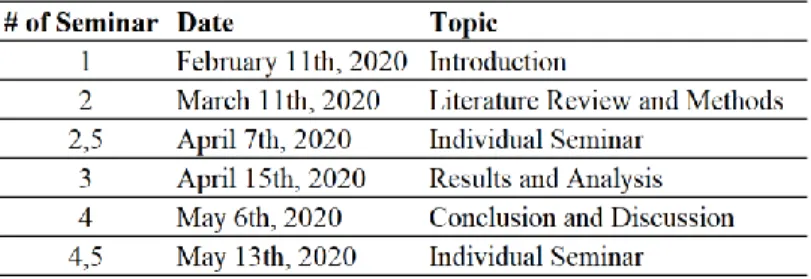

Table 2.1: Result of the literature review process ... 6Table 3.1: Timetable and topics of the feedback seminars ... 19

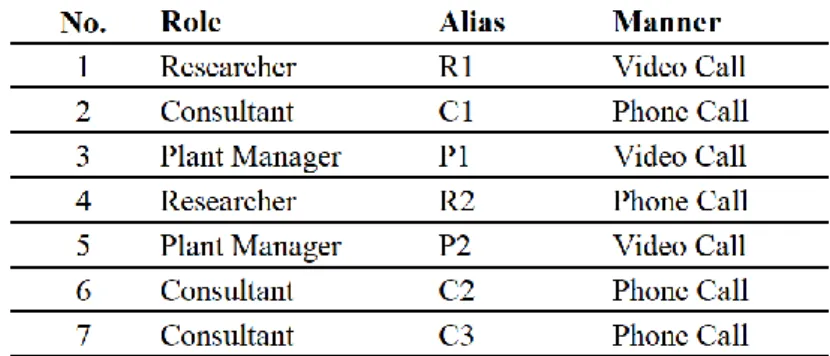

Table 4.1: Overview of conducted interviews ... 22

List of abbreviations

RFID – Radio Frequency Identification CPS – Cyber Physical System

AI – Artificial Intelligence IoT – Internet of Things

IIoT – Industrial Internet of Things

PWC – PricewaterhouseCoopers (Management Consultancy) BCG – Boston Consulting Group (Management Consultancy) US – United States of America

1 Introduction

The following chapter is providing the reader with an introduction to the topic of this paper. By guiding the reader through the industrial revolutions of past times and finally leading towards today's changes and the concept of Industry 4.0, a holistic picture of the context of this study is given. Furthermore, an explanation of the understanding of the term Industry 4.0 within this paper is presented. The problem description outlines the areas of previous research and defines the area of investigation in this study, which is concerned with providing a managerial perspective on the topic of successfully implementing Industry 4.0. Lastly, the purpose as well as the research question of this paper are outlined and described.

1.1 Background – The Path Towards the Fourth Industrial Revolution

Change is the new constant (Legris, Ingham, & Collerette, 2003). This is not only applicable for everyone's daily life but also for companies all around the world today, as well as for companies back in the early 17th century (Ayres, Ayres, & Warr, 2003). The manufacturing of goods was a procedure characterised solely by manual labour. This changed dramatically when the steam engine got introduced at the end of the 18th century (Andreoni & Scazzieri, 2014) which led to many manual activities being supported by the power of the steam engine (Hopkins, 1982). This time period is now referred to as the first industrial revolution and marks a milestone after which the working and living conditions improved significantly (Matthias, 2013).

The second industrial revolution is characterised by the famous quote from Henry Ford: "Any customer can have a car painted any colour that he wants so long as it is black" (Ford & Crowther, 2002, p. 31). After the demand for Ford’s Model T grew to a number which current production systems could not cope with anymore, a new approach had to be developed. Line production was introduced (Laird & Sherratt, 2010). With this radical innovation, productivity grew immensely, and massive cost savings could be realised (Alizon, Shooter, & Simpson, 2009).

Roughly 70 years later the introduction of microprocessors and computers in producing companies marked the third industrial revolution, also known as digital revolution (Rayna & Striukova, 2016). With the help of these devices, companies were able to monitor, process and use data that were intangible for previous generations (Lucas & Goh, 2009).

While many companies are still focussing on mass production and increased productivity by standardising products and services to the maximum, recent studies have shown that people nowadays more and more strive for individualisation and customisation rather than standardisation (Pil & Holweg, 2004). For companies, this translates into complex challenges which compel the production lines to be able to cope with these diverse demands. The root cause of the complexity lies in smaller lot sizes due to customisation which generally speaking means a drawback on the efficiency and productivity of manufacturing lines (Kiel, Muller, Arnold, & Voigt, 2017).

This is where the concept ‘Industry 4.0’, first introduced by the German Government, has its origin. By using effective data management and smart technologies it aims to enable the production of small lot sizes with customer specific solutions while maintaining the increased efficiency of mass production lines (Brendle, Stamm, Sibold, & Vogel, 2016). ‘Smart Technology’ refers to the concept of a complete integration of devises which are able to communicate to form a collaborative system (Kang et al., 2016). This can be seen in a pilot project in Germany which illustrates the possibilities of Industry 4.0: a chemical company offers to create entirely customised soaps and shampoos in which every bottle has the potential of being unique, and the only human interaction comes from the customer placing an order online. The production line itself is autonomous and does not require humans to manage the processes (Wang, Wan, Li, & Zhang, 2016).

With this initiative the German Government intends to boost the competitive position of German companies in the globalised world (Ramsauer, 2013; L. D. Xu, Xu, & Li, 2018). This approach contains a big contrast to the industrial revolutions of the past. Instead of conducting analysis in retrospect which showed innovations marking the beginning of a new era, the fourth industrial revolution was proclaimed a priori leaving room for heated debates on whether the actual development will able to keep up with the high expectations (Drath & Horch, 2014). The trends underlying this fourth industrial revolution has not only been noticed by the German Government but have gained worldwide interest. This results in strategic initiatives and plans of industries and governments from all over the world being directed towards these changes (Liao, Deschamps, Loures, & Ramos, 2017).

The present scientific literature in this field is focussing on the technological aspects by giving three critical features. The first deals with the integration within one single company, focusing mainly on intra-company procedures and communication. This is followed by the creation of a network of different corporations within the same industry which is described as "an efficient ecosystem" (Wang, Wan, Li, et al., 2016, p. 2). The third aspect focuses on the product perspective and the corresponding supply chain (Wang, Wan, Zhang, Li, & Zhang, 2016). Here, the physical producibility throughout all involved corporations and the inter-company communication form the foundation for a successful implementation (Wang, Wan, Li, et al., 2016). Based on these three components, numerous new technologies are being utilised. In the following, three essential technologies mentioned by Wang, Wan, Li et al. (2016) are briefly explained to give insights into the complexity of the topic. Starting with Big Data, the strategic generation and evaluation of vast amounts of data (for example waiting times during the production process or reoccurring production errors), continuing with the Internet of Things, in which physical objects are transferred to the digital world and thus made accessible for real-time simulations (given the example of the soap factory, each bottle is equipped with a Radio Frequency Identification (RFID)-tag which sends information to the network), and finally cyber physical systems (CPS)1, “where physical artefacts and informational entities are deeply integrated” (Wang, Wan, Li, et al., 2016, p. 3) (Atzori, Iera, & Morabito, 2010; H. C. Chen,

1 Tangible and digital objects are merged into a framework which is called “Cyber Physical System (CPS)”.

Chiang, & Storey, 2012; Zuehlke, 2010). An example of a CPS is the connection of the physical shampoo bottle with its digital copy to a single object (Wang, Wan, Li, et al., 2016).

The arising of the concept of Industry 4.0 at this point in time can be explained due to recent developments coinciding in two different fields. Firstly, changes in the market demand for a new way of production to meet the customers' needs of individualisation on demand, flexibility or shortened development periods. Simultaneously, the development of technical capabilities enabling companies to cope with these changes, has reached a new (Lasi et al., 2014). These new technologies build the foundation of the concept of Industry 4.0 and have been described in the respective literature to a great extent (L. D. Xu et al., 2018). A number of highly cited articles are describing in detail the technical aspects underlying this fourth industrial revolution (Wang, Wan, Li, et al., 2016; Wang, Wan, Zhang, et al., 2016). Besides the technical applications presenting necessities on the roadmap of implementing the concept of Industry 4.0, a considerable amount of research has been devoted to analysing and proposing an architectural design of so-called smart factories facilitating Industry 4.0 (B. T. Chen et al., 2018).

Being introduced in 2011 the term Industry 4.0 has already experienced almost 10 years of academic as well as practitioner-oriented research. During this period however only a very little amount of work has been done on the managerial perspective on the topic (Arnold, Kiel, & Voigt, 2016; Schneider, 2018). Consequently, one can even speak of a backlog in management research.

1.2 Problem

While the potential benefits as well as the technical challenges that companies still have to overcome in order to successfully employ Industry 4.0 have been subject of many previous studies leading to a clear picture in this area, the managerial competencies needed in order to guide this successful implementation have almost been neglected (B. T. Chen et al., 2018; Schneider, 2018; Wang, Wan, Li, et al., 2016). It is however obvious that radical changes like the implementation of Industry 4.0 cannot only be achieved by allowing for the technical necessities. It must rather be given increased attention to the people perspective in this process for it is very well known that the managerial challenges in a change process like this will become decisive for the success of the implementation of Industry 4.0 (Brendle et al., 2016). This point can be strengthened by looking at a study recently conducted amongst manufacturing companies from three leading industries in Germany. Focussing on economic, ecological and social benefits and challenges of Industry 4.0 one of the outcomes of the study is a generated list of challenges from which a considerable amount will have to be tackled by management positions (Kiel et al., 2017).

1.3 Purpose

The purpose of this paper is therefore to contribute towards the little managerial research conducted in the field of successfully implementing Industry 4.0 until now. Insights into this area will be helpful for any organisation to exploit the great potential which is associated with this new approach.

Overall, the managerial challenges itself will be investigated and compiled to generate a broad picture of the implementation process of Industry 4.0. Additionally, conclusions on how these challenges could be met will be presented. This leads to the corresponding research question which we are addressing in this paper. The research question shall read as follows:

What are the managerial challenges of implementing Industry 4.0 and how could these be met?

2 Theoretical Frame of Reference

This chapter is guiding the reader through the process of the literature review by detailing the methods used to identify the literature worth investigating. After clarifying how and where to search, an in-depth explanation of the basic concept Industry 4.0 within this paper together with its enabling technologies is given. The concept is further outlined by describing different viewpoints on how a smart factory could be implemented. In order to present the state of the art to the reader in a comprehensible way, the results of previous studies related to the management perspective are presented. Finally, the topic is viewed in the light of change management, which as a discipline is dealing with the transition from old to new processes as it is the case when implementing Industry 4.0 related elements. All these aspects are combined in a research model, showing our understanding of the respective literature of the field and placing the study on hand amongst them.

2.1 Explanation of the Literature Review Process

To distinguish which articles are suitable for investigation, different methods were used. The first aspect that is characterising the investigated literature is amount of relevance and importance inherited by a specific article with respect to the research question. In this case, importance describes the significance that a particular article has on the state of art. Relevance is more focusing on the research topic itself and how well the article fits to it (Easterby-Smith, Thorpe, Jackson, & Jaspersen, 2018).

The amount of citations is one of the indicators evaluating importance. Here, a high number compared to other articles in the field indicates high importance. The aim of this is to get insides into the topic and understand the underlying concepts (Webster & Watson, 2002). Additionally, the ranking of the journal in which the article is published is brought into consideration. At this point, the ABS list, where journals are ranked according to their citation ratings and the evaluations of leading scientists (Easterby-Smith et al., 2018), is used to separate high- and low-quality journals from one another. The state of the art on how to perform a high-quality literature review suggests a reasonable mix of the most relevant together with the most recent literature (Webster & Watson, 2002). By that it is ensured to not only uncover the most important aspects but also link them to current developments in the area under investigation. Throughout the literature research, only peer-reviewed articles are investigated further. This is to maintain a high-quality standard of the reviewed literature (Easterby-Smith et al., 2018). Together, the methods described form a set of criteria that was used to decide whether or not an article should be examined more closely. The platform used to find the literature was the data base ‘Web of Science’ due to its wide range of accessible literature and its possibility to rearrange the search setting to the research topic’s demands. For instance, it is possible to include or explicitly exclude certain categories in the search. In this paper, this feature was used to shed light on the state of the art in business and management by including these categories and excluding the others. Of course, this function was not the only one relied upon, and adjacent categories were not ignored either.

The fourth industrial revolution has been initiated by the German term "Industrie 4.0", which is therefore forming the starting point for investigating the literature. The fourth industrial revolution is a global phenomenon, which is why different countries use different words for the same concept. Nevertheless, the overall goals remain the same. Therefore, each of the search terms are treated equally, leading to the search term: "Industrial Internet" OR "Industry 4.0" OR "Made in China 2025" OR Industrial Internet of Things OR "Industrie 4.0" OR "Fourth Industrial Revolution".

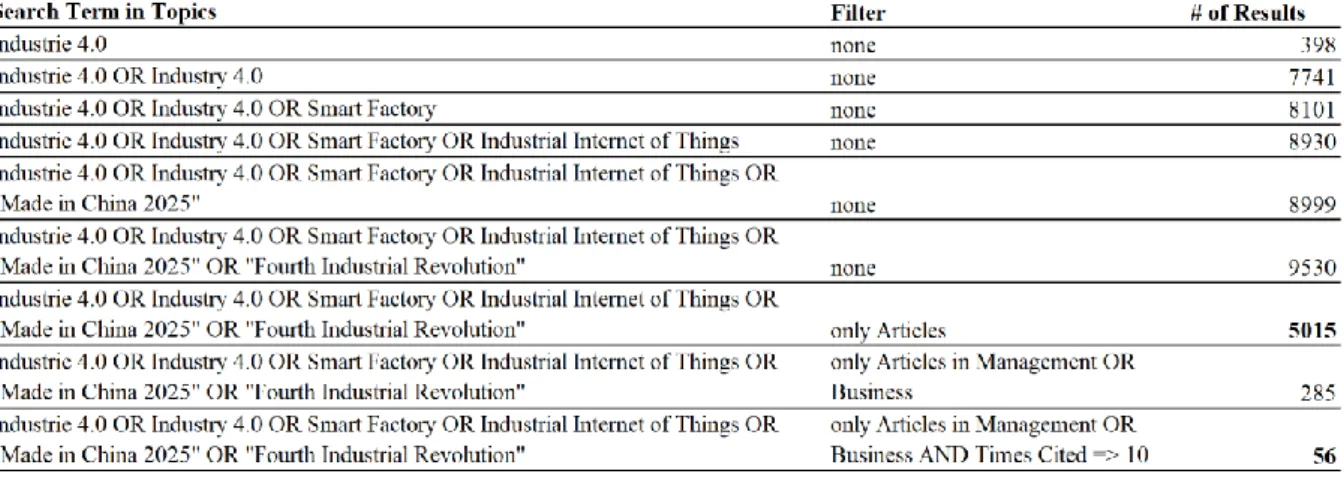

Table 2.1: Result of the literature review process

Table 2.1 shows the result of the conducted search. It is to be noted, that to gain a deep understanding of the topic itself, not only management and business literature but also the most important and most recent literature independent from the focus has been investigated. Furthermore, the review is structured concept-centric to enhance the synthesis between the investigated literature (Webster & Watson, 2002). Based on this, the abstracts of over 100 articles were read. The result are 56 thematically matching articles which were further used, and their contents got transferred to a list summarising the literature.

2.2 The Concept “Industry 4.0”

"Industrie 4.0", the German version of the term was first used during the Hannover fair in 2011 (Drath & Horch, 2014). It presents one of the future projects elaborated by the German government which is directed towards establishing a leading role in the manufacturing sector (Liao et al., 2017; L. D. Xu et al., 2018). However, the concept has attracted attention from various governments and industries all over the world and has been implemented into national plans under different names. While the USA has titled their efforts in this area as "Advanced Manufacturing Partnership" the French government has released their initiative "La Nouvelle France Industrielle" shortly after. At the same time the United Kingdom launched their "Future of Manufacturing" campaign. But also economic powers in Asia have put their focus on these new capabilities and included corresponding goals into their strategies. So did the Korean government by announcing the "Innovation in Manufacturing 3.0" as well as China through their "Made in China 2025" strategy. Equally, Japan adopted the "5th Science and Technology Basic Plan" (Liao et al., 2017, pp. 3609, 3610). This short digression serves to show the significance of Industry 4.0 gaining worldwide attention. Also, it shows that the terms attached to the phenomenon vary greatly depending on the environment in which it is investigated.

However, the underlying understanding of the concept remains largely unchanged (Liao et al., 2017) and is described in-depth in the following.

So far, there exists no commonly agreed on definition in the literature. However, this can be explained due to the vast number of concepts which are being united under the term Industry 4.0 (Lasi et al., 2014). Generally, the term refers to the fourth industrial revolution and therefore the "introduction of internet technologies into industry" (Drath & Horch, 2014, p. 57). Several researchers describe the subject in relation to the changes it brings to manufacturing processes. These will again be driven by internet technologies and aim at real-time optimisation (Kagermann, Wahlster, & Helbig, 2013; Lasi et al., 2014; L. D. Xu et al., 2018). Also, using cyber physical systems within industrial production systems is decisive for many researchers when classifying Industry 4.0 (Drath & Horch, 2014; Ghobakhloo, 2018; Kagermann et al., 2013). This optimisation of manufacturing processes is also stressed in the definition of Jabbour et al. (2018) describing key principles of Industry as "the horizontal and vertical integration of

production systems driven by real-time data interchange and flexible manufacturing to enable customised production" (p. 19). Additionally, a definition presented in the final report of the

Industry 4.0 working group around Kagermann (2013) shall be mentioned at this point. In their eyes "Industrie 4.0 will involve the technical integration of CPS into manufacturing and

logistics and the use of Internet of Things and Services in industrial processes [leading to] implications for value creation, business models, downstream services and work organisation"

(p. 14). Based on their status as pioneers in the field and the high number of citations, this understanding is meaningful (Liao et al., 2017) and will guide the definition of the term Industry 4.0 within this report.

Factories facilitating these new production processes are referred to as smart factories in which smart products are being manufactured. These smart products do not only know their own history and target state but can also be located at any time and therefore "actively support the

manufacturing process" (Kagermann et al., 2013, p. 19) thus enabling to incorporate

last-minute changes. This allows the production of single pieces and therefore customisation of each product, presenting one of the key characteristics of Industry 4.0 (Kagermann et al., 2013). A manifold number of opportunities and benefits are anticipated to be unfold by the implementation of Industry 4.0 (Hofmann & Rusch, 2017). Potential benefits can be found in different areas. Firstly, increased flexibility in the whole production creates the possibility to profitably manufacture one-off items and therefore serve individual customer demands. Real time data and thorough transparency is said to optimise entire value chains in terms of productivity and efficiency. But also, entirely new opportunities for value creation through new services or business models can be realised (Hofmann & Rusch, 2017; Kagermann et al., 2013; Kiel et al., 2017). Apart from these economic changes, ecological benefits like reduced energy consumption can be expected due to optimised production processes (Kiel et al., 2017). Furthermore, Industry 4.0 is associated with presenting an opportunity to overcome demographic difficulties by designing adaptive workplaces. By relying on socio-technical collaborations an improved work-life-balance can be achieved bringing social benefits alongside the technical improvements (Kagermann et al., 2013; Kiel et al., 2017). However, at

this point all these predicted gains are very promising but not proven. Any actual implications are uncertain and still require profound research (Kiel et al., 2017).

While the predicted benefits seem overwhelming, a number of major challenges may offset the potential of Industry 4.0 (L. D. Xu et al., 2018). These fall under different categories according to their focus. On one hand, technical challenges like the supply of a sufficient broadband infrastructure as well as data management and data mining techniques still need to be solved in order to exploit the potential of the concept (Kagermann et al., 2013; Lee & Lee, 2015; L. D. Xu et al., 2018). On the other hand, gathering these vast amounts of data implies big responsibilities in regards to data security and privacy protection (Kagermann et al., 2013; Kusiak, 2018; Lee & Lee, 2015). Additionally, due to its interdisciplinary nature, combining different areas of the firm and grouping whole companies into supplier networks, standardisation is seen as essentially important. This starts as early as establishing a common approach towards the concept (Kagermann et al., 2013; Kusiak, 2018; L. D. Xu et al., 2018). Apart from these technical challenges, the implementation of Industry 4.0 within manufacturing industries is associated with bringing a multitude of other challenges to be considered (Hofmann & Rusch, 2017). Focussing on the level of a single company, it will be up to the management to successfully facilitate the implementation (Schneider, 2018). Building a suitable ground at this level presents a lengthy challenge of Industry 4.0 (Agostini & Filippini, 2019). This is affecting issues like work organisation and design, but also long-term strategic orientation. Additionally, the availability of professionally trained employees filling these positions should be guaranteed and kept up by providing relevant trainings (Kagermann et al., 2013; Schneider, 2018).

Despite these various challenges, the rise of the phenomenon Industry 4.0 is said to be inevitable and bears great potential. Industries and societies around the world will be able to exploit this when overcoming the barriers outlined above through intense cooperation between all parties involved (Drath & Horch, 2014).

2.3 Technologies Enabling Industry 4.0

A wealth of literature exists in the area of technical realisation of Industry 4.0. Accordingly, there are many different opinions as to which type of enabling technologies have the greatest influence on the implementation and are therefore most important. Wang, Wan, Li et al. (2016) mention the most important technologies, naming big data, artificial intelligence (AI), cloud computing and the Internet of Things (IoT). Due to the high relevance of the article (487 citations, last revised: 07/05/2020), it offers a suitable starting point to explain the technical fundamentals. At this point it should be noted that due to the different names for the same phenomenon, the technology IoT in this case is attributed to the use of RFID chips. Therefore, the RFID technology will be discussed in the upcoming section as well.

In order to make production lines efficient, even when the lot sizes are reduced due to individualised products, all necessary information have to be considered when making a production related decision (Brendle et al., 2016). A big part of these information such as the production route a product has to take to get processed further, which modifications have to be

made and the times the pre-assembled product has to wait before it is processed further lie in the product itself (Agostini & Filippini, 2019; Jabbour et al., 2018; Wang, Wan, Zhang, et al., 2016). Therefore, a technology is needed that transfers the data from tangible objects into digital information (Gubbi, Buyya, Marusic, & Palaniswami, 2013). Tangible and digital objects are merged into a framework which is called “Cyber Physical System (CPS)”. Here, both parts are no longer distinguishable from one another (Lasi et al., 2014). One technology that makes this possible is called radio frequency identification (RFID) which is made use of through installing corresponding chips (Gubbi et al., 2013; Ren et al., 2015). These are attached to a manufacturing platform or the product itself and are able to produce and communicate data forming a so-called smart artefact (M. Chen, Mao, & Liu, 2014; Wang, Wan, Li, et al., 2016). With the help of them, a huge amount of unbiased and complete data is created (Gubbi et al., 2013). This is denoted as “Big Data” (Jabbour et al., 2018). The data are used to widen the knowledge about production processes as well as root causes for machine downtimes and storage management (Wang, Wan, Li, et al., 2016). Therefore, it can be said that the value of smart artefacts lies in the collection and analysis of the given data (Ghobakhloo, 2018). At this point, the third enabling technology besides Big Data and RFID comes into play - AI (Li, 2018). Although there is no uniform and generally valid definition of what AI is, in its origin it describes the imitation of human intelligence using computers (Olsen & Tomlin, 2020). Meanwhile, research in this field has developed further and often the performance of AI exceeds that of the human brain (Wang, Wan, Li, et al., 2016). Therefore, in Industry 4.0 the generated data is analysed and processed using this technology (D. W. Huang, Sherman, & Lempicki, 2009; Kagermann et al., 2013; Wang, Wan, Li, et al., 2016).

Lastly, to fully implement Industry 4.0 a fourth enabling technology, cloud computing, is described as necessary (Kang et al., 2016). It is the concept of an on-demand system for computer services (B. Q. Huang, Li, Yin, & Zhao, 2013). This means, that companies purchase computing power depending on the demand they have at the exact moment (Armbrust et al., 2010). This enables companies to deal with the huge amount of data collected and the related activities for which they need the computing power (X. Xu, 2012). When referring to a manufacturing context, cloud computing is sometimes named cloud manufacturing (Kang et al., 2016). Nonetheless, the underlying principles remain the same, videlicet external data storage and processing as well as the opportunity to access the relevant data from wherever necessary (Armbrust et al., 2010).

Bringing these concepts in relation to our research question, it is obvious that data emerge during all stages of the production cycle and in all production facilities all around the world. However, currently these data remain largely unused for most companies, as appropriate technologies are not fully applied to make them accessible. Although, due to the demand for increasing customisation, it is advisable for production lines to make use of these data to maintain a high productivity even when lot sizes decrease. Through RFID chips, these real time data are accessible and therefore usable to make decisions. While managers have a larger base to justify their decisions, the data are not distorted or inaccurate due to manual processing not being supported by technology. Moreover, RFID chips enable the physical artefacts to

network of Industry 4.0. Based on this and with the help of AI, patterns in the collected data are identified. This can help to improve product quality, increase productivity and reduce downtimes as well as production errors and eventually support the decision makers by providing valuable information. One could even say that due to AI-analytics based on patterns of the past, the managers to some degree are able to predict the future.

2.4 Previous Studies of Industry 4.0 With a Non-technical Focus

As already mentioned, conducted research in the area of Industry 4.0 so far has mainly been concerned with the technical issues of the topic (Wang, Wan, Li, et al., 2016; Wang, Wan, Zhang, et al., 2016; L. D. Xu et al., 2018). Only a limited amount of studies have been contributing to the investigation of non-technical elements of the field (Arnold et al., 2016; B. T. Chen et al., 2018; Schneider, 2018). To provide the reader with an overview of what has already been done in this direction by other researchers, this part of the paper outlines a number of studies in the field of Industry 4.0 inheriting a non-technical focus. These studies have been found by performing a literature review as described previously.

First of all, it is noticeable that by dividing the current research into "technical" and "non-technical" fields, the latter contains the by far bigger range of covered topics. However, due to the lack of research being done in this direction, it is essential to look in detail at what has been done. Generally, there seems to be a consensus on the choice of manufacturing companies to build the framework for their studies (Ghobakhloo, 2018; Lasi et al., 2014; Schneider, 2018; Sommer, 2015; T. Zheng, Ardolino, Bacchetti, Perona, & Zanardini, 2019). This choice becomes reasonable by bringing back to mind the core of Industry 4.0 as being related to changes in manufacturing processes in order to meet individualised customer demand.

Naturally, the various researchers set different foci within their studies. The specific role of small and medium sized enterprises (SMEs) however has been under investigation repeatedly (Agostini & Filippini, 2019; Moeuf, Pellerin, Lamouri, Tamayo-Giraldo, & Barbaray, 2018; Schneider, 2018; Sommer, 2015). Their important role in supplier networks but also the manufacturing trade in general increase the need for SMEs to master this fourth industrial revolution alongside established and bigger companies (Sommer, 2015). Previous research however paints a different picture. At this point in time knowledge as well as engagement in Industry 4.0 initiatives seem to be dependable on the size of the company and increase with the number of employees (Sommer, 2015; T. Zheng et al., 2019). Moeuf et al. (2018) conclude their research by describing SMEs as being "ill-equipped to face [the] new possibilities" (p. 1118) and Sommer (2015) even predicts a relation between the enterprise size and the risk of "[becoming] victims instead of beneficiaries of this revolution" (p. 1512). Reasons for this may be the general lack of resources which makes it especially difficult for SMEs to make big investments in the areas of research and development (Moeuf et al., 2018).

Above and beyond, many authors see several benefits and opportunities which arise through Industry 4.0 (Hofmann & Rusch, 2017; Kiel et al., 2017; Lee & Lee, 2015). For example, experts are anticipating "opportunities in terms of decentralization, self-regulation and

efficiency" (Hofmann & Rusch, 2017, p. 23) when it comes to logistics management and rate

the IoT as qualified "for an industrial value creation that complies with sustainability

expectations and requirements" (Kiel et al., 2017, p. 26). On the other hand, a number of

challenges are expected (Agostini & Filippini, 2019; Hofmann & Rusch, 2017; Kiel et al., 2017; Lee & Lee, 2015; Schneider, 2018). These are mainly concerned with managing the large amount of data in terms of organisation but also privacy and security issues (Lee & Lee, 2015). Additionally, through his research Schneider (2018) gathered a total of 18 managerial challenges which he uses as a basis to outline directions for future research in this field. A number of studies investigates the influence of Industry 4.0 and the Industrial Internet of Things (IIoT) on a business level (Arnold et al., 2016; Laudien & Daxbock, 2016). Looking at five different German industries, the researchers examine a number of aspects in which the business models of the respective industry change in a more or less strong way. This allows them to conclude several managerial implications (Arnold et al., 2016). Another study directed towards a very similar purpose was able to point out three distinct archetypes of business models which allow firms to draw on the implied benefits of IIoT (Laudien & Daxbock, 2016). Overall, the academics of the field seem to share the aim to benefit from the changes the fourth industrial revolution is bringing. In line with this, research has been carried out to identify several critical success factors guiding an implementation of Industry 4.0 alongside environmentally-sustainable manufacturing (Jabbour et al., 2018).

2.5 Change Management at the Intersection of Industry 4.0

For companies, the introduction of Industry 4.0 means that conventional processes and procedures might no longer be applied as before. This is due to the need of adjusting processes to meet the changing customer demand (Albach, Meffert, Pinkwart, & Reichwald, 2015; P. Zheng, Chen, & Shang, 2019). For example, conventional production key figure systems using handwritten data are being replaced by automatic computer-controlled data acquisition (Albach et al., 2015). This transition from old to new approaches is called change (Sirkin, Keenan, & Jackson, 2005).

In their study, Sirkin et al. (2005) differentiate soft and hard elements when managing change. While soft elements like culture, leadership and motivation have been in the focus of many change management publications, they themselves created their study around the purpose of finding out more about hard elements which can be directly influenced by organisations. In their findinings they introduce four key factors of managing change, namely duration, integrity, commitment and effort which they term as hard elements. Besides this, the literature sees good preparation and precisely formulated goals as decisive for the success or failure of the transformation processes (Albach et al., 2015; Brunelli, Lukic, Milon, & Tantardini, 2017). The activities related to these processes are summarised in the term Change Management (Sirkin et al., 2005). It should be noted that there is no uniformly accepted definition of Change Management, but the term is always used to describe the management of transformation processes from an initial state to a desired final state (Tupa, Simota, & Steiner, 2017).

One reason why the description of Change Management is so general is the diversity of the changes that are implemented. Company processes are highly complex and vary from case to case. Every change project is different and the methods and techniques need to be adjusted to make them fit the purpose (Reijiers & Mansar, 2005). This is where the difficulty lies in relation to Industry 4.0. Due to the newness of the topic and the associated lack of experience in dealing with the introduction of Industry 4.0, many companies are faced with the challenge of introducing something that they have not yet grasped in their entirety (Tupa et al., 2017; P. Zheng et al., 2019). However, playing an active role in this recent development of implementing Industry 4.0 in the own production is seen as vital for sustainable success (Albach et al., 2015) Another important aspect in the context of Industry 4.0 are the many different areas within a company structure that are influenced by the implementation of the concept. The processes can no longer be clearly associated with single departements and therefore have to be elaborated with the whole company or even the whole supply chain in mind (Hotho & Champion, 2011; Schumacher, Erol, & Sihn, 2016). Furthermore, research has shown, that many companies do not focus on the people involved in the process, even though this is seen a crucial for the success of change projects (Schumacher et al., 2016).

Brunelli et al. (2017) recommend approaching the implementation of Industry 4.0 as a change management project rather than a solely IT-driven project because of its influence on several different departments. They argue that establishing clearly defined guidance and authorisation enables the company to pursue the process in a controlled and structured manner. Adding to this, Kagermann (2015) expresses the importance of a precise plan to guide the implementation of the project.

2.6 Research Model

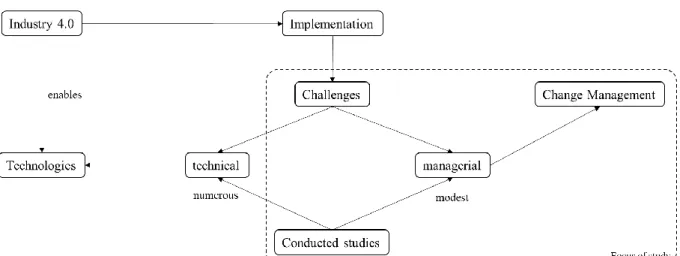

The examined literature builds the basis for this study. Based on the information extracted from previous research in this field, the following research model was crafted (see Figure 2.1).

Figure 2.1: Research model

Industry 4.0 as a concept is enabled through current advances in the area of smart technologies. When it comes to implementing the concept in a production environment, a number of challenges arise. While numerous studies have been conducted on the technical side of these

issues, the managerial perspective is currently lacking profound research. Additionally, the topic of change management which naturally comes into mind when speaking about implementation processes is playing a role in this research study. Drawing upon the fundamentals of this field and analysing their role with regards to the implementation of Industry 4.0 will also be part of this research. Finally, this research model is designed to serve the investigation of managerial challenges and conclude on ways on how to address these to implement Industry 4.0 as stated in the research question.

3 Method

This method chapter is outlining the research process. Presenting the qualitative research design allows the reader to participate in each step and gain a holistic picture of the study. Starting with the underlying philosophical assumptions enabling to place the study within its wider context, the design of the empirical study is discussed in detail. Afterward, by describing how each of the four main criteria of trustworthiness is approached in this paper, an indication of the overall quality is given. The chapter finishes with a thorough consideration of ethical issues that may arise from both the methodical execution as well as the content of the research study.

3.1 Philosophical Assumptions

Turning towards any underlying philosophical assumptions at a very early stage of a research project is of great importance for the quality of the generated outcomes. Several reasons are accounting for this importance which are mainly concerned with the ability of the researcher to address the research questions appropriately and to design the research study accordingly (Easterby-Smith et al., 2018). Additionally, every researcher holds their own set of assumptions influencing the understanding and interpretation of the information collected. Being aware of their reflexive roles helps the researchers to understand this influence and minimise its impact on the outcomes of the study (Travers, 2001).

The philosophical assumptions consist of an interplay between ontology, describing how the nature of reality can be viewed in different ways and different perspectives of how this nature can be approached most appropriately, a field which is termed epistemology (Easterby-Smith et al., 2018). Also, there is a clear linkage between the two aspects meaning working with one specific ontological view translates directly into the associated epistemological view and vice versa (Easterby-Smith et al., 2018). Moreover, the methodology and therefore the exact methods and techniques chosen to acquire the knowledge to answer the research question should be in line with these philosophical assumptions as well (Easterby-Smith et al., 2018). Being directed towards the investigation of a set of challenges this research is located within the area of social constructionism giving account to the idea that there is no external reality, but it is rather created through individuals and their daily interaction (Easterby-Smith et al., 2018). The phenomenon of Industry 4.0 is very complex including different elements and is, therefore, lacking a generally agreed on definition of the term. This means that different people have a differing understanding of the concept. To gain a deep understanding of the topic, it is important to comprehend how people make sense of it in their daily lives. To approach the research question of this paper it is therefore essential to gather different experiences of people dealing with the phenomenon as well as the meaning they attach to these (Easterby-Smith et al., 2018). The fact that the phenomenon referred to in this paper as "Industry 4.0" has been given different names in other countries around the world, serves as a valuable insight into the meaning of language in this context.

This orientation towards social constructionism translates into a relativist position on the continuum of ontological viewpoints. Again, this perspective stresses the idea "that phenomena

depend on the perspectives from which [individuals] observe them" (Easterby-Smith et al.,

2018, p. 114).

3.2 Research Approach

Generally, the scholarly community is divided into two big fields conducting namely quantitative and qualitative research (Easterby-Smith et al., 2018). Each direction applies a set of particular approaches and techniques that are very different from each other. This distinction is however not simply characterised by a choice between methods but is rather based on the underlying philosophical assumptions (Travers, 2001). Being aimed at mapping a set of challenges and elaborating on ways to meet these, this research builds on inductive reasoning meaning the general approach will happen from the bottom up. Only after the collection and analysis of data, a pattern will emerge leading to the generation of a theoretical model (Graneheim, Lindgren, & Lundman, 2017).

3.3 Research Strategy and Methodology

In line with the inductive approach taken, this study is placed within a qualitative environment allowing the researchers to view the information retrieved in their context (Myers, 2020). Being directed towards the understanding of how individuals make sense of their world (Easterby-Smith et al., 2018), qualitative research presents the matching framework for this study. Therefore, one can speak of a qualitative research strategy guiding the research project.

After having elaborated on the ontological and epistemological viewpoints of this study, the methodology takes these considerations one step further and presents a combination of methods utilised to approach the research question. As noted before the focus of the research on investigating a set of challenges and further elaborating on these, necessitates the generation of qualitative data through qualitative research. In the eyes of Myers (2020) this direction is beneficial for research in the area of business and management, bridging the gap between the academic and the practical world. Bringing back to mind the inductive approach of the study leads to the choice of qualitative research, consisting of a number of semi-structured interviews as well as qualitative data analysis. This presents a matching tool within this research project. Being aimed at investigating the set of managerial challenges associated with Industry 4.0 implementation as well as finding ways on how to overcome these challenges, a qualitative study presents a reasonable method to answer these research questions.

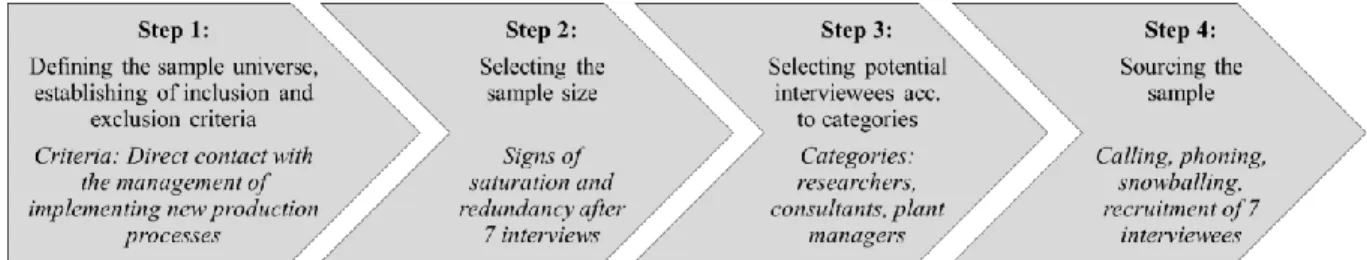

3.4 Sampling Strategy

The activities of identifying and selecting participants from a broad population to gain valuable insights into the topic under investigation while following a defined pattern are combined and described in a sampling strategy (Easterby-Smith et al., 2018; Palinkas et al., 2015). A variety of different sampling strategies exist with “purposeful sampling” being the most favourable choice for the study on hand because of its possibility to most effectively use limited resources (Palinkas et al., 2015). To approach the sampling process methodically and therefore raise the trustworthiness of the conducted study, we followed the four-step sampling approach presented by Robinson (2014) as depicted in the image below (see Figure 3.1).

Figure 3.1: Sampling strategy acc. to Robinson (2014)

Step one defines the sample universe. Here inclusion, as well as exclusion criteria of potential interview candidates, are established. For this research, we aim to get insights into a specific topic from people who have experience in that environment. This means we included managers, researchers, and other people who are or have been in direct contact with the management of implementing new production processes. Due to the novelty of Industry 4.0, we also explicitly include people who have introduced smart processes even if they were not carried out under the name "Industry 4.0".

Step two deals with the sample size. To maintain high credibility, the right size of the sample has to be selected carefully (Sandelowski, 1995). Furthermore, the aim is to select a sample size that is not too small nor too big. This is to achieve theoretical saturation (Corbin & Strauss, 1990) and information redundancy (Lincoln & Guba, 1985) signalling a sufficient amount of collected information. To gather different perspectives on the phenomenon, we planned to start by conducting seven interviews with participants of different backgrounds. Since after this first round of interviews signs of saturation and redundancy could be experienced, no further interviews were scheduled.

The third step is the sampling strategy and describes the process of selecting possible interview partners by sorting them into categories. For this, we have chosen to interview researchers in the field of applied smart technologies, plant managers who have or had responsibility for smart production processes and consultants who supported and guided companies in the introduction of smart production processes.

The last step is the sourcing of the sample. Here, we recruited participants by calling and emailing those who we previously defined as suitable for our research. Overall, we have contacted over 40 people and received positive answers from six of them. Further, we used a snowballing technique which enabled us to conduct one additional interview. Many of the respondents showed a high interest in the research topic which can be seen as their incentive to participate in the study.

3.5 Data Collection Technique

Given the research question, the data collection needs to take the people’s view on the subject into account. In this case, Easterby-Smith et al. (2018) present different approaches to craft the needed data, ranging from written primary and secondary data to qualitative interviews. Since the purpose of this paper is to find out the topics, with which different managers are faced in order to implement Industry 4.0, the focus is on the subjective experience of each individual.

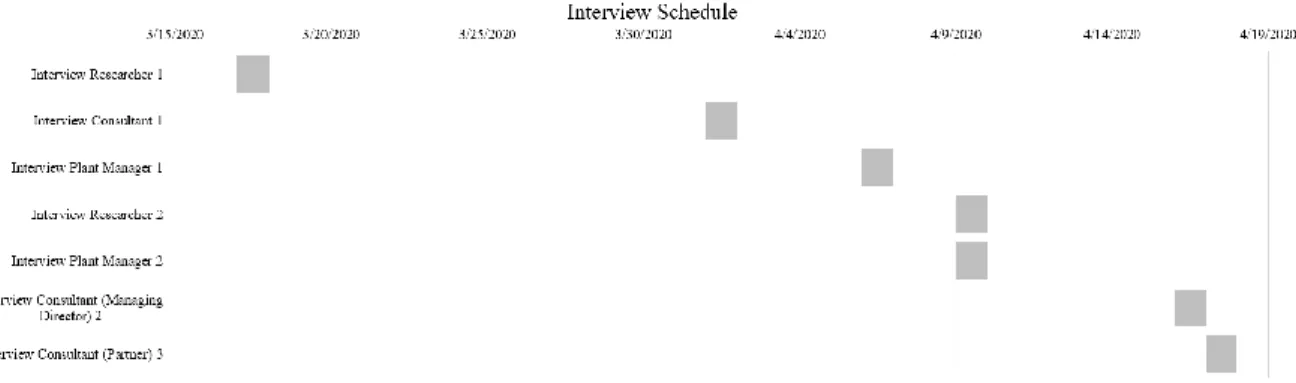

Given this, the most reasonable choice of data collection for the stated purpose is to conduct semi-structured interviews using an interview guide (see appendix 1) (Easterby-Smith et al., 2018). By only defining a framework in which the interview is thematically based, the interview partners are still given room for thoughts going further than the actual questions enabling the researchers to investigate more than initially asked (Kallio, Pietila, Johnson, & Kangasniemi, 2016). This is especially important in research questions dealing with problems and challenges related to a subjective topic (Rabionet, 2009) which is the case for the research question investigated in this paper. Furthermore, a pilot-test was performed to ensure the applicability of the interview guide (Kallio et al., 2016). In total, roughly 10 hours of interview material were being conducted over a period of one month (see Fig 3.2).

Figure 3.2: Interview schedule

Before the interviews could be conducted, the in-depth literature review performed was aimed to gain detailed knowledge (Kallio et al., 2016) about Industry 4.0 on one hand and on the other hand understand all topics (Rabionet, 2009) which might arise during the interview (Turner, 2010). Naturally, formal steps like preparing a consent form were performed at an early stage. Hereby, at the beginning of the interview, the use and purpose of the interview were defined and clarified for every participant (Easterby-Smith et al., 2018).

After conducting interviews, the next step was to transfer the spoken word into written form. This activity is called transcription (Easterby-Smith et al., 2018; Kallio et al., 2016; Turner, 2010). The main important aspect for the researcher hereby is to gather all relevant information from the interview (Poland, 2001). An interview is often characterised as a dialogue on an equal level, in which the flow of the conversation is structured by questions that are connected and build on each other. Given this is the case, the summarising transcription is the most reasonable choice for this study because of the possibility to combine what has been said at different points in time and therefore create a structure early on in the transcription (Jefferson, 2004).

3.6 Data Analysis

The analysis of the data begins during the collection of the first bit of data. Although, the major part of the analysis starts after the transcription of the interview material is finished (Corbin & Strauss, 1990). There are several different approaches on how to bring the different perspectives into common themes (Easterby-Smith et al., 2018) with “grounded analysis” being the favoured

variables and through that creating a broader picture of the matter under investigation enabled us to understand the problem holistically (Easterby-Smith et al., 2018). This goes in line with the inductive nature of this research study making grounded analysis a matching method to create a theory based on the collected information.

The analysis of the data was done according to Corbin and Strauss (1990). Each interview was analysed, and several different codes were examined. These codes contain the most important arguments made by the interviewee and characterise the specific perspectives the interviewee has (Easterby-Smith et al., 2018). Then, these codes were allocated into categories, where each category tackles one aspect of the problem (Easterby-Smith et al., 2018). To make these categories more abstract for the development of a theoretical model, they are further summarised in themes. These then form the starting point for the mentioned theoretical framework. In other words, with the grounded analysis, it is possible to elaborate a common theoretical framework based on several different perspectives and individual standpoints (Corbin & Strauss, 1990). This again refers back to the inductive approach of the study on hand aiming at theorising on the managerial challenges encountered through implementing Industry 4.0.

Concerning the research topic, the grounded analysis can be seen as a reasonable choice due to its openness to new patterns that emerge during the interviews and its resistance to bias coming from pre-interview assumptions (Easterby-Smith et al., 2018).

3.7 Trustworthiness

For research to be trusted, it has to fulfil four main criteria, namely credibility, dependability, transferability, and confirmability (Guba, 1981; Rolfe, 2006; Shenton, 2004). Several complementary methods exist to secure the credibility of a study. For research to be credible, it has to be valid in itself, meaning that the study measures “what is actually intended” (Shenton, 2004, p. 64). This requires the researchers to be engaged in the research topic for a reasonable amount of time to understand it in depth. It is followed by a peer debriefing process, in which the researchers distance themselves from the drawn conclusions to re-evaluate the findings. Finally, it involves triangulation, which describes the process of not relying on single sources, perspectives, and methods (Denzin, 1978; Guba, 1981). To ensure credibility, we began with an in-depth analysis of the state-of-the-art literature to gain knowledge about Industry 4.0. We then took part in a regular review process (see Table 3.1) in which different topics were challenged and investigated by colleagues and supervisors from different perspectives.

Table 3.1: Timetable and topics of the feedback seminars

Lastly relying on a mix of data sources (interviews, secondary case studies, and research papers) ensured unbiased deductions to build the basis for later theories.

The triangulation is also part of the second main criteria, namely dependability. It is described as the repeatability by other researchers and the consistency of the gained information (Shenton, 2004). By overlapping different methods, the disadvantages of single methods can be overcome to form a complete and seamless view on the matter under investigation (Guba, 1981) and thereby making the outcome of the study replicable and comprehensible (Lincoln & Guba, 1985). Furthermore, the reader gets the chance to investigate how the conclusions were drawn and thus making the research itself transparent for the reader (Shenton, 2004). This so-called “audit trail” (Guba, 1981) further strengthens the trustworthiness of the paper on hand. Through the review procedure (see table 3.1) it is ensured, that the conclusions drawn are verified by independent researchers, and the methods used to reach the conclusions are applied correctly. Moreover, engaging in a storytelling mode by presenting the interview guide and the codes (Appendix 1 & 2) allows the reader to follow the research process and to draw their own conclusions. By detailing the thoughts and decision that lead to conclusions and findings the study is presented transparently for others.

The third criterium is confirmability. To be confirmed, the research outcome has to be based on the information gathered and may not be biased by the researchers' own opinions and viewpoints (Shenton, 2004). Strictly all information gained through conducted interviews were transcribed and served as the basis for findings and outcomes. Moreover, the thought process, as well as the line of conclusions drawn, are presented in detail in the corresponding result chapter of this paper. By being aware of our role as researchers, and elaborating on this position and the limitations it brings to this research project demonstrates a certain degree of reflexivity, which is described as a main method to achieve confirmability within a research study.

While confirmability is characterised by internal validity (Guba, 1981; Shenton, 2004), transferability is concerned with the external validity (Lincoln & Guba, 1985), meaning that when conducting qualitative research, the data collected is always depending on the context in which the research was conducted (Guba, 1981; Lincoln & Guba, 1985). Therefore, special focus should be put on how to transfer the knowledge gained towards a more general conclusion (Lincoln & Guba, 1985; Rolfe, 2006). To succeed, the researchers are advised to gain as much information from as many different perspectives as possible to answer the research question (Guba, 1981). By using different data sources and incorporating the information obtained in

addressed. For example, this can be seen in the described sampling strategy aiming at talking to respondents from different backgrounds. Furthermore, we describe the context of the obtained data in detail and offer thoughts on the transferability of the analysed outcomes to other situations.

Additionally, we are aware of the fact, that methodical limitations have to be considered. Conducting a qualitative study always entails relying on individuals and their personal perspectives on the issue under investigation. The sample strategy outlined was specially designed and used to overcome the danger of "cherry-picking" meaning that relevant information could be ignored which in turn limits the generalisability of the data (Guba, 1981). Nevertheless, the knowledge extracted from the interviewees which formed the basis for the conclusions presented later on is closely linked to these individuals. However, we decided that placing the study within a social constructionist environment presents the matching choice to elaborate on our research question. The at this point limited knowledge available in the field reasons the inductive approach taken within our study. Therefore, aiming at gathering different experiences concerned with the topic and extracting these through qualitative interviews promises to generate valuable insights. Out of these reasons, the advantages of engaging in this research direction for us outweigh the limitations presented above.

3.8 Ethical Considerations

Doing research in business and management naturally involves interactions with real people. This is the point where ethics come into play and should be considered seriously (Myers, 2020). Ethics in general are describing the moral principles everybody holds that lead them in their thoughts and actions concerning particular situations. Turning to research ethics specifically outlines the ethics involved in all parts of conducting a study (Maylor & Blackmon, 2005; Myers, 2020). Overall, the minimum that is expected of any researcher is to do no harm (Easterby-Smith et al., 2018; Maylor & Blackmon, 2005). Furthermore, the additional goal should be to provide benefits to everybody involved. These aspects can be summarised as a call to all researchers to "treat others as you for yourself would want to be treated and provide

benefit to the organisation and individuals involved in your work" (Maylor & Blackmon, 2005,

p. 281).

Generally, the ethical responsibilities of researchers can be divided into two groups according to their direction. On one hand, the participating respondents have to be protected. On the other hand, the integrity of the researcher and the academic community must be maintained (Easterby-Smith et al., 2018). The following comments explain in detail how both aspects are addressed in this study.

These responsibilities start before the actual conduction of the study. Already during the phase of researching the literature of the field the threat of plagiarism has to be identified and prevented (Maylor & Blackmon, 2005; Yin, 2018). Within this paper special focus is put on that issue and strictly all used sources are cited. Moreover, the responsibilities towards the academic world in this phase include issues like honesty, being up to date with recent research in the field, and providing the needed accuracy (Yin, 2018). These can be achieved by

undergoing a thorough review of all literature in the field. Working on this research study as a team allows the supervision of the individual researcher and a contact person in any case of uncertainty regarding ethical issues.

During the actual phase of data collection another set of ethical issues needs to be considered. Relying on individuals as a source of data raises the importance to consider their own goals and expectations within the research study. However, by approaching all respondents individually from each other and without committing to further collaborations of any kind concerning the research study on hand allowed us to stay mostly independent with only a limited number of stakeholders influencing the research process. During the following data analysis honesty again plays an essential role. Regardless of prior expectations or obtained pressure findings should not be manipulated into one direction or the other (Maylor & Blackmon, 2005).

Finally, during the step of writing the research report confidentiality of the individuals involved has to be guaranteed (Myers, 2020). Additionally, the control over the data gathered in previous stages lays by the researcher who has to act ethically responsible and ensure the privacy protection of all information (Easterby-Smith et al., 2018). This research paid high attention to the privacy as well as the confidentiality of every respondent and made sure to protect these during all phases of the research. The consent form used during the interviews can serve as an exemplary measure utilised to achieve this.

After having discussed all the technicalities and the concerning ethical issues of the study, the actual content itself also needs to be considered. Drawing a set of managerial challenges and ways that could help the implementation of Industry 4.0 has the potential to directly influence management positions in manufacturing companies. Individuals possessing favourable characteristics will likely be preferred over others in the search for appropriate persons to hold such a position. This leads to people being disadvantaged because their education had not yet disposed of specific contents being directed towards these issues in the environment of the fourth industrial revolution.

Additionally, the outcomes of the study might reveal that a skill portfolio different from the one current managers possess would be preferred to guide the implementation of Industry 4.0 which might have negative consequences for those. On the other hand, these findings could open up a direction for training for the corresponding individuals. But not only the managerial role is meant to change, operators and workers on lower level within the firm are likely to face a similar shift of required skills and competencies. While this can translate into an opportunity to personally grow and develop for some, others who are not able to adapt to the changes might no longer be able to perform the work they are required to.

4 Empirical Results

This chapter gives an overview of the empirical data gathered during the study. Giving insights into each interview conducted highlights the different perspectives gained by speaking to respondents from different backgrounds and shows how these enrich each other. At the same time the individual respondents are grouped according to their profession allowing for comparison and contrasting within and between these groups. By presenting quotes from the actual interviews we enable the reader to participate in these as a virtual witness and get a feeling for the individual interviewees.

Before taking a look at the actual findings, it is worth mentioning that all interviewees can be clustered into three corresponding groups according to their occupation. While the researchers offered a very theoretical insight into the field and the current state of the research, the plant managers and consultants added a more practical perspective to the study. All areas enriched each other so that a broad picture of the situation could be created. Refer to table 4.1 to learn more about the interviews in detail and how they were conducted.

Table 4.1: Overview of conducted interviews

In the following the interviews are presented one by one allowing the reader to become a virtual witness of the conversations that took place. After a short introduction of the individual persons, the content of the interviews is summarised, and a first stage interpretation is performed. The results are structured according to topics covered during the interviews. After presenting technological facets, we show which managerial aspects were brought up. Finally, specific statements made, concerning organisational elements that may support the successful implementation of smart production processes, are shown.

4.1 Interviews With Researchers

Researcher 1

Starting off the interview series, we conducted an interview with an academic researcher working at a Swedish university. Having an engineering background, the respondent has just recently defended his/her Ph.D. in the field of managing maintenance operations in production in the context of the ongoing technological shift towards Industry 4.0. Having spent years on researching these connections the interviewee differentiates between two general challenges occurring when implementing smart technology into production processes.