VTI notat 8-1998 '

Validation of indirect tensile

test for fatigue testing of

bituminous mixes

Author

Safwat F. Said

Research division Highway Engineering

Project number

60410

Project name

Deterioration of bituminous layer

Sponsor

Swedish National Road

Administration

Distribution

Free

Swedish National Road and

'7i'ansportResearch Institute

Index

Page

Introduction 5

Verification of ITT in respect to other fatigue methods 5

Using ITT in practice 9

Other benefits of ITT 12

Conclusions 13

Acknowledgement 11

References 14

Appendix

VALIDATION OF INDIRECT TENSILE TEST FOR

FATIGUE TESTING OF BITUMINOUS MIXES

Introduction

The Indirect Tensile Test (ITT) was introduced in Sweden more than 10 years ago. A description of the ITT has been presented earlier and its practical advantages and disadvantages have been discussed [1, 2, 3]. The ITT has been adopted by ASTM (ASTM D 4123) and FAS (The Swedish Asphalt Pavement Association) (FAS Method 454) for evaluating the elastic stiffness (resilient modulus) of bituminous materials. In Sweden, thousands of specimens from various types of bituminous mixes have been subjected to fatigue tests and tests to determine elastic stiffness and tensile strength. Nowadays, the reliability of the ITT, including fatigue test, is judged to be fully adequate for routine use by Operating agencies. The VTI's test procedure for determination of fatigue Characteristics of bituminous mixes is presented in the attached Appendix.

Verification of ITT in respect to other fatigue methods

The fatigue life of bituminous mixes determined from laboratory tests depends on the definition of initial strain/stress and the definition of failure. The results can be presented in plots of initial stress vs. number of cycles, but normally they are presented in plots of initial strain vs. number of cycles. All fatigue tests include repetitive deformations, with bothelastic and plastic deformations. In bending or flexural tests, the beam specimen is either loaded for a given time and then forced to its original undeflected position, or it is sinusoidally loaded with reversal stresses. The strain is computed from the total (maximum) deformation during a loading period. In ITT, the cylindrical specimen is also loaded for a given time, but is then left to recover the deformation by itself. The strain can be computed from the total (maximum) deformation or resilient (elastic) deformation (Figure 1). In certain earlier investigations, the strain was computed from the resilient deformation, which is unsuitable for fatigue experiments, particularly in respect to temperature. The temperature susceptibility of the bituminous mix has a noticeable effect on the fatigue life of asphalt concrete. At higher temperatures, asphalt mixes demonstrate higher resistance to fatigue loading.

TD = Total deformation RD = Resilient deformation PD = Plastic deformation RD De fo rm at io n Time

Figure 1 Definition Qfdaformations.

Figure 2 shows the influence of the total strain and the resilient strain on fatigue curves using ITT with respect to temperature [4].

1000 100 Ini tialt ot al st ra in (m ic ro st ra in) 10 1000 10000 100000 1000000 Number of Ioads A1000 .E E 175 E .9 E, .E E 1000: E .9 .E .72 :E "' 10 1000 10000 100000 1000000 Number of Ioads

FigureZ Efect of total and resilient stram on fatigue life prediction with

respect to temperature.

The strain from the ITT must be computed from the total strain in order to be comparable with the fatigue results obtained with the flexural tests, especially in regard to the effect of temperature or stiffness of the mixes. These results are in agreement with the conclusions reported by Ruthand Olson [5] and Kim, Khosla and Kim [6].

An investigation coordinated by Nordic collaboration (NVF) [7] was carried out to find out the correlation between fatigue test methods used in northern countries. A typical asphalt concrete (Ab 16t) from Norway has been tested by four laboratories at ISOC. Specimens were manufactured with the California Kneading Compactor. The resultsare presented in Figure 3. It is concluded that the differences are primarily due to the test procedure, and the fatigue curves obtained with the lTT do not differ from curves obtained with other methods.

Strain, ;.18

.I

_I _/I

/I

u H_ I I' II 1000 "' H II II./I

N \.\l N . § hä. §§\ Il 100 L! 1 I l> 6 103 104 105 10 No. Of load applicationsFigure 3 Fatigue life relationshipsfor various test methods [7].

S(KS); Sweden, constant-stress, ITT, 01/14 sec, D(KS); Denmark, constant-stress, 3-p0int beam, 40 Hz. N(KT); Norway, constant-strain, supported beam, 0 05/0 95 sec, F(KT); Finland constant-strain, supported beam, 0 05/0 95 sec, N(KS); Norway, constant-stress, supported beam, 0 05/0 95 sec, F(KS); Finland, constant-stress, supported beam, 005/095 sec,

An interlaboratory test coordinated by RILEM (TClOl, TC152) was carried out to compare different test procedures and test equipments for the measurement of mechanical Characteristics of bituminous materials [8]. The VTI took part in the interlaboratory test for measuring elastic stiffness and fatigue resistance of asphalt concrete using ITT. The authors concluded that the moduli from ITT and bending were in good agreement at OOC and 20°C. However, the fatigue results obtained With the various methods are presented together in Figure 4. Unfortunately, there are no comments on the individual test method. VTI's results using ITT are redrawn in Figure 4 for the sake of comparison.

Figure 4 Fatigue curves ofa mix at diferent temperatures obtained by different laboratories [8] and the fatigue curve obtained by [TTfor the same

Wllx.

Presenting fatigue results in stress vs. number of load applications, Kennedy [9] has tested the fatigue life results obtained with ITT against fatigue results reported by different investigators using other test methods, see Figure 5. It was found that the results obtained from ITT were compatible if the applied stress was expressed in terms of stress difference to account for the biaXial state of stress,

which exists in the ITT.

Stress Difference N/mu2

10'!

. '? |o3 'o_1 1 1111111' 1 1111111'

5 K'z values are for stress difference m pei

: K'z (for "ren in N/cmz) : (|45'") K'z 107-_ E Momsmolh et al - nz=35l 0 _ 4551:10 5 Rodhby 8. T:$3°F '0 E Sterlmg : :120.87 : K'f3.65l 'O 1 T: 77° '05% 2 q 5 \ g lot: \\ D I c - \ Ls - \ MOnusmum et al _ \ nz : 9 Kå=|.78 x 10'6 IOL T : 40°F : mKennedy et al \ Pc et 0' _ mdureci 'ensaon \\ 02* 3.9 .2

2 oPell etal Kid'o l '0

'0 ____ rovolmg canhlever T = 50° F : Monismilh et ut o 2 0 flexure _. AR a Kennedy et 0! d allhby Slerlmg _ direct Iension "2- 3 88 H \ x; I 03x IO

IO-é |805ed on stress)_/> 7:750';

: Kennedy el ul \ "' t3.88 . * sz4.76 1 :0 1 T: 75°F 0 1 1 I I I I 1 I I I I I I 1 I | I IO !0I 2 to3 Stress Diffemcemsi

Figure 5 Fatigue life relationshipsfor various test methods [9]

A comparison between ITT using Nottingham Asphalt Tester (NAT) and a two-point bending test has been done at the University of Nottingham [16]. The author is concluded that the correlation is good between the tests results in the region of tensile strain which is of interest.

Consequently, the comparisons between test methods indicate an insignificant effect of the test methods on the fatigue results. Alternative explanations for the differences may be different test conditions or the procedure used in analyzing fatigue results.

Using ITT in practice

Case 1 (details published at ISAP 1997, ref. 12)

More than 300 cores with a diameter of 100 mm were drilled from roadbase layers on 15 test sections when new, and used among other tests for fatigue testing in the laboratory. Eleven of these test sections have been under observation for almost 10 years in order to develop a field-based asphalt fatigue criterion. Development of distress in the road sections is followed by FWD measurements for calculating tensile strain at the bottom of roadbase layers, in addition to traffic counts and pavement distress surveys [10, 4].

The field-based criterion is used here to validate the laboratory-based fatigue criterion. The cores from roadbase layers on the eleven test sections were tested at two temperatures and the fatigue relationships are presented in Figure 6.

The statistical analysis for each test section has shown the significant effect of temperature at the 5% level. The variations in the fatigue results were expected due to a high variation within and between the roadbase mixes on the test sections [11,12]. This variation is of the same order as the variation in the fatigue life in the field [4]. The effect of temperature is fairly small (Figure 6). This is probably due to the low binder content in the roadbase mix (42%). The effect of temperature has also been verified by testing laboratory manufactured specimens.

The calculated fatigue relationship at 10°C based on laboratory measurements at 40 and 15°C is compared with the field fatigue relationship representing field conditions at 10°C, which is presented in Figure 7. These relationships are thus developed independently. A shift factor of magnitude 10 is obtained, depending on the level of strain. It is concluded that there is a good agreement between laboratory results using ITT and the field fatigue criterion. The ITT, which is relatively simple and rapid to perform, is also sufficiently accurate for routine use.

1 000 w :L c.

'5

173 E '52 1001E+2 1E+3 1E+4 1E+5 1E+6 1E+7

No. of applications 1 000 W :5. c.

'§

*01 .72i

1001E+2 1E+3 1E+4 1E+5 1E+6 1E+7

No. of applications

Figure 6 Fatigue curves Ofroadbase layer, mix AG25.

Roadbase layer (A625), 10°C In it ia l st ra in , pe

n=2.9 k=1.1E11 k = 14.1 E10 100 9aw

8+

-*37: 7__ - _ _ _ . . . _ _ . _ _ . _ _ _ .6 FTFITIH I Iilllli I lillill iiillln

1E+3 1E+4 1E+5 1E+6 1E+7

Applications to failure

Figure 7 Laboratory andfzeldfatigue criteria of the roadbase layer AG25 at +10°C

Case 2 (details published at 4th Int. RILEM symposium 1997, ref. 14)

In order to study the performance of mixes used in roadbase layers, eight test sections have been built into a newly constructed road. Accelerated pavement testing by a Circular Test Track (Neste - Finland) and experiments in the laboratory are the first part of this work, which is presented here. The bituminous mixes used in two of the Test Track sections were from the same materials as those used in the road sections. The reference mix (AG25/B180) is compared to a modified stone mastic asphalt (SMA25) with highvoid ratio and similar to porous asphalt. It is used as a roadbase layer in this work. Stiffness and fatigue properties of cores drilled from the circular test sections have been determined in the laboratory using Indirect Tensile Test. Both the test track and laboratory tests are carried out at a temperature of 10°C. Fatigue lives of the mixes obtained in the laboratory are compared with the results obtained from the Test Track.

The construction of pavements at the Test Track, installation of load cells and strain gauges and the follow-up of the deterioration of the test pavements have been performed and reported by Neste Oy and VTT (Technical Research Centre of Finland) [13].

A comparison between Test Track and ITT results [14] has been made with respect to initial transversal tensile strains measured by strain gauges at the bottom of roadbase layers ofthe Test Track sections. Fatigue relationships of the roadbase layers obtained by ITT are presented in Figure 8. Fatigue lives of the AG and SMA layers have been obtained from their fatigue relationships at the initial strains measured in the Test Track. The calculated fatigue lives show longer fatigue life for the AG layer than the SMA layer. This is in agreement with the conclusions from accelerated testing at the Test Track. The indirect tensile test has ranked the tested mixes similar to accelerated testing. It has also proved to be a

practical and accurate tool for determination of fatigue resistance of mixes in routine use.

These results will be verified by testing cores obtained from road_ sections in the laboratory and following up the deterioration of the road sections during a five-year period.

1000

:m

l

rum

m SMAZS WAGZSt = %?3.

ä

't as

* ä W

s å ä år; "53 \\ så e l- i. 3%?ä

N

*a* t

,å

se

\ % Q\

\\'\ 100 N-1E+4 1E+5 1E+6

N0. of applications Figure 8 Comparison between roadbase layers.

Other benefits of ITT

Simulation of field

The pavement layers are exposed to different types of stresses and strains during wheel passage. The longitudinal and transversal cracks in the wheel paths are mainly induced by the transversal and longitudinal strains respectively. According to Huhtala et al. [15], the longitudinal strain signal is compression first, then tension, then compression again. After the wheel passage, the strain will be zero (no permanent deformation). However, the transversal strain signal is only tension, which slowly decreases to zero. The transversal strains are usually larger in magnitude and loading time than the longitudinal strains under the same loading conditions. Thus the transversal strains are more destructive than the longitudinal strains and this is probably the reason why the longitudinal cracks are usually observed first on the pavement. surface.

The deformation signal generated by the ITT is comparable to the transversal strain signal form measured during a vehicle passage. Only tension is present and this slowly decreases to zero. Therefore, ITT simulates well the field conditions in respect to fatigue cracking caused by traffic loading [12].

Maximum tensile stress

The bending test introduces tensile stresses on the surface of the test beam. The fatigue life is affected by irregularities on the beam surface. However, the maximum stress in the ITT is at the centre of the specimen, which is relatively uniform.

Precision statements

Precision statements are not arranged. However, for homogeneous specimens it has been shown that 10 specimens or even fewer are sufñcient for determination of a fatigue curve.

Conclusions

The repeated-load indirect tensile test has been increasingly used in the last decade. It has been investigated widely, primarily due to its practical advantages.

The disadvantage of this method is the accuracy of stiffness determination because the stress distribution is only valid under ideal elastic conditions when the behaviour of bituminous mixes is predominantly linear. Furthermore, the Poisson's ratio must be assumed for the determination of strain across a horizontal diameter.

On the other hand, the great advantages of the indirect tensile test are its simplicity, speed and economy. Also, it can be used both by Operating agencies and research institutes. The ITT is suitable for quality control and mix design. Cylindrical specimens are used which are relatively easy to fabricate in the laboratory or to drill from the road layer or a slab. The test has proved sufñciently accurate for routine measurements.

Acknowledgement

This report is a part of the project "Deterioration of bituminous layer". The author is grateful to the Department of Highway Engineering at the Swedish National Road Administration for their ñnancing of this project.

References 10. 11. 12. 13. 14. 15. 16. 14

Göransson N-G och Hultqvist B-Å, Provning av mekaniska egenskaper hos Marshallprovkroppar , VTI meddelande no. 437, Linköping 1987. Said S.F, Tensile and F atigue Properties of Bituminous Mixtures Using Indirect Tensile Method , Ph.D. Dissertation, Dept. of Highway Engineering, Royal Inst. of Technology, Stockholm 1989.

Said S.F, Resilient Modulus by Indirect Tensile Test , Proceedings of the 4th International RILEM Symposium, Budapest, October 1990.

Djärf, L., Said, S.F, Laboratory Fatigue Properties Compared with Field Performance 5th Eurobitume Conference Stockholm June 1993.

Ruth, B.E. and Olson, G.K, Creep Effects on Fatigue Testingof Asphalt Concrete Proceedings of the Association of Asphalt Paving Technologists, Vol. 46, 1977.

Kim, Y.R., Khosla, N.P. and Kim, N, Effect of Temperature and Mixture

Variables on Fatigue Life Predicted by Diametral Fatigue Testing Transportation Research Record No. 1317, 1991.

NVF -Report, Utmattningkriterier for asfaltbelegningar , Utvalg 33 Asfaltbelegningar Rapport no. 7, 1992.

Francken L., Eustacchio E., Isacsson U., and Partl M.N., Recent

Activities of RILEM TC 152-PBM- Performance of Bituminous

Materials , Proceedings of 8th Int. Conf. on Asphalt Pavements, Seattle

August 1997.

Kennedy, T.W., Characterization of Asphalt Pavements Materials Using the Indirect Tensile Test . Proceedings of the Association of Asphalt Paving Technologists, 1977.

Djärf, L, Performance Based Asphalt Strain Criteria 3rd Int. Conf. on Bearing Capacity of Roads and Airfields, Norway 1990.

Said S.F, Fatigue and Stiffness Properties of Roadbase layer Using Indirect Tensile Test , The Euroasphalt & Eurobitume Congress, Strassbourg May 1996.

Said S.F., Variability in Roadbase Layer Properties Conducting Indirect Tensile Test , Proceedings of 8th Int. Conf. on Asphalt Pavements, Seattle August 1997.

Pienimäki M. & Pihlajamäki J., , Fatigue Testing in Neste Circular Test Track Neste Oy Research Report 89/95, Finland 1996.

Said S.F. & Johansson S., Mechanical Properties of Bitumen Roadbase Mixes Proceedings of the 5th Int. RILEM Symposium, MTBM Lyon May

1997.

Huhtala M., Alkio R., Philjamäki J., Pienimäki M. and Halonan P.,

Behav-iour of Bituminous Materials under Moving Wheel loads Journal of the Association of Asphalt Paving Technologists, Vol. 59, 1990 p. 622.

Read J.M., Practical Fatigue Characterisation of Bituminous Paving Mixtures The Asphalt Yearbook 1997, The Institute ofAsphalt Technology, UK.

Appendix :Page'1(8)

BITUMINOUS MATERIALS

Determination of fatigue of bituminous

mixtures

VTI method

1 Scope and field of application

This method is aimed at characterising the behaviour of bituminous mixtures under repeated load fatigue testing with a constant load mode using Indirect Tensile Test

(ITT). A cylindrical specimen manufactured in a

laboratory or cored frcm151 road layer can kxa used in this test.

2 Principle

A cylinder-Shaped test specimen is exposed to repeated compressive loads with a haversine load signal through the vertical diametral plane. This loading develops a relatively uniform tensile stress perpendicular to the direction (ME the applied load.enui along tima'vertical diametral plane, which causes the specimen to fail by

splitting along the central part of the vertical

diameter. The resulting horizontal deformatbmn of the specimen is measured and an assumed Poisson's ratio is used to calculate the tensile strain at the centre of

the specimen. Fracture life is defined as the total

number" of load. applications before fracture of the

specimen occurs.

3 Apparatus and accessories

The testing machine shall be capable of applying

repeated haversine load pulses with rest periods at a

range of load levels.

The VTI's Material Testing System (VMS) is a

servo-hydraulic testing' machine with a loading

capacity of-*up to 25 kN. It can be controlled

either through force, deformation or strain. A PC'

with ATS software is used for system control and

data acquisition.

Appendix Page 2 (8)

Loading: The system shall be capable of applying a

load ranging from 0.5 to 10 kN with an accuracy of

O.25%.

The maximum load capacity required depends on the

size of the specimen, the testing temperature and

character' of' the .material. For example, up to

20000.N has been used for specimens of basecourse

mixture with a diameter ofSZlSO mm at _4OC.

Deformation: The deformation along the horizontal

diametral plan is measured using two extensometers

connected ill series. (Hua extensometers snudd_ have aa

resolution < 1 um with a measuring range of 3.75 mm.

Type 632.11C' extensometers .famn AHE? Corporation

are used in the VMS.

Thermostatic Chamber: The thermostatic Chamber shall be capable of control over a temperature range from 2 to

ZOOC and with an accuracy of ilOC.

The normal test temperature is lOOC. If fatigue tests are conducted at two temperatures, the test temperatures shall be 4 and l5OC.

Recording and measuring system: During the test, the

compressive load and the horizontal deformations are

measured at preselected intervals. All recording and

measuring devices shall be able to conduct at a minimum frequency of 10 Hz.

Loading device: The loading device (Figure l) consists

of two ;platens 'with loading strips :mounted. on lmall

bushing guided posts, which centre the specimen, keep

the loading strips in the vertical plan, and eliminate

undesirable movement of the specimen during testing.

The upper platen. weighs 1000 g, which provides an

additional static load on the specimen. Loading strips

with concave surfaces and rounded edges shall have a.

radius (M5 curvature equal tm) the radius of time test

specimen Specimens shall :have 51 diametexf of either

ølOZ mm or ø152 mm, in which case the width of the

loading strips vnjj_ be 12.7 Imn and. 19.1 Imn

respectively.

Deformation strips: The deformation transducers are

fixed tx: two cmumnxi steel strips vüüxül are glued cn1

opposite sides (ME the horizontal diametral plan. See

Appendix Page 3 (8)

Figure 1. The deformation strips are 2 mm thick, 10 mm

wide and normally 80 mm long. The length of the strips

depends on the specimen thickness. It is recommended to have a set of strips with different lengths. At each end of the strips there is a screw with a plastic nut

for adjusting tina measuring range (HE the deformation

transducers.

Gluing rig: The gluing rig will help positioning of the

deformation strips at the opposite sides of the

horizontal diametral plane. The rig, illustrated in

Figure 2, is suitable for both ølOZ mm and ø152 mm

diameter specimens and for the various lengths of the deformation strips.

Glue: A quick hardening cyanoacrylate type glue has

been found suitable.

Load cell

Asphalt specimen Extensometer Deformation strip Loading strip

Figure 1. The loading device with loading and

deformation strips and specimen in place.

Appendix Page 4 (8)

Figure 2. The glue rig with deformation strips and

specimen.

4 Specimen preparation

Prepare 10 to 18 test specimens according to laboratory

compacting standards or using cores from the road

layer. The specimen shall have a thickness of at least 40 mm and a diameter of 100 mm for a maximum aggregate size of 25 mm, and a thickness of at least 60 mm and a diameter of 150 mm for a maximum aggregate size of 38 mm.

Measure the cünmmsions (ME the specimens according to

the standards.

Glue the deformation strips on the horizontal diametral plane of each specimen.

Place tina specimens in time thermostatic Chamber' and

expose them to tina specified test temperature for at least 4 hours prior to testing.

5 Test procedure

The test shall be planned to cover a strain level range

of approximately 100 to 400 ps which is expected in the initial life of roads.

The calculated tensile strains at the bottom of

roadbase layers in Swedish conditions vary between

100 and 350 us,.measured at 2m_year after opening.

Appendix Page 5 (8)

The specimen shall be positioned in the loading device

so that the aXis of the deformation strips is

perpendicular to the axis of the loading strips.

The deformation transducers shall be mounted and

adjusted so that the total gauge length can be used.

During time test, the load enui horizontal deformation

are sensed continually and recorded at the preselected

intervals.

The test shall normally start at about 250 kPa loading amplitude. Apply a repeated haversine load with 0.1 sec

loading time and 0.4 sec rest time (a frequency of 2

Hz). If the deformation shown on the Hmnitor during

the first 10 applications is outside the strain range

(100 - 400 us) the test shall be smopped immediately

and the load level adjusted.

In almost every case, 250 kPa has been found to be a. practical stress .level. .Experienceri operators can choose a suitable stress level with regard to

the stiffness of the tested material.

The tests are also planned so that the fatigue life of

tested material will be in a range between 103 and 106

number of applications.

When obvious cracking is shown on the vertical aXis, the test is stopped.

6 Calculation and reporting of results

6.1 The following procedure shall be carried out

for each specimen tested:

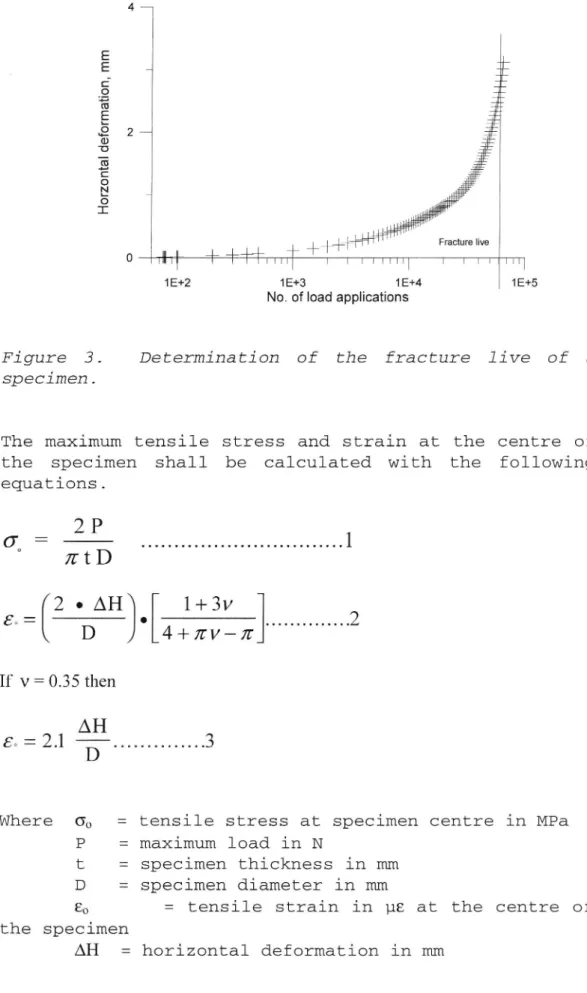

Determine tina fracture life. THME fracture life (IE a

specimen is the total number of load applications that

causes a complete fracture of the specimen. The

fracture life is obvious from the relationship between

log' number" of lrxxi applications euui horizontal

deformation. See Figure 3.

Appendix Pag66(8) 4_ E E _ C. .9 Ti

E

8(D 2-_ '0 3c 0 E _ o I un_|_ _L_ _1_| | + _ ' FractureliveO HIIII I Illlllll I IIIIHI. I III III!

1E+2 1E+3 1E+4 1E+5

No. of load applications

Figure .3. Determination cdf tina fractUIEe live CU? a

specimen.

The maximum tensile stress and strain at the centre of

the specimen shall be calculated with the following

equations. ZP (70 = --- ... ..1 ntD (2.zni)[ 1+3v ] a: ---- ... .2 D 4+nv-n Lf\/=(l35then ZlAH 3

a: .-- ...

DWhere 00 = tensile stress at specimen centre in MPa

P = maximum load in N

t = specimen thickness in mm

D = specimen diameter in mm

&) = tensile strain in us at the centre of

the specimen

AH: = horizontal deformation in mm

Appendix :Page'7(8)

The initial strain is calculated from the total

horizontal. deformation en: the ZUNTh loaci application,

which is illustrated in Figure 4.

The initial strain shall be calculated after the

deformation has been stabilised, which normally

occurs before 60 load applications. The initial

strain value is calculated' from the difference

between the average of the total horizontal

deformations of 5 load applications from 98 to 102

and tina average (if the IMULUMHD horizontal

deformations of 5 load applications from 60 to 64.

ThiS'_procedure .makes it easy' to <aalculate the

initial strain by computer from the data sheet for the specimen. TD = Total deformation RD = Resilient deformation PD = Plastic deformation De fo rm atio n RD 'LÅPD 4 Time

Figure 4. Definition (lf the txnxil horizontal

deformation.

The fatigue criterion for an individual bituminous

material is determined from the tested specimens. The least-squares regression relationship shall lya fitted

tm) the data CMS the log (ME the initial strain as an1

independent variable and time data of tina log (HE the

fracture life en; a. dependent 'variable according to

equations 4 and 5.

Log Nf = k+n10g 80 ... ..4

n 1 Nfzk _ . . . . Q whereNf = number of load applications

k and n = material constants

80 = tensile strain in us at the centre of

the specimen.

Appendix Page 8 (8)

7 Report

The test report shall include:

- a statement that the test has been performed

according to this standard, and the testing date,

- the identification of the mixture,

- identifications of the specimens,

- testing temperature,

* 51 graphical enui mathematical. presentation (ME the

fatigue criterion,

- the R2 value

![Figure 2 shows the influence of the total strain and the resilient strain on fatigue curves using ITT with respect to temperature [4].](https://thumb-eu.123doks.com/thumbv2/5dokorg/4916743.135402/5.892.206.675.190.407/figure-influence-strain-resilient-strain-fatigue-respect-temperature.webp)

![Figure 4 Fatigue curves ofa mix at diferent temperatures obtained by different laboratories [8] and the fatigue curve obtained by [TTfor the same](https://thumb-eu.123doks.com/thumbv2/5dokorg/4916743.135402/7.892.236.656.103.444/figure-fatigue-diferent-temperatures-obtained-different-laboratories-obtained.webp)