ISSN 0347-6049

_VIImedaelande

608)

_

1990

_ Tire/road noise. on rubberized asphalt and

cement concrete surfaces in Sweden

UIf Sandberg, Jerzy A. Efsmont and Eva Gustavsson

Vag- och Trafik- Statens vag- och trafikinstitut (VTI) * 581 01 Linkoping

[SS/V 0347-6049

__V__7_'__l__:_neadelandea:

1990

Tire/road noise on rubberized asphalt and

cement concrete surfaces in Sweden

Ulf Sandberg, Jerzy A. Ejsmont and Eva Gustavsson

w 00/7 Irafik- Statens va'g- och trafikinstitut (VTI) - 581 01 Linkdping l StltUtBt Swedish Road and Traffic Research Institute - 8-581 01 Linkeping Sweden

PREFACE

This investigation, which has been financed by the Swedish Association of

Local Authorities, is part of a larger research programme; a project by

the Swedish Council for Building Research named "Use of rubber powder

and rubber granulate in road surfaces". The purpose of this project is to establish how and to what extent maintenance costs, winter maintenance,

traffic security and noise levels can be influenced if a rubberized asphalt surfacing of type "RUBIT" is laid on longer, continuous stretches of road.

Mr. Kent Gustafson, the Swedish Road and Traffic Research Institute

(VTI), has been project manager for the VTI part of the programme.

The investigation was also linked with a parallel study of noise emission on cement concrete surfaces in Sweden which is part of a more general

study of such surfaces, sponsored by the Swedish Road Administration.

Mr. B.A. Hultqvist, VTI, was project manager for this project.

Dr. Ulf Sandberg, VTI, has planned the experiments, assessed the results

and produced the main parts of the report. All measurements have been

performed by Dr. Jerzy A. Ejsmont, Technical University of Gdansk,

Poland, who also collaborated in the planning of the experiments and production of some parts of the report as well as analysed some of the measurements. A special measuring trailer from the University of Gdansk has been used for the noise measurements as part of a regular research

collaboration.

Ms. Eva Gustavsson, VTI, has assisted at the experiments and analysed part of the measurements as well as conducted all computer evaluations. In part of the tests, Ms. Maria Berlin and Mr. Glenn Lindqvist, VTI, have assisted. The report has been typed by Ms. Karin Nilsson and Ms. Barbro

Stjarnborg.

The Regional Road Administration in Malmohus léin have provided security

vehicles, signs and an assistant for the measurements in Skane. The Police

and the Swedish Army have successfully contributed several times to the

"protection" of the measurement trailer registered in Poland...

.\ l. \l .\ l. \l.\ l. \l .\ l \1 g xg xm ox um u v1 4 3 4 : 4 }? ? ? \I O\ \n ~P \»N t-m wh wwh -o xuwr uf x 0 0 0 0 0 0 0 0 W N W CONTENTS PREFACE SUMMARY SAM MANFATTNING BACKGROUND PURPOSE

HYPOTHESES ABOUT NOISE EMISSION ON ROADS WITH A RUBBERIZED ASPHALT SURFACING

PREVIOUS NOISE MEASUREMENTS ON RUBBERIZED ASPHALT

Tire/Road Noise in A-weighted Levels

Noise Emission at Low Frequencies Noise Emission at High Frequencies

Traffic Noise

Other Measurements

Other Rubberized Asphalt Surfaces

ROAD SURFACES

Test Surfaces Reference Surfaces Texture Measurements

MEASURING METHOD AND INSTRUMENTATION

Test Method Selection

Description of the Test Trailer

The Test Tires

REMARKS ON THE MEASUREMENTS Safety Precautions

Test Site RUBIT Norrkoping

Test Site RUBIT Arboga Test Site RUBIT Glumslov

Test Site Cement Concrete (CE4)

Test Site Cement Concrete (CE6)

Speed Control

RESULTS

A-weighted Sound Levels

Frequency Spectra

Comments Regarding Drainage Asphalt Surfaces

VTI MEDDELANDE 608A

III \ J ' I U I K J I U ' I -P \l _ IO 12 14 I5 17 l9 l9 I9 19 20 20 20 20 21 21 22

9. DISCUSSION 10. CONCLUSIONS

REFERENCES

APPENDIX 1: Description of Different Measuring Methods

APPENDIX 2: Discussion of Problems with the Trailer Method

VTI MEDDELANDE 608A

43 45 #6

TIRE/ROAD NOISE ON RUBBERIZED ASPHALT AND CEMENT CON-CRETE SURFACES IN SWEDEN

by

Ulf Sandberg

Swedish Road and Traffic Research Institute

Linkoping, Sweden

and

Jerzy A. E jsmont

Technical University of Gdansk

Gdansk, Poland

and

Eva Gustavsson

Swedish Road and Traffic Research Institute

Linkoping, Sweden

SUMMARY

Three road surfaces of the RUBIT type, i.e. asphaltic concrete mixed with

rubber granulate, so called rubberized asphalt, have been tested for

external noise emission. These have beencompared with a conventional,

smooth asphaltic concrete surface (HABIZT) and a conventional, rough

chip seal surface (Y1 8-12).

Similarly, three cement concrete surfaces have been tested in a parallel

project where the same reference surfaces were used.

The RUBIT surfaces all contained 3 % rubber and had 12 mm maximum chip size. They were, however, in somewhat different conditions; one surface being quitenew and one being two years old and densely trafficked.

The tests have been performed with the so-called trailer method. A special trailer constructed to measure tire/road noise, from the Technical University of Gdansk, has been used. Sound levels as well as frequency spectra have been measured.

II

Five different types of car tires have been used for the tests: one smooth reference tire, two "summer" type tires, one "winter" type tire and one

studded "winter" tire. These cover more or less the whole range of car tires, regarding noise emission.

The results show that the RUBIT surfaces emitted noise equivalent to that

from the reference surfaces. The exceptions were that the "summer" tires

gave 1-3 dB(A) higher noise levels on the oldest RUBIT surface than on the other surfaces (including the reference surfaces), and the non-studded "winter" tire gave the lowest noise on the rough reference surface.

Consequently, traffic noise reduction can not be used as an argument for using RUBIT surfaces of the types tested here. If a RUBIT surface shall

have a potential to reduce traffic noise to a considerable extent, it must

probably have an unrealistic large proportion of rubber.

Concerning cement concrete surfaces they proved to be more noisy than the conventional bituminous surfaces used as references here. The highest difference was noticed between a rough chip seal and the cement concrete surfaces for a tire with a winter tread pattern.

In all cases the high-frequency noise (over 1 kHz) and low-frequency noise

(below 250 Hz) was much higher on the cement concretes than on the

bituminous surfaces. The differences between cement concrete surfaces

of different age and wear were relatively small.

III

BACK/VKGBANEBULLER PA GUMMIASFALTBELAGGNINGAR OCH CEMENTBETONGBELAGGNINGAR I SVERIGE

av

Ulf Sandberg

Statens véig- och trafikinstitut Linkoping , Sverige

Jerzy A. Ejsmont

Tekniska hogskolan i Gda sk

Gda sk, Polen

och

Eva 'Gustavsson

Statens véig och tra kinstitut Link'o'ping, Sverige

SAMMANFATTNING

Tre vagbelaggningar av typen RUBIT, dvs asfaltbetongbelaggningar med inblandning av gummigranulat, har provats vad avser extern buller-emission. Dessa har jéimforts med en konventionell, slat asfaltbetongbe-laggning (HABIZT) och en konventionell, skrovlig ytbehandling (Y1 8 12). Vidare har tre cementbetongbelaggningar provats i ett "parallellt" pro-jekt. RUBIT-belaggningarna har samtliga haft 3% (viktsprocent) gummi andel och 12 mm max stenstorlek. De har déiremot skilt betydligt i tillsténd, frén en alldeles nylagd yta till en tvé 3r gamma] starkt

trafikerad yta.

Provningarna har utforts med hjalp av den 5 k slapvagnsmetoden. En speciell slapvagn, byggd for matn ing av dack/vagbanebuller, frén Tekniska hogskolan i Gda sk har anvéints. Ljudnivéer som har viktats med 5 k

A-kurva har uppméitts liksom frekvensspektra.

Fem olika déicktyper (personbilsdack) har anvéints vid provningarna: Ett sléitt referensdack, tva sommardack, ett odubbat vinterdack och ett dubbat vinterdéick. Dessa tacker i stort sett in alla forekommande fall vad

avser bulleremission.

Resultaten visar att RUBIT belaggningarna gav en bullerpéverkan som ar likvardig med den frén referensbeléggningarna. Skillnaderna overstiger

IV

knappast ca 1 dB(A). Undantagen var dels att den éildsta RUBIT-ytan gav

1-3 dB(A) hogre buller

n de ovriga ytorna (inkl. referenserna) for

sommardéick, dels att det odubbade vinterdéicket gav léigst bullet pé den skrovliga referensytan.

Man kan séledes inte motivera anvc indning av RUBIT-beléggningar av héir

provad typ med att de reducerar végtrafikbullret. For att en RUBIT

beléggning skall ha utsikt att reducera trafikbullret néimnvéirt méste den antagligen ha orealistiskt stor gummiandel.

Vad géiller cementbetongbeléiggningar, visade de sig ge hogre bulleremis sion in de bituminosa beléiggningar som var jéimforelseobjekt. Skillnaderna var omkring 2 dB(A) till cementbetongens nackdel. Bullerokningarna var i

stort sett koncentrerade till léga frekvenser (under 250 Hz) och

medel-hoga och medel-hoga frekvenser (over 1 kHz). Cementbetongytorna var éiven

bullrigare an RUBIT-ytorna.

Skillnaderna i bulleremissionen frén de monstrade bildéicken var smé

mellan de olika cementbetongvégarna oavsett beléiggningarnas élder och grad av slitage.

1. BACKGROUND

Investigations at the Swedish Road and Traffic Research Institute (VTI)

have shown that the variation of traffic noise levels on different road surfaces, with similar traffic, is as large as the variation of vehicle noise . levels from separate vehicles on one surface. This applies to free-flowing

traffic at a posted speed of more than 50 km/h. Consequently, it is as easy or as difficult to influence the overall traffic noise by choice of road surface as by selection of vehicles.

A consequence of the above is that the road authorities as well as vehicle manufacturers and drivers should assume the responsibility for reduction

of traffic noise.

The type of road surface which is regarded as the one giving the lowest emission of road traffic noise is drainage asphalt. When new, such a surface can give at least 5 dB(A) lower traffic noise than a non porous and

smooth asphaltic concrete surface (Ref. 1). There are also some indica

tions that a soft surface gives lower noise than a hard one for example

with an extreme porous all-rubber surface, reductions in vehicle noise

have been measured to 10 dB(A) (Ref. 2).

A rubberized asphalt surface contains normally about 3 % rubber in

granulated form which has been supposed to give a significant reduction

of noise. Such surfaces exist under the trademark "RUBIT" (in USA "Plus Ride"). Recently, a number of RUBIT surfaces have been laid in Sweden for experimental reasons and the VTI has been commissioned to

investi-gate their function; including also the noise properties.

In the noise measurements, it was found necessary to coordinate the measurements of noise properties on cement concrete and RUBIT surfaces with the testing of noise properties of some car tires, the latter of which was planned to be conducted in another experiment. Certain tires and reference surfaces could thereby be used for all three purposes and measuring equipment borrowed from Poland could be used to rationalize

the measurements.

2. PURPOSE

The purpose of this study was to investigate how the noise emission from tires rolling on RUBIT surfaces and cement concrete surfaces in Sweden differ from the noise emission from tires rolling on conventional asphalt

surfaces.

3. HYPOTHESES ABOUT NOISE EMISSION ON ROADS WITH A RUBBERIZED ASPHALT SURFACING

There are two properties in a rubberized asphalt surface which can

contribute to a relatively low noise emission:

. The rubber mixture makes the road surface somewhat softer. This can

lead to lower noise being emitted from the road surface itself (nearest to the tire/road contact patch) as well as the impact between tire pattern blocks and road surface perhaps being a little "softer", that is the tire/ road mechanical impedances will be different compared to the

case when the surface is a normal asphaltic concrete.

The VTI has shown that brand new asphaltic concrete surfaces are somewhat more silent than those that are older (at least one winter season), and that this difference cannot be a consequence of the difference in macrotexture only. Furthermore, bituminous surfaces

seem to be more silent than cement concrete when the same texture is

concerned. The differences are small, but measurable. See further

Ref. 8.

in hardness between rubberized and the

However, as the difference

conventional asphaltic concrete surfaces is rather small,

difference in noise, if any, is expected to be small.

The macrotexture of new RUBIT surfaces is more or less like that of conventional asphaltic concrete when it is still new. Asphaltic concretes will, normally, become compact and smooth with time and

wear, whereas the macrotexture of RUBIT surfaces will stay rough or

even become rougher with time. This has been observed in earlier

experiments with RUBIT surfaces laid near VTI.

Since a too smooth macrotexture usually gives higher noise levels than

surfaces with a certain moderate macrotexture, a RUBIT surface

should present a good compromise between smooth and rough texture. However, the noise effect of this is probably quite small.

4. PREVIOUS NOISE MEASUREMENTS ON RUBBERIZED ASPHALT

At the VTI, measurements were made from 1977 to 1979 on a RUBIT with

3 % rubber granulate and 12 mm maximum chipping size and a RUBIT with 6 % and 16 mm maximum chipping size. The results are summarized in the following.

4.1 Tire/ Road Noise in A-weighted Levels

According to Appendix 1, which is an extract from VTI Reprint No. 45,

the RUBIT surfaces gave about 1 dB(A) lower tire/road noise than

conventional, dense asphaltic concrete surfaces and 2-3 dB(A) lower noise than the relatively new chip seals. 1 dB(A) is approximately the smallest change in noise that the ear can detect under ideal conditions.

4.2 Noise Emission at Low Frequencies

Due to the noise insulation of buildings, the character of sound is changed when transmitted through facades into dwellings. This means that low-frequency traffic noise is the most important within dwellings. This applies when all windows are properly closed and made draughtproof. The

low frequency noise also strongly dominates inside vehicles. It is,

conse-quently, interesting to distinguish the influence the RUBIT surfaces have

partly on the low-frequency noise, partly on the high-frequency noise. Please see extracts from VTI Reprint No. 56 in Appendix 2 (Figs. 7-8, noise from "summer" and "winter" tires, respectively). There one can see that the RUBIT surfaces emit low noise levels only when they are new, i.e. when they are extra soft; but also asphaltic concrete surfaces emit

low noise levels directly after the laying.

After one or several winter seasons, the RUBIT surfaces gave noise levels that were neither low nor high. Consequently, there is no significant advantage in using RUBIT for improving the indoor environment.

4.3 Noise Emission at High Frequencies

High or medium frequencies are important near the road (outdoors) and, together with low frequency noise, also for indoor environment when windows are more or less open. See Figs. 11 12 in Appendix 2. The RUBIT surfaces give medium noise levels at high frequencies.

4.4 Traffic Noise

As traffic noise is strongly dominated by tire/road noise in free-flowing traffic, it is possible to generalize the above to traffic noise as a whole provided it comes from free-flowing traffic. If the traffic accelerates or decelerates, the difference between the surfaces, as regards traffic noise, is smaller than for tire/ road noise - frequently even negligible.

4.5 Other Measurements

The authors know only two more measurements that have been performed on noise emission from rubberized asphalt. The first was made about 10

years ago as part of a thesis at the Chalmers University of Technology.

The tire/road noise on 7 different surfaces was compared: three Topeka,

one RUBIT (3 0/0 rubber, 16 mm chipping size), one conventional asphaltic concrete with 22 mm chippings, one "Mastiphalt" and one "SCB special".

The result was that the RUBIT surface was'one of the three loudest; however, the differences were very small (Ref. 3).

The second one was made in Denmark (Ref. 10) on a RUBTO P surface

with max 8 mm chippings. It was found that traffic noise on this surface

was within 0.5 dB(A) from other similar surfaces of conventional

con-struction.

4.6 Other Rubberized Asphalt Surfaces

It is not impossible that a RUBIT surface with somewhat better noise properties than the ones tested, can be manufactured. In this case it ought VTI MEDDELANDE 608A

to contain more rubber than 6 °/o (percentage by weight) and the chippings

should not be bigger than 12 mm, preferably maximum 10 mm. It should furthermore be manufactured with a relatively open texture.

It has been suggested that a rubber additive in the binder could possibly have an effect on noise. Some years ago VTI tested a drainage asphalt

(HABIZD) with a rubber additive in the binder (road E4 at Nykoping). The

rubber proportion there was 18 % (by weight) of the binder. It did not give

lower noise than the corresponding surface without such rubber additive. For such an additive to be efficient, the proportion of rubber probably

must be increased considerably.

5. ROAD SURFACES

5.1 Test Surfaces

The following road surfaces were included in the measurement programme

as test objects:

RUBIT Glumslov (E6)

This is an asphaltic surface with 3% rubber (by weight), 12 mm maximum chipping size and a larger proportion of stone than conventional surfaces.

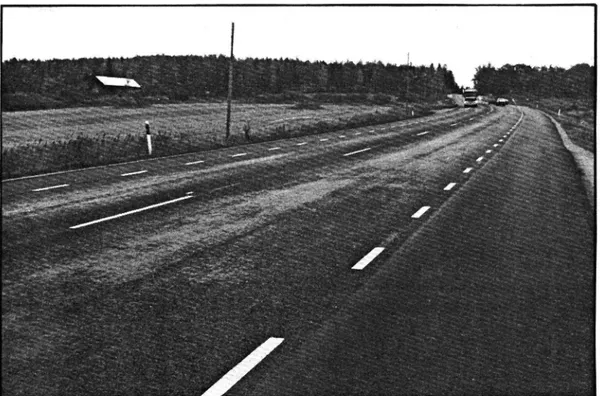

It is laid on the E6 motorway (with ll- lanes and a posted speed of 110 km/h) between Glumslov and Hilleshog, for a stretch of about 1 km, but only in the southbound lanes. The surface was slightly more than 2 years

old at the time of the measurements. The noise was measured in the right wheel track of the right lane. See Fig. 1.

RUBIT Norrkoping

The same type of surface as at Glumslov is laid on deerleden (2 lanes, 70

km/h) in Norrkoping, for a stretch of 450 m at the underpass under road

799. The surface was slightly more than one year old at the time of the

measurements. The right wheel track in both directions was used for the

measurements.

RUBIT Arboga (E3)

This is the same type of surface as at Glumslov but laid with repaving. It

is situated on road E3/E18 (2 lanes, 90 km/h) from the exit at Arboga

(direction Crebro) to the province border, about 13 km. The surface was about one month old at the time of measurements. The texture of the

surface was very inhomogeneous with patches of bleedings and patches of

fairly open texture. See Figs. 2-3. ~

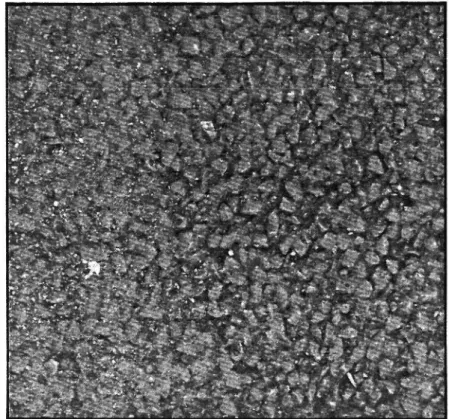

Figure l The RUBIT surface at Glumsl'o'v. The surface is two years old

and one can see the dark rubber particles between the bright Chippings.

Figure 2 The RUBIT surface at Arboga. This surface is completely new. The same scale as above.

Figure 3 The RUBIT surface at Arboga. Note the inhomogeneity of the surface, with patches of bleedings mixed with more open-textured areas.

CE}, in wheel track

This cement concrete surface was 11 years old at the time of the

measurements and is situated on the E4 between Véila and Hyllinge north

of Helsingborg (LL-lane motorway, 110 km/h) for a stretch of about 4 km.

The right wheel track of the right lane was used in both directions for the

measurements.

CE6, in wheel track

The second cement concrete surface was 17 years old. This site is on the

E6 between Fosie and Vellinge (about 12 km), south of Malmo (ti-lane motorway, 110 km/h). The measurements were made in the right wheel track of the right lane in both directions. See Fig. 4.

CE6, between wheel tracks

As above, but the measurements were performed in the left lane, between the wheel tracks, i.e. on the part of the road surface that was least worn. See Fig. 5.

10

Fi ure 4 The surface of the cement concrete CE6 (in the right wheel track). The chippings are exposed.

Fi ure 5 The surface of the cement concrete CE6 (between the wheel

tracks). The chippings are relatively unexposed.

11

5.2 Reference Surfaces

The test surfaces were compared to the following "conventional" road

surfaces:

HABIZT

HABIZT was a smooth, dense asphaltic concrete surface with 12 mm

maximum chipping size. This surface was ll- years old at the time of measuring. It is situated on road RV 34, 1 km south of the roundabout at Jéigarvallen, Linkoping, where there is a 2-lane long straight with very wide shoulders. The posted speed is 90 km/h. Measurements were

performed in both directions.

Yl 8-12

This rough reference surface was a single chip seal with 8-12 mm chippings, one year old at the time of measurements. It is laid on road

1025 (2 lanes, 70 km/h) within the Regional Road Administration in

Gstergotlands lan, just south of the T-intersection with road 1024; at

Véisterlosa, 5 km north of Mantorp and it has been only lightly trafficked. Measurements were made in both directions between the wheel tracks.

Qualification as Reference Surfaces According to ECE Proposal

The HABIZT surface meets the requirements for the smooth reference surface for tire/road noise measurements according to the proposed

standard (Ref. 4), while the Yl 8-12 surface satisfies the demands on the rough reference surface.

12

5.3 Texture Measurements

In another investigation, the road surface texture has been measured by VTI on the reference surfaces HAB12T and Y1 8-12 with the mobile laser

profilometer (Ref. 9). This yielded the following results:

HABIZT

Macrotexture level, LMa = 48.4 dB (corresponding to 0.26 mm RMS)

Megatexture level, LMe = #7.8 dB (corresponding to 0.25 mm RMSl

Y1 8 12

Macrotexture level, L a = 61.5 dB (corresponding to 1.19 mm RMS)

MMegatexture level, LMe = 57.0 dB (corresponding to 0.71 mm RMS)

Based on studies of the correlation between the profilometer values and

sandpatch measurements, the macrotexture values above can be con-verted to an estimated equivalent sandpatch texture depth of

for HAB12T: 0.40 mm for Y1 8-12: 2.50 mm

The sandpatch texture depth of the RUBIT surfaces has been measured by

the VTI Road Department to:

RUBIT Glumslov 0.93 mm (measured 4 months before the noise

mea-surements)

RUBIT Norrkoping 0.9l mm (measured 5 months before the noise

measurements)

RUBIT Arboga 0.54 mm (measured the same month)

13

On the cement concrete surfaces there are no known texture measure-ments. However, using a complicated procedure, the sandpatch texture

depth has been estimated from the low-frequency noise emission of the

P tire by inter- and extrapolating the measurement values of HABIZT and

Y1 8-12. This has given the following roughly estimated sandpatch

texture depth for the cement concrete surfaces:

CE4, in wheel track 0.2 mm

CE6, in wheel track 0.4 mm

CE6, between wheel tracks 0.5 mm

l4

6. MEASURING METHOD AND INSTRUMENTATION

6.1 Test Method Selection

There are four "on the-road" methods which can be used for road surface noise comparisons, namely the coast-by, trailer, on-board and traffic methods. The first two are subject to international standardization trials

by the ECE (United Nations Economic gommission for Europe). See Refs.

4 and 5.

In the coast-by method, the vehicle with the test tires coasts by a roadside microphone which is placed 1.2 m above the road level and 7.5 m from the centre line of the vehicle path. At least five runs should be made and averaged. This method is judged to be the most relevant when emission to the external environment is considered but is also the most

time-consuming and weather dependent. The method is very sensitive to

disturbance from other traffic and background noise. It is practically impossible to use this method on a motorway with very dense traffic, not only because of disturbances but also due to safety and technical problems (e.g. to turn around, it is necessary to use road exits which are usually

quite distant).

In the trailer method, a test wheel is mounted on a trailer which is towed by a car or truck. A microphone is positioned close to the tire/road contact area. The microphone position recommended for passenger car tires by the ECE proposal is 0.2 m outside the undeflected tire sidewall 0.1 m above the road level and 0.2 m behind the vertical axle plane (Ref. 4). The wheel and microphone can be screened from outside noise by a special enclosure. The method is relatively independent of wind conditions and noise from other traffic and requires only one test tire at a time. The method is recommended in environments with disturbing traffic, for instance on highly trafficked motorways where no other method is possible without closing the road. The biggest disadvantages are that it is a near-field type of measurement and that it is unsuitable for testing on surfaces with significant sound absorption, unless some corrections are applied (which are difficult to determine).

15

The on-board microphone method is similar to the trailer method, with the exception that one of the wheels of the vehicle is used as the test wheel; thus no enclosure can be used for reduction of disturbing noise, and also sound reflections are uncontrolled. The on board method is less suitable for measurements in noisy environments than the trailer method. The traffic method is based upon measurements of overall noise emitted by single vehicles passing by a stationary microphone at the roadside. To

get reliable results, it is necessary to measure noise from at least 100

cars and 30 trucks as well as their speed. Grades on the test sites cannot be accepted and there must be no reflecting objects within 50 m from the micrOphone. The results cannot be related to any particular type of tires.

In this project, the trailer method was chosen as its advantages overrun the disadvantages. All of the measured road surfaces were placed on roads

with high or medium traffic. None of the surfaces had any significant sound absorption. As the test trailer from the Technical University of Gdansk was readily available, and to be used in other, similar measure-ments, the cost of these additional measurements was very low. An extra advantage was that it was possible to utilize some results of measure-ments by the trailer method on reference surfaces, which had to be performed for other reasons. Grades on two of the sites and reflective environments on at least one of the sites made it impossible to use the traffic method, which otherwise would have beenthe most relevant.

6.2. Description of the Test Trailer

The trailer used for the measurements, "Tiresonic Mk3", was built at the Technical University of Gdansk, Poland. It is shown in Fig. 6. The test wheel of the trailer is enclosed in a semi-anechoic enclosure formed by the sound-reflective road surface and the trailer chamber lined with polyurethane foam to suppress reflections. The suspension was designed to make possible a ground clearance under the lower edge of the chamber of 20-40 mm. The measuring microphone was positioned as described in paragraph 6.1.

16

.

° .. , a.

-Figure6 The test trailer from the Technical University of Gdansk utilized in the measurements.

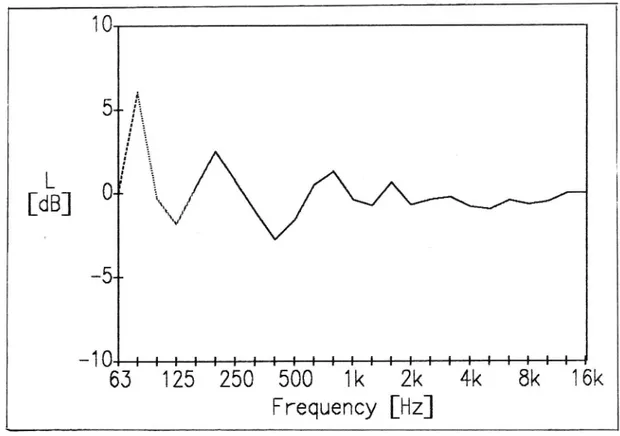

During preliminary tests at the TUG laboratory (with the trailer at standstill), the amplitude and frequency response of the semi anechoic

chamber was investigated by comparing the noise when the chamber was

in position and when it was lifted away. The latter represents a free-field case (with reflecting road surface). See Fig. 7. The response charac-teristic was found to be reasonably flat, at least for the important range of frequencies. For ~a typical tire with summer tread pattern, the

difference from free field conditions in A-weighted sound level amounts

to max. $0.5 dB(A) over the range 250-10 000 Hz. Any deviations from

ideal characteristics are the same for each tested road or tire so that the relations between the tested roads are not disturbed in this study.

The trailer was also tested for background noise influence which appeared to be negligible for typical tire/ road combinations (see Ref. 5).

l7

10

5»;

0-.

Raw,_5__

10:lhillllltlllflfilflhll

63

125 250 500

1k

2k

4k

8k

16k

Frequency [HZ]

Figure 7 The influence of the trailer chamber on the acoustic free field

conditions (with reflecting ground) in the standard micrOphone

position

During all measurements the tires were loaded to 3.0 kN and the cold inflation pressure was 190 kPa.

For each tire/road/speed combination, at least 3 or 4 runs were averaged. Each run was 16 s in duration, except on some of the reference surfaces when sometimes 8, 32 or 64 s was used. Even with the minimum 3 times 16 s, the measuring accuracy is practically uninfluenced by random errors, except those arising from inhomogeneous texture on the road surfaces.

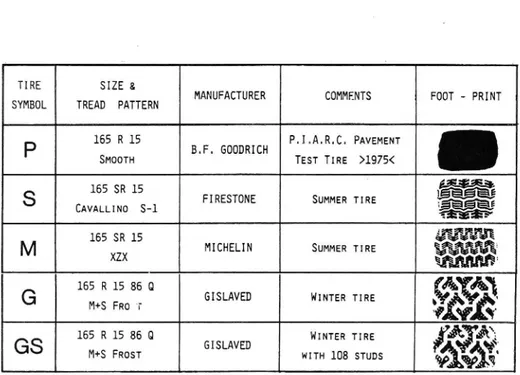

6.3 The Test Tires

To reliably compare noise emission on the road surfaces it is necessary that different and representative tires be used during themeasurements. Tires of different types may interact with road surfaces in different and

18

sometimes even opposite ways. The tires chosen for the experiment were selected in such a way as to cover a wide range of designs typical of present cars. All tires were of the 165Rl5 size. A short description of the

test tires is given below (see also Fig. 8).

0 Tire P is a standard reference tire whithout tread which can represent the extreme case when the tire tread pattern is worn out.

o The tires 5 and M represent ordinary "summer" tires.

0 The tire G represents "winter" (snow) tires without studs, in this case

with a relatively aggressive pattern. There are "winter" tires with

more "closed" patterns but these are, in terms of noise emission, more

similar to the S and M tires.

0 « The tire GS is the same as G, but with studs, and thereby represents the most common tire type in wintertime in Sweden.

TIRE SIZE 8

MANUFACTURER COMMENTS FOOT - PRINT

SYMBOL TREAD PATTERN

165 R 15 P.I.A.R.C. PAVEMENT

P B.F. GOODRICH

SMOOTH TEST TIRE >1975<

S

CAVALLINO S-l165 SR 15

FIRESTONE

SUMMER ere

W

165 SR 15

M MICHELIN SUMMER TIRE gaga

xzx W=

165 R 15 86 0 J32. A

G ms FRO m GISLAVED WINTER TIRE , i I

'

2 V 8"

165 R 15 86 0

WINTER nae

3 ;

GS M+S FROST GISLAVED WITH 108 STUDS :9? Q! qgr

Figure 8 The selected test tires

19

7. REMARKS ON THE MEASUREMENTS

7.1 Safety Precautions

The trailer method, if performed in a proper way, is a.very safe method. During all the measurements the trailer was marked with reflective signs "MATNING" (= measurement) and the towing car had yellow flashing

lights on the roof. Measurements on the motorways E4 and E6 were

additionally supported by two follow-up trucks supplied by the road authorities. The first truck was running approx. 100 m behind the test trailer and the second about 700 m behind. Whenever it was necessary to exchange tires, these were exchanged in safe parking areas.

7.2 Test Site RUBIT Norrkoping

These tests were performed in September 1989. The weather was clear and sunny. The measuring site was located in a very inconvenient place: in

a grade, in a curve and with a junction on one side. The traffic volume of

light vehicles was very high and some runs had to be repeated. During some of the runs a grass mower operated close to the roadside, but it was not audible in the earphones. The measurements were performed in both directions, one test at a time.

7.3 Test Site RUBIT Arboga

The tests were performed in September 1989. The humidity was very high and the measurements were interrupted by drizzles several times. Each time they were resumed when the surface appeared dry. The traffic intensity was rather low. The surface of the test site was very nonuniform due to bleeding on some spots and it was audible that noise was related to the trailer position on the road. See Fig. 3. The measurements were performed in both directions.

20

7.4 Test Site RUBIT Glumslov

The tests were performed in September 1989. The humidity was very high and there were occasional showers near the road. The measuring site was located on a small hill and in a gentle curve. The traffic was very dense and some of the tests were repeated because of traffic disturbances. The measuring runs were conducted only in one direction, in the right lane.

7.5 Test Site Cement Concrete (CELL)

The tests were performed in September 1989. The weather was good and the traffic was of medium or low intensity. Part of the road was under reconstruction which was a big nuisance since the trailer had to pass an

area sprayed with bitumen. Fortunately, it was after passing the

measuring site. The measurements were performed in both directions.

7.6 Test Site Cement Concrete (CE6)

The tests were performed in September 1989. The weather was unstable with a constant danger of rain. Traffic intensity was medium or low. The measurements were performed in two lanes (left and right) and in both

directions (to and from Malmo). In the left lane, the test wheel was

running between the wheel tracks while in the right lane it was running in

the right wheel track.

7.7 Speed Control

The test speed was controlled by the driver by aid of a specially designed

speedometer showing the deviation between nominal and true speeds of

the car and trailer unit. The precision in the speed adjustments was

mostly better than £1 km/h - typically 0.5 km/h.

8. RESULTS

8.1 A-weighted Sound Levels

21

The sound levels in dB(A) are to be found in Table 1. Note that these levels are measured with the trailer method, i.e. with the microphone in the near field. According to Ref. 5, 20 dB should be subtracted from these values to correspond to the levels which would have been measured with the coast-by method 7.5 m from the vehicle.

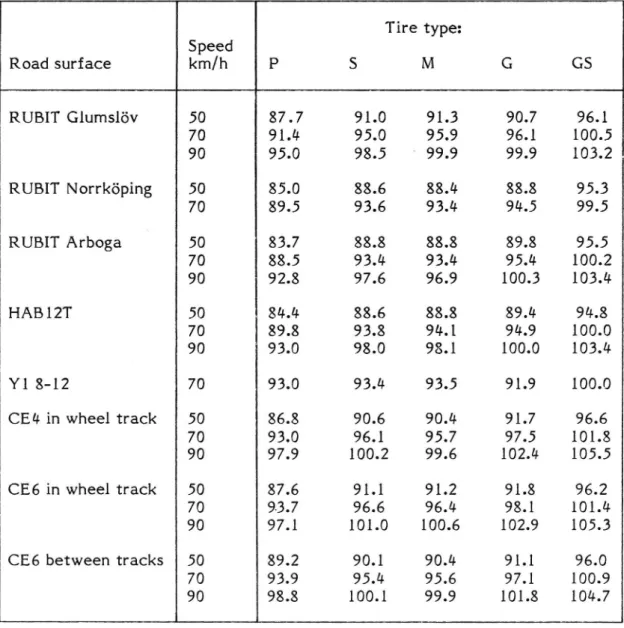

Table l. The measured sound levels in dB(A) for all the surfaces and tires that were included in the investigation.

Tire type: Speed Road surface km/h P S M G GS RUBIT Glumslo v 50 87 7 91.0 91.3 90.7 96.1 70 91.4 95.0 95.9 96.1 100.5 90 95 0 98.5 99.9 99.9 103.2 RUBIT Norrkoping 50 85.0 88.6 88 4 88.8 95.3 70 89 5 93.6 93 4 94.5 99.5 RUBIT Arboga 50 83.7 88.8 88.8 89.8 95.5 70 88.5 93.4 93.4 95.4 100.2 90 92.8 97.6 96.9 100.3 103.4 HABlZT 50 84 4 88.6 88 8 89.4 94.8 70 89 8 93.8 94 1 94.9 100.0 90 93 0 98.0 98 1 100.0 103.4 Y1 8-12 70 93.0 93.4 93.5 91.9 100.0

CE4 in wheel track 50 86.8 90.6 90.4 91.7 96.6

70 93.0 96.1 95.7 97.5 101.8

90 97.9 100.2 99.6 102.4 105.5

CE6 in wheel track 50 87.6 91.1 91.2 91.8 96.2

70 93.7 96.6 96.4 98.1 101.4

90 97.1 101.0 100.6 102.9 105.3

CE6 between tracks 50 89.2 90.1 90.4 91.1 96.0

70 93.9 95.4 95.6 97.1 100.9

90 98.8 100.1 99.9 101.8 104.7

22

The results are presented as charts in Figures 9-13. In the charts the bars

are located from left to right in ascending roughness order of the road

surfaces, i.e. the smoothest texture to the left and the roughest to the right. Observe that the lowest level in the charts is not the "zero level". Furthermore this lower level is different for different speeds. A

difference of l dB(A) is said to be the absolutely smallest difference detectable by the human hearing and a difference of 9-10 dB(A) is said to

represent a doubling of the subjective impression.

Corresponding comparisons for the cement concrete surfaces are shown in Figures 14-18.

8.2 Frequency Spectra

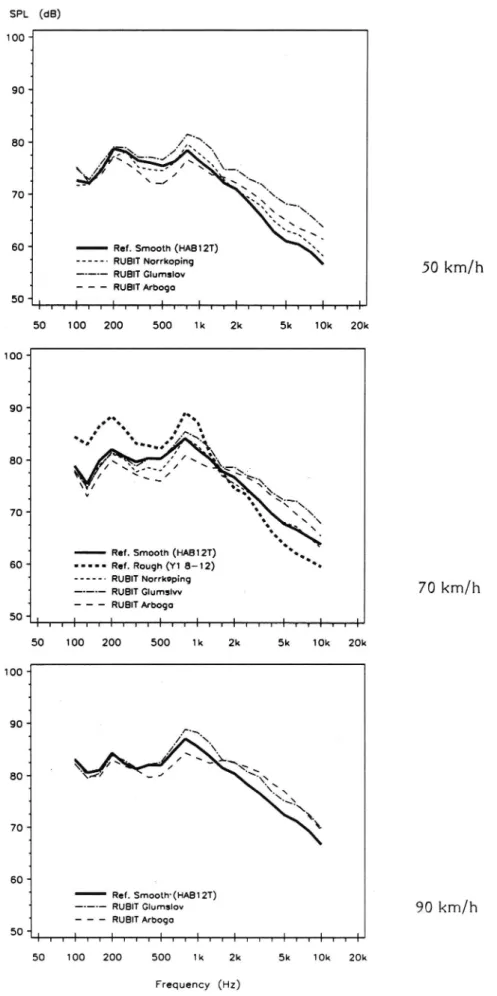

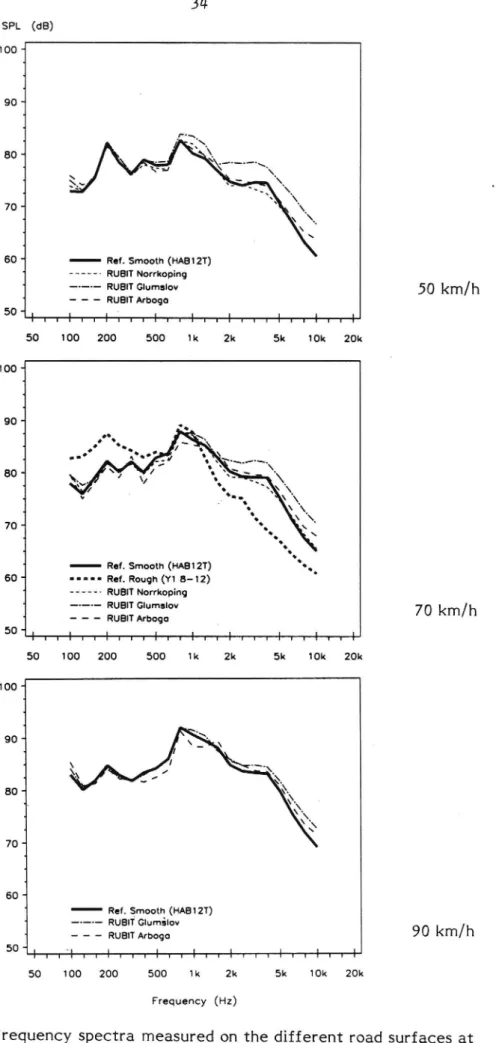

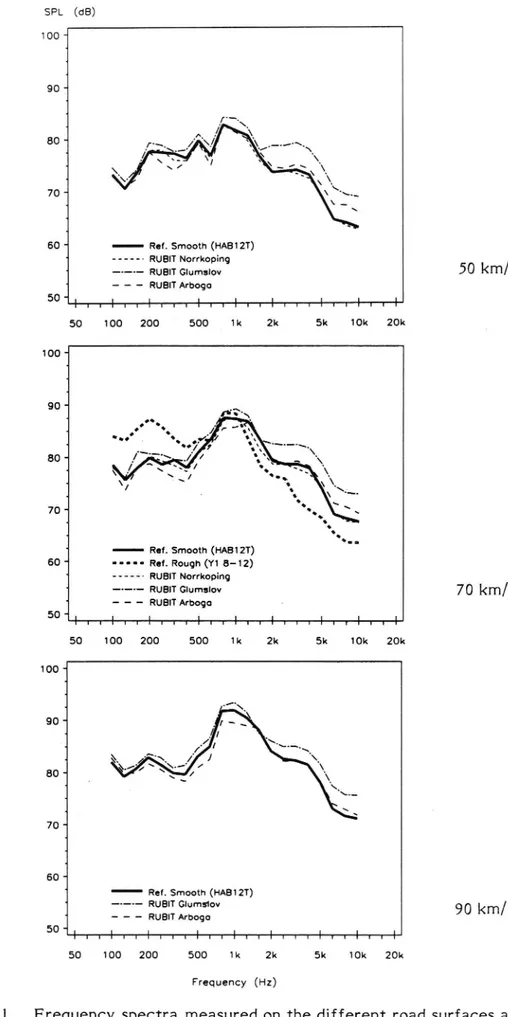

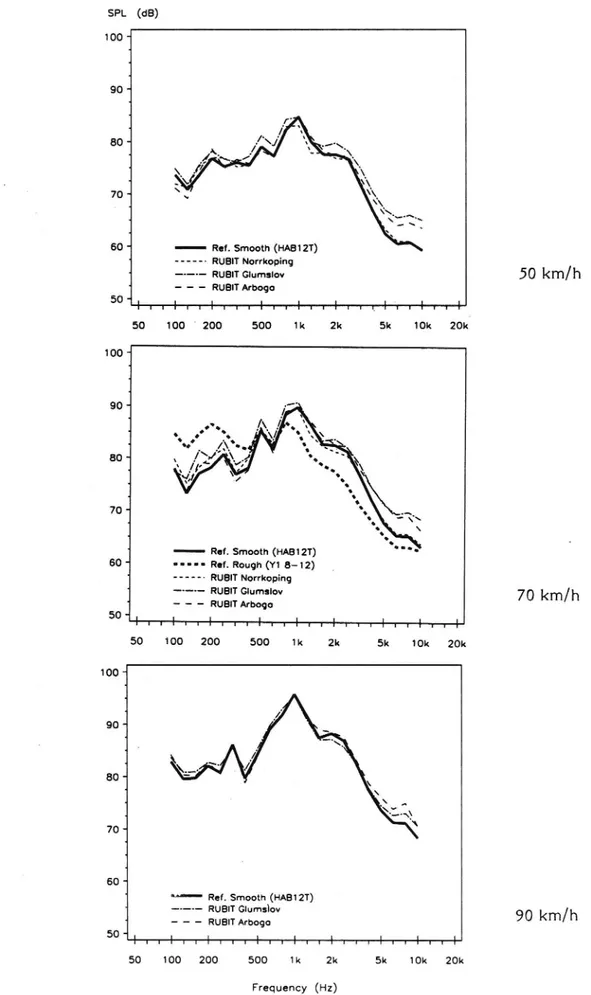

In Figures 19-23, the frequency spectra in third octave bands of the RUBIT surfaces are presented and compared to the smooth reference

surface HABIZT as well as the rough surface (Y1 8-12).

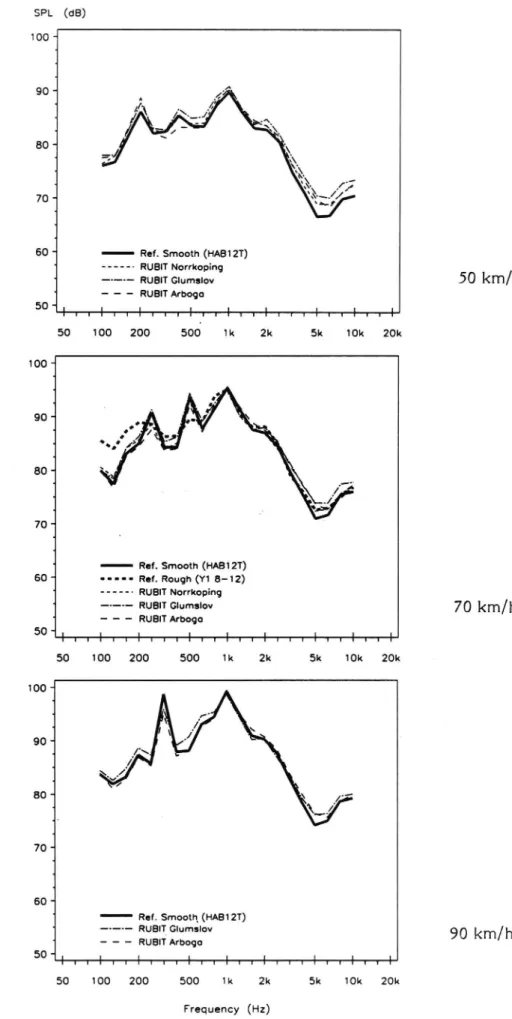

Similarly, in Figures 24-28 the corresponding spectra for the cement concrete surfaces are presented and compared to the smooth reference

surface HABIZT as well as the rough reference surface Y1 8-12.

8.3 Comments Regarding Drainage Asphalt Surfaces

As previously reported, no porous asphaltic concrete surface (drainage asphalt) was included among the reference surfaces although this would have been interesting. However, the effect of drainage asphalt on traffic noise is well known already, see e.g. Table l in Ref. 6. This table applies to overall road traffic noise, whereas in this reoort tire/road noise is discussed. However, at speeds at or above 50 km/h the overall noise is more or less equal to tire/road noise. I_f_ a drainage asphalt surface (0 1 years old) had been included in Figures 9-13, its bar would have ended at least 5 dB(A) beneath the one for surface HABIZT, pTovided the measure-ment had been performed with an appr0priate method (the trailer method is not suitable in this case).

23 W I M E D D E L A N D E 60 8 A

W

S

I

W

Rough Y18 12 RUBIT Norrkpg Glumslov RUBIT RUBIT Arbogo Smooth Rough Y18 12 RUBIT Norrkpg Glumslov RUBIT RUBIT Arbogo Smooth Reugh Y18 12 ' RUBIT Norrkpg Glumslov RUBIT RUBIT Arbogo Smooth HABiZT HAB12T HA81 2T peeds of 50, 70 and 90 km/h.Sound levels in dB(A) measured on the different road surfaces at the 5

Tire P is the smooth reference tire from PIARC.

24 VT I M E D D E L A N D E 60 8 A (D to 00 (D

at the speeds of 50, 70 and 90 km/h.

ed on the different road surfaces

"Summer" type tire, Firestone Cavallino Sl. ound levels in dB(A) measur

S

Tir eS:

25 Vl' I M E D D E L A N D E 60 8 A

at the speeds of 50, 70 and 90 km/h.

ad surfaces

tro

on the differen

dB(A) measured

ummer" type tire, Michelin XZX.

l

"S

d

26 , 90 km/h el (dB(A)) I r r l O m (D O O! G) Tire G, 70 km/h el (dB(A)) ' l ' l 1' O O) O) v I v I t ' . I , I I I [ I I r l I . 50 km/h el (dB(A)) W I M E D D E L A N D E 60 8A ' I 1 ' I ' I ' I ' l ' co (0 V on CD 0

at the speeds of 50, 70 and 90 km/h. ad surfaces

nt r0

ed on the differe

' non-studded, Gislaved M+S Frost. l e s in dB(A) measur W t typ t Soundlev Tire G : " ' " Figure 12

27 . 90 km/h (/3O V evel (dB(A)) ' 1 ' I -I -0 co 0 V O O! O! O! ' Tire cs, 70 km/h (dB(A)) Tire GS, 50 km/h cl (dB(A)) . I v g v l -. -I ' I r V N O ID to 0" Oi O, 0 no VT I M E D D E L A N D E 60 8A

at the speeds of 50, 70 and 90 km/h.

ound levels in dB(A) measur

28 N O! w m VT I M E D D E L A N D E 60 8A

W

k\\\\\

\\\\\\

\\

W

W

84CE6 CE6 Rough

Y I 3 1 2 CE4 (RWT) Smooth ~css Rough Y18 12 CE6 CE4 Smooth CE6 Rough Y18 12 CE6 CE4 Smooth (BWT) (awn HAB I 2T (RWT) (RWT) (BWT) HA8? 2T (RWT) (RWT) (BWT) HA81 2T peeds of 50, 70 and 90 km/h.

Sound levels in dB(A) measured on the different road surfaces at the 5

Tire P is the smooth reference tire from PIARC.

Figure 14

Cement concrete, in right wheel track Cement concrete in right wheel track Cement concrete, between wheel tracks

. -... EE x 3 % ? 0 1 m m d \ D \ D m um U U U

No

<3 ZmDUm >ZUm mom >

8 6 8 8 (R WT) (R WT ) (R WT ) (R WT ) (B WT ) at th e sp eeds of 50 , 70 an d 90 km /h. 5 e C a f r. U S da1 8 05 kkw r0 cca aar. tnn.l tttFr. 8 11d mm eee f eeh d an e +L+L .mnto hhw88 t all.ch n5 rrt 0m nne lam .l.lb my eee, ue ttt Sr. wee aol 8+. CCC e nnn mo. 000 )VJ CCC t tt mm- nnm anr. 668 de mmm nm eee

um ccc

IU :2: es Vn TTT. .m: WWW d5 RRB we 1466 O. SLEE ST. CCC F i g ur e 1530 8' (d B( A) )

VTI MEDDELANDE 608A

- U 1 I (D u: 00 In Y l I l v I r I I (R WT ) (R WT ) (B WT ) (R WT ) (R WT ) (R WT ) (R WT ) at th e spee ds of 50 , 70 and 90 km /h . 3L. m3 we) (DO) LL93 U 0 CCC O o 4-a+-» C *5 00(1)

___

___

_.

W(H)

3 MAG 9213

3 2 Mm 9213

DUDE 9 93 = mm +233

f)

P

(Map) [SID PQPPnlsHP q), u 1+ 1+ H J J B e AB 1 H/Qu S+W p P ) lJOJci I'q/um 06 pue 0; 0g ;0 speeds am 19 39:)

( ) ( ) '1 6 , .7

_._

_g

lZlBVH ((V)ap) Ma) m32 km/h e el (dB(A)) . I . I . l . I . I . l . N O on CD ' ' O O O! O! 03 ' Tire GS. 70 km/h (dB(A)) m 00 V' N O . 0! 03 at O! O! m/h § el (dB(A)) Y I . I v ; -I r 1 -l ' ' N (D to 0| 0) Q Q VT I M E D D E L A N D E 60 8 A (RWT) (RWT) (RWT) (RWT) (RWT) (RWT)

at the speeds of 50, 70 and 90 km/h.

ad surfaces ved M+S Front.nt r0 cur d 0 0 ¢) right whe ght wh red on # 4 . ; 83 3 wa s )

0

0

8

ound levels in dB(A

C m

:: Ceme

C m

5

Tire GS : "Winter" type ti

C134 RWT : e en oncr e, in

CE6 RWT CE6 BWT

Figure 19 33

SPL (dB) 100 90 ' 80 _ . '/" .\.\ 7O " \

60 " Ref. Smooth (HAB12T)

' ---- -- RUBIT Norrkoping --- RUBIT GIumslov 50 km/h - - - RUBIT Arbogo 50 I I I I L I I I I r I I I I I I I I I I I I I I I I I T T I I I I I I I 50 100 200 500 1k 2k 5k 10k 20k 100 " 90 80 '1 7O

Ref. Smooth (HAB12T) N

60 " - - -- - Ref. Rough (Y1 8 12)

-- -- -- -- ---- RUBIT Norrk0ping ---- RUBIT Glumslvv 70 km/h - - - RUBIT Arbogo 50 I l l I I I I I I r I I I I I I I I I I I I I I r I I I I I I I I T I I 50 100 200 500 1k 2k 5k 10k 20k 100 90 " 80 " 7O ' 60 " . - Ref. Smooth'(HAB12T) -- - RUBIT Glumslov 90 km/h - - RUBIT Arbogo 50 II I I LI I I II I I I II I I II I I II I I I jL I I II I I II 50 100 200 500 1k 2k 5k 10k 20k Frequency (Hz)

Frequency spectra measured on the different road surfaces at

the speeds of 50, 70 and 90 km/h.

Tire P is the smooth reference tire from PIARC. VTI MEDDELANDE 608A

3L! SPL (dB) 100 90 80 7O '

60 - Ref. Smooth (HAB12T)

---- -- RUBIT Norrkoping ---- RUBIT Glumslov - RUBIT Arboga 50 I I I ' I I l I I I I I I I I I I I I I I I I I I I I I I I 1 I I I I I 1 50 100 200 500 1k 2k 5k 10k 20k 100 90 80 " J 70 "

' Ref. Smooth (HAB12T) 3,.

60 ' -- -- - Ref. Rough (Y1 8 12)

* - - ~ - -- RUBIT Norrkoping 4 --- RUBIT Glumslov k m - - - RUBIT Arbogo _ 50 " LI I I LI I I lI I I I II I I II I I II I I I II I I II r 1 II 50 100 200 500 1k 2k 5k 10k 20k 100 90 80 " 7O " 60 "

' Ref. smooth (HAaIzr)

- -- RUBIT Glumélov

- - RUBIT Arbogo 90 km/h

50 _ I I I ~I I I I I I I I r I I I I I I I I I I I I I I I

50 100 200 500 1k 2k 5k 10k 20k

Frequency (Hz)

Figure 20 Frequency spectra measured on the different road surfaces at

the speeds of 50, 70 and 90 km/h.

Tire S 2 "Summer" type tire, Firestone Cavallino Sl. VTI MEDDELANDE 608A

35 SPL (dB) 100 " 90 -80 70 "

60 Ref. Smooth (HAB12T)

- - - - -- RUBIT Norrkoping - -- RUBIT Glumsl0v 50 km/h ' - - - RUBIT Arbogo 50 ' I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I I 50 100 200 500 1k 2k 5k 10k 20k 100 " 90 80 ' 70

' - Ref. Smooth (HABIZT)

60 - - --- Ref. Rough (Y1 8 12)

' - - --- RUBIT Norrkoping --- RUBIT Glumslov - - - RUBIT Arbogo v 50 d II I I II I r 1l I I T rI I I II I I II I I I II I T II I I II 50 100 200 500 1k 2k 5k 10k 20k 100 d 90 " 80 7O " 60 "

Ref. Smooth (HABIZT) - -- RUBIT Glurns10v

- - - RUBIT Arbogo 90 km/h

50 " II I IAI I I LI I I I IL I I II I I lI I I I II I I Ir r I II

50 100 200 500 1k 2k 5k 10k 20k

Frequency (Hz)

Figure 21 Frequency spectra measured on the different road surfaces at

the speeds of 50, 70 and 90 km/h.

Tire M : "Summer" type tire, Michelin XZX. VTI MEDDELANDE 608A

36 SPL (dB) 100 90 " 80 7O

-60 " Ref. Smooth (HAB12T)

' ---- -- RUBIT Norrkoping ---- RUBIT Glumslov 50 km/h» ' - - RUBIT Arbogo 50 ' I I l 1 1 l 1 I I I I I I I I I I I I I l l I I I I f I I I I j F I 50 100 200 500 1k 2k 5k 10k 20k 100 90 80 -7O '-.C I Ref. Smooth (HAB12T)

60 ' --- -- Ref. Rough (Y1 8 12)

' ---- -- RUBIT Norrkoping ---- RUBIT Glumslov 70 km/h ' - RUBIT Arbogo 50 - I I I I I I I I I I I I I I I I I l I I I I I 50 100 200 500 1k 2k 5k 10k 20k 100 90 'i 80 '. 7O 60

_ Ref. Smooth (HAB12T)

- --- RUBIT GlumsIov

- - RUBIT Arbogo

50 .1 I I I I I I I I I I I I I I I I I l I I I I I I I Ti 1

50 100 200 500 1k 2k 5k 10k 20k

Frequency (Hz)

Figure 22 Frequency spectra measured on the different road surfaces at

the speeds of 50, 70 and 90 km/h.

Tire G = "Winter" type tire, non-studded, Gislaved M+S Frost.

37 SPL (dB) 100 " 90 80 70

-60 ' Ref. Smooth (HAB12T)

- - - - -- RUBIT Norrkoping - -- RUBIT Glumslov - - RUBIT Arbogo 50 q I I I I I I I I l I IL I I I I I I I I T I I I I T IiT 50 100 200 500 1k 2k 5k 10k 20k 100 ' 90 ' 80 -7O "

- Ref. Smooth (HAB12T)

60 - --- Ref. Rough (Y1 8 12)

---- -- RUBIT Norrkoping ---- RUBIT Glumslov ' - - - RUBIT Arbogo

5°':..:.,i...:r,:.,:,.,:1.:..%

50 100 200 500 1k 2k 5k 10k 20k 100 90 ' 80 7O -60'-Ref. Smooth (HAB12T)

- -- RUBIT Clumslov

- - RUBIT Arbogo

50 " 1I I I lI I I lI I I T ir I l I1 I I lI r I I JI I I LI T T T1

50 100 200 500 1k 2k 5k 10k 20k

Frequency (Hz)

Figure 23 Frequency spectra measured on the different road surfaces at

the speeds of 50, 70 and 90 km/h.

Tire GS = "Winter" type tire, studded, Gislaved M+S Frost. VTI MEDDELANDE 608A

Figure 24 38

SPL (dB) 100 90 " 1 \ - § 80 \ \. , /Q\§ I \ 7O "

60 - Ref. Smooth (HAB12T) *

---- -- Cement Concrete E4 (RWT) --- Cement Concrete E6 (RWT) km /h ' - - - Cement Concrete E6 (BWT)

5° i1.:1.:. rennij mmn:

50 100 200 500 1k 2k 5k 10k 20k 100 a 90 ' 8O 7O-- Ref. Smooth (HAB12T) a 60 - --- Ref. Rough (Y1 8-12) ' o

' --=- .-- Cement Concrete E4 (RWT)

- --- Cement Concrete E6-(RWT) k

m - - Cement Concrete E6 (BWT) / h 50 - I1 I I I I I I I I I I I I I I I IL I l I I I T I I I I 50 100 200 500 1k 2k 5k 10k 20k 100 90 -80 " 7O

-60 ' Ref. Smooth (HAB IZT)

---- m Cement Concrete E4 (RWT) ' ~ -- Cement Contrete E6 (RWT) - - - Cement Concrete E6 (BWT)

Hui :.,.:r.:..:.,,ir1:.ri

50 100 200 500 1k 2k 5k 10k 20k Frequency (Hz)Frequency spectra measured on the different road surfaces at

the speeds of 50, 70 and 90 km/h.

Tire P is the smooth reference tire from PIARC. VTI MEDDELANDE 608 A

39 SPL (dB) 100 90 4 80 70

so - Ref. Smooth (HAB IZT)

. . - - - -- Cement Concrete E4 (RWT) - --- Cement Concrete E6 (RWT) 50 h « Cement Concrete E6 (BWT) 50 - lIII!IIIIIIIIIIIIIIIIIIYT11'l l ' I I l I l 50 100 200 500 1k 2k 5k 10k 20k 100 90 '1 80 " 70 "

- - - Ref. Smooth (HABIZT)

x .

60 ' --- Ref. Rough (Y1 8 12)

. ---- -- Cement Concrete E4 (RWT) _. -- Cement Concrete E6 (RWT) - - - Cement Concrete E6 (BWT) 50':":ll%l":ll}.1%1114fr#1l: 50 100 200 500 1k 2k 5k 10k 20k 100 " 90 80 7O '

60 - Ref. Smooth (HAB IZT)

. . - - -- Cement Concrete E4 (RWT) - -- Cement Concrete E6 (RWT) 4 - Cement Concrete E6 (BWT) 50 :lrllrl} ll+vlittitttirtirv: 50 100 200 500 1k 2k 5k 10k 20 Frequency (Hz)

Figure 25 Frequency spectra measured on the different road surfaces at

the speeds of 50, 70 and 90 km/h.

Tire S 2 "Summer" type tire, Firestone Cavallino Sl. VTI MEDDELANDE 608A

4O SPL (dB) 100 90 ' 80 ' 7O 60 " ROI. (HABIZT) ' ---- -- Cement Concrete E4

-- -- Cement Concrete E6. right lane - - - Cement Concrete E6. left lane

50 ' I I l I I l I I I I I I I I I I I I I I I I I I I I I I I I I I I r I I l 50 100 200 500 1k 2k 5k 10k 20k 100 90 ' 80 -7O

' Ref. Smooth (HAB12T)

60 " --- -- Ref. Rough (Y1 8 12)

' ---- -- Cement Concrete E4 (RWT) --- Cement Concrete E6 (RWT) ' - - - Cement Concrete E6 (BWT) h 50 ' I I l l I I I I I I I I I I I I I I I I I I I I I I r I r I I I I I I I 50 100 200 500 1k 2k -5k 10k 20k 100 90 " .1 80 7O

-60 '- Ref. Smooth (HAB12T)

- - n - - Cement Concrete E4 (RWT) --- Cement Concrete E6 (RWT) ' - - - Cement Concrete E6 (BWT) 50 q II I I II I I II I I j II I I II I I II I I I lI I I II I I II 50 100 200 500 1k 2k 5k 10k 20k Frequency (Hz)

Figure 26 Frequency spectra measured on the different road surfaces at

the speeds of 50, 70 and 90 km/h.

Tire M = "Summer" type tire, Michelin XZX. VTI MEDDELANDE 608A

#1

SPL (dB) 100 90 -' A " \ 80 7O

60 " Ref. Smooth (HAB12T)

* ---- -~ Cement ConCrete E4 (RWT) ---- Cement Concrete E6 (RWT) h ' - - - Cement Concrete E6 (BWT) 50 l l 1 1 l l 1 I 1 I I r I I I I I I I l T I I I I I I I I I I I I I I I 50 100 200 500 1 k 2k 5k 10k 20k 100 " 90 80 -70

- - - Ref. Smooth (HABIZT) ' "

60 " -- - - - Ref. Rough (Y1 8-12)

---- -- Cement Concrete E4 (RWT) --- Cement Concrete E6 (RWT) km/ h - - - Cement Concrete E6 (BWT) 50 - L L I I I I I I I I I I I I I I [r I I I I T I 50 100 200 500 1k 2k 5k 10k 20k 100 ' 90 80 70

-60 - Ref. Smooth (HABtZT)

- - - - -- Cement Concrete E4 (RWT) ~ - Cement Concrete E6 (RWT) - - Cement Concrete E6 (BWT) 50 - l I I I I I I I I I I I I I I r I I I I I I I I Ir 50 100 200 500 1k 2k 5k 10k 20k Frequency (Hz)

Figure 27 Frequency spectra measured on the different road surfaces at

the speeds of 50, 70 and 90 km/h.

Tire G = "Winter" type tire, non-studded, Gislaved M+S Frost. VTI MEDDELANDE 608A

[+2 SPL (dB) 100 90 " 80 70

60 - _ Ref. Smooth (HAB12T)

« ---- -- Cement Concrete E4 (RWT) _.. -- Cement Concrete E6 (RWT) - - - Cement Concrete E6 (BWT) 50 .1 l l ' l 1 I I I l IIIIIIIIIIIVI "'r1 rr I 50 100 200 500 1k 2k 5k 10k 20k 100 " 90 " 80 " 7O

- - Ref. Smooth (HABIZT)

60 - III-I Ref. Rough

4 .... -- Cement Concrete E4 (RWT) ._._- Cement Concrete E6 (RWT) . - Cement Concrete E6 (BM) 50 " | 1 l L L I I Illllllllllirt v1lilll' ' so 100 200 500 1k 2k 5k 10k 20k 100 " 90 " 80 70 '

50 - Refn Smooth (HAB12T)

. . a a -- Cement Concrete E4 (RWT) - -- Cement Concrete E6 (RWT) . _ - -s Cement Concrete E6 (BWT)

5° :.i..il.i:..:,.:m :.ri

t

50 100 200 500 1k 2k 5k 10k 20k Figure 28 Frequency (Hz)the speeds of 50, 70 and 90 km/h. _

Tire GS = "Winter" type tire, studded, Gislaved M+S Frost. VTI MEDDELANDE 608A

50 km/h

70 km/h

90 km/h

#3

9. DISCUSSION

The measured noise levels for the three RUBIT surfaces show that the

surface in Glumslov is 1-3 dB(A) noisier than the others, if the "winter"

type tires are excluded. This could e.g. be on account of: - It is rougher than the others

- It has become stiffer (more compacted) than the other two (it is the oldest one and has been exposed to the most intensive traffic)

- Owing to chip loss, cavities have appeared in the texture. These may

cause high frequency "air pumping" or "air resonant" noise (the enclosed air is compressed and expanded when the tires roll over the

cavities).

It should also be noted that the Glumslov site is not fully representative

of RUBIT, since it has too small a proportion of fine material (< 4 mm) and thus too big a pr0portion of the big stones. Because of this deficiency in the proportioning of the mix, the surface has a rough texture and it

could also have influenced the chip loss tendency.

On the whole, the RUBIT surfaces in Norrkoping and Arboga are, as concerns noise, equivalent to the reference surface HABIZT. The

differences are essentially within 1 dB(A).

For the winter tires, the differences between the surfaces are only 0-2

dB(A), which is almost negligible. The only notable thing is that the rough

chip seal (Y1) is the most silent one when testing with tire G.

Usually, new asphalt surfaces (like the "RUBIT Arboga" here) are 1-2 dB(A) more silent than old asphalt surfaces like the HABIZT. In spite of the RUBIT surfaces being considerably younger than the HABIZT surface,

they display no advantage concerning noise. The oldest one even seems to

be worse than the reference surfaces.

As regards frequency spectra, their form is influenced by the texture. Smoother surfaces usually emit less noise at low frequencies and more VTI MEDDELANDE 608A

#4

noise at high frequencies and vice versa. The RUBIT surface at Glumslov seems to give more noise even at high frequencies (though not when using "winter" tires). In order to cause such an effect, its texture ought to be both rougher and denser and this could be the case due to wear and

compacting. However, it is likely that the "pockets" in the surface due to

the chip loss play a role here to generate the high frequency noise, and

the roughness may have caused the low frequency noise.

As to the rest, the frequency spectra of the surfaces are similar and

cannot be interpreted as more or less discriminating for any of the

surfaces.

Are there better RUBIT surfaces as regards noise influence? All those

that have been tested here have had a rubber proportion of 3% and 12 mm

maximum chipping size. Bigger chippings would give higher noise levels, while smaller chippings would give lower levels; however, the same applies to conventional road surfaces. A larger rubber proportion would

maybe reduce noise; however, 6% would probably not be enough, but even larger proportions would have to be used.

The cement concrete surfaces used in this experiment appeared noisier

than both the smooth and rough reference surfaces no matter what tires

and what test speeds were used. Generally, they also appeared noisier

than the RUBIT surfaces. The typical increase of noise in comparison to

the smooth asphalt road surface was around 2 dB(A). For the "winter" tire

without studs, the increase was ashigh as 6 dB(A) in comparison to the

rough chip seal. It must be pointed out that the tested cement concrete

surfaces had _n_o artificial anti-skid treatment like brushing, grooving etc., in which case they might have been even noisier.

For most speed and tire combinations the highest sound levels were

observed on the worn cement concrete CE6 (RWT). However, with the exception of the results for the P tire, the difference in noise between the concrete surfaces was no more than i dB(A).

Generally, low-frequency noise (up to 250 Hz) emitted by the tires when

running on the cement concrete surfaces, was higher than on the smooth

45

aSphalt road, but lower than on the rough chip seal. In the range

250-1000 Hz, the differences between all the surfaces were rather small. Above 1 kHz the cement concrete surfaces were louder than the smooth

asphalt surface and very much louder than the rough surface. The highest

difference was actually observed for the smooth tire P. One possible

explanation, which is supported by a visual inspection of surface photos, is

that in some cement concrete surfaces there has been a considerable chip loss, which has created small cavities in the surface. The cavities are

sealed by the tread rubber, particularly when the tread is completely

smooth, and this increases noise generated by the air-pumping mechanism.

The same phenomenon was observed in Ref. 8 (Fig. 8, p. 7:20).

A good deal could be said about comparisons between the different tires,

but this is not within the scope of this report.

Note that these measurements only deal with the noise in the vicinity of the road. The noise inside the vehicles can be affected differently by the

road surfaces.

10. CONCLUSIONS

The RUBIT surfaces that have been tested here don't give lower noise

levels than conventional asphalt surfaces or chip seals but areessentially

equivalent to these. On the contrary, the oldest RUBIT surface seems to increase the noise level somewhat when using "summer" type tires. The

increase is, however, not very alarming.

As RUBIT surfaces do not reduce noise significantly, good noise properties cannot be incentives for using such surfaces. Any marketing of present

types of RUBIT surfaces for noise reduction would appear false.

The use of cement concrete surfaces of the type tested here would mean

higher traffic noise than the use of conventional bituminous surfaces, no

matter if they are smooth- or rough-textured.

46

REFERENCES

1.

10.

SANDBERG, U.: Reduktion av trafikbuller genom anvéindning av dréinerande vagbelaggning (Reduction of traffic noise by using drainage

road pavement). VTI Preprint No. 92, Swedish Road and Traffic

Research Institute, Linkoping (1984). (In Swedish)

NILSSON, N-A.; ZETTERLING, T.: The Poroelastic Road Surface - A

Tool for Traffic Noise Reduction at the Source. From "Proceedings from Workshop on Rolling Noise Generation", Institution for Technical

Acoustics, Technical University of Berlin, (October 10/ 11 1989).

ENGMAN, B.; MATTSSON, M.-O.: Undersokning av bulleralstring déick-véigbana, med avseende pa olika véigbeléiggningar.(Investigation of noise generation on tire-road with regard to different road

pave-ments). MSc Thesis, Inst. for Road Construction, Chalmers Technical

University, Gothenburg, Sweden (1975). (In Swedish)

ECE/GRB Ad hoc Group on Methods for Measurement of Tyre/Road

Noise: "Methods for Measurement of Tyre/Road Noise Proposed

Methodology." TRANS/SCl/WP29/GRB/R.85, 25 April 1986.

SANDBERG, U.: EJSMONT, J.A.: "Development of Three Methods for Measurement of Tire/Road Noise Emission: Coast-by, Trailer and

Laboratory Drum". Published in Noise Control Engineering Journal, Vol. 27, No 3, 1989. Institute of Noise Control Engineering, USA.

SANDBERG, U.: Méitmetod for jamforelse av trafikbuller pa olika

vagytor (Measuring method for comparison of traffic noise on

differ-ent road pavemdiffer-ents). VTI Notat TF 52-14, Swedish Road and Traffic

Research Institute, Linkoping (1990). (In Swedish)

SANDBERG, U.: Bulleremission fran lastbilsdéick - Slutrapport (Noise Emission from Truck Tires - Final Report). VTI Notat TF 52-10, Swedish Road and Traffic Research Institute, Linkoping (1987). (In Swedish)

SANDBERG, U.: Tire/Road Noise Studies of the Mechanisms of Noise

Generation, Methods of Measurement and Road Surface Characteriza-tion. PhD Dissertation No. 166, p. 7:40, Department of Physics and

Measurement Technology, Linkoping University, Linkoping, Sweden

(1987).

SANDBERG, U.: Road Macro- and Megatexture Influence on Fuel

Consumption. ASTM STP 1031, Surface Characteristics of Roadways:

International Research and Technologies, American Soc. for Testing

and Materials, Philadelphia, 1990, pp 458-477.

BENDTSEN, H.: Vejbelaegninger og stoj i Danmark (Road Surfaces and

Noise in Denmark). Dansk Vejtidsskrift, No. 8, 1989, pp. 182-187 (in

Danish).

47

APPENDIX 1: SUMMARY OF EARLIER COMPARISONS

Difference in tire/road noise between some road surfaces. The most

interesting bars to compare are those marked by shadowing. RUBIT seems to

be equal to or somewhat more silent than the "conventional" asphalt

concrete HABIZT and HABl6T as well as the chip seal (surface dressing) Yl 12-16.

SPL diff. ll dB(A) 8 . l. d w --l (,2 (g .._... 3 EB g (D 2 - q: >. CD > x x x 2 N C N r x O «u a

o\° O\° O\° O\°

_2

m

(0)

(1)

co (Q co 0')

F 1 12 . 8 8 12 16 16 16 16 16 12 12 , 16 20

3 3.2 OGEAMLL _JL v

o u o - .

9- 3 Dramage asphalt concrete rubber bltumen con- surface

asphalt crete dressing

Extract from VTI Reprint No. #5 (Figure No. 2 in this Reprint):

Difference between tire noise on pavement OGEAM and other pavements.

Dry roads, 90 km/h. Volvo 142 (1972) with tires Firestone Sl Cavallino

1655R15 ("summer" type). ,

Notes: The dashed bar is power train noise calculated from measurements of overall vehicle noise and tire noise respectively. The numbers above the

pavement specification, are the maximum aggregate size (mm). Pavements

marked x are typical on Swedish roads. Others are experimental, uncommon or temporary.

48

APPENDIX 2: \lOISE AT LOW AND HIGH FREQUENCIES VERSUS ROAD TEXTURE (EARLIER MEASUREMENTS)

Extract from VTI Reprint No. 56.

Comments: The figures show tire/road noise at low frequencies (400 or 500

Hz, Figs. 6-9 in the Reprint) and at high frequencies (2 500, 3 150 or 8 000

Hz, Figs. 10-13) respectively, as a function of the macrotexture of the road surfaces. Filled triangles represent RUBIT surfaces. When these fall beneath

the regression lines, it means that they are more silent than the majority of

the surfaces. V'I-CRR - SOC I) I SPL V -'"- " A vn-cnn. soc mm |SP1. c181k (500 Hz) dB (1.00 Hz) :21 (400 Hz) 754 J 75 TIRE x . nae w :32: sh eo kmlh / 80 km/h m 70. / 70. 6/46 232a 70. 6/46 23cm: :9

. so

o of .6/46

V '0/ ~ 0 o I. o o/ a o . . .o ' . '9' 3/42 23¢. a / 65 / new 55 / . . / . 4.. /o // LALD / / . 504 60. I/I ; 65. L (80 mmT "Hf",L 55 55 Y r 9 55 ' ' '7 ' ' v yr Y 0 ab 40 so as so 30 40 so as so _ 3° 0 50 d5 6v rA SPL m-cnaocmu d875. HZ) RE P dBA SPL(3150 Hz) ""c ~5°c " AL SPL vu-cmnsacum dB (2500Hz) 80kn h 65 "RE x 55- o nae w _ BOkm/h 80km/h 7° 6/46 new ,1 60. (/4; [gun 0 v 65 . a. t . S IzzmnN ' nov-554 60. L,m0mm) 'L 12mm) Luzomm) 55 v y , v : 5° - y ; 50 f . .: 30 40 so as 60 20 30 40 dB so 20 30 40 dB so

0 yrl-cnn-socnua A HI-Ck .SOC I2r19

d8 (3150 Hz) . dai (8000Hz)

55. me 5 55J TIRE P

wkm/h 80km/h

\.

\ qua Fig 6-13: Noise vs

I C

60 ( texture critical band 5%

' y 3/3 levels. The actual

re-V gression in fig. 7

./ ,

3/42 23 " 7 ° could be seen as the

5i 6/46 23:44' superposition of 2- . , & roughness exc1tations.

LALD due to tire tread,

50 LJZDmm) LALV due to payement; 4n L zsmil

v v V' see procedure in /14/ 20 56 50 d3 56

20 30 40 as so