The impact of

additive manufacturing

on sustainability of

inbound transportation

MASTER DEGREE PROJECT THESIS WITHIN: Business Administration NUMBER OF CREDITS: 30 ECTS

PROGRAMME OF STUDY: International Logistics and Supply Chain Management

AUTHORS: Johan Carlek and Lennart de Jonge JÖNKÖPING: May 2020

i

Master Thesis in Business Administration

Title: The impact of additive manufacturing on sustainability of inbound transportation

Authors: Johan Carlek and Lennart de Jonge

Tutor: Susanne Hertz

Date: 2020-05-18

Key terms: Additive manufacturing, 3D printing, sustainability, inbound transportation, triple bottom line

Abstract

Background: Emerging technologies enables manufacturing companies the opportunity to stay competitive and at the same time focus on increasing their

sustainability impact. One such technology is additive manufacturing which has the potential to change the way manufacturing is performed and impact entire supply chains of manufacturing companies. Multiple studies have been done in the twenty-first century regarding additive manufacturing’s sustainability impact on logistics, although there is little research that focus on impact of additive manufacturing on transportation from a sustainable perspective.

Purpose: The purpose of this study is to explore the impact additive manufacturing has on the sustainability of inbound transportation.

Method: A qualitative research strategy was used to explore the field of study through a multiple case study method. Through two cases, raw material providers and manufacturers within the additive manufacturing industry, data was gathered using semi-structed interviews.

Conclusion: Findings from this study shows that additive manufacturing may have a

sustainable impact on inbound transportation from an environmental, societal, and economic perspective. Additive manufacturing is more environmentally sustainable than conventional manufacturing for the inbound transportation leg from the raw material supplier to the

manufacturing company since the technology requires lower volume of raw material to be transported, it leads to a higher transport efficiency, less frequent transportation need, and requires no return transportation. In economic impact it leads to fuel savings, less frequent transportation with less material, and a reduced inventory holding. Access to remote areas together with easier and safer material handling is the societal impact from using additive manufacturing instead of conventional

ii

Table of Contents

1. Introduction ... 1

1.1 Background ... 1 1.2 Problem description ... 2 1.3 Purpose ... 4 1.4 Definition of terms ... 5 1.4.1 Additive manufacturing ... 5 1.4.2 Sustainability ... 5 1.4.3 Inbound transportation ... 6 1.5 Delimitations ... 6 1.6 Outline ... 62. Literature review ... 8

2.1 Additive manufacturing ... 82.1.1 The additive manufacturing process ... 10

2.1.2 Additive manufacturing and transportation ... 11

2.2 Sustainability ... 12

2.2.1 Environmental impact of additive manufacturing ... 12

2.2.2 Societal impact of additive manufacturing ... 14

2.2.3 Economic impact of additive manufacturing ... 16

2.3 Frame of reference ... 19

3. Methodology ... 21

3.1 Research philosophy ... 21

3.2 Nature of the research ... 22

3.3 Research Approach ... 22

3.4 Research design ... 23

3.5 Time horizon ... 24

3.6 Data collection ... 24

3.6.1 Secondary data collection ... 25

3.6.2 Primary data collection ... 26

3.6.3 Impact from the Coronavirus ... 27

3.7 Selection of interviewees ... 27 3.8 Data analysis ... 30 3.9 Research quality ... 32 3.9.1 Credibility ... 32 3.9.2 Dependability ... 32 3.9.3 Confirmability ... 33 3.9.4 Transferability ... 33 3.10 Research ethics ... 34

4. Empirical findings ... 36

4.1 Description of interviewees ... 364.2 Facilities using additive as manufacturing technology ... 38

4.2.1 Application of additive manufacturing ... 39

4.2.2 Manufacturing process ... 39

4.2.3 Waste material ... 40

4.2.4 Inventory and location of production ... 41

4.2.5 Cost reduction ... 42

4.2.6 Competence and knowledge ... 44

iii

4.3 Suppliers of raw materials ... 45

4.3.1 Application of additive manufacturing ... 46

4.3.2 Waste material ... 47

4.3.3 Inventory and location of production ... 48

4.3.4 Cost reduction ... 49

4.3.5 Competence and knowledge ... 50

4.3 Different perspectives among interviewees ... 51

5. Analysis ... 52

5.1 Environmental impact ... 52

5.2 Societal impact ... 55

5.3 Economic impact ... 57

5.4 Refined conceptual model ... 59

6. Conclusion ... 62

7. Implications and further research ... 64

7.1 Practical implications ... 64 7.2 Theoretical implications ... 64 7.3 Limitations ... 65 7.4 Further research ... 66

Reference list ... 68

Appendix ... 73

Appendix 1: GDPR Thesis Study Consent Form ... 73

Appendix 2: Interview Guides ... 76

iv

Figures

Figure 1 Conceptual model………...20 Figure 2 Refined Conceptual model……… . ...58

Tables

Table 1 Additive manufacturing processes………...10 Table 2 Interview participants………...28

1

1. Introduction

__________________________________________________________________________________

This thesis explores the topic of sustainability impact of additive manufacturing (AM) on logistics when it comes to the inbound transportation part. Since AM is an emerging technology, this chapter will provide a short overview of AM and its sustainability aspects in the background section. Followed by the identified problem, the purpose of the study and the research questions, definition of key terms, delimitations, and lastly an outline section for the thesis.

1.1 Background

There is a significant transformation regarding how products are being produced and delivered due to the emerging changes in the manufacturing industry. This transformation is called industry 4.0, which stands for the fourth industrial revolution, and it is predicted to revolutionize the entire manufacturing industry in a whole new way due to emerging digitalization (Forbes, 2018). The concept of Industry 4.0 builds upon the development of integrating advanced technologies into the manufacturing industry and thereby decrease lead-times, increase flexibility, enable more efficient processes and produce higher-quality products at lower costs, among other things (Junge, 2019; Niaki, Nonino, Palombi & Torabi, 2019). The advanced technologies in the Industry 4.0 concept includes Internet of things, augmented reality, big data, cloud computing, simulation, industrial automation, cybersecurity and additive manufacturing (Nascimento, Alencastro, Quelhas, Caiado, Garza-Reyes, Lona & Tortorella, 2019). This study will focus on additive manufacturing (AM) in this concept, also called three-dimensional printing (3DP). As the modern society becomes more aware of sustainability concerns, companies increasingly understand the importance of this in a wider extent. This encourage them to invest in new technology, as industries and customers are inclined to take sustainability into consideration when choosing a product. AM is a production technology that is seen by many as more sustainable than traditional manufacturing due to its ability to recycle materials and products (Gandha, Ouyang, Gupta, Kunc, Paranthaman & Nlebedim, 2019; Nascimento et al., 2019), improve energy efficiency, decrease waste and amount of material used, improve manufacturing processes, reduce material flows and locate the

2

production closer to the point of consumption (Ford & Despeisse, 2016;Peng, Kellens, Tang, Chen, C. & Chen, G., 2018). This gives manufacturing companies the opportunity to affect their environmental, societal as well as economic impact and thereby become more sustainable by employing this emerging technology.

Sustainability of additive manufacturing on logistics has been studied for example in terms of recycling through closed-loop supply chains and circular economies (Despeisse, Baumers, Brown, Charnley, Ford, Garmulewicz, Knowles, Minshall, Mortara, Reed-Tsochas & Rowley, 2017; Dev, Shankar & Qaiser, 2020; Santander, Cruz, Boudaoud, Camargo & Ieee, 2018), more sustainable logistics and supply chain processes (Chowdhury, Shahvari, Marufuzzaman, Francis & Bian, 2019; Feldmann, Delke & Wasserman, 2019; Junge, 2019), and the difference between AM and conventional manufacturing in terms of sustainability (Bockin & Tillman, 2019; Kellens, Baumers, Gutowski, Flanagan, Lifset & Duflou, 2017). Although a lot of research has been done in the twenty-first century regarding additive manufacturing’s sustainability impact on logistics, there is little research that focus on impact of additive manufacturing on transportation from a sustainable perspective.

Literature shows that AM might impact transportation in terms of location of production (Caviggioli & Ughetto, 2019; Rauch,Dallasega & Matt, 2016), number of intermediates in the supply chain (Jia, Wang, Mustafee & Hao, 2016) and as a way to maximize transport capacity (Li, Jia, Cheng & Hu, 2017), but there is still a gap in research of how AM will impact transportation in terms of sustainability. Transportation is an important part of sustainability since it accounts for a large part of the world’s carbon dioxide emissions among other things (Boon & van Wee, 2018). Therefore, this study will focus on the impact of additive manufacturing on sustainability of transportation. Transportation in this study will be limited to inbound transportation since this will be more affected by AM as compared to outbound transportation, due to additive manufacturing’s abilities to affect the supply chain before the end product is produced. 1.2 Problem description

Additive manufacturing has the potential to change manufacturing significantly, even to the extent that it could become a new industrial revolution (Economist, 2012). Regardless,

3

it is a new manufacturing technique that can be a solution in sectors such as the aerospace, automotive, dental or medical industries, where it is currently being used (Bockin & Tillman, 2019; Despeisse et al., 2017). Traditional manufacturing in the global economy means that semi-finished parts are collected at the place of assembly to then be transported further down the supply chain. In this network of semi-finished products, manufacturers would be obsolete when a product can be produced close to the end-consumer. Although this decentralization of production is not as beneficial from a sustainability point-of-view (Bockin & Tillman, 2019). Cerdas, Juraschek, Thiede and Herrmann (2017) states that additive manufacturing will still have major implications on transportation, due to the need to transport raw materials used in the additive manufacturing process. Transportation of finished goods would only be necessary from the manufacturer to the consumer. Mainly within the transportation before products are additively manufactured, changes compared to traditional manufacturing are foreseen, of which one is that the production process is a lot shorter (Gebler,Uiterkamp & Visser 2014). Therefore, additive manufacturing could have major sustainability benefits in terms of transportation throughout the supply chain, specifically within transportation of raw materials occurring before production of the final product.

Major 3D printing manufacturers offer solutions for the aerospace and defence, automotive, machine tool production, consumer goods, dental, durable goods, healthcare, construction, fashion and jewellery industries (Bockin & Tillman, 2019; Despeisse et al., 2017). Audi is expanding the use of 3D printing to create auxiliary tools to help employees on the assembly line (Audi, 2019). On the website of the major 3D printer supplier of 3D systems (3D Systems, 2017), it is said that the Renault Formula 1 team prints parts that will be put on the car, as well as use it to develop prototypes (3D Systems, 2017), while Boeing uses it to create lightweight parts in the aerospace industry (Boeing, 2017). Within the dental industry, aligners can be made on site with high precision that also cut delivery times (Stratasys, 2020). It is also used for training, education and artificial replacements of human body parts (Durfee & Iaizzo, 2019; Singh & Jonnalagadda, 2020). This shows that additive manufacturing is currently being used more extensively and is developing in these industries. Boeing stated that “additive manufacturing is becomes a mainstream fabrication method”, showing the future of additive manufacturing (Boeing, 2017).

4

What is not mentioned by those companies, is the sustainability benefits additive manufacturing can offer. In times of frequent record-shattering temperatures due to carbon dioxide emissions, more focus on manufacturing’s impact on society, together with economic incentives, the sustainability benefits from additive manufacturing should be attractive to companies acting on sustainability. Additive manufacturing is considered a green manufacturing technology, regarding carbon emissions. Besides the cost reductions and the energy savings, the manufacturing method has the potential to reduce carbon dioxide emissions by 130.5–525.5 Mt by 2025 (Gebler et al., 2014). As more companies use it, the impacts will be greater too. The implications of additive manufacturing could be large to supply chains where it is being used, although it is not believed that it will replace mass-production (Chan, Griffin, Lim, Zeng, & Chiu, 2018). Companies need to understand how additive manufacturing can create sustainability gains within their scope.

3D printing is getting used increasingly more by companies that see it as a solution. With the sustainability benefits it can provide, it is important to understand how the manufacturing technology will affect transportation to understand the impacts and to optimize the sustainability gains companies can achieve. There is plenty of literature on the impacts of additive manufacturing on supply chains regarding sustainability, but this thesis will focus on inbound transportation specifically, where there is little research about. We will qualitatively investigate how additive manufacturing will impact inbound transportation regarding sustainability.

1.3 Purpose

The purpose of this study is to explore the impact additive manufacturing has on the sustainability of inbound transportation. Therefore, the research questions that should be answered by this study are:

• RQ1: What are the environmental impacts of additive manufacturing on inbound transportation?

• RQ2: What are the societal impacts of additive manufacturing on inbound transportation?

5

• RQ3: What are the economic impacts of additive manufacturing on inbound transportation?

1.4 Definition of terms

This study contains certain key terms which will be defined briefly in this section to give the reader a solid overview of the terms used throughout the thesis.

1.4.1 Additive manufacturing

Additive manufacturing (AM), also called three-dimensional printing (3DP), is a manufacturing technology that allows physical components to be made from virtual three‐ dimensional computer models by building the physical component layer-by-layer until the component is complete (Ford & Despeisse, 2016; Verboeket & Krikke, 2019). It is a disruptive technology which has affected supply chains globally in several industries. Initially AM was used as a tool to make conceptual and functional prototypes, but nowadays AM technologies has been developed far enough to be used for producing end-use products such as spare parts and small complex parts to save time and money or to provide greater flexibility and agility in certain supply chains (Ma, Harstvedt, Dunaway, Bian & Jaradat,, 2018). The layer-by-layer production process makes it possible to manufacture products with complex geometry that are difficult to produce using material removal processes as in conventional manufacturing (Huang, Liu, Mokasdar & Hou, 2013) and it also enables a more sustainable way of production (Ma et al., 2018). AM and 3DP is used interchangeably throughout this thesis.

1.4.2 Sustainability

Mota, Gomes, Carvalho and Barbosa-Povoa (2015) defines sustainability as a way to meet the present needs without compromising the ability for future generations to meet their needs while taking the three dimensions of sustainable development into consideration, which is environmental, societal and economic sustainability. These are the dimensions that will be used when exploring the sustainability of AM in this study. Environmental sustainability includes environmental protection, decreasing harmful emissions in the environment, limiting the use of energy and natural resources, and also developing and using environmentally friendly materials. Societal sustainability concerns the effect on population’s health and wellbeing from an organization’s activities, products, or services. While the economic sustainability is built upon sustainable

6

operations that survive for a long time, which includes the impact of economic aspects of the industry and the cost structures (Mota et al., 2015).

1.4.3 Inbound transportation

Inbound transportation is a part of inbound logistics (IL), which includes processes that take possession of materials that will be processed further (Dehning,Richardson & Zmud, 2007). Inbound transportation specifically, is defined as the movement of materials from the supplier’s site to the production process or storage site (CSCMP, 2013). It is important to highlight here that it involves both the supplier and the manufacturer. Therefore, inbound logistics are crucial for manufacturing organizations to start production. In the case of additive manufacturing, the raw materials are dependent on the processing category that is chosen. Inbound transportation in this thesis, is therefore seen from the perspective of the facility that uses additive manufacturing as a manufacturing technique. 1.5 Delimitations

The chosen topic is in the context of supply chain management and logistics, which is the field we are studying. There is lots of research on the impacts of additive manufacturing on supply chain management and sustainability, but not specifically on inbound transportation. We chose inbound transportation specifically, because there the largest savings can be gained compared to traditional manufacturing methods. Once the product is finished, it is a question of distribution to the customer, as within traditional manufacturing supply chains. Therefore, this study only considers the raw material supply into the additive manufacturing facility. Data collection is done in Sweden since we are based in Sweden and this is our area of interest. Despite our primary search location for interviewees, international interviewees are not rejected or avoided.

1.6 Outline

This section will provide an overview of how the thesis is structured. The first chapter gives an introduction of the background and problem discussion of the studied topic. Followed by the description of the purpose and research questions of the thesis. Thereafter the delimitations and definition of terms is presented for the study. The second chapter presents the underlying theoretical background of the frame of references based on a literature review. Chapter three provides the research methodology used for the thesis including the philosophy, nature, approach, and design of the research. Furthermore, the

7

data collection, selection and analyses together with research quality and ethics are presented. In chapter four the empirical findings are presented which will then be analysed in chapter five. Chapter six will discuss results, conclusions and managerial implications followed by limitations of the study and suggestions for future research.

8

2. Literature review

_____________________________________________________________________________________

This chapter provides an overview of the theoretical background of additive manufacturing, its process and the relationship between additive manufacturing and transportation. Furthermore, additive manufacturing’s sustainability impact is explored from an environmental, societal, and economic perspective. Thereby, the chapter provides a more comprehensive although general understanding of the topic of the thesis and works as a groundwork for the empirical study.

______________________________________________________________________ 2.1 Additive manufacturing

Additive manufacturing started as rapid prototyping, which enabled companies to create physical conceptual structures to evaluate the shape and fit of the end-product (Garrett, 2014). Throughout the years, rapid prototyping evolved into additive manufacturing, which continues to rely on adding layer-by-layer to form a product. This is the opposite of traditional manufacturing techniques that take away material to create a form (ASTM, 2012). This creates the following benefits to the products: Lightweight, multi-material, ergonomic and optionally with integrated mechanisms. The benefits are achieved through the increased complexity of the shape additive manufacturing enables and the ability to make homogenous products as well as heterogenous products with the same technology (Jimenez, Romero, Dominguez, Espinosa & Dominguez, 2019; Kellens, Baumers, et al., 2017). This makes it possible for the industries of consumer-electronics, automotive, medical/dental, aerospace, architecture, and food to create prototypes, models, parts, and products. There are industries that are researching the use of additive manufacturing for their specific case, such as the jewellery and toys industries (Jimenez et al., 2019). Further benefits include the ability to repair damaged products with additive manufacturing methods, and decentralization of manufacturing, which enables production to move closer to the end-consumer and reduces the need for inventory holding (Kellens, Baumers, et al., 2017). The decentralization of manufacturing still reduces transportation, but the savings are small compared to the high energy usage of additive manufacturing (Cerdas et al., 2017; Kellens, Baumers, et al., 2017). The topic of transportation in the context of additive manufacturing will be discussed further on in this literature review. Whether or not companies should invest in additive manufacturing technology, depends on the company that is adopting the technology (Oettmeier & Hofmann, 2016), which is also

9

what Niaki et al. (2019) found. They identified that the following factors have an influence on the cost advantage additive manufacturing can give when used as rapid prototyping: Production volume, materials used, firm size and firm experience. Although the article was published in 2014, Garrett (2014) was uncertain about the speed with which additive manufacturing would develop and be adopted in manufacturing. Jimenez, et al. (2019) state that it can still be applied in many industries and also still speak of additive manufacturing as a potential next industrial revolution.

Additive manufacturing enables many advantages, however there are also challenges that additive manufacturing faces. Ford and Despeisse (2016) listed challenges within the themes of product redesign, material input processing, component and product manufacturing, product use, repair, remanufacturing and recycling. The challenges described here are narrow which include a lack of knowledge about additive manufacturing among engineers, lack of regulation concerning certificates and regulation for additive manufacturing, limited reliability of the technology, challenges to integrate it with existing technology, and also some challenges in recycling material for certain products (Ford & Despeisse, 2016). The study by Ahuja, Karg & Schmidt (2015) provides a wider view of the challenges, by identifying factors within strategic, technological, organizational, operational, supply chain, research and intellectual property. Therefore creating a wider view of the challenges, as compared to Ford, et al. (2016).

The wider challenges include that additive manufacturing might be seen as a technology-push strategy to invest in since it is so emerging and upcoming. In some cases, it requires a restructure of the organization to implement additive manufacturing. For the operational challenges is it stated that the technology has limited material options for manufacturing together with higher costs in some scenarios since it requires new tools and practices. Additive manufacturing may also lead to more complex supply chains due to the change in parties involved. Additionally, challenges in research exist as additive manufacturing are still considered relatively new, consequently it requires a constant research effort for the true appreciation. Lastly, there is a lack of regulation in intellectual property. This creates a challenge since drawings of products might be copied and distributed wrongfully (Ahuja et al., 2015).

10

Verboeket, et al. (2019) identified bottlenecks that hinder additive manufacturing from reaching its potential. They found that there is product (product characteristics), processing (production characteristics) and regulation (lack of regulation in areas such as intellectual property, quality assurance, certification, process qualification and testing/inspection) related bottlenecks. Chan, et al. (2018) recognize the same challenges as Ahuja et al. (2015) within the areas of supply chain, technology and intellectual property within the additive manufacturers in China.

Though there are challenges, the impact additive manufacturing has on businesses is significant, mostly on the supply chain. The supply will be much closer to a demand chain, where the end-consumer drives demand directly (Christopher, 2014). Changing impacts can be expected when firms adopt additive manufacturing techniques, throughout different phases of the supply chain (Zanoni, Ashourpour, Bacchetti, Zanardini & Perona, 2019). These also has implications on the relationship with the customer, as well as with the supplier. Quality control activities and strategic production planning influence the relationship with suppliers (Oettmeier & Hofmann, 2016). To cope with these changes within customer/supplier relationships, order fulfilment, demand management, product development and service capacity, innovations are expected to be made to deal with the activities more effectively (Luomaranta & Martinsuo, 2019). With this introduction of additive manufacturing, there is a need to look into the process of additive manufacturing. 2.1.1 The additive manufacturing process

Yosofi, Kerbrat and Mognol (2018) describes four stages of the additive manufacturing process. Initially, a computer-aided design (CAD) file is prepared that virtually represents the design. This file is sent to the printer. The next stage is warming the printer up, followed by the forming of the object. Finally, the product is optionally modified in a post-process treatment.

Depending on the process category (described later), different materials can be used to form objects with. Different raw material inputs can be used, such as polycarbonate, steel, metal powder, epoxy resin and polyamide (Yosofi et al., 2018).

After forming, the object might need to have a different surface quality or need separating from supports. This is done in the post treatment stage, which involves human intervention (Kellens, Mertens, Paraskevas, Dewulf & Duflou, 2017).

11

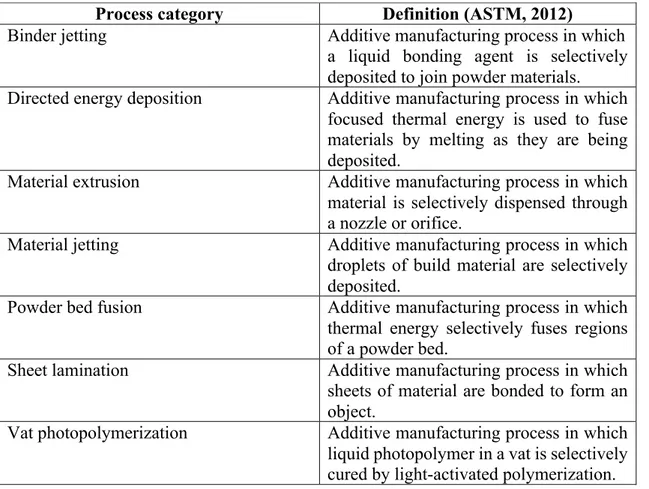

ASTM International (2012) defined 7 distinct process categories within additive manufacturing: Binder jetting, directed energy deposition, material extrusion, material jetting, powder bed fusion, sheet lamination and vat photopolymerization. Definitions of these process categories can be found in table 1.

2.1.2 Additive manufacturing and transportation

Additive manufacturing will have an impact on transportation. First and foremost, the location of production can be placed closer to the end-user, through the decentralization of production (Rauch et al., 2016). Additional benefits of decentralization of production are an opportunity to cut out intermediate parties in the supply chain (Jia et al., 2016) and reshoring production to wealthy countries where the salaries are high (Campbell, Williams, Ivanova & Garrett, 2011). However, the benefit of a centralized production system is that the maximum capacity of transports can be utilized, which reduces transportation costs (Boon & van Wee, 2018; Li et al., 2017). Further research show that a centralized or a decentralized production system is not necessarily better than the other,

Process category Definition (ASTM, 2012)

Binder jetting Additive manufacturing process in which

a liquid bonding agent is selectively deposited to join powder materials.

Directed energy deposition Additive manufacturing process in which

focused thermal energy is used to fuse materials by melting as they are being deposited.

Material extrusion Additive manufacturing process in which

material is selectively dispensed through a nozzle or orifice.

Material jetting Additive manufacturing process in which

droplets of build material are selectively deposited.

Powder bed fusion Additive manufacturing process in which

thermal energy selectively fuses regions of a powder bed.

Sheet lamination Additive manufacturing process in which

sheets of material are bonded to form an object.

Vat photopolymerization Additive manufacturing process in which

liquid photopolymer in a vat is selectively cured by light-activated polymerization.

12

when the sustainability dimension is included in the review (Cerdas et al., 2017). Tziantopoulos, Tsolakis, Vlachos & Tsironis (2019) argues that a hybrid production method is more feasible in regard to securing profitability. City-level hubs are most likely, since they can coordinate material flows and have the expertise (Boon & van Wee, 2018). Furthermore, additive manufacturing will decrease the distribution and inventories companies need to manage (Janssen,Blankers, Moolenburgh & Bineke, 2014). Unlike semi-finished products as with traditional manufacturing, additive manufacturing allows the input to the process, for example raw materials, to be transported in bulk without much need for packaging (Janssen et al., 2014). Besides the previously mentioned aspects, Boon and van Wee (2018) found that experts think that additive manufacturing does not influence the time of delivery, development of transport technologies and traffic safety. Diverging opinions were noticed on whether additive manufacturing will increase transport volumes and the impact on the environment.

2.2 Sustainability

Manufacturing processes is about converting material input into output of goods and services. The efficiency of this conversion is the main factor of the sustainability associated to manufacturing. When industries are developing towards more sustainable and smart manufacturing processes, AM has a key role in this development and contributes considerably in making the processes more sustainable (Ford & Despeisse, 2016). Agrawal and Vinodh (2019) argues that sustainability of AM can be presented in a triple bottom line perspective focusing on the aspects of environmental, societal and economic impact.

2.2.1 Environmental impact of additive manufacturing

Environmental impact is the changes to the environment from an organization’s activities, products, or services (Mota et al., 2015). The literature suggest that additive manufacturing has the potential to significantly decrease the environmental impact due to its technological advancements and development of the manufacturing processes.

By comparing additive manufacturing with conventional manufacturing, it can be concluded that the AM process can both decrease energy consumption and reduce

13

environmental impact. AM has the potential to use more environmentally friendly materials (Tang, Mak & Zhao, 2016) and less harmful emissions for the environment (Peng et al., 2018) in the manufacturing process as compared to conventional manufacturing processes. It can therefore generate less than half the carbon dioxide emissions as compared to conventional manufacturing (Tang et al., 2016) and be less harmful for the environment in terms of other harmful emissions (Peng et al., 2018). According to Peng et al. (2018), AM can reduce the waste material by as much as 90% compared to conventional manufacturing in the full process of manufacturing a product. The AM process is using different materials and is producing less waste due to its more material efficient layer-by-layer manufacturing process as compared to the subtractive conventional manufacturing process (Peng et al., 2018; Tang et al., 2016). It can also use a more lightweight design for the parts manufactured due to its design flexibility, which generates less energy consumption as compared to conventional manufacturing (Nyamekye, Leino, Piili & Salminen, 2015; Tang et al., 2016).

Tziantopoulos et al. (2019) shows that additive manufacturing can lead to a reduction of 75% in the material volumes used. The material volumes are decreased through redesigns in the production design, resulting in improved environmental impacts from the company. It is also shown that AM uses less energy consumption and produces less carbon dioxide emissions compared to conventional manufacturing (Tziantopoulos et al., 2019). AM enables make-to-order production in a higher extent since this manufacturing process is not dependent on distribution in the same way as conventional manufacturing. It thereby reduces the need for make-to-stock inventory and hence the material consumption (Ford & Despeisse, 2016; Nyamekye et al., 2015; Verboeket & Krikke, 2019).

Additive manufacturing can also be used in the process of recycling or reusing material and products. One way to do this by AM is through a Closed Loop Supply Chain (CLSC). This works as a network that integrates the forward and reverse supply chain. Meaning that the goods from the raw material supplier through the manufacturer to the end consumer is distributed by the forward supply chain. While the reserve supply chain retrieves the products or material for recycling or reuse from the end consumer to either the raw material supplier to recycle it to powder or the manufacturer to recycle it to a new product (Feldmann et al., 2019; Santander et al., 2018). This manufacturing process also

14

provides the opportunity to design products that can use recycled material as input when manufacturing new products, which leads to a decrease in resource consumption and negative environmental impact since little or no new material needs to be added in the manufacturing process. It thereby reduces waste and overproduction (Feldmann et al., 2019; Nascimento et al., 2019).

One example of such a product is bonded magnets. Gandha et al. (2019) showed in their study that it is possible to reuse the materials from bonded magnets, process the material, and then produce new bonded magnets using this material as input in AM. The product even showed improved density and remanence after being remanufactured, enabling the possibility to ensure sustainability in materials for permanent bonded magnet production. Another example is recycled plastic. According to Zander, Gillan and Lambeth (2018) a number of companies now sell input material for AM made from recycled plastics. This material is made from 100% recycled polyethylene terephthalate (PET) from bottles and packaging. When the PET is properly cleaned and dried it is shown to be a suitable material for AM, which offers substantial environmental benefits due to its recycling possibilities.

The literature shows that additive manufacturing has a significant potential to reduce the materials required in the manufacturing process by recycling and reusing, and at the same time decrease the need for energy-intensive, wasteful, and polluting manufacturing processes. This results in more sustainable manufacturing due to AM.

2.2.2 Societal impact of additive manufacturing

Another way to look at sustainable manufacturing is to take the societal impact into consideration. The social impact is the effect an organization’s activities, products, or services have on a population’s health and wellbeing (Huang et al., 2013). Little research is focusing on the societal impact of additive manufacturing, but the one that does states that it can be used to improve the populations health and wellbeing.

One way that additive manufacturing can impact a populations health and wellbeing is through healthcare products. AM can be used to manufacture customized healthcare products that meet individuals needs in personalized healthcare due to the flexibility and

15

ability to produce complex products using AM. (Agrawal & Vinodh, 2019; Huang et al., 2013). Healthcare products that can be manufactured by AM includes customized surgical implants and hearing aids that function well and has a shorter lead time than conventionally manufactured implants (Huang et al., 2013). A number of dentistry products such as bridges, crowns and braced are also commercially available through AM technology (Agrawal & Vinodh, 2019). Since AM enables the production of complex and lightweight products without mass manufacturing, it can also be used to produce custom-fit safety equipment. The safety equipment produced using AM is for example helmets and protective garments. This equipment has the ability to provide outstanding protection while being comfortable to the user due to its custom-fit ability since the production is based upon the individual’s needs and is easily adaptable (Huang et al., 2013).

Another societal impact of additive manufacturing is that this manufacturing process might shift supply chains from being centralized to becoming decentralized. This decentralization leads manufacturing closer to consumers in more localized facilities. By decentralizing the manufacturing to more localized facilities it will lead to more thriving communities and less centralized facilities (Caviggioli & Ughetto, 2019; Gebler et al., 2014; Turner, Moreno, Mondini, Salonitis, Charnley, Tiwari & Hutabarat, 2019). AM also present the opportunity for on-demand manufacturing. This changes the manufacturing supply chain by making them simpler which facilitates cheaper products to the consumers with faster delivery times (Huang et al., 2013; Luomaranta & Martinsuo, 2019).

Since AM allows product customization in a wide extent and provides the opportunity to manufacture in small scale through home-printing solutions or through local print shops, it will give the consumer an increasingly important role in the supply chain (Caviggioli & Ughetto, 2019). Manufacturing instructions and design for products produced through AM are available to share through digital platforms, therefore it encourages participants in different manufacturing industries to share their ideas and developments with each other through collaboration. This opportunity develops different communities for AM in the society (Jimenez et al., 2019; Turner et al., 2019). The increasingly important role of consumers in the supply chain is also seen by the radical innovation that is happening in the AM technology. Due to the communities there is a lot of product development and

16

innovative solutions being discovered through AM, which leads to new benefits in products and increased interest in this technology (Agrawal & Vinodh, 2019; Luomaranta & Martinsuo, 2019). A negative societal impact of AM is that it can change labour structures due to a higher degree of manufacturing automation. This might eliminate manual jobs in the manufacturing industry. From the positive side though, it might also create demand for new labour structures which requires new knowledge and expertise about AM (Caviggioli & Ughetto, 2019; Gebler et al., 2014).

Based on the literature about the societal impact of additive manufacturing it can be shown that AM has the possibility to improve the populations health and wellbeing by giving access to new and customized products, create localized facilities for manufacturing, and at the same time provide a community for innovation and development. It might also lead to new labour structures in both negative and positive aspects. All of this contributes to more sustainable manufacturing in terms of societal impact.

2.2.3 Economic impact of additive manufacturing

Apart from environmental and societal impact of additive manufacturing, there is also the economic impact of AM on sustainability. The economic impact is about how AM technology will impact economic aspects of the industry and the cost structures (Mota et al., 2015). The literature shows that additive manufacturing has high economic impact and can help to develop new economic concepts.

Using AM technologies might mainly lead to cost reduction for products manufactured in low volume with high value and that are customized for the consumer (Gebler et al., 2014) and for new product development (Agrawal & Vinodh, 2019; Niaki et al., 2019) since AM enables more cost-effective manufacturing processes for these kind of products as compared to conventional ones. AM also offers more manufacturing flexibility than conventional manufacturing which gives more cost-efficient supply chains and increased economic low volume production (Li et al., 2017; Tziantopoulos et al., 2019).

According to Tziantopoulos et al. (2019) AM can reduce the total production cost of around 10% due to its ability to shorten and decrease the complexity of supply chains, reducing transportation need and reduce the overall lead time. AM might also reduce the

17

capital investment by companies as compared to conventional manufacturing. This capital investment is reduced due to this technology’s ability to reduce the need for different tools in production and shorten the production process by having fewer tiers in the supply chain, resulting in a lower capital investment (Agrawal & Vinodh, 2019; Gebler et al., 2014). In conventional manufacturing the supply chains are forced to hold more inventory in order to avoid stock-outs. AM hold lower inventory levels in the supply chains due to increased flexibility and production based on the demand of the consumer. Therefore, the administrative and investment cost for holding inventory is also reduced (Li et al., 2017). On the other hand, prices for the materials used as input in AM is often significantly higher than that of conventional manufacturing. But this is generally compensated by the much higher material efficiency of AM as compared to conventional manufacturing (Gebler et al., 2014)

One big economic impact of additive manufacturing is that it taps into economies of scope rather that economies of scale (Despeisse et al., 2017; Li et al., 2017; Niaki et al., 2019). Economies of scope that is enabled by AM is more sustainable as it reduces the need to hold safety inventory (Despeisse et al., 2017) and enables on-demand manufacturing which decreases the warehousing demand of products and spare parts (Garrett, 2014). The reason that AM enables economies of scope is that this manufacturing technology has the ability to print different types of products without changing the tools needed, meaning that manufacturing can be customized without additional costs. Therefore, AM is an cost-effective production option to conventional manufacturing in terms of low-volume production of customized products with complex design (Garrett, 2014; Niaki et al., 2019). This leads to mass customization instead of mass production, which is seen by many as more economically sustainable (Garrett, 2014; Niaki et al., 2019). When it comes to mass production, conventional manufacturing is preferred over AM in terms of cost-effective manufacturing processes due to its ability to exploit economies of scale and thereby lower the cost per produced product (Agrawal & Vinodh, 2019; Niaki et al., 2019).

Literature suggest that additive manufacturing might also develop the concept of circular economy to a new extent due to its ability to reuse and recycle material and products for a more sustainable economic impact (Despeisse et al., 2017; Nascimento et al., 2019;

18

Turner et al., 2019). Circular economy is a new economic approach that uses waste as input material in production systems, and thereby transforming it into circular chains leading to minimized waste emissions and energy leakage (Nascimento et al., 2019). AM might have a huge impact in circular economies since it provides the possibility for materials or products to be recycled and reused in circular chains to generate new value-added products or reuse worn out components (Despeisse et al., 2017; Nascimento et al., 2019). Using AM in a circular economy might redesign the waste infrastructure to instead become a base for production and increase the circular flows in the economy (Despeisse et al., 2017). This might lead to an improvement in local waste infrastructure which generates jobs, improves the economic performance and leads to more sustainable production (Nascimento et al., 2019; Turner et al., 2019). According to Despeisse et al. (2017) it is still very uncertain if AM adoption will lead to an improved circular economy or if it will instead generate more resource consumption due to an economic development of less efficient small scale production combined with demand for more customized products.

The decentralization and localization of production as described earlier also has the potential to reduce global economic imbalances as AM could work as a new form of import substitution, as export countries surpluses are reduced and import countries is not that dependent on import any more (Garrett, 2014). The higher degree of automation following AM could also benefit the economy for developed countries with ageing populations (Gebler et al., 2014). For developing countries, remote locations and rural areas, AM can have a positive sustainable impact on the economy since it might enable recycling and bridge the spatial gaps in the markets for these countries (Gebler et al., 2014; Zander et al., 2018)

By analysing the literature concerning economic impact of additive manufacturing it can be seen that AM may have the ability to lead to cost reduction in manufacturing processes, especially for low volume production of goods that is high-valued, complex or require customization. Due to its abilities it is also very useful for new product development and might save cost in terms of inventory and necessary investments. Moreover, the literature suggest that AM could develop new economic concepts and enable the move from mass production to mass customization.

19

2.3 Frame of reference

Additive manufacturing is a technology that is impacting the manufacturing industry in multiple ways. As mentioned earlier in this chapter it might lead to a decentralization of production which will place the production closer to the end-user, cut out intermediates in the supply chain, reshoring production, maximize the transport capacity used, and lead to more complex supply chains. All of these aspects will impact transportation in supply chains for companies involved in the additive manufacturing industry. There is research concerning the impact of additive manufacturing on transportation, but it does not concentrate on sustainability and mainly focuses on the transportation between the manufacturing companies and the end-consumer or distributors. Hence, there is still a gap in research of how this technology impacts the inbound transportation from the raw material suppliers and the manufacturing companies using this technology.

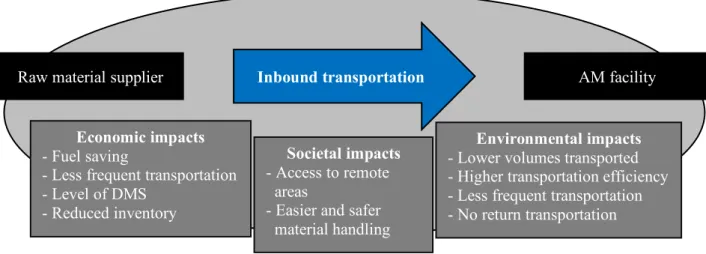

Since additive manufacturing is perceived as a sustainable manufacturing technology, we used the same approach as Agrawal and Vinodh (2019) to explore the sustainability impact of additive manufacturing. This approach includes environmental, societal, and economic impact. Based on the sustainability influences of additive manufacturing focusing on the aspects of environmental, societal, and economic impact, a conceptual model was developed in which the research questions are presented, which is shown in figure 1. As can be seen, our research is focused on the inbound transportation between the entities of the raw material supplier and the additive manufacturing facility. It is clear from earlier studies that additive manufacturing will impact inbound transportation between these entities in some extent based on the affect the technology has on transportation within the supply chain. Therefore, the raw material supplier, inbound transportation and AM facility parts in the conceptual model are grounded from the literature, while the three sustainability impacts discussed earlier in the literature review are depicted in grey as these are questions based on the gaps from the literature. As seen in the research questions, we want to identify the impact of additive manufacturing on inbound transportation based on the three sustainability aspects of environmental, societal, and economic impact.

20

Raw material supplier Inbound transportation AM facility

Economic impacts?

Environmental impacts?

Societal impacts?

21

3. Methodology

_____________________________________________________________________________________

The following chapter discusses the underlying methodology for the thesis. It starts with defining the research philosophy, then leading to the nature of research, the research approach, and the design. Thereafter the time horizon is discussed followed by the explanation of data collection, selection and analysis. Lastly, the quality of the research is discussed leading to the research ethics.

______________________________________________________________________ 3.1 Research philosophy

Research philosophy could be described as the belief and assumption in how data about an outcome of a situation should be collected, analyzed and used to develop research, which concerns the source, nature and development of knowledge (Saunders, Lewis & Thornhill, 2016). To conduct a coherent, well-structured, and scientifically supported research study, there needs to be some basic assumptions about the research philosophy being made at the beginning of the study. According to Easterby-Smith, Thorpe and Jackson (2015) the majority of discussions concerning research philosophy is about ontology and epistemology. Where ontology concerns the nature of reality and existence, and epistemology concerns the nature of knowledge and ways to examining this knowledge into the world.

When it comes to the philosophical assumptions about the nature of reality this thesis follows the ontology of relativism which makes the assumption that there are multiple “truths” depending on the perspective, time and place of the observer (Easterby-Smith et al., 2015). We assume that the perspective of sustainability and its impact differs depending on the viewpoint and belief of the observer, as well as from different companies using additive manufacturing. The same applies to the perspective of how additive manufacturing will impact the manufacturing industry, which also differs among the participants. Therefore, the sustainability impact of additive manufacturing depends on the perspective and viewpoint of the observer and the participating firms using additive manufacturing and is valid for a particular context in a particular period.

To examine and apply the knowledge into the physical and social world we choose an epistemological perspective. This thesis follows the epistemology view of social

22

constructionism which make the assumption that reality is constructed through observation and that the observer is part of what is being observed. It focuses on the way people see their experience and reflect that reality is created by people instead of objects and external factors (Easterby-Smith et al., 2015). Since our thesis aims to explore the impact of additive manufacturing on sustainability of inbound transportation, we will be a part of what is being observed through a literature review combined with qualitative data in the form of interviews. We aim to increase the basic understanding of additive manufacturing and its impact on sustainability though literature, the data is collection in a small number of cases chosen for specific reasons, which also include the stakeholder perspective to compare and generate a theory of how additive manufacturing impact the sustainability of inbound transportation. This is a characteristic approach of social constructionism according to Easterby-Smith et al. (2015).

3.2 Nature of the research

According to Saunders et al. (2016) the purpose of a research study can be either exploratory, descriptive, explanatory or a combination of the three mentioned. An exploratory research study should be undertaken when there is little known research within an area, or when the problem is not clearly defined. It aims to seek new insights to access the area from a new perspective (Saunders et al., 2016). Given the gap in literature about the impact of additive manufacturing on inbound transportation and due to the limited research with regards to its sustainability impact, the exploratory nature of a research study is the most suitable approach for this thesis. Hence, this research study is based on an exploratory approach to gain insight on the impacts additive manufacturing has on transportation regarding sustainability. We aim to gain new insight into the sustainability impacts of additive manufacturing on transportation, since it could have a significant influence and therefore could change transportation within supply chains. 3.3 Research Approach

The three research approaches to theory development are deductive, inductive and abductive approaches (Saunders et al., 2016). This thesis is based on an own developed conceptual framework founded on relevant academic research where a research gap has been identified. This conceptual framework has later been tested and evaluated through

23

empirical findings from a small sample of interviews. This approach is characteristic for an inductive approach which is followed in this thesis (Saunders et al., 2016)

An inductive approach assumes that the gap between the premises observed and the conclusion will be supported by the observations made in the empirical finding. This means that the research starts with observations and that theories are developed and proposed as a result of the observations which are viewed as evidence of truth for the conclusion (Saunders et al., 2016). The purpose of this thesis is to explore the impact additive manufacturing has on the sustainability of inbound transportation. This was explored based on empirical findings in form of qualitative data. The theoretical groundwork was established through a literature review to explore the sustainability impact of additive manufacturing and thereby create a conceptual framework based on the identified research gap leading to the purpose. Thus, the research approach is corresponding with the important characteristics of induction as presented by Saunders et al. (2016).

3.4 Research design

The research design describes and justifies what data will be collected and how it will be collected and analysed to answer the research questions (Easterby-Smith et al., 2015). A choice can be made on what method suits the research optimally, and depends on previous methodological choices, such as the epistemology. Besides a distinction between epistemology, there is also a distinction between whether the researchers want to be involved or detached with the objects of the research.

We chose social constructionism as the epistemology of this research, as described earlier. Therefore, a choice needed to be made whether our research style would be involved or detached. To identify and describe the impacts, we conducted multiple interviews within different companies, and investigated how adopting additive manufacturing impacted inbound transportation for them, regarding sustainability. To create valid results, we also needed information on the setting the company is in, because the impacts might differ per company. However, we also needed to be objective to yield valid results. Therefore, our research style was in-between detached and involved.

24

Easterby-Smith et al. (2015) describes three different case methods based on the positivist or constructionist epistemologies. The positivist case study has a pre-determined design, where the data is analysed across cases, to assure validity. Contrarily, in a constructionist case study, the issue of validity is less of a concern, because the data is analysed within the case. However, there is also a middle-road that takes aspects of both the positivist and constructionist epistemologies (Eisenhardt, 1989). This approach to case studies holds a flexible research design, while the data is both analysed across cases and within cases. This approach allows cross-case studying, while maintaining a constructionist epistemology, which makes this type of case study fitting to our research.

This research therefore uses a multiple case study method, with which data is collected and analysed. This fits with the constructionism epistemology, because the interviewees that represent the cases may have differing perspectives on the impacts depending on the setting of the company that they work for. With the multiple case study research design, we can construct a reality across multiple cases and yield findings that we can indicate the level of generalizability of, due to the attention paid to the setting interviewees are in. 3.5 Time horizon

Easterby-Smith et al. (2015) makes a distinction between the time horizons of the research design. There are two possibilities: A longitudinal or comparative study. A longitudinal study studies the (same) case over time, whereas a comparative study compares the cases at one moment. Our aim is to find the impacts the cases have in common. The impacts one case experiences do not mean they are valid for other cases. We are also not interested in how the impacts change over time. Therefore, a longitudinal study would not be useful, while a comparative study achieves our research aim much better.

3.6 Data collection

To get a profound summary of the existing body of research for this thesis topic a literature review was first conducted by collected secondary data. Through the secondary data we explored what was already known about additive manufacturing and its environmental impact, to be able to find a gap within the research literature. Primary data was later collected by performing interviews to gain access to knowledge to cover this gap.

25

3.6.1 Secondary data collection

In order to gather enough data to create a profound summary of the already existing research, we needed to critically review the existing literature regarding our topic. According to Saunders et al. (2016), the secondary data collection is necessary to first generate and refine the research proposal, and thereafter critically review the literature to provide the context and theoretical framework for the thesis. As described by Easterby-Smith et al. (2015), a literature review should give a truthful and balanced perspective of the research and knowledge that exist on the chosen topic. Easterby-Smith et al. (2015) also states that peer-reviewed journal articles are considered to be the most important source of information for most academic disciplines. Therefore, we chose to focus on peer-reviewed journal articles as secondary data to first construct the research proposal, and thereafter critically review the literature through a literature review to generate a conceptual model.

In order to gain access to relevant literature for this research body, the Web of Science was used to identify peer-reviewed journal articles that was relevant for our topic. The main keywords initially used for the research were “environment”, “sustainability”, “additive manufacturing”, “3D printing”, “supply chain”, “value chain”, “logistics” and “transportation”. Every search executed had different combinations but included at least “additive manufacturing” or “3D printing” to remain relevant for our topic. The choice was also made to search with multiple keywords in different combinations to move from broad to narrow literature. As our knowledge deepened in the subject and we found new areas of applicability after reading relevant articles, we expanded the search by including keywords related to logistics such as “packaging”, “order fulfilment”, “storage”, “warehousing”, “material handling”, “inventory control”, “inventory management”, “forecasting”, “production planning”, “scheduling”, “procurement”, sourcing”, “customer service”, “facility location”, “spare parts” and “reverse logistics”, still in combination with at least “additive manufacturing” or “3D printing” to broaden our search.

The relevant articles for our topic was chosen after reading the abstracts of the articles generated through our search terms. This resulted in 56 relevant articles that required thoroughly reading. By reading these articles we also found other relevant articles that

26

we added to the list of useful literature. These articles were later summarized and themed according to their categories, topics, theories, findings, and other useful information. By summarizing the articles relevant for our thesis and dividing them into different themes, it enabled us to identify gaps in the research field which served as a base to the research questions and the generation of our purpose for the thesis.

3.6.2 Primary data collection

Primary data is data that is collected from first-hand sources by the researchers, gathered through methods such as surveys, observations, experiments, or interviews. It is gathered for a specific research project, directly from primary sources to gain access to their knowledge and build empirical data (Easterby-Smith et al., 2015).

For our primary data collection, interviews were held with employees connected to transportation within a company that uses additive manufacturing to produce products as well as suppliers of raw materials for additive manufacturing. More specifically, semi-structured interviews were performed. This was fitting for our research design, since we needed to understand the setting of the interviewee, or the “world” as Easterby-Smith et al. (2015) put it. Semi-structured interviews allow the interviewee more freedom to bring up specific topics, compared to a highly structured interview. This is favourable since our research is explorative. An unstructured interview could create diversion from the specific impacts we are interested in, hence this type would be unfavourable.

Not many companies have adopted additive manufacturing, which made our population narrow. Additionally, our research focusses on one activity within the companies: Transportation. Although finding companies that adopted additive manufacturing was possible using a search engine, snowball sampling also helped us to get more interviewees within the same company. This facilitated us to understand the setting of the company better, since we could compare answers within the same company to identify potential differing perspectives. To secure privacy of our interviewees, a statement describing how the data from the interview will be handled (according to GDPR-guidelines), was given to the interviewee before the interview commencement.

27

3.6.3 Impact from the Coronavirus

In the end of 2019/beginning of 2020, a new virus started to spread worldwide, namely the Coronavirus. Most people infected by the Coronavirus have experienced mild to moderate respiratory illness and usually recover without any special treatment necessary. Although, older people and people with underlying medical problems have been more likely to develop serious illness that might be life-threatening (WHO, 2020). Due to this virus spread, most people have been forced to go into quarantine to stay protected. In Sweden, there are now widespread quarantine guidelines that most companies and people abide to.

Since the companies we have been interviewing for this thesis are based in Sweden it thereby also affected our research in terms of primary data collection. With the new quarantine guidelines, it was harder to reach out to the companies and to get people to participate in our studies, since the situation has caused a great deal of stress in terms in both health and financial precautions. As the Coronavirus spreads through human contact, we have been forced to change our interview structure to only include web-based interviews and thereby eliminating face-to-face interviews due to the contagion risk. 3.7 Selection of interviewees

Since our purpose with this thesis is to explore the impact additive manufacturing has on the sustainability of inbound transportation, we targeted experienced employees that is connected to transportation in an additive manufacturing supply chain. More precisely, the selection of interviewees was based on that their position is connected to inbound transportation when it comes to additive manufacturing technology. As described earlier, inbound transportation is the movement of materials form the supplier’s site to the production process or storage site (CSCMP, 2013). In this thesis, the inbound transportation is seen from the perspective of the facility that uses additive manufacturing to produce products. It is therefore important to stress the fact that it involves both the supplier of raw materials and the manufacturer using additive manufacturing. Thus, we made the decision to collect primary data from employees within raw material suppliers since their outbound transportation of material will be the inbound transportation for the facility using additive manufacturing. Hence, it important to gain access to their knowledge of how additive manufacturing impacts that flow of material. We also

28

collected primary data from employees at companies that facilitate additive manufacturing in their production. Here we got the knowledge from employees that see directly how the inbound transportation is impacted by additive manufacturing.

Not many companies have adopted additive manufacturing in Sweden since it is a newly emerging technology. This made our interviewee pool quite narrow. Since we are focusing on the Swedish market and want to get an impartial perspective on the additive manufacturing industry, we chose to interview selected participants from some of the biggest Swedish manufacturing companies that have additive manufacturing as a segment within the company to make raw material or products, combined with small and medium-sized Swedish companies that only focus on additive manufacturing.

The researchers reached out through email to the companies of interest or directly to the selected employees when possible, in which the research topic and interview guidelines were illustrated to ask for the possibilities of performing an interview. In the cases where we did not receive a reply within three business days, we sent a friendly reminder to see if there was any interest. Eventually, we managed to get six interviewees in total from both raw material suppliers and product manufacturers using additive manufacturing technologies. By using snowball sampling, we managed to get additionally one interviewee from the primary interviewees. Once we got confirmation from the participants, more detailed information, and A General Data Protection Regulation (GDPR) form was sent out before agreeing on a date and time for the interview. Table 2 below shows the essential information about the interviewees and the conduction of the interview.

29

Participant Role Position Direct

professional AM experience Date and length of interview Interview type Interviewee 1 Manufacturer using AM (Manufacturer 1) Manager Electromechanics R&D 3 years 23-03-2020. 37 minutes Web-based with video Interviewee 2 Raw material supplier (Supplier 1)

Product Manager 2 years

25-03-2020. 46 minutes Web-based with video Interviewee 3 Raw material supplier (Supplier 2) Head of Technology 7 years 06-04-2020. 52 minutes Web-based without video Interviewee 4 Manufacturer using AM (Manufacturer 2) Chief Executive Officer 5 years 07-04-2020. 46 minutes Web-based without video Interviewee 5 Manufacturer using AM (Manufacturer 3) Engineering Support Manager 2 years 07-04-2020. 49 minutes Web-based with video Interviewee 6 Raw material supplier (Supplier 3)

Export manager 5 years

14-04-2020. 39 minutes Web-based with video Interviewee 7 Manufacturer using AM (Manufacturer 4) Production coordinator 3 years 15-04-2020. 43 minutes. Web-based without video