ores evsPruive

No. 114A - 1976

Statens vag- och trafikinstitut (VTI) - Fack - 581 01 Linkoping

National Road & Traffic Research Institute - Fack ' 581 01 Linkoping - Sweden

Road Surface Characterization

with Respect to Tire Noise

A Proposed Recommendation

FOREWORD

This report is essentially a translation from a

chap-ter of an earlier report written in Swedishx. The work was originally started as part of the project "Tire noise - recommendation regarding a measurement method" financed by the Swedish Board for Technical Develop-ment and run by IFM Akustikbyran in cooperation with

the National Swedish Road and Traffic Research

Insti-tute. The following text was also included as part of the final report for that project (in Swedish)XX

x Sandberg, U.: vagbanekarakterisering med avseende

pa dackbuller. Report No 92, Statens vag och

trafikinstitut (National Swedish Road and Traffic Research Institute), Linkoping 1976.

xx Gadefelt, G., Bennerhult, O.,Sandberg,[L: Forslag

till metod for matning av externt dackbuller fran motorfordon. Report No 74 4746 a+b, Styrelsen for

teknisk utveckling (Swedish Board for Technical

DevelOpment), Stockholm 1976.

N N N N N N M N N N N M N N N N N N N @ d a c n m a > ~u m wi t h m ¢> + b g U J I Q H P A P A H CONTENTS SUMMARY SAMMANFATTNING INTRODUCTION

CHARACTERIZATION OF ROAD SURFACE BY

PROFILO-METER MEASUREMENT

Road surface characteristics Roughness

Recommendation

Remarks

Units

Spatial frequency range of interest

Frequency resolution

General

Recommended octave bands

Total power and root mean square value

General

Recommendation Measurement tracks

Statistical significance Instrumentation

Method of measurement and analysis

The profilometer Calibration

Presentation of results

(RMS)

CLASSIFICATION OF ROAD SURFACE BY SUBJECTIVE RANKING

REFERENCES

VTI REPORT NO. 114A

Page o o xo o o o o o o q m c n o xm wm m wwwm w +4 H }_ J U. ) 16

H

SUMMARY

Road Surface Characterization with Respect to Tire

Noise - A Proposed Recommendation

In order to get well defined test conditions for tire

noise, a method for characterization of the road

sur-face with respect to tire noise generation is presented. The method implies that the power spectral density

(PSD) of a measured road profile is computed for spatial frequencies between 2 and 1000 cycles/meter (correspond ing to wavelengths l - 500 mm). Analysis with frequency resolution corresponding to octave or thirdoctave bands

is recommended.

The described method does not give a complete descrip

tion of the road parameters influencing tire noise, but can be considered as an important partial solution.

II

SAMMANFATTNING

Végbanekarakterisering med avseende p5 déckbuller -Férslag till rekommendation

I avsikt att erhélla Valdefinierade testférhéllanden fer déckbuller presenteras en metod fer karakterisering

av végbanors egenskaper med avseende p5 dackbuller-generering. Metoden innebér att profilkurvor som upp métts fer den aktuella Végbeléggningen frekvensanalyse ras, sé att ett effekttéthetsspektrum fbr beléggningens

skrovligheter erhélls. Dérvid har spatiala frekvenser mellan 2 och lOOO perioder per meter (motsvarande vag

léngder l - 500 mm) medtagits, och den erforderliga frekvensupplbsningen fareslés motsvara oktav- eller tersoktavband.

Den beskrivna metoden ger inte négon komplett beskriv-ning av de végbaneparametrar som paverkar déckbullret, men bér utgéra en betydelsefull dellésning.

INTRODUCTION

As a consequence of the need for tire noise research the question of adequate and standardized measurement methods has become urgent. The noise measurement in

itself brings no overwhelming difficulties. However,

it is not sufficient to measure the noise, but it is

also necessary to characterize the ambient factors influencing the level and the frequency content of the noise. It is commonly agreed that the texture of the road surface affects the generation of tire noise. In fact, many investigators suggest that the tire and the road surface should be considered together and not the tire separately. The influence of the road sur face is one of the reasons for the variations in

mea-sured noise level and spectrum between different test

sites. Comparison of tire noise measured at different

test sites and/or different occasions is meaningless,

if the condition and characteristics of the pavement

is not at the same time described.

In order to get well defined test conditions for tire

noise, it is consequently of great importance that the qualities of the pavement influencing tire noise can be adequately described. The recommendation presented in this report has that purpose, but does not consti-tute a complete method for road surface characteriza-tion. Neither does it constitute an official standard in any way.

The recommendation is based on theoretical and practi cal studies supporting the importance and evident

influences of the road surface macrotexture profile on tire noise. Comparison of frequency spectra from the

profile with tire noise spectra, has shown that, for some of the tested tire/road combinations, profile

spectra has a strong influence on noise spectra. It is, however, important to observe that characterization

by the macrotexture profile spectrum alone not seems to be sufficient, but only a partial solution to the problem. These studies are reported in Swedish in re-ference /55/. Rere-ference /55/ also contains a

compre-hensive reference list, but after it was written,

some new reports - important as an additional back-ground for this recommendation - has come to the authors' knowledgex.

CHARACTERIZATION OF ROAD SURFACE BY PROFILOMETER MEASUREMENT

Road surface characteristics

BQESDE§§§

Knowledge of the relative importance of the different

generation mechanisms is too limited to determine with

confidence which parameters should be used to

charac-terize the noise influencing qualities of the road. Probably the most important road-depending mechanism is tire vibrations caused by the roughness of the

pavement. "Roughness" here means macroscopic roughness

of wavelengths approximately 1 250 mm.

The amplitude and frequency distribution of the rough-ness is important, and can be expressed by means of the fourier transform of the surface profile, whose absolute value is squared to obtain a power density

spectrum.

x In this report the complete updated reference list

is given. It is interesting to note that one of the new references (/57/) has used a very similar

technique to the one utilized here to obtain a pro-file spectrum, and that reference /56/ has analyzed data by a new technique showing evidence of radially excited tire vibrations due to the road macrotexture.

Recommendation

It is recommended that the roughness of the pavement is included as a parameter influencing tire noise, and is expressed as the power spectral density (PSD) of the road surface profile as a function of the spatial frequency. The profile of the road surface is measured

in the direction of vehicle travel.

Remarks

Power spectral density is a function of frequency; in this case the designation "spatial frequency" is used to indicate that it is not a conventional oscillation but a periodicity, or length distribution, in the longitudinal profile of the road surface.

A power spectral density description does not give a complete characterization with respect to parameters

influencing tire noise, but should, when further

know-ledge has been obtained, be completed by information about for example friction prOperties, sound absorp tion and drainage capacity.

Units

The vertical displacement in the profile, here denoted

h, has the unit /m/ (alternatively /mm/). h is a

func-tion of horizontal displacement, 1.

For the mean square (MS) of 11(1), also called power

or variance, here denoted S, the unit is /m2/. The reference plane is assumed chosen so that the mean value of h equals 0 for the desired length interval, eliminating any {XI component in the spectrum.

The root mean square value (RMS) of the profile is

denoted hrms and the unit is /m/. It is equal to the

standard deviation.

Spatial frequency is here written fSp and has the unit

/m_l/. It is the inverse to wavelength. An alternative

unit is (c/m] (cycles per meter).

Power spectral density is written G(fsp) or, where risk for mixing withanxnu szequivalents is negligib le, G(f). The dimension is power per frequency inter

1)

val, and the unit in this case will be (mZ/m- or Qua/c/mj.

Due to the wide deviation in the values of G(f) and the desirable equivalence with noise measures, it is convenient to relate the actual power Spectral densi ty to a reference level, thereby establishing a rela tive measure called power Spectral density level (PSD

level):

LG: lO-lOlog 3 )

ref

where LG==PSD level in dB relative to the reference

Gref. An apprOpriate value for Gref lS prOposed

_ -12 2 Gref lO Hl/b/m

With this reference actual profile PSD levels will be in the range O-80 dB. In a similar manner power level,

LS, is defined:

L = lO-lOlog S

S S ref where _ 12 2 Sref -lO mSpatial frequency range of interest

In order to cover the important frequency range for vibration excited tire noise, we recommend the

analy-zed spatial frequency range to be at least 8-500 c/m and preferably 4- lOOO c/m. In the latter case corre-sponding wavelengths are l-250 mm.

Note 1: If vibration included tire noise is considered

the range of 4- lOOO c/m covers, at vehicle speeds

between 36 and 108 km/h, at least the noise and vibra-tion frequencies l20-lOOOO Hz.

Note 2: At a vehicle speed of v m/s across a roughness of periodicity fSp c/m, corresponding vibration- and noise frequency will be

Frequency resolution

General

Investigated pavements have shown a power spectral

density of random nature without marked narrow band frequency components. Therefore it is not necessary to

Lu abetter frequency resolution than octave bands. Exceptions are characterization of periodically groo

ved pavements, or when only a short, well defined

distance of the road is considered for narrow band comparison with tire noise. Special notice should be given to statistical prOperties. Int mmxacases where it is easier to perform analysis in l/3 octave bands, this could be accepted, provided that the frequency range of interest is covered and the band limits coin cide where possible.

2.4.2

Bessmms9§s§_992§ys_b§2§§

Spatial frequency Band nzr range c/m] L 4 8 2 8 - l6 3 l6 - 32 4 32 - 64 5 64 - 125 6 125 - 250 7 250 - 500 8 500 - 1000Total power and root mean square value (RMS)

General

Under many circumstances a summarizing measure repre senting the road surface roughness is desirable, be cause it makes possible fast and convenient compari sons. Information thus obtained is of course more limited in value depending on the lack of frequency

information.

Recommendation

As a summarizing measure of the roughness, it is for the time being recommended to use the total power

(variance) level in the spatial frequency range 4- lOOO c/m, here denoted LStot.

As a secondary basis the corresponding linear quanti

ty, Stot, or hrmS (=u/StOtH=RMS value,or standard deviation), could be used.

After gaining better knowledge about the effect of the road surface on tire noise, it is perhaps possible to determine a weighting function for the spectrum of the roughness, that is a function of spatial frequency proportional to the importance of the different fre-quencies of the roughness, and thereafter to compute the power level. This will then be a counterpart to the A-weighting curve (among others) in acoustics.

Measurement tracks

Certain minimum requirements of the measurement tracks should be fulfilled to get sufficient representativity of the result.

1. At least 4 tracks, each of 0,5 m or longer, should

be analyzed. The power spectral density of the diffe-rent tracks should be averaged.

2. The tracks chosen shall be as representative as possible of that part of the road where the tires are rolling.

3. The pavement shall be free from loose particles

such as stones.

Note 1: Experience has shown that the profile can have different characteristics in transverse direction re

lative to the longitudinal direction due to wear.

Determination of the transverse profile can give mis leading results because of "wear tracks" and is not recommended. Instead it is suggested that the position of the different longitudinal tracks is varied some-what in the transverse direction to get a reasonable average of that part of the road where the tires are rolling.

Note 2: The minimum length of the tracks, 0,5 m, is

caused by the interest in wavelengths as long as 0,25 m (4 c/m) and the desired frequency resolution (the lowest octaVe band). To get better statistical signi ficance, longer tracks should be analyzed if possible.

Statistical significance

Investigations made so far indicates that, due to the limitations in primary data (four measurement tracks

each of 0,5 m), the statistical uncertainty is of the

following order of magnitude:

:1 dB

Octave band level: i2 dB

Narrow band levels (bandwidth 2 c/m) i3 dB Total power level:

This is expressed as maximum standard deviation, i e

the confidence level is 68%. For 99,9% confidence the

values should be multiplied by 3, provided that the

distribution is Gaussian (normal).

Instrumentation

M2229§_9£_m§§§2£§m§22_§2§_§a§ly§i§

A profilometer with electrical output signal and a tape recorder (or other corresponding apparatus) is used to register the profile of the pavement. The power spectral density can then be obtained in essen tially three ways:

a. Calculation of the auto correlation function of the

profile and fourier transformation thereof.

b. Fourier transformation of the profile curve, and

squaring of the absolute value of the transform. c. Spectral analysis by a parallel filter bank, or by

a sweeping analyzer (in reality a hardware version of the method in b.). In practice, a very fast

scanning of the profile is required, possibly rea-lized by speed transformation on tape recorder or by means of digital technique (time compression).

None of the methods is recommended relative to the

others, but we would like to point out the danger of aliasing distortion if sampling is used.

Ibs_p£9£ll9msés£

A profilometer with electrical output and a measure-ment range covering 0,5 m or more is required. The resolution longitudinally must be better than 0,5 mm to fulfil the sampling theorem at a desired upper

spatial frequency limit of 1000 c/m.

Vertically the profilometer should have a measuring range of at least 15 mm and an accuracy better than

i0,2 mm.

To make possible frequency analysis of the profile, it is usually necessary for the profilometer to have a constant scanning speed, or a sampling unit giving samples at a constant length interval.

Note: According to the low power content in the high-est octave band on current pavements, it is, if neces sary, possible to decrease the measurement range to 4-500 c/m which will require at least 1 mm

resolu-tion oh the profilometer. The total power level will

suffer'insignificantly.

lO

Calibration

A careful calibration of the profile measuring device

(both the vertical and horizontal-coordinate) shall be

made on every measured pavement. It is desirable that the complete measuring and analysis system is included. This can be accomplished by scanning a profile of

sinusoidal-, step- or pulse shape with accurately known dimensions, and using its frequency spectrum

(which can be calculated) as a reference.

Presentation of results

The following presentation of the result is recommen-ded:

I. General information

a. Date and location of measurements.

b. Rough description of the road surface with avai lable data or by a visual estimation.

c. Number of tracks and their length.

d. Type of profilometer. Resolution and accuracy (briefly).

e. Method of analysis.

II.Results

a. Octave band diagram or table. Alternatively third

octave band diagram. Scales.

b. If necessary: Narrow band spectral diagram. Also RMS value, h

c. Total power level, LStOt-

rms

(not necessary).

d. In special cases it can be practical, as a comple-ment, to transform the spatial frequency scale to

the corresponding noise frequency scale for the

vehicle speed in question. This will facilitate comparison of noise and profile spectra.

11

Example of presentation of results:

General information

Measurement made 1976 09-25 on national trunk road 55,

nas.

6 km south of crossing with E3 outside

Strang-Surface treatment Yl, constructed 1975. 4 tracks of 0,5 m.

Mechanical stepping profilometer with stylus sensor. aggregate size 12-l8 mm,

Electrical output through linear potentiometer. Step length 0,4 mm. Stylus diameter 1 mm. Calibra tion by scanning a step 7,4 mm high, 10,2 mm long. Narrow band analysis, nominal bandwidth 2 c/m. Time

compression spectrum analyzer (Federal Scientific UA-SOO).

bands in computer (HP 2100 S).

Summation of narrow bands into octave

Result

See next page.

P S D l e ve l 12 50 40 30 20 {d B re l 10 1 2 mé/ c/ m] 10 1000 4 8 16 32 64 126 250 500 Spatial frequency (c/m)

Total power level:

12 2

1: 66,7 dB rel 10 m

Range 4-1000

l3.

CLASSIFICATION OF ROAD SURFACE BY SUBJECTIVE RANKING

In cases where the apprOpriate instrumentation is not

available and can not be obtained, another

characteri-zation method should be used. If a profilometer is accessible but frequency analysis is impossible to make, it is suggested that the profile of the road

surface is recorded on paper. In other cases the fol-lowing method for subjective ranking based on Visual inspection of the pavement is recommended. It should, if possible, be completed by other available data of

interest for noise generation.

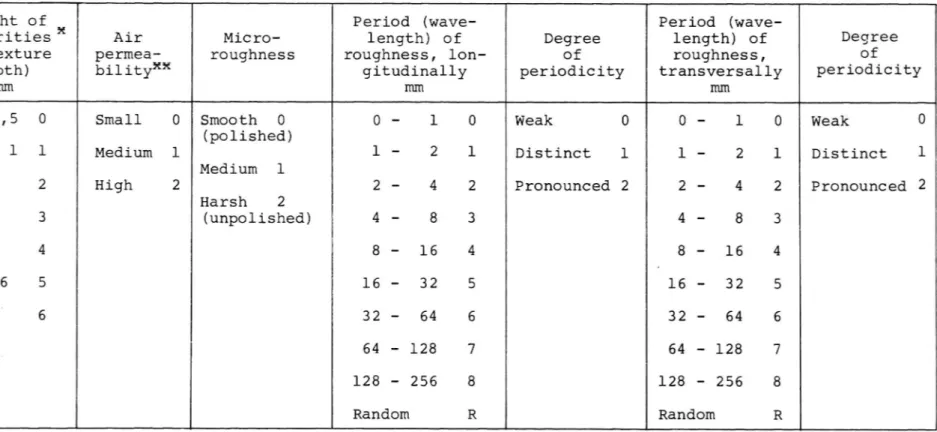

Typical dimensions of the roughness (expressed as

wavelengths) in transversal and longitudinal direction

is estimated, as well as the degree of periodicity. The height of the asperities is also estimated. The air permeability of the pavement is estimated from a visual inspection of the macrostructure of voids and channels in the surface. Finally the harshness (micro roughness) of the surface is estimated.

An evaluation according to table 3.1 is made. Then the pavement is characterized by a configuration of figures, for example:

2 1 2 30/41/8lx RXX

X Only intervals where there seems to be a periodic

structure, or distinct size distribution, are in

cluded. If there is no such interval, the roughness is considered random ("R").

xx If roughness is the same in transversal direction as in longitudinal, the symbol is omitted.

14

Which means:

2 The height of the asperities is on the

average l-2 mm.

1 The surface has a medium air permeability.

The surface is harsh.

30 There is a longitudinal roughness,

perio-dicity weak, of approximately 4-8 mm. 3

41 As above, 8-l6 mm distinct periodicity. 81 As above, 128-256 mm distinct periodicity.

R Transversally the roughness is random.

Of course this method has all the serious disadvanta ges of subjective rating, but it gives some indication of what is felt to be important for tire noise

gene-ration, and it should be better than no characteriza-tion at all.

Table 3.1. Proposal for subjective ranking method for road surface classification. Height of asperities (2-texture depth) Period (wave-length) of Degree roughness, of transversally periOdiCity Period (wave-length) of Degree roughness, lon- of gitudinally periodicity x . Micro-roughness Air permea _ bilityxx V T I R E P O R T N O . 1 1 4 A mm mm 16 0, 16 5 l Small Medium 1 High 0 Smooth 0 (polished) Medium 1 2 Harsh 2 (unpolished)

16 - 32 32 64 64 - 128 128 - 256 Random 0 Weak 0 l Distinct l 2 Pronounced 2 R

16 - 32 5 32 - 64 6 64 128 7 128 - 256 8 Random R Weak 0 Distinct l Pronounced 2 15 XX

sand patch method.Estimation of peak to-peak-value. Can be substituted by (texturedepth)-2 measured by the Here: The capability of the pavement to remove air enclosed in the contact patch between tire and road; drainage through the surface as well as between the tire contact patch and the road surface.

/l/

/2/

/3/

/4/

/5/

/6/

/7/

/8/

/9/

/10/

/ll/

/12/ REFERENCESBARSON, C.W., GOUGH, V.E., HUTCHINSON, J.C., JAMES,

D.H. Tyre and vehicle vibration. The Institution

of Mechanical Engineers, AD P7/65, 1965.

BENNERHULT, O., SANDBERG, U. Metod for matning av

ex-ternt dackbuller fran motorfordon, Styrelsen for

teknisk utveckling (STU), Stockholm, 1976. »

BROWN, J.R. Pervious bitumen-macadam surfacings laid to reduce splash and Spray at Stonebridge,

War-wickshire. Transport and Road Research Laboratory, \

report LR 563, 1973.

COOPER, D.R.C. Measurement of road surface texture by

a contactless sensor. Transport and Road Research Laboratory, Laboratory Report 639, 1974.

CORCORAN, D.A. Effects of Operating parameters on truck tire sounds. Publ. in SP 373 (SAE) Truck tire noise. Society of Automotive Engineers,

Inc., New York, paper 720925, 1972.

DARLINGTON, J.R. Evaluation and application study of

the General Motors Corporation Rapid Travel Pro filometer. Research Report No. R-73l, Michigan State Highway Commission, 1970.

DODDS, C.J., ROBSON, J.D. The description of road surface roughness. Journal of Sound and Vibra-tion (1973) 31 (2), 175-183.

GILLESPIE, T.D. Pavement surface characteristics and their correlation with skid resistance. The Pennsylvania State University, Dep. of Mech.

Eng., report no. 12, June 1965.

Glissance, Special, F. Bulletin de liaison des Labora-toires Routiers Ponts et Chaussées: L'appareil du

Laboratoire Central. Pp. 170 171. Nov. 1966. '

HANKINS, K.D. Pavement surface texture as related to skid resistance. Texas Highway Department,

Research Report No. 45-4, 1967.

HARLAND, D.G. Rolling noise and vehicle noise. Tran sport and Road Research Laboratory, Laboratory Report 652, 1974.

HAYDEN, R.E. Roadside noise from the interaction of a

rolling tire with the road surface. Bolt Beranek

and Newman Inc. (Noise and Vibration Contr.Engv

Purdue 1971, Ed M.J. Crocker).

/l3/

/l4/

/15/

/l6/

/l7/

/18/

/l9/

/20/

/21/

/22/

/23/

17HAYS, D.F., BROWNE, A.L. The Physics of Tire Traction

(Proc of the Symposium on the Physics of Tire

Traction, General Motors Res Lab 1973). Panel

discussion, pp 367 372.

HENRY, J.J., HEGMON, R.R. Pavement texture measurement

and evaluation. ASTM STP 583, American Society for Testing and Materials, 1975, pp 3 17.

HOLBROOK, L.F., DARLINGTON, J.R. Analytical problems encountered in the correlation of subjective

response and pavement power Spectral density functions. Highway Research Record, Washington DC. No. 471, 1973, pp 83-90.

HOUBOLT, J.C., WALLS, J.H., SMILEY, R.F. On spectral

analysis of runway roughness and loads developed during taxiing. National Advisory Committee for

Aeronautics, Technical Note 3484, 1955.

HOUBOLT, J.C., WALLS, J.H., PRESS, H. Some measure-ments and power spectra of runway roughness. National Advisory Committee for Aeronautics, Technical Note 3305, 1954.

HUDSON, W.R., WALKER, R.S. Estimating pavement service

ability by using profile wave amplitude estimates. Center for Highway Research, The University of Texas at Austin (presented at PIARC, The Hague, Holland, 1973).

ISO Recommendation, Measurement of noise emitted by motor vehicles. ISO R 362, lst edition, 1964.

JOHANSEN, J.M. Dekkstoy. Vegdekkets betydning for trafikkst¢y (forelopig rapport). Statens Veg-vesen, Veglaboratoriet, Oslo. Intern rapport 519, dec 1973.

KANESIGE, I. Measurement of power spectra of vehicle vibration and vehicle road roughness. Proc of the 10th Japan National Congress for Appl. Mech., 1960 (V-15).

KAWAI, H., MORISAKI, K. Measurement and analysis of road roughness and its influensis on car

vibra-tion ride comfort using power spectral technique.

Mitsubishi Technical Review, Vol 2, No. 2, 1965.

KNOFLACHER, H. Erstellung von Bewertungsziffern zur Erfassung der Ebenheit von Bundesstrassen.

Bun-desministerium f r Bauten und Technik,

Strassen-forschung. Heft 14, Wien 1974.

18

/24/ KOZIN, F., BOGDANOFF, J.L. On the statistical

prOper-ties of the ground contour and its relation to the study of land locomotion. Proc of the Inter-national Conference on the Mechanics of Soil-Vehicle Systems, Torino 1961, pp 224 243.

/25/ KOZIN, F., BOGDANOFF, J.L., COTE, L.J. Introduction to

a statistical theory of land locomotion.

Part I. Journal of Terramechanics, 1965, Vol 2, No. 2, pp 17-23.

Part II. Ground Roughness. J of Terramech., 1965,

Vol 2, No. 3, pp 17-27.

Part III. Vehicle Dynamics. J of Terramech., 1966, Vol 3, No. 3, pp 69-81.

Part IV. Effects of vibration of the contents of the vehicle and conclusions. J of

Terramechanics, 1966, Vol 3, No. 4,

pp 47-51.

/26/ LA BARRE, R.P., FORBES, R.T., ANDREW, s. The

measure-ment and analysis of road surface roughness. MIRA Report No. 1970/5.

27/ LEES, G., TAM, K.K. The design of non-grooved, high

friction concrete surfacings. University of

Birmingham, Department of Transportation and Environmental Planning.

28/ LEES, G., WILLIAMS, A.R. The relation between tyre and road surface design. International Road

Federa-tion Congress, Munich C3, 1973.

29/ LEES, G., WILLIAMS, A.R., BOND, R. An approach towards

the understanding and design of the pavement s textural characteristics required for Optimum per-formance of the tyre. Proc of the Symposium on the Physics of Tire Traction, General Motors Res

Lab, 1973 (Edited by Hays, D.F, and Browne, A.L.)

30/ New Concepts in road surfacing. Dunlop Limited, Sept.

1973.

'31/ NILSSON, N.A., SANDBERG, U. Forskningsprojekt dack

buller, parameterstudier; reserapport fran stu dieresa i England och Frankrike. Styrelsen for

teknisk utveckling (STU), Stockholm, 1976.

'32/ REITER, W.F., EBERHARDT, A.C., HARPER, L.J., ATKINSON,

T.L. Truck noise VII-A. Experimental investiga

tion of the truck tire sound and vibration. Dep

of Transportation, Washington D.C., Report No DOT TST-75 60. 1974.

/33/

/34/

/35/

/36/

/37/

/38/

/39/

/40/

/41/

/42/

/43/

/44/

/45/

19Rubber Manufacturers Association (RMAL Truck Tire noise. Presentation to the Office of Noise Abatement and Control of the Environmental Pro tection Agency, Washington, D.C., 1971.

Road Research Laboratory, Road Note No 27 (2nd Edi

tion). Instructions for using the portable skid

resistance tester, 1969.

SCHOLES, W.E., FOTHERGILL, L.C. An international sur-vey of research into road traffic noise. Building Research Establishment, Watford, England, 1975,

p 7.

SCHONFELD, R. Skid numbers from stereo-photographs. Department of Highways, Ontario, Canada. D.H.O.

Report No. RR155, Jan 1970.

SCHONFELD, R. Pavement surface texture classification

and skid resistance photo interpretation. Proc. of the Symposium on the Physics of Tire Traction,

General Motors Res Lab 1973 (Edited by Hays, D.F.,

Browne, A.L.f

Society of Automotive Engineers, Inc., Sound levels of highway truck tires, PrOposed SAE recommended practice XJ57.

STEERE, L.B. Noise levels associated with plant mix

seals. Federal Highway Administration, Report No.

FHWA RD-73-50, 1973.

STILL, P.B., WINNETT, M.A. Development of a contact

less displacement transducer. TranSport and Road Research Laboratory, Laboratory Report 690, 1975.

Svenska Elektriska Kommissionen. Matning av

motorfor-donsbuller. SIS 02 51 31. Sveriges Standardise ringskommission, Stockholm, 1966.

THURMAN, G.R. Effect of road surface and bed clear ance on truck tire noise. Society of Automotive Engineers, Inc., paper 740607, 1974.

Trafikbullerutredningen: Trafikbuller, del l vagtra fikbuller. Statens offentliga utredningar, SOU 1974:60, Kommunikationsdepartementet, Stockholm. Transport and Road Research Laboratory. Road surface

texture and noise. Leaflet LF 577, 1975.

UNDERWOOD, M.C.P. A preliminary investigation into lorry tyre noise. Transport and Road Research Laboratory; Report LR 601, 1973.

/46/

/47/

/48/

/49/

/50/

/51/

/52/

/53/

/54/ /55/ /56/ 20VERES, R.E., HENRY, J.J., LAWTHER, J.M. Use of tire noise as a measure of pavement macrotexture. ASTM

STP 583, American Society for Testing and Mate

rials, 1975, pp 18 28.

WALKER, J.C., MAJOR, D.J. Noise generated at the tyre

road interface. Tyre Research Department, Dunlop Limited, Birmingham (presented at Annual Conferen ce, Stress Analysis Group of Institute of Physics, Stress, Vibration & Noise Analysis in Vehicles,

Univ of Aston, Birmingham, 1974).

WATERS, P.E. Commercial Road Vehicle Noise, Journal of Sound and Vibration (1974), 35 (2), pp 155-222. GACHIGNARD, G., SARDIN, P. Influence de la nature de

la chaussée sur 1e bruit produit par 1e contact pneumatique/chaussée. Bulletin de Liaison des

Laboratoires Ponts et Chaussées, Paris. N:r 74,

nov dec 1974, pp 87 96.

ENGMAN, B., MATTSSON, M O. Undersokning av bulleralst

ring dack-vagbana, med avseende pa olika

vagbe-laggningar. Examensarbete 1975, Chalmers Tekniska Hogskola, Institutionen for vagbyggnad.

KANEYASU, K. Vehicle noise and tire noise. Annual

Report of Roads, 1974, Japan Road Association, Tokyo, pp 78-85.

VISSER, A.T., WALKER, R.N. Skid resistance and noise

generation of surfaces. Report RR 179, National

Institute for Road Research, Pretoria, 1974. MAYNARD, D.P., LANE, F.E. Road noise with particular

reference to grooved concrete pavements. Interim

Technical Note ITN 2 August 1971, Cement and

Concrete Ass., London.

MITREY, R.J., AMSLER, D.E., SUURONEN, D.E. Effects of selected pavement surface textures on tire noise.

New York State Dep. of Transportation, Report NYSDOT-ERD-75-RR 28. 1975.

SANDBERG, U. Végbanekarakterisering med avseende pa

dackbuller. Report Nr 92, Statens vag och trafik

institut (National Swedish Road and Traffic Research Institute), Linkoping 1976.

GADEFELT, G., BENNERHULT, 0., SANDBERG, U. Forslag

till metod for matning av externt dackbuller fran motorfordon. Report Nr 74-4746 a+-b, Styrelsen

for teknisk utveckling (Swedish Board for

Techni-cal Development), Stockholm, 1976.

/57/

/58/

/59/

/60/

/61/

/62/

/63/

/64/

21NILSSON, N A. Generating Mechanisms of External Tire Noise. TR 3.709.14 IFM Akustikbyran AB, Stockholm

1976.

LAWTHER, J.M., HENRY, J.J. Characterization of

Pave-ment Macrotexture by Profile Spectral Analysis. NBS GCR 75-35, Pennsylvania Transportation

Institute/Pennsylvania State University, 1974. FULLER, W.R., POTTS, R.L. A Study of Automobile and

Light Truck Tire/Pavement Interaction Noise Levels. SAI-76 557-LA, Sience Applications,

Incorporated, El Segundo, Calif., 1975.

VERES, R.E. A Tire Noise Investigation and Test Method. SAE paper 760152, Society of Automotive Engineers,

Warrendale, Pa., 1976.

VERES, R.E. Pavement Macrotexture Characterization by

Tire Noise. Thesis Mec Eng, Pennsylvania State University, June 1974.

NILSSON, N-A. Tire Noise and Tire Vibration Biblio

graphy. TM 3.709.04 IFM Akustikbyran AB, Stock holm, 1976.

WILLIAMS, A.R., BOND, R., PENNELLS, J.H. The Tyre/Road Interface - Its effect on Braking. Inst. of Mech.

Eng., C 25/76, 1976. (Noise and road surface statistics; pp 73-74, 80).

LUPTON, G.N., WILLIAMS, T. Study of the Skid Resistance

of Different Tire Tread Polymers on Wet Pavements

with a range of Surface Textures. Skid Resistance

of Highway Pavements, ASTM STP 530, American Soc.

for Testing and Materials, 1973, pp 101-116.

(Characterization by profile spectrum, pp 104-105).