Mälardalen University Press Dissertations No. 167

ON RELIABLE AND DEADLINE-CONSTRAINED

COMMUNICATION IN WIRELESS INDUSTRIAL NETWORKS

Kan Yu

2014

School of Innovation, Design and Engineering Mälardalen University Press Dissertations

No. 167

ON RELIABLE AND DEADLINE-CONSTRAINED

COMMUNICATION IN WIRELESS INDUSTRIAL NETWORKS

Kan Yu

2014

Mälardalen University Press Dissertations No. 167

ON RELIABLE AND DEADLINE-CONSTRAINED COMMUNICATION IN WIRELESS INDUSTRIAL NETWORKS

Kan Yu

Akademisk avhandling

som för avläggande av teknologie doktorsexamen i datavetenskap vid Akademin för innovation, design och teknik kommer att offentligen försvaras måndagen den 8 december 2014, 13.15 i Delta, Mälardalens högskola, Västerås. Fakultetsopponent: Associate Professor Song Han, University of Connecticut, USA

Akademin för innovation, design och teknik Copyright © Kan Yu, 2014

ISBN 978-91-7485-171-7 ISSN 1651-4238

Mälardalen University Press Dissertations No. 167

ON RELIABLE AND DEADLINE-CONSTRAINED COMMUNICATION IN WIRELESS INDUSTRIAL NETWORKS

Kan Yu

Akademisk avhandling

som för avläggande av teknologie doktorsexamen i datavetenskap vid Akademin för innovation, design och teknik kommer att offentligen försvaras måndagen den 8 december 2014, 13.15 i Delta, Mälardalens högskola, Västerås. Fakultetsopponent: Associate Professor Song Han, University of Connecticut, USA

Akademin för innovation, design och teknik

Mälardalen University Press Dissertations No. 167

ON RELIABLE AND DEADLINE-CONSTRAINED COMMUNICATION IN WIRELESS INDUSTRIAL NETWORKS

Kan Yu

Akademisk avhandling

som för avläggande av teknologie doktorsexamen i datavetenskap vid Akademin för innovation, design och teknik kommer att offentligen försvaras måndagen den 8 december 2014, 13.15 i Delta, Mälardalens högskola, Västerås. Fakultetsopponent: Associate Professor Song Han, University of Connecticut, USA

Abstract

Along with the quick development of wireless communication technologies, industrial automation networks are also in steady evolution. Industrial wire-less sensor and actuator networks (IWSANs) have been increasingly adopted in industrial automation systems. Although there are a number of advantages of replacing cables with wireless links, such as cost reduction, enhanced scal-ability and flexibility, the stringent requirements on communication reliscal-ability and meeting firm deadlines from industrial mission-critical applications must still be fulfilled. Also, transmissions over wireless channels in industrial envi-ronments are prone to noise and interference, resulting in frequent erroneous packet deliveries. Although industrial automation systems are usually designed to be tolerant to certain communication errors, successive transmission failures may still cause downtime of industrial applications, which might lead to sig-nificant economic losses or even serious accidents.

This thesis addresses the problems mentioned above and aims to provide reliable and deadline-constrained communication via IWSANs for industrial automation systems. On the MAC layer, existing IWSAN standards utilize automatic repeat request (ARQ) to improve reliability at the cost of additional transmission latency. An alternative method is to use Forward Error Correction (FEC) schemes to provide reliable communication by recovering erroneous data and avoiding unnecessary retransmissions. On the MAC layer, Time Divi-sion Multiple Access (TDMA) is usually applied in current IWSAN standards for collision-free and deterministic communication. An inappropriate schedul-ing scheme may introduce high transmission jitter and degrade the quality of control. On the network layer, routing protocols play an important role in both communication reliability and latency. Existing solutions are either hardly able to fulfill all stringent requirements from the mission-critical industrial applica-tions, too complicated to be realized, or lack verification in reality.

The contributions of this thesis consist of (i) the possibilities of using FEC i

Abstract

Along with the quick development of wireless communication technologies, industrial automation networks are also in unceasing evolution. Industrial wireless sensor and actuator networks (IWSAN) have been increasingly adopted in industrial automation systems. Although there are a number of advantages of replacing cables with wireless links, such as cost reduction, enhanced scalability and flexibility, the stringent requirements on communication reliability and meeting firm deadlines from industrial mission-critical applications must still be fulfilled. Also, transmissions over wireless channels in industrial environments are prone to noise and interferences, resulting in frequent erroneous packet deliveries. Although industrial automation systems are usually designed to be tolerant of certain communication errors, successive transmission failures may still cause downtime of industrial applications, which might lead to significant economic losses or even serious accidents. This thesis addresses the problems mentioned above and aims to provide reliable and deadline-constrained communication via IWSANs for industrial automation systems. On the MAC layer, existing IWSAN standards utilize automatic repeat request (ARQ) to improve reliability at the cost of additional transmission latency. An alternative method is to use Forward Error Correction (FEC) schemes to provide reliable communication by recovering erroneous data and avoiding unnecessary retransmissions. On the MAC layer, Time Division Multiple Access (TDMA) is usually applied in current IWSAN standards for collision-free and deterministic communication. An inappropriate scheduling scheme may introduce high transmission jitter and degrade the quality of control. On the network layer, routing protocols play an important role in both communication reliability and latency. Existing solutions are either hardly able to fulfill all stringent requirements from the mission-critical industrial applications, too complicated to be realized, or lack verification in reality. The contributions of this thesis consist of (i) the possibilities of using FEC schemes in IWSANs is explored under the requirements of existing standards on the MAC layer. A compatible and flexible FEC scheme on the MAC layer for IWSANs that does not violate the standard is proposed and evaluated by simulations. (ii) To guarantee an acceptable control quality, a TDMA scheduling scheme is presented aiming for low communication jitter, and it is compared to classic scheduling schemes. (iii) The advantages of exploiting flooding in IWSANs is discussed; a reliable controlled flooding-based routing protocol is proposed and compared to both traditional routing protocols and other flooding-based protocols. (iv) A complete IWSAN platform is built and the whole protocol stack is implemented. Measurements were conducted in a real industrial environment to verify the correctness of the proposed solution.

ISBN 978-91-7485-171-7 ISSN 1651-4238

Abstract

Along with the quick development of wireless communication technologies, industrial automation networks are also in steady evolution. Industrial wire-less sensor and actuator networks (IWSANs) have been increasingly adopted in industrial automation systems. Although there are a number of advantages of replacing cables with wireless links, such as cost reduction, enhanced scal-ability and flexibility, the stringent requirements on communication reliscal-ability and meeting firm deadlines from industrial mission-critical applications must still be fulfilled. Also, transmissions over wireless channels in industrial envi-ronments are prone to noise and interference, resulting in frequent erroneous packet deliveries. Although industrial automation systems are usually designed to be tolerant to certain communication errors, successive transmission failures may still cause downtime of industrial applications, which might lead to sig-nificant economic losses or even serious accidents.

This thesis addresses the problems mentioned above and aims to provide reliable and deadline-constrained communication via IWSANs for industrial automation systems. On the MAC layer, existing IWSAN standards utilize automatic repeat request (ARQ) to improve reliability at the cost of additional transmission latency. An alternative method is to use Forward Error Correction (FEC) schemes to provide reliable communication by recovering erroneous data and avoiding unnecessary retransmissions. On the MAC layer, Time Divi-sion Multiple Access (TDMA) is usually applied in current IWSAN standards for collision-free and deterministic communication. An inappropriate schedul-ing scheme may introduce high transmission jitter and degrade the quality of control. On the network layer, routing protocols play an important role in both communication reliability and latency. Existing solutions are either hardly able to fulfill all stringent requirements from the mission-critical industrial applica-tions, too complicated to be realized, or lack verification in reality.

The contributions of this thesis consist of (i) the possibilities of using FEC i

ii

schemes in IWSANs is explored under the requirements of existing standards on the MAC layer. A compatible and flexible FEC scheme on the MAC layer for IWSANs that does not violate the standard is proposed and evaluated by simulations. (ii) To guarantee an acceptable control quality, a TDMA schedul-ing scheme is presented aimschedul-ing for low communication jitter, and it is com-pared to classic scheduling schemes. (iii) The advantages of exploiting flood-ing in IWSANs is discussed; a reliable controlled floodflood-ing-based routflood-ing pro-tocol is proposed and compared to both traditional routing propro-tocols and other flooding-based protocols. (iv) A complete IWSAN platform is built and the protocol stack is implemented. Measurements were conducted in a real indus-trial environment to verify the correctness of the proposed solution.

Sammanfattning

Parallellt med den snabba utvecklingen av tr˚adl¨os kommunikationsteknik ut-vecklas ¨aven industriella automationsn¨atverk. Dessutom ¨okar acceptansen f¨or industriella tr˚adl¨osa n¨at f¨or sensorer och st¨alldon (IWSAN) i industriella au-tomationssystem. Trots att det finns ett antal f¨ordelar med att ers¨atta kablar med tr˚adl¨osa f¨orbindelser, s˚asom minskade kostnader, f¨orb¨attrad skalbarhet och flexibilitet, m˚aste de h¨oga kraven som de industriella applikationerna st¨aller p˚a kommunikationss¨akerhet, samt kraven att m¨ota strikta tidsgr¨anser, fortfaran-de uppfyllas. ¨Overf¨oring via tr˚adl¨osa kanaler inom industriella milj¨oer har h¨og risk att uts¨attas f¨or st¨orningar, vilket resulterar i frekventa leveranser av fe-laktiga datapaket. Trots att industriella automationssystem oftast ¨ar utformade f¨or att vara toleranta mot vissa kommunikationsfel, kan alltf¨or m˚anga miss-lyckande ¨overf¨oringar orsaka produktionsstopp f¨or industriella till¨ampningar, vilket kan leda till betydande ekonomiska f¨orluster eller till och med allvarliga olyckor.

Denna avhandling tar upp de problem som n¨amns ovan och syftar till att ge tillf¨orlitlig kommunikation med begr¨ansade f¨ordr¨ojningar med IWSANs f¨or industriella automationssystem. I MAC-skiktet utnyttjar befintliga IWSAN-standarder Automatic Repeat Request (ARQ) f¨or att f¨orb¨attra tillf¨orlitligheten till priset av ytterligare f¨ordr¨ojningar i ¨overf¨oringen. En alternativ metod ¨ar att anv¨anda Forward Error Correction (FEC) f¨or att tillhandah˚alla tillf¨orlitlig kom-munikation genom att r¨atta felaktiga data och undvika on¨odiga oms¨andningar. I nuvarande IWSAN-standarder till¨ampas ¨aven Time Division Multiple Access (TDMA) i MAC-skiktet f¨or kollisionsfri och deterministisk kommunikation. En ol¨amplig schemal¨aggning kan inf¨ora en h¨og variation i ¨overf¨oringskapacite-ten samt i f¨ordr¨ojningen, vilket f¨ors¨amrar kvalite¨overf¨oringskapacite-ten p˚a styrningen av pro-cesserna. I n¨atverksskiktet spelar routingprotokollen en viktig roll b˚ade f¨or kommunikationens tillf¨orlitlighet och f¨ordr¨ojning. Befintliga l¨osningar kan antingen inte uppfylla alla str¨anga krav fr˚an s¨akerhetskritiska

ii

schemes in IWSANs is explored under the requirements of existing standards on the MAC layer. A compatible and flexible FEC scheme on the MAC layer for IWSANs that does not violate the standard is proposed and evaluated by simulations. (ii) To guarantee an acceptable control quality, a TDMA schedul-ing scheme is presented aimschedul-ing for low communication jitter, and it is com-pared to classic scheduling schemes. (iii) The advantages of exploiting flood-ing in IWSANs is discussed; a reliable controlled floodflood-ing-based routflood-ing pro-tocol is proposed and compared to both traditional routing propro-tocols and other flooding-based protocols. (iv) A complete IWSAN platform is built and the protocol stack is implemented. Measurements were conducted in a real indus-trial environment to verify the correctness of the proposed solution.

Sammanfattning

Parallellt med den snabba utvecklingen av tr˚adl¨os kommunikationsteknik ut-vecklas ¨aven industriella automationsn¨atverk. Dessutom ¨okar acceptansen f¨or industriella tr˚adl¨osa n¨at f¨or sensorer och st¨alldon (IWSAN) i industriella au-tomationssystem. Trots att det finns ett antal f¨ordelar med att ers¨atta kablar med tr˚adl¨osa f¨orbindelser, s˚asom minskade kostnader, f¨orb¨attrad skalbarhet och flexibilitet, m˚aste de h¨oga kraven som de industriella applikationerna st¨aller p˚a kommunikationss¨akerhet, samt kraven att m¨ota strikta tidsgr¨anser, fortfaran-de uppfyllas. ¨Overf¨oring via tr˚adl¨osa kanaler inom industriella milj¨oer har h¨og risk att uts¨attas f¨or st¨orningar, vilket resulterar i frekventa leveranser av fe-laktiga datapaket. Trots att industriella automationssystem oftast ¨ar utformade f¨or att vara toleranta mot vissa kommunikationsfel, kan alltf¨or m˚anga miss-lyckande ¨overf¨oringar orsaka produktionsstopp f¨or industriella till¨ampningar, vilket kan leda till betydande ekonomiska f¨orluster eller till och med allvarliga olyckor.

Denna avhandling tar upp de problem som n¨amns ovan och syftar till att ge tillf¨orlitlig kommunikation med begr¨ansade f¨ordr¨ojningar med IWSANs f¨or industriella automationssystem. I MAC-skiktet utnyttjar befintliga IWSAN-standarder Automatic Repeat Request (ARQ) f¨or att f¨orb¨attra tillf¨orlitligheten till priset av ytterligare f¨ordr¨ojningar i ¨overf¨oringen. En alternativ metod ¨ar att anv¨anda Forward Error Correction (FEC) f¨or att tillhandah˚alla tillf¨orlitlig kom-munikation genom att r¨atta felaktiga data och undvika on¨odiga oms¨andningar. I nuvarande IWSAN-standarder till¨ampas ¨aven Time Division Multiple Access (TDMA) i MAC-skiktet f¨or kollisionsfri och deterministisk kommunikation. En ol¨amplig schemal¨aggning kan inf¨ora en h¨og variation i ¨overf¨oringskapacite-ten samt i f¨ordr¨ojningen, vilket f¨ors¨amrar kvalite¨overf¨oringskapacite-ten p˚a styrningen av pro-cesserna. I n¨atverksskiktet spelar routingprotokollen en viktig roll b˚ade f¨or kommunikationens tillf¨orlitlighet och f¨ordr¨ojning. Befintliga l¨osningar kan antingen inte uppfylla alla str¨anga krav fr˚an s¨akerhetskritiska

iv

ningar, eller ¨ar alltf¨or komplicerade f¨or att bli realiserade, eller saknar verifier-ing i verkligheten.

Bidragen i denna avhandling best˚ar av att (i) m¨ojligheterna att anv¨anda FEC-system i IWSANs utforskas i enlighet med kraven fr˚an befintliga stan-darder inom skiktet. Ett kompatibelt och flexibelt FEC-protokoll i MAC-skiktet f¨or IWSANs som inte bryter mot standarden f¨oresl˚as och utv¨arderas genom simuleringar. (ii) F¨or att garantera en godtagbar reglerkvalitet pre-senteras en TDMA-schemal¨aggningalgoritm som syftar till att begr¨ansa vari-ationer i kommunikationsf¨ordr¨ojningen, och den utv¨arderas mot andra, klas-siska, schemal¨aggningsalgoritmer. (iii) F¨ordelarna med att utnyttja flooding i IWSANs diskuteras; ett p˚alitligt routingprotokoll baserat p˚a kontrollerad flood-ing f¨oresl˚as och j¨amf¨ors mot traditionella routflood-ingprotokoll samt mot andra flooding-baserade protokoll. (iv) En komplett IWSAN-plattform har byggts och hela protokollstacken ¨ar implementerad i inbyggda system. M¨atningar har genomf¨orts i en verklig industriell milj¨o f¨or att verifiera till¨ampbarheten av den f¨oreslagna l¨osningen.

iv

ningar, eller ¨ar alltf¨or komplicerade f¨or att bli realiserade, eller saknar verifier-ing i verkligheten.

Bidragen i denna avhandling best˚ar av att (i) m¨ojligheterna att anv¨anda FEC-system i IWSANs utforskas i enlighet med kraven fr˚an befintliga stan-darder inom skiktet. Ett kompatibelt och flexibelt FEC-protokoll i MAC-skiktet f¨or IWSANs som inte bryter mot standarden f¨oresl˚as och utv¨arderas genom simuleringar. (ii) F¨or att garantera en godtagbar reglerkvalitet pre-senteras en TDMA-schemal¨aggningalgoritm som syftar till att begr¨ansa vari-ationer i kommunikationsf¨ordr¨ojningen, och den utv¨arderas mot andra, klas-siska, schemal¨aggningsalgoritmer. (iii) F¨ordelarna med att utnyttja flooding i IWSANs diskuteras; ett p˚alitligt routingprotokoll baserat p˚a kontrollerad flood-ing f¨oresl˚as och j¨amf¨ors mot traditionella routflood-ingprotokoll samt mot andra flooding-baserade protokoll. (iv) En komplett IWSAN-plattform har byggts och hela protokollstacken ¨ar implementerad i inbyggda system. M¨atningar har genomf¨orts i en verklig industriell milj¨o f¨or att verifiera till¨ampbarheten av den f¨oreslagna l¨osningen.

Acknowledgement

About four years ago, I made my decision to become a Ph.D. student. At that time, several friends told me that to finish the Ph.D. study might be a long journey full of frustration and tedium, but all these did not Shake my determination at all. Now four years have passed. I have to admit that I was a little overoptimistic in the beginning. During these four years a lot of things happened, but I have to say that these four years are the most rewarding years of my life. I have got a lot of chances to meet different people, travel in different countries and experience different cultures. My real gain is not only knowledge or skills, but also academic mindset and inner strength.

There are many people I have to acknowledge for making this dissertation possible. First I would like to thank my supervisors Mats Bj¨orkman(MDH), Maria Lind´en(MDH), Mikael Gidlund(ABB Corporate Research) and Johan ˚Akerberg(ABB Corporate Research), not only for giving me the opportunity to become a Ph.D. student, but also teaching me how to become a well qualified Ph.D. graduate. When I went into a deep depression, you are always patient and offer me your supports in all the ways you can. I owe all of you a great debt of gratitude for the guidance, not only in my work, but also in my life.

I would also like to express my thanks to Elisabeth Uhlemann, Mikael Ek-str¨om, Martin Ekstr¨om and Marcus Bergblomma for all the helps they gave me from the first day of my PhD study. All the discussions with you gave me a lot of valuable inspirations for my research. I would like to thank Thomas Nolte and Mikael Sj¨odin for helping and guiding me through my studies. Thank Thomas Nolte again, as well as Emma Nehrenheim for the PhD introduction course, which is very helpful in the beginning of my research. Also thank Gordana Dodig-Crnkovic and Jan Gustafsson for very useful course: Research Methods in Natural Sciences and Engineering. I want to thank Nikola Petrovic. You are so patient for helping me with the spectrum analyzer. I would also like to thank Professor Peter Stenumgaard from Link¨oping Univeristy. You gave

Acknowledgement

About four years ago, I made my decision to become a Ph.D. student. At that time, several friends told me that to finish the Ph.D. study might be a long journey full of frustration and tedium, but all these did not Shake my determination at all. Now four years have passed. I have to admit that I was a little overoptimistic in the beginning. During these four years a lot of things happened, but I have to say that these four years are the most rewarding years of my life. I have got a lot of chances to meet different people, travel in different countries and experience different cultures. My real gain is not only knowledge or skills, but also academic mindset and inner strength.

There are many people I have to acknowledge for making this dissertation possible. First I would like to thank my supervisors Mats Bj¨orkman(MDH), Maria Lind´en(MDH), Mikael Gidlund(ABB Corporate Research) and Johan ˚Akerberg(ABB Corporate Research), not only for giving me the opportunity to become a Ph.D. student, but also teaching me how to become a well qualified Ph.D. graduate. When I went into a deep depression, you are always patient and offer me your supports in all the ways you can. I owe all of you a great debt of gratitude for the guidance, not only in my work, but also in my life.

I would also like to express my thanks to Elisabeth Uhlemann, Mikael Ek-str¨om, Martin Ekstr¨om and Marcus Bergblomma for all the helps they gave me from the first day of my PhD study. All the discussions with you gave me a lot of valuable inspirations for my research. I would like to thank Thomas Nolte and Mikael Sj¨odin for helping and guiding me through my studies. Thank Thomas Nolte again, as well as Emma Nehrenheim for the PhD introduction course, which is very helpful in the beginning of my research. Also thank Gordana Dodig-Crnkovic and Jan Gustafsson for very useful course: Research Methods in Natural Sciences and Engineering. I want to thank Nikola Petrovic. You are so patient for helping me with the spectrum analyzer. I would also like to thank Professor Peter Stenumgaard from Link¨oping Univeristy. You gave

viii

me very valuable advices in my licentiate defense. Great thanks also go to Professor Youzhi Xu from J¨onk¨oping University. You came to V¨aster˚as sev-eral times to give me the important guidance to my research work. I should also say thank you to all the administrative staff at IDT who offer me a lot of helps in daily affairs, in particular, Carola Ryttersson, Susanne Fronn˚a and Sofia J¨ader´en.

This work would not have been possible without the great supports of staffs from ABB Corporate Research. Especially I would like to thank Peter L¨ofgren, Zhibo Pang, Tomas Lennvall, Jonas Neander, Ewa Hansen, Krister Landern¨as, Niclas Ericsson, Gargi Bag, Eva Stenqvist and Jimmy Kjellson for supporting and encouraging me all the way from the first day. I also would like to thank Nils-Olof Eriksson from ABB Low Voltage Systems. You offered me great helps on the measurement in the workshop.

Since I spend most of my time in ABB Corporate Research, I did not have many chances to chat and have Fika with my colleagues in IDT, but every time when I came back to IDT I can feel the friendly and encouraging atmosphere. Thus I want to say thank you to all my colleagues in IDT, in particular, Hans Hansson, Svetlana Girs, Hang Yin, Jiale Zhou, Meng Liu, Elena Lisova, Dag Nystr¨om, Cristina Seceleanu, Saad Mubeen, Rafia Inam, Mohammad Ashjaei, Sara Afshar, Leo Hatvani, Moris Behnam, Yue Lu, etc. Many thanks go to all my friends both in the university and ABB Corporate Research for all the laughs and funs.

Particularly, I would like to express my greatest thanks and deepest loves to my fianc´ee Wei Wang. If anyone asks me what is the most important thing happened in the past four years or even in my life, I will tell him/her that the answer is having you, not getting a Ph.D. degree. Although you are on the other side of the earth, you are always supportive of me. Every time when I felt down, your smiley face can always cheer me up. Some people fight for honor, some people fight for money, but I fight for your happiness.

Finally, I would express my deepest gratitude to my dear parents for all the supports, loves and happiness that you have been giving me all the time.

Kan Yu V¨aster˚as, September 20, 2014

List of Publications

Papers Included in the thesis

1Paper A K. Yu, M. Gidlund, J. ˚Akerberg, M. Bj¨orkman, Reliable and Low La-tency Transmission in Industrial Wireless Sensor Networks, the First

In-ternational Workshop on Wireless Networked Control Systems (WNCS),

Canada, September, 2011

Paper B F. Bara´c, K. Yu, M. Gidlund, J. ˚Akerberg, M. Bj¨orkman, Towards Reliable and Lightweight Communication in Industrial Wireless Sensor Networks, IEEE 10th International Conference on Industrial

Informat-ics (INDIN), Beijing, China, July, 2012,Best Paper Finalist

Paper C K. Yu, M. Gidlund, J. ˚Akerberg, M. Bj¨orkman, Low Jitter Schedul-ing for Industrial Wireless Sensor and Actuator Networks, The 39th

An-nual Conference of the IEEE Industrial Electronics Society (IECON),

Vienna, Austria, November, 2013

Paper D K. Yu, Z. Pang, M. Gidlund, J. ˚Akerberg, M. Bj¨orkman, REALFLOW: Reliable Real-time Flooding-based Routing Protocol for Industrial Wire-less Sensor Networks, International Journal of Distributed Sensor

Net-works Volume 2014 (2014)

Paper E K. Yu, M. Gidlund, J. ˚Akerberg, M. Bj¨orkman, Performance Eval-uation and Measurement of REALFLOW Routing Protocol in Wireless Industrial Networks, submitted to IEEE Transaction on Industrial

Infor-matics

1The included articles have been reformatted to comply with the doctoral dissertation layout

viii

me very valuable advices in my licentiate defense. Great thanks also go to Professor Youzhi Xu from J¨onk¨oping University. You came to V¨aster˚as sev-eral times to give me the important guidance to my research work. I should also say thank you to all the administrative staff at IDT who offer me a lot of helps in daily affairs, in particular, Carola Ryttersson, Susanne Fronn˚a and Sofia J¨ader´en.

This work would not have been possible without the great supports of staffs from ABB Corporate Research. Especially I would like to thank Peter L¨ofgren, Zhibo Pang, Tomas Lennvall, Jonas Neander, Ewa Hansen, Krister Landern¨as, Niclas Ericsson, Gargi Bag, Eva Stenqvist and Jimmy Kjellson for supporting and encouraging me all the way from the first day. I also would like to thank Nils-Olof Eriksson from ABB Low Voltage Systems. You offered me great helps on the measurement in the workshop.

Since I spend most of my time in ABB Corporate Research, I did not have many chances to chat and have Fika with my colleagues in IDT, but every time when I came back to IDT I can feel the friendly and encouraging atmosphere. Thus I want to say thank you to all my colleagues in IDT, in particular, Hans Hansson, Svetlana Girs, Hang Yin, Jiale Zhou, Meng Liu, Elena Lisova, Dag Nystr¨om, Cristina Seceleanu, Saad Mubeen, Rafia Inam, Mohammad Ashjaei, Sara Afshar, Leo Hatvani, Moris Behnam, Yue Lu, etc. Many thanks go to all my friends both in the university and ABB Corporate Research for all the laughs and funs.

Particularly, I would like to express my greatest thanks and deepest loves to my fianc´ee Wei Wang. If anyone asks me what is the most important thing happened in the past four years or even in my life, I will tell him/her that the answer is having you, not getting a Ph.D. degree. Although you are on the other side of the earth, you are always supportive of me. Every time when I felt down, your smiley face can always cheer me up. Some people fight for honor, some people fight for money, but I fight for your happiness.

Finally, I would express my deepest gratitude to my dear parents for all the supports, loves and happiness that you have been giving me all the time.

Kan Yu V¨aster˚as, September 20, 2014

List of Publications

Papers Included in the thesis

1Paper A K. Yu, M. Gidlund, J. ˚Akerberg, M. Bj¨orkman, Reliable and Low La-tency Transmission in Industrial Wireless Sensor Networks, the First

In-ternational Workshop on Wireless Networked Control Systems (WNCS),

Canada, September, 2011

Paper B F. Bara´c, K. Yu, M. Gidlund, J. ˚Akerberg, M. Bj¨orkman, Towards Reliable and Lightweight Communication in Industrial Wireless Sensor Networks, IEEE 10th International Conference on Industrial

Informat-ics (INDIN), Beijing, China, July, 2012,Best Paper Finalist

Paper C K. Yu, M. Gidlund, J. ˚Akerberg, M. Bj¨orkman, Low Jitter Schedul-ing for Industrial Wireless Sensor and Actuator Networks, The 39th

An-nual Conference of the IEEE Industrial Electronics Society (IECON),

Vienna, Austria, November, 2013

Paper D K. Yu, Z. Pang, M. Gidlund, J. ˚Akerberg, M. Bj¨orkman, REALFLOW: Reliable Real-time Flooding-based Routing Protocol for Industrial Wire-less Sensor Networks, International Journal of Distributed Sensor

Net-works Volume 2014 (2014)

Paper E K. Yu, M. Gidlund, J. ˚Akerberg, M. Bj¨orkman, Performance Eval-uation and Measurement of REALFLOW Routing Protocol in Wireless Industrial Networks, submitted to IEEE Transaction on Industrial

Infor-matics

1The included articles have been reformatted to comply with the doctoral dissertation layout

x

Additional Papers, not Included in the thesis

Conferences

• K. Yu, F. Bara´c, M. Gidlund, J. ˚Akerberg, M. Bj¨orkman, A Flexible

Error Correction Scheme for IEEE 802.15.4-based Industrial Wireless Sensor Networks, the 21st IEEE International Symposium on Industrial

Electronics (ISIE), Hangzhou, China, May, 2012

• K. Yu, F. Bara´c, Mikael Gidlund, J. ˚Akerberg, M. Bj¨orkman, Adaptive

Forward Error Correction for Best Effort Wireless Sensor Networks,

In-ternational Workshop on Wireless Sensor Actor and Actuator Networks 2012(WiSAAN), Canada, June, 2012

• K. Yu, M. Gidlund, J. ˚Akerberg, M. Bj¨orkman, Reliable RSS-based

Routing Protocol for Industrial Wireless Sensor Networks, the 38th

An-nual Conference of the IEEE Industrial Electronics Society(IECON),

Canada, October , 2012

• K. Yu, T. Zheng, Z. Pang, M. Gidlund, J. ˚Akerberg, M. Bj¨orkman,

Reli-able flooding-based downlink transmissions for Industrial Wireless Sen-sor and Actuator Networks, 2013 IEEE International Conference on

In-dustrial Technology (ICIT), Cape Town, South Africa, February, 2013 • Z. Pang, K. Yu, M. Gidlund, J. ˚Akerberg, An RTOS-based

architec-ture for industrial wireless sensor network stacks with multi-processor support, 2013 IEEE International Conference on Industrial Technology

(ICIT), Cape Town, South Africa, February, 2013

• K. Yu, M. Gidlund, J. ˚Akerberg, M. Bj¨orkman, Reliable Real-time

Rout-ing Protocol for Industrial Wireless Sensor and Actuator Networks, the

8th IEEE Conference on Industrial Electronics and Applications (ICIEA 2013), Melbourne, Australia, June, 2013

• Y, Yitbarek, K. Yu, M. Gidlund, J. ˚Akerberg, M. Bj¨orkman,

Implementa-tion and evaluaImplementa-tion of error control schemes in Industrial Wireless Sen-sor Networks , 2014 IEEE International Conference on Industrial

Tech-nology (ICIT), Busan, South Korea, February, 2014,Best Paper Award.

Contents

I

Thesis

1

1 Introduction 3 1.1 Research Problems . . . 5 1.2 Research Questions . . . 7 1.3 Research Hypotheses . . . 8 1.4 Research Method . . . 8 1.5 Thesis Contributions . . . 10 1.6 Thesis Outline . . . 122 Background and Research Challenges 15 2.1 Industrial Automation . . . 15

2.2 Wireless Industrial Networks . . . 19

2.2.1 Industrial Wireless Channel Conditions . . . 20

2.2.2 IWSAN Standards . . . 22

2.2.3 Reliable Communication in IWSAN . . . 28

2.2.4 TDMA Scheduling in IWSANs . . . 30

3 Related Work 31 3.1 FEC in WSN . . . 31

3.2 Real-time scheduling in WSNs . . . 32

3.3 Routing protocols in WSN . . . 34

4 Research Solutions and Results 39 4.1 Applying FEC in IWSAN . . . 39

4.1.1 Timing constraint . . . 40

4.1.2 Compatible FEC coding scheme . . . 42

4.2 Low jitter TDMA Scheduling in IWSAN . . . 44 xi

x

Additional Papers, not Included in the thesis

Conferences

• K. Yu, F. Bara´c, M. Gidlund, J. ˚Akerberg, M. Bj¨orkman, A Flexible

Error Correction Scheme for IEEE 802.15.4-based Industrial Wireless Sensor Networks, the 21st IEEE International Symposium on Industrial

Electronics (ISIE), Hangzhou, China, May, 2012

• K. Yu, F. Bara´c, Mikael Gidlund, J. ˚Akerberg, M. Bj¨orkman, Adaptive

Forward Error Correction for Best Effort Wireless Sensor Networks,

In-ternational Workshop on Wireless Sensor Actor and Actuator Networks 2012(WiSAAN), Canada, June, 2012

• K. Yu, M. Gidlund, J. ˚Akerberg, M. Bj¨orkman, Reliable RSS-based

Routing Protocol for Industrial Wireless Sensor Networks, the 38th

An-nual Conference of the IEEE Industrial Electronics Society(IECON),

Canada, October , 2012

• K. Yu, T. Zheng, Z. Pang, M. Gidlund, J. ˚Akerberg, M. Bj¨orkman,

Reli-able flooding-based downlink transmissions for Industrial Wireless Sen-sor and Actuator Networks, 2013 IEEE International Conference on

In-dustrial Technology (ICIT), Cape Town, South Africa, February, 2013 • Z. Pang, K. Yu, M. Gidlund, J. ˚Akerberg, An RTOS-based

architec-ture for industrial wireless sensor network stacks with multi-processor support, 2013 IEEE International Conference on Industrial Technology

(ICIT), Cape Town, South Africa, February, 2013

• K. Yu, M. Gidlund, J. ˚Akerberg, M. Bj¨orkman, Reliable Real-time

Rout-ing Protocol for Industrial Wireless Sensor and Actuator Networks, the

8th IEEE Conference on Industrial Electronics and Applications (ICIEA 2013), Melbourne, Australia, June, 2013

• Y, Yitbarek, K. Yu, M. Gidlund, J. ˚Akerberg, M. Bj¨orkman,

Implementa-tion and evaluaImplementa-tion of error control schemes in Industrial Wireless Sen-sor Networks , 2014 IEEE International Conference on Industrial

Tech-nology (ICIT), Busan, South Korea, February, 2014,Best Paper Award.

Contents

I

Thesis

1

1 Introduction 3 1.1 Research Problems . . . 5 1.2 Research Questions . . . 7 1.3 Research Hypotheses . . . 8 1.4 Research Method . . . 8 1.5 Thesis Contributions . . . 10 1.6 Thesis Outline . . . 122 Background and Research Challenges 15 2.1 Industrial Automation . . . 15

2.2 Wireless Industrial Networks . . . 19

2.2.1 Industrial Wireless Channel Conditions . . . 20

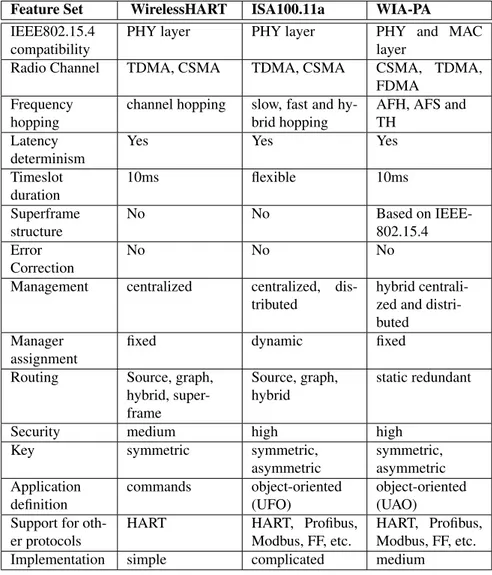

2.2.2 IWSAN Standards . . . 22

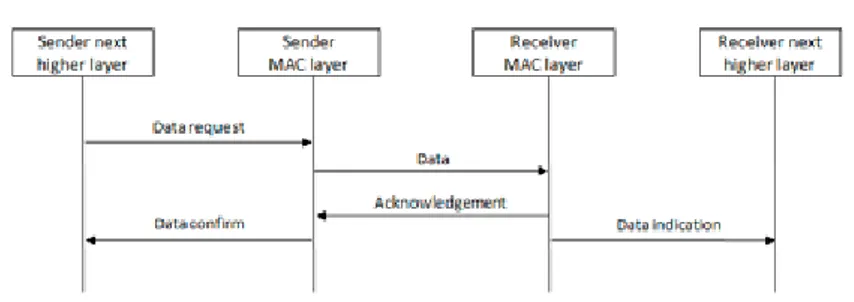

2.2.3 Reliable Communication in IWSAN . . . 28

2.2.4 TDMA Scheduling in IWSANs . . . 30

3 Related Work 31 3.1 FEC in WSN . . . 31

3.2 Real-time scheduling in WSNs . . . 32

3.3 Routing protocols in WSN . . . 34

4 Research Solutions and Results 39 4.1 Applying FEC in IWSAN . . . 39

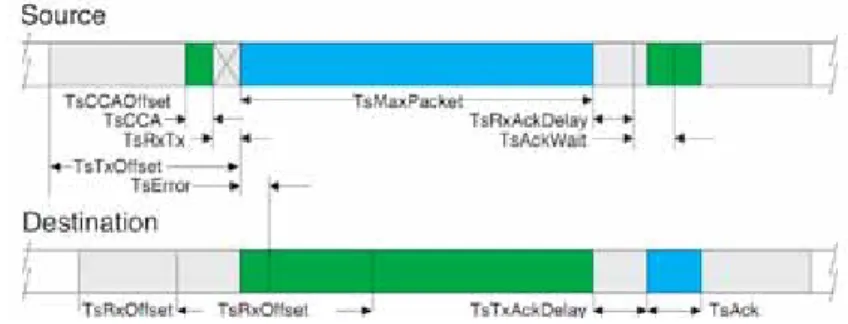

4.1.1 Timing constraint . . . 40

4.1.2 Compatible FEC coding scheme . . . 42

4.2 Low jitter TDMA Scheduling in IWSAN . . . 44 xi

xii Contents

4.2.1 IWSAN Scheduling Requirements . . . 44

4.2.2 TDMA Scheduling aiming for low jitter . . . 46

4.2.3 Research results . . . 46

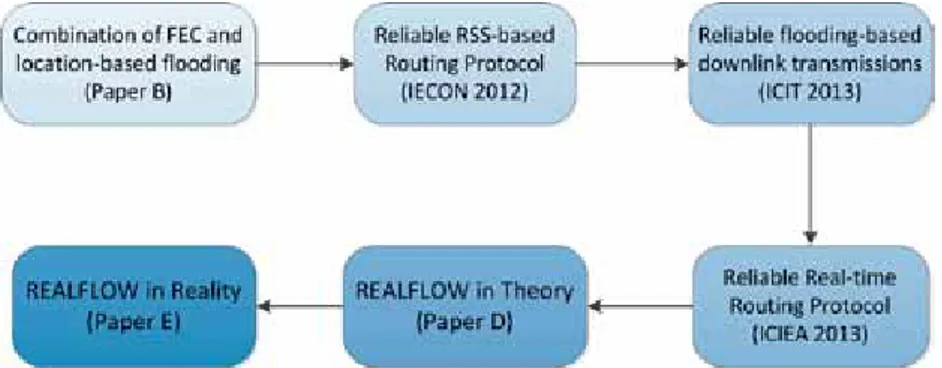

4.3 Reliable flooding-based routing in IWSAN . . . 47

4.3.1 Exploiting Flooding in IWSAN . . . 47

4.3.2 Evolution of Proposed Routing . . . 49

4.3.3 REALFLOW Routing Protocol . . . 50

4.3.4 Research results . . . 51

4.4 System Implementation and Measurement . . . 52

4.4.1 Prototype Implementation . . . 53

4.4.2 Measurement in a Real Industrial Environment . . . . 59

4.4.3 Measurement Results . . . 60

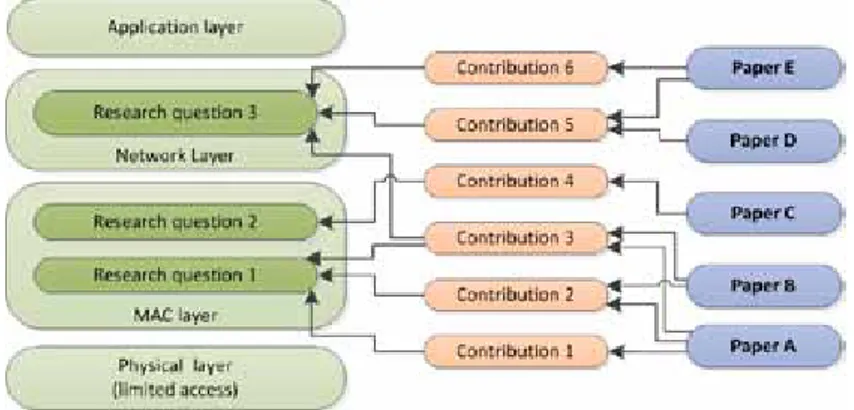

5 Scientific Contributions of Included Papers 63 5.1 Paper A . . . 64

5.2 Paper B . . . 66

5.3 Paper C . . . 67

5.4 Paper D . . . 68

5.5 Paper E . . . 70

6 Conclusions and Future work 73 6.1 Summary and Research Questions Revisited . . . 73

6.2 Future Work . . . 76

Bibliography 78

II

Included Papers

93

7 Paper A: Reliable and Low Latency Transmission in Industrial Wireless Sen-sor Networks 95 7.1 Introduction . . . 977.2 IEEE 802.15.4 and Industrial Wireless Channel Conditions . . 98

7.3 Applying Forward Error Correction Technology in IWSN . . . 99

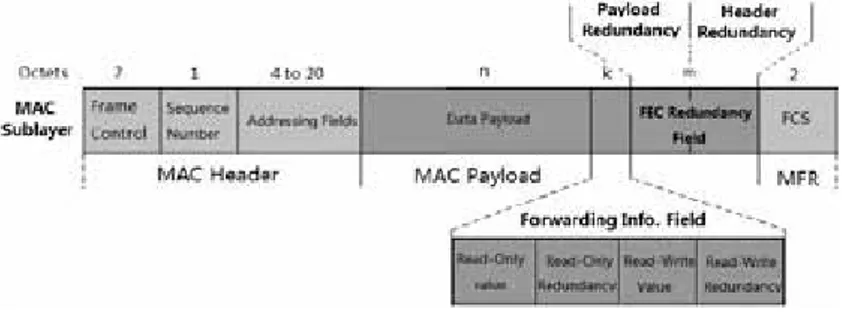

7.3.1 Applying FEC Codes at the MAC Layer . . . 100

7.3.2 Timing Requirement . . . 103

7.4 Performance Evaluation . . . 105

7.4.1 Selection of FEC codes for evaluation . . . 105

7.4.2 Experimental Setup . . . 105

Contents xiii 7.4.3 Evaluation Results . . . 106

7.5 Analysis and Discussion . . . 108

7.6 Conclusions and Future Work . . . 109

References . . . 109

8 Paper B: Towards Reliable and Lightweight Communication in Industrial Wireless Sensor Networks 111 8.1 Introduction . . . 113

8.2 Proposed FEC-coded Lightweight Routing Scheme . . . 114

8.2.1 The lightweight and reliable transmission scheme . . . 115

8.2.2 Theoretical Performance Analysis . . . 119

8.3 Simulation Setup and Scenarios of interest . . . 122

8.3.1 Channel model and the choice of FEC coding . . . 122

8.3.2 Simulation Scenarios . . . 123 8.4 Evaluation Results . . . 123 8.4.1 Scenario I . . . 124 8.4.2 Scenario II . . . 126 8.5 Conclusions . . . 129 References . . . 129 9 Paper C: Low Jitter Scheduling for Industrial Wireless Sensor and Actuator Networks 133 9.1 Introduction . . . 135

9.2 preliminary . . . 136

9.2.1 Industrial Wireless Sensor and Actuator Network and Existing Standards . . . 136

9.2.2 IWSANs Scheduling Requirements . . . 137

9.2.3 Controlled Flooding-based Routing Scheme . . . 139

9.3 Low Jitter Scheduling Scheme For IWSANs . . . 139

9.3.1 Notations and Task Model . . . 139

9.3.2 Scheduling Scheme Aiming for Low Jitter . . . 140

9.4 Evaluation . . . 145

9.4.1 Simulation Setup . . . 145

9.4.2 Simulation Results and Analysis . . . 145

9.5 Conclusions . . . 146

xii Contents

4.2.1 IWSAN Scheduling Requirements . . . 44

4.2.2 TDMA Scheduling aiming for low jitter . . . 46

4.2.3 Research results . . . 46

4.3 Reliable flooding-based routing in IWSAN . . . 47

4.3.1 Exploiting Flooding in IWSAN . . . 47

4.3.2 Evolution of Proposed Routing . . . 49

4.3.3 REALFLOW Routing Protocol . . . 50

4.3.4 Research results . . . 51

4.4 System Implementation and Measurement . . . 52

4.4.1 Prototype Implementation . . . 53

4.4.2 Measurement in a Real Industrial Environment . . . . 59

4.4.3 Measurement Results . . . 60

5 Scientific Contributions of Included Papers 63 5.1 Paper A . . . 64

5.2 Paper B . . . 66

5.3 Paper C . . . 67

5.4 Paper D . . . 68

5.5 Paper E . . . 70

6 Conclusions and Future work 73 6.1 Summary and Research Questions Revisited . . . 73

6.2 Future Work . . . 76

Bibliography 78

II

Included Papers

93

7 Paper A: Reliable and Low Latency Transmission in Industrial Wireless Sen-sor Networks 95 7.1 Introduction . . . 977.2 IEEE 802.15.4 and Industrial Wireless Channel Conditions . . 98

7.3 Applying Forward Error Correction Technology in IWSN . . . 99

7.3.1 Applying FEC Codes at the MAC Layer . . . 100

7.3.2 Timing Requirement . . . 103

7.4 Performance Evaluation . . . 105

7.4.1 Selection of FEC codes for evaluation . . . 105

7.4.2 Experimental Setup . . . 105

Contents xiii 7.4.3 Evaluation Results . . . 106

7.5 Analysis and Discussion . . . 108

7.6 Conclusions and Future Work . . . 109

References . . . 109

8 Paper B: Towards Reliable and Lightweight Communication in Industrial Wireless Sensor Networks 111 8.1 Introduction . . . 113

8.2 Proposed FEC-coded Lightweight Routing Scheme . . . 114

8.2.1 The lightweight and reliable transmission scheme . . . 115

8.2.2 Theoretical Performance Analysis . . . 119

8.3 Simulation Setup and Scenarios of interest . . . 122

8.3.1 Channel model and the choice of FEC coding . . . 122

8.3.2 Simulation Scenarios . . . 123 8.4 Evaluation Results . . . 123 8.4.1 Scenario I . . . 124 8.4.2 Scenario II . . . 126 8.5 Conclusions . . . 129 References . . . 129 9 Paper C: Low Jitter Scheduling for Industrial Wireless Sensor and Actuator Networks 133 9.1 Introduction . . . 135

9.2 preliminary . . . 136

9.2.1 Industrial Wireless Sensor and Actuator Network and Existing Standards . . . 136

9.2.2 IWSANs Scheduling Requirements . . . 137

9.2.3 Controlled Flooding-based Routing Scheme . . . 139

9.3 Low Jitter Scheduling Scheme For IWSANs . . . 139

9.3.1 Notations and Task Model . . . 139

9.3.2 Scheduling Scheme Aiming for Low Jitter . . . 140

9.4 Evaluation . . . 145

9.4.1 Simulation Setup . . . 145

9.4.2 Simulation Results and Analysis . . . 145

9.5 Conclusions . . . 146

xiv Contents 10 Paper D:

REALFLOW: Reliable Real-time Flooding-based Routing Proto-col for Industrial Wireless Sensor Networks 149

10.1 Introduction . . . 151

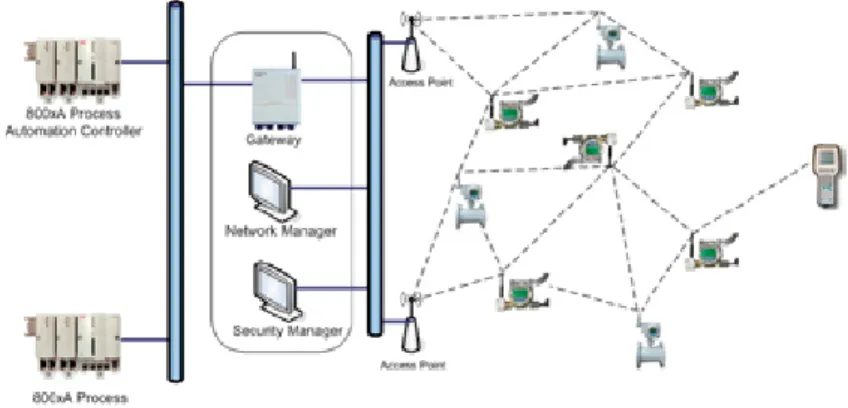

10.2 Industrial Wireless Sensor Network Architecture . . . 154

10.3 Proposed Reliable Real-time Flooding-based Routing Protocol 155 10.3.1 Definitions and Notations . . . 156

10.3.2 Establishing and Maintaining Routes . . . 157

10.3.3 Packet Forwarding Method . . . 163

10.3.4 Example: Reliable Real-Time Flooding-based Routing Protocol . . . 165

10.3.5 Theoretical Analysis of REALFLOW . . . 167

10.4 Experimental Setup . . . 172

10.4.1 Simulation settings . . . 172

10.4.2 Simulation Scenarios . . . 174

10.5 Evaluation Results and Analysis . . . 178

10.5.1 Packet Deliver Ratio . . . 178

10.5.2 End-to-End Latency . . . 179

10.5.3 Network Recovery Time . . . 181

10.6 Conclusions and Future work . . . 181

References . . . 182

11 Paper E: Performance Evaluation and Measurement of REALFLOW Rout-ing Protocol in Wireless Industrial Networks 187 11.1 Introduction . . . 189

11.2 Related Work . . . 190

11.3 Preliminaries . . . 192

11.3.1 System Model . . . 192

11.3.2 Exploiting Flooding in IWSANs . . . 193

11.4 REALFLOW in IWSANs . . . 193

11.4.1 Route establishment and maintenance . . . 194

11.4.2 Schedule Distribution Method . . . 195

11.4.3 Packet Forwarding Criteria . . . 196

11.4.4 An example of REALFLOW . . . 196

11.5 Simulations and Analysis . . . 197

11.5.1 Simulation settings . . . 197

11.5.2 Evaluation criteria . . . 197

11.5.3 Simulation Scenarios . . . 198

Contents xv 11.5.4 Simulation Results and Analysis . . . 199

11.6 Implementation and Measurements . . . 206

11.6.1 System Implementation . . . 206

11.6.2 Measurement Settings . . . 206

11.6.3 Measurement Results Analysis . . . 208

11.7 Conclusions and Future work . . . 211

xiv Contents 10 Paper D:

REALFLOW: Reliable Real-time Flooding-based Routing Proto-col for Industrial Wireless Sensor Networks 149

10.1 Introduction . . . 151

10.2 Industrial Wireless Sensor Network Architecture . . . 154

10.3 Proposed Reliable Real-time Flooding-based Routing Protocol 155 10.3.1 Definitions and Notations . . . 156

10.3.2 Establishing and Maintaining Routes . . . 157

10.3.3 Packet Forwarding Method . . . 163

10.3.4 Example: Reliable Real-Time Flooding-based Routing Protocol . . . 165

10.3.5 Theoretical Analysis of REALFLOW . . . 167

10.4 Experimental Setup . . . 172

10.4.1 Simulation settings . . . 172

10.4.2 Simulation Scenarios . . . 174

10.5 Evaluation Results and Analysis . . . 178

10.5.1 Packet Deliver Ratio . . . 178

10.5.2 End-to-End Latency . . . 179

10.5.3 Network Recovery Time . . . 181

10.6 Conclusions and Future work . . . 181

References . . . 182

11 Paper E: Performance Evaluation and Measurement of REALFLOW Rout-ing Protocol in Wireless Industrial Networks 187 11.1 Introduction . . . 189

11.2 Related Work . . . 190

11.3 Preliminaries . . . 192

11.3.1 System Model . . . 192

11.3.2 Exploiting Flooding in IWSANs . . . 193

11.4 REALFLOW in IWSANs . . . 193

11.4.1 Route establishment and maintenance . . . 194

11.4.2 Schedule Distribution Method . . . 195

11.4.3 Packet Forwarding Criteria . . . 196

11.4.4 An example of REALFLOW . . . 196

11.5 Simulations and Analysis . . . 197

11.5.1 Simulation settings . . . 197

11.5.2 Evaluation criteria . . . 197

11.5.3 Simulation Scenarios . . . 198

Contents xv 11.5.4 Simulation Results and Analysis . . . 199

11.6 Implementation and Measurements . . . 206

11.6.1 System Implementation . . . 206

11.6.2 Measurement Settings . . . 206

11.6.3 Measurement Results Analysis . . . 208

11.7 Conclusions and Future work . . . 211

I

Thesis

I

Thesis

Chapter 1

Introduction

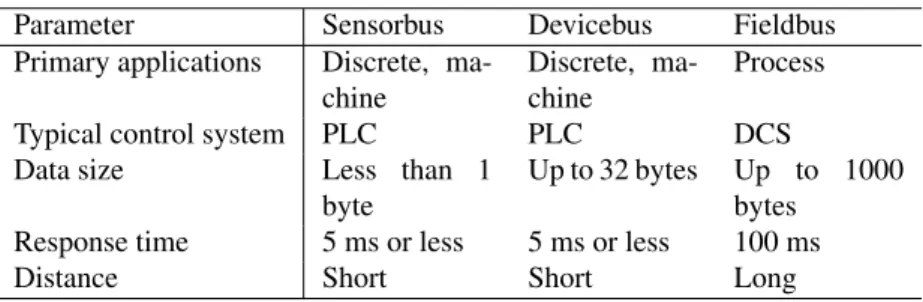

Wired communication has been used for industrial automation systems for decades. Existing solutions, such as Fieldbus systems, have been specifically designed for solving automation or control tasks that interconnect controllers with sensors or actuators with cables. The primary goal of these systems is to provide reliable and deterministic communications to fulfill stringent require-ments of industrial applications. However, low flexibility and poor scalability leads to high installation and maintenance costs [1]. As wireless technologies evolve, wireless communication systems have led to a number of solutions, such as cellular networks, wireless local area networks (WLAN), wireless per-sonal area networks (WPAN) etc. One of the solutions applied in the indus-trial domain is indusindus-trial wireless sensor and actuator networks (IWSANs). IWSANs have been exhibiting their advantages over traditional wired counter-parts in industrial automation systems. An estimation was made by Emerson Process Management that up to 90% cost savings can be achieved by applying IWSANs in industrial automation systems [2]. Besides low cost, the adoption of wireless solutions at the machine level also offers other advantages, such as support for mobility and flexible installation.

Although IWSANs have been increasingly applied in industrial automation due to the benefits mentioned above, their applicability in industrial environ-ments is still in the development stage. The majority of traditional wireless so-lutions pay more attention to bit rates or low power rather than high reliability or low latency, which is unsuitable for industrial mission-critical applications. Some industrial applications such as packaging and manufacturing have very strict requirements on communication. Data exchange must be reliable and

Chapter 1

Introduction

Wired communication has been used for industrial automation systems for decades. Existing solutions, such as Fieldbus systems, have been specifically designed for solving automation or control tasks that interconnect controllers with sensors or actuators with cables. The primary goal of these systems is to provide reliable and deterministic communications to fulfill stringent require-ments of industrial applications. However, low flexibility and poor scalability leads to high installation and maintenance costs [1]. As wireless technologies evolve, wireless communication systems have led to a number of solutions, such as cellular networks, wireless local area networks (WLAN), wireless per-sonal area networks (WPAN) etc. One of the solutions applied in the indus-trial domain is indusindus-trial wireless sensor and actuator networks (IWSANs). IWSANs have been exhibiting their advantages over traditional wired counter-parts in industrial automation systems. An estimation was made by Emerson Process Management that up to 90% cost savings can be achieved by applying IWSANs in industrial automation systems [2]. Besides low cost, the adoption of wireless solutions at the machine level also offers other advantages, such as support for mobility and flexible installation.

Although IWSANs have been increasingly applied in industrial automation due to the benefits mentioned above, their applicability in industrial environ-ments is still in the development stage. The majority of traditional wireless so-lutions pay more attention to bit rates or low power rather than high reliability or low latency, which is unsuitable for industrial mission-critical applications. Some industrial applications such as packaging and manufacturing have very strict requirements on communication. Data exchange must be reliable and

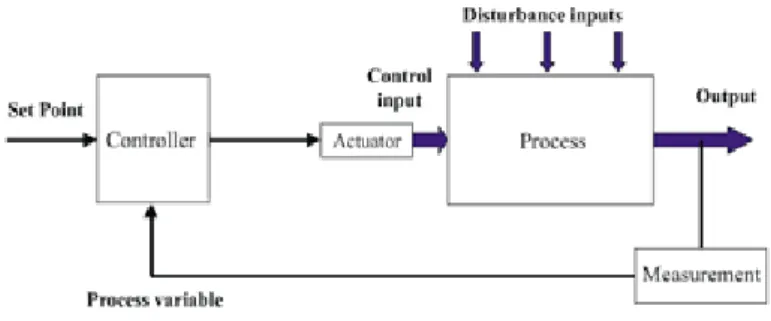

4 Chapter 1. Introduction

terministic; latency must be in the order of seconds or milliseconds to correctly close control loops e.g. between twin drives, and transmission jitter should be one order of magnitude lower than transmission delay. As a consequence of transmission failures or deadline misses, the quality of control may be se-riously degraded. More serious consequences could be significant economic losses and human safety accidents. However, more challenges lie ahead. Since wireless signals are prone to getting interfered by attenuation, shadowing or multipath effects, the reliability and latency performance are more likely to be deteriorated than over a wired channel. Moreover, IWSANs are foreseen to be deployed in harsh industrial environments, which are dusty, humid, full of metallic equipment with high temperature and vibrations. All these factors may seriously affect the wireless signals. Therefore, running mission-critical industrial applications in such environments can be quite challenging.

Until now several standards have been published for WSNs. Among them, WirelessHART, ISA 100.11a and WIA-PA are specifically designed for indus-trial process measurement and control applications. All of them exhibit their properties to ensure reliable and real-time communication. The successful de-ployments of IWSANs for Wireless monitoring for certain industrial applica-tions have shown some confidence in these standards. However, actuators, as the other essential component of IWSANs, are still not fully supported, which have hampered the deployment rate of IWSANs in reality [3]. Thus, there is still a long way to go to provide reliable and deadline-constrained transmission for industrial mission-critical applications.

Improvements of reliability and transmission latency can be achieved from different aspects. On existing devices, limited efforts can be taken on the phys-ical layer due to restrictions imposed by hardware and/or software limitations. Some approaches might be to increase the transmission power or adjust an-tenna parameters. On the MAC layer, a number of techniques can be applied to improve reliability, such as automatic repeat-request (ARQ), forward error cor-rection codes (FEC), channel hopping and black listing. In harsh industrial en-vironments, transmission failures occur quite often. The improvement of relia-bility by applying ARQ is at the cost of additional transmission latency. Chan-nel hopping and black listing are also effective methods, but still insufficient to provide reliable communication. Using FEC, communication can avoid trans-mission failures without introducing significant additional delay, but it is not currently included in any existing IWSAN standard. Furthermore, to provide deterministic and collision-free communication, Time division multiple access (TDMA) is specified on the MAC layer in all IWSAN standards. Thus the timeslot allocation should be distributed to each node in the network for packet

1.1 Research Problems 5 sending and receiving. However, none of these standards specify any particu-lar scheduling algorithm. Therefore, users should define their own scheduling scheme according to their requirements. On the network layer, the routing pro-tocol plays an extremely important role in achieving high reliability and low latency [4], but the current standards also fail to provide sufficient guidance on how to guarantee reliable transmission within the constrained deadlines by us-ing appropriate routus-ing protocols. Although a number of research efforts have been taken to design reliable real-time routing protocols for IWSANs, there is still no sufficient evidence to show that the problem has been fully solved in reality. Therefore, this research work attempts to bridge all the gaps mentioned above and explores effective and systematic approaches to achieve reliable and deadline-constrained communication on both MAC and network layers for in-dustrial mission-critical applications.

1.1 Research Problems

IWSANs are usually designed to transmit sensor readings and actuating com-mands between sensors/actuators and industrial controllers. The characteristics of packet transmissions in IWSANs are the presence of requirements of high reliability, firm deadlines and the predominance of short packets. Moreover, a number of previous research works [5–14] have observed harsh wireless chan-nel conditions in real industrial environments. Packet delivery in IWSANs may be jeopardized by various types of interference. The loss of packets or deadline misses of process data or high packet delivery jitter may lead to degradation of control quality, instability of control loops and even industrial application fail-ures. Once industrial mission-critical applications are terminated by commu-nication errors, it may take the whole system up to several hours to achieve full production rates again, resulting in significant production losses [3]. Therefore, It is a challenge to provide reliable communication with deadline requirements considered in IWSANs for industrial mission-critical applications in industrial environments. As we mentioned, several IWSAN standards are published for industrial automation. A number of realizations and solutions based on these standards have been seen in the market. However, those existing solutions are mainly for wireless monitoring for non-mission-critical applications where high reliability and meeting deadlines is not strictly required. The absence of full support for actuators has hampered the deployment rate of IWSANs in reality [3]. Therefore, in order to fully support both wireless sensing and actuating for industrial mission-critical applications in industrial automation

4 Chapter 1. Introduction

terministic; latency must be in the order of seconds or milliseconds to correctly close control loops e.g. between twin drives, and transmission jitter should be one order of magnitude lower than transmission delay. As a consequence of transmission failures or deadline misses, the quality of control may be se-riously degraded. More serious consequences could be significant economic losses and human safety accidents. However, more challenges lie ahead. Since wireless signals are prone to getting interfered by attenuation, shadowing or multipath effects, the reliability and latency performance are more likely to be deteriorated than over a wired channel. Moreover, IWSANs are foreseen to be deployed in harsh industrial environments, which are dusty, humid, full of metallic equipment with high temperature and vibrations. All these factors may seriously affect the wireless signals. Therefore, running mission-critical industrial applications in such environments can be quite challenging.

Until now several standards have been published for WSNs. Among them, WirelessHART, ISA 100.11a and WIA-PA are specifically designed for indus-trial process measurement and control applications. All of them exhibit their properties to ensure reliable and real-time communication. The successful de-ployments of IWSANs for Wireless monitoring for certain industrial applica-tions have shown some confidence in these standards. However, actuators, as the other essential component of IWSANs, are still not fully supported, which have hampered the deployment rate of IWSANs in reality [3]. Thus, there is still a long way to go to provide reliable and deadline-constrained transmission for industrial mission-critical applications.

Improvements of reliability and transmission latency can be achieved from different aspects. On existing devices, limited efforts can be taken on the phys-ical layer due to restrictions imposed by hardware and/or software limitations. Some approaches might be to increase the transmission power or adjust an-tenna parameters. On the MAC layer, a number of techniques can be applied to improve reliability, such as automatic repeat-request (ARQ), forward error cor-rection codes (FEC), channel hopping and black listing. In harsh industrial en-vironments, transmission failures occur quite often. The improvement of relia-bility by applying ARQ is at the cost of additional transmission latency. Chan-nel hopping and black listing are also effective methods, but still insufficient to provide reliable communication. Using FEC, communication can avoid trans-mission failures without introducing significant additional delay, but it is not currently included in any existing IWSAN standard. Furthermore, to provide deterministic and collision-free communication, Time division multiple access (TDMA) is specified on the MAC layer in all IWSAN standards. Thus the timeslot allocation should be distributed to each node in the network for packet

1.1 Research Problems 5 sending and receiving. However, none of these standards specify any particu-lar scheduling algorithm. Therefore, users should define their own scheduling scheme according to their requirements. On the network layer, the routing pro-tocol plays an extremely important role in achieving high reliability and low latency [4], but the current standards also fail to provide sufficient guidance on how to guarantee reliable transmission within the constrained deadlines by us-ing appropriate routus-ing protocols. Although a number of research efforts have been taken to design reliable real-time routing protocols for IWSANs, there is still no sufficient evidence to show that the problem has been fully solved in reality. Therefore, this research work attempts to bridge all the gaps mentioned above and explores effective and systematic approaches to achieve reliable and deadline-constrained communication on both MAC and network layers for in-dustrial mission-critical applications.

1.1 Research Problems

IWSANs are usually designed to transmit sensor readings and actuating com-mands between sensors/actuators and industrial controllers. The characteristics of packet transmissions in IWSANs are the presence of requirements of high reliability, firm deadlines and the predominance of short packets. Moreover, a number of previous research works [5–14] have observed harsh wireless chan-nel conditions in real industrial environments. Packet delivery in IWSANs may be jeopardized by various types of interference. The loss of packets or deadline misses of process data or high packet delivery jitter may lead to degradation of control quality, instability of control loops and even industrial application fail-ures. Once industrial mission-critical applications are terminated by commu-nication errors, it may take the whole system up to several hours to achieve full production rates again, resulting in significant production losses [3]. Therefore, It is a challenge to provide reliable communication with deadline requirements considered in IWSANs for industrial mission-critical applications in industrial environments. As we mentioned, several IWSAN standards are published for industrial automation. A number of realizations and solutions based on these standards have been seen in the market. However, those existing solutions are mainly for wireless monitoring for non-mission-critical applications where high reliability and meeting deadlines is not strictly required. The absence of full support for actuators has hampered the deployment rate of IWSANs in reality [3]. Therefore, in order to fully support both wireless sensing and actuating for industrial mission-critical applications in industrial automation

6 Chapter 1. Introduction

systems, providing reliable and deadline-constrained communication for both uplink and downlink in IWSANs is a top priority. According to the existing IWSAN standards and the previous research works, several research problems must be solved from different aspects to achieve the goal. These problems include:

1. ARQ mechanisms are applied on the MAC layer in current IWSAN stan-dards to improve reliability, but at the cost of transmission latency due to retransmissions. When deploying IWSANs in harsh industrial envi-ronments, retransmissions may be triggered frequently because of trans-mission failures. Excessive retries will prolong communication delay and lead to the expiration of packet delivery. Then successive dead-line misses may terminate the mission-critical applications and result in economic losses or human safety accidents. Furthermore, excessive re-transmissions may cause network traffic overload, or even network con-gestion. A serious congestion of the network may halt the applications. Therefore, an alternative solution to improve reliability without increas-ing latency on the MAC layer is required.

2. TDMA schemes are usually applied on the MAC layer in current IWSAN standards to provide collision-free and deterministic transmissions. Time slots should be scheduled and assigned to all devices in the network to determine their packet sending and receiving times. However, the exist-ing standards do not specify the use of any particular schedulexist-ing algo-rithm. The ways of allocating timeslots have direct impact on the net-work communication behavior. Inappropriate TDMA scheduling schemes may affect the quality of control. Therefore, how to properly assign timeslots for each node to improve the overall control quality is vi-tally important. Currently, the majority of existing TDMA schedul-ing schemes for wireless networks mainly focus on schedulability, real-time, or latency. Although schedulability and latency is important for a scheduling algorithm, how these properties relate to the overall con-trol quality is still not fully investigated. Jitter, as an important factor to influence the control quality, should also be taken into consideration. A few works can be found regarding jitter reduction [15–19], but for different purposes, such as for video-based networks or distribution net-works. However, there is still a lack of research on TDMA scheduling to reduce jitter and improve the control quality in centralized multihop mul-tichannel IWSANs, suitable for both single-path and multipath routing protocols.

1.2 Research Questions 7 3. On the network layer, traditional routing protocols for normal wireless systems are not initially designed for process and control purposes. Such protocols fail to meet the stringent requirements on high reliability and strict deadlines posed by mission-critical applications. Thus current IW-SAN standards, such as WirelessHART, specify that each node should have alternative paths from the source to the destination. Once the packet transmission via the main path fails, the alternative paths will be used. Although packets have more chances to reach the destination by using the approach suggested in the standards, problems still remain. Firstly, the transmission deadline is still not considered in the design of rout-ing protocols. Once a node notices that the main path is blocked by several attempts and switch to the alternative path to deliver packets, ad-ditional transmission latency has been introduced, and the firm deadline may be missed. Secondly, to maintain several paths for each node from the source to the destination results in additional network management overhead. Excessive control message overhead not only makes transmis-sions inefficient, but may also make network resources more constrained. Besides the approach specified by the standards, other existing routing protocols for IWSANs may have the following problems: i) designed to minimize or balance the power consumption; ii) not consider both reli-ability and firm deadlines; iii) under some special assumptions, such as localization ability or channel status awareness ability; iv) not designed for centralized management; v) overcomplicated to be implemented in reality; vi) not further verified in real industrial environments. There-fore, a lightweight, reliable routing protocol with deadlines considered for IWSANs is highly demanded. This routing protocol should be not only verified by simulation, but also by realization and measurement in real industrial environments.

1.2 Research Questions

The research problem addressed in this thesis can be refined and formulated into the following research questions:

1. On the MAC layer, how to decrease the number of retransmissions if ARQ is applied and how to increase reliability without prolonging trans-mission latency?

qual-6 Chapter 1. Introduction

systems, providing reliable and deadline-constrained communication for both uplink and downlink in IWSANs is a top priority. According to the existing IWSAN standards and the previous research works, several research problems must be solved from different aspects to achieve the goal. These problems include:

1. ARQ mechanisms are applied on the MAC layer in current IWSAN stan-dards to improve reliability, but at the cost of transmission latency due to retransmissions. When deploying IWSANs in harsh industrial envi-ronments, retransmissions may be triggered frequently because of trans-mission failures. Excessive retries will prolong communication delay and lead to the expiration of packet delivery. Then successive dead-line misses may terminate the mission-critical applications and result in economic losses or human safety accidents. Furthermore, excessive re-transmissions may cause network traffic overload, or even network con-gestion. A serious congestion of the network may halt the applications. Therefore, an alternative solution to improve reliability without increas-ing latency on the MAC layer is required.

2. TDMA schemes are usually applied on the MAC layer in current IWSAN standards to provide collision-free and deterministic transmissions. Time slots should be scheduled and assigned to all devices in the network to determine their packet sending and receiving times. However, the exist-ing standards do not specify the use of any particular schedulexist-ing algo-rithm. The ways of allocating timeslots have direct impact on the net-work communication behavior. Inappropriate TDMA scheduling schemes may affect the quality of control. Therefore, how to properly assign timeslots for each node to improve the overall control quality is vi-tally important. Currently, the majority of existing TDMA schedul-ing schemes for wireless networks mainly focus on schedulability, real-time, or latency. Although schedulability and latency is important for a scheduling algorithm, how these properties relate to the overall con-trol quality is still not fully investigated. Jitter, as an important factor to influence the control quality, should also be taken into consideration. A few works can be found regarding jitter reduction [15–19], but for different purposes, such as for video-based networks or distribution net-works. However, there is still a lack of research on TDMA scheduling to reduce jitter and improve the control quality in centralized multihop mul-tichannel IWSANs, suitable for both single-path and multipath routing protocols.

1.2 Research Questions 7 3. On the network layer, traditional routing protocols for normal wireless systems are not initially designed for process and control purposes. Such protocols fail to meet the stringent requirements on high reliability and strict deadlines posed by mission-critical applications. Thus current IW-SAN standards, such as WirelessHART, specify that each node should have alternative paths from the source to the destination. Once the packet transmission via the main path fails, the alternative paths will be used. Although packets have more chances to reach the destination by using the approach suggested in the standards, problems still remain. Firstly, the transmission deadline is still not considered in the design of rout-ing protocols. Once a node notices that the main path is blocked by several attempts and switch to the alternative path to deliver packets, ad-ditional transmission latency has been introduced, and the firm deadline may be missed. Secondly, to maintain several paths for each node from the source to the destination results in additional network management overhead. Excessive control message overhead not only makes transmis-sions inefficient, but may also make network resources more constrained. Besides the approach specified by the standards, other existing routing protocols for IWSANs may have the following problems: i) designed to minimize or balance the power consumption; ii) not consider both reli-ability and firm deadlines; iii) under some special assumptions, such as localization ability or channel status awareness ability; iv) not designed for centralized management; v) overcomplicated to be implemented in reality; vi) not further verified in real industrial environments. There-fore, a lightweight, reliable routing protocol with deadlines considered for IWSANs is highly demanded. This routing protocol should be not only verified by simulation, but also by realization and measurement in real industrial environments.

1.2 Research Questions

The research problem addressed in this thesis can be refined and formulated into the following research questions:

1. On the MAC layer, how to decrease the number of retransmissions if ARQ is applied and how to increase reliability without prolonging trans-mission latency?

qual-8 Chapter 1. Introduction

ity of control in a centralized multihop and multichannel IWSAN for industrial automation systems?

3. On the network layer, how to design a routing protocol that is lightweight and can provide reliable and deadline-constrained communication, and be tolerant of sudden topology changes in IWSANs for industrial au-tomation systems?

1.3 Research Hypotheses

In order to address these research questions, based on the current knowledge and state-of-the-art research, the following research hypotheses are proposed and considered as the main drivers for the work presented in this thesis:

1. When a packet is partly corrupted due to interference, by applying for-ward error correction coding schemes, erroneous bits can be recovered, so retransmissions can be avoided and the transmission reliability can be improved.

2. TDMA scheduling schemes aiming for low jitter, rather than latency, in a centralized multihop and multichannel IWSAN, can improve the quality of control in industrial automation systems.

3. Due to the simplicity and multipath diversity, flooding-based routing protocols can be a suitable solution to provide reliable and deadline-constrained transmissions in IWSANs.

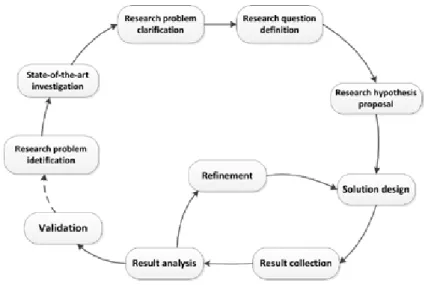

1.4 Research Method

Research is a scientific and systematic process to search for pertinent informa-tion in a specific area. The purpose of research is to investigate existing theo-retical or practical problems, review current knowledge, provide corresponding solutions, or even generate new knowledge and so on. Depending on different research topics, appropriate research methods should be selected to address the main research goal. This thesis is carried out by following a deductive method. The research process used in this thesis is illustrated in Figure 1.1. It consists of eight steps described as follows.

The process starts with the identification of practical problems and ends up with providing validated solutions to the problems. Firstly, we considered

1.4 Research Method 9

Figure 1.1: Research process steps

the general research problem, which is the need to apply IWSANs instead of wired solutions in harsh industrial environments for mission-critical applica-tions in industrial automation systems. Then in order to deeper understand the existing problems, we reviewed the latest literature and investigated state-of-the-art research works. Based on the findings, we discovered that the problems exist on different layers in the current IWSAN standards, which is described in section 1.1. We noticed that according to the current situation, some prob-lems can presently hardly be solved. For instance, to apply coding schemes on the physical layer is a very effective method to improve reliability. However, due to restrictions imposed by hardware and/or software limitations, limited efforts can be taken on the physical layer. Therefore, we defined several re-search questions to address problems from different aspects. Before coming up with research solutions, we proposed the corresponding research hypothe-ses to the questions. In the next phase, we developed solutions to confirm our research hypotheses. Then we conducted simulations to verify the correctness of our proposed solutions. Based on analysis and discussions, we identified if the research hypotheses had been confirmed or there were still some space for improvement. This process may continue through several iterations un-til the search hypotheses being confirmed. For instance, we first proposed a reliable RSS-based routing protocol using signal strength indicators to weight