VTI särtryck

Nr 254 ' 1996

Fatigue and Stiffness Properties of

Roadbase Layer Using Indirect Tensile Tes

Safwat F. Said

Paper prepared for presentation at the Eurasphalt &

Eurobitume Congress, Strasbourg, 1996

Swedish Road and

VTI särtryck

Nr 254 0 1996

Fatigue and Stiffness Properties of

Roadbase Layer Using Indirect Tensile Test

Safwat F. Said

Paper prepared for presentation at the Eurasphalt &

Eurobitume Congress, Strasbourg, 1996

(Lib

Väg- och

transport-farskningsinstitutet

'

Fatigue and Stiffness Properties of Roadbase Layer Using Indirect

Tensile Test.

Said, Safwat F.

Swedish National Road and Transport Research Institute

ABSTRACT

Quality control and evaluation of bituminous pavement layers often have to be performed by highway engineers. In many cases, determination of the mix composition is insufficient for an evaluation of the mix properties. However, mechanical properties such as fatigue strength and stiffness modulus can provide much applicable information. The mechanical properties of bituminous mixes can be determined by various methods, but these require special equipment and speci-mens of a particular configuration. Asphalt specispeci-mens are relatively easy to fabri-cate in the laboratory, but they are very difficult or even impossible to obtain from existing bituminous layers.

In this work, the stiffness modulus and fatigue properties of bituminous pavement

layers have been determined in the laboratory. Indirect tensile test (lTT) has been

conducted primarily due to its advantages in practice. It has the benefit of using cylindrical specimens which can be cored from pavement layers. It is concluded that the ITT, which is relatively simple and rapid to conduct, is also sufficiently accurate for routine measurements.

Caractéristiques de fatigue et de rigidité des couches de base pour route par essai de traction radial

Safwat F. Said

Institut National de Recherche sur les Infrastructures Routieres et les Transports, Linköping, Suede

RESUME

Le contröle de qualité et l'évaluation des couches de chaussée bitumeuse doivent souvent étre effectués par des ingénieurs-constructeurs de routes.,Dans bien des

cas, le choix de la composition des enrobés donne une évaluation insuffisante des

caractéristiques de fatigue. Néanmoins, certaines caractéristiques mécaniques telles que re sistance åla fatigue et coefficient de rigidité peuvent foumir une information tres utile. Les caractéristiques mécaniques des enrobés bitumeux peuvent étre déterminées par différentes méthodes, mais celles-ci exigent un e quipement spe cial et des Specimens d'une con guration particulere. Les spécimens asphaltiques sont'relativement faciles a re aliser en laboratoire, mais tres difficiles sinon impossibles a obtenir a partir de couches bitumeuses déja existantes.

Dans cet ouvrage, le module de rigidité et les caracte ristiques de fatigue de différentes couches de chaussée bitumeuse ont été déterminées en laboratoire. Le test de traction radiale (ITT, indirect tensile test) a été appliqué surtout pour ses avantages pratiques. Il perrnet d'utiliser des specimens cylindriques qui peuvent étre prélevés sur des couches de chaussse. Ii ressort de cette expérience que le test ITT, relativement simple et rapide å réaliser, est aussi suffisamment précis pour effectuer des mesures de routine.

Ermiidungs- und Steifigkeitseigenschaften bei Strassenbelägen in bezug auf

die Anwendung von Indirect Tensile Test Safwat F. Said

Staatliches Schwedisches Strassen und Verkehrsforschungsinstitut ZUSAMMENFASSUNG

Die Qualitätskontrolle und die Bewertung von bituminösen Strassenbelägen

werden oft von Strassenbauingenieuren durchgefiihrt. In vielen Fallen ist die Bestimmung der Zusammensetzung der Mischung fiir die Beurteilung der Mischungseigenschaften unzureichend. Mechanische Eigenschaften wie die Ermijdungsfestigkeit und das Steifigkeitsmodul können jedoch eine Menge anwendbare Information liefern. Die mechanischen Eigenschaften von biturninösen Mischungen sind mit Hilfe verschiedener Methoden bestimmbar, diese erfordern jedoch Spezialausriistung und Proben von der Obertlächenstruktur der Asphaltbeläge. Asphaltproben sind relativ einfach im Laboratorium herzustellen. Es ist jedoch sehr schwierig oder sogar unmöglich, diese von bereits

existierenden bituminösen Belägen zu nehmen.

In dieser Arbeit wurden das Steifrgkeitsmodul und die Ermiidungseigenschaften von bituminösen Strassenbelägen im Laboratorium untersucht. Der Indirect Tensile Test (ITT) wurde in erster Linie aufgrund seiner Vorteile in der Praxis durchgefiihrt.

Der Vorteil besteht darin, dass zylindrische Proben benutzt werden, die direkt

vom Strassenbelag stammen.

Man kann zu dem Ergebnis, dass der ITT, der relativ einfach und schnell

durchzufiihren ist, auch genijgend genaue Ergebnisse bei Routine Messungen

Fatigue and Stiffness Properties of Roadbase Layer Using

Indirect Tensile Test

1

Introduction

In many cases the control of the mix composition (void content, aggregate

grading, binder content and type) is not enough for an evaluation of the mixes.

However, mechanical properties normally used in evaluation models can give much applicable information. The mechanical properties of bituminous materials such as stiffness modulus and fatigue strength are required for analytical pavement design, mechanistic mix design and evaluation of existing pavement layers. Bitu minous mixes are inhomogeneous and anisotropic material and their behaviour is mostly dependent on temperature and loading history but also on the compaction procedure of the mixes. Stiffness and fatigue properties of mixes may be deter

mined by various methods such as bending, uniaxial, triaxial and indirect tensile

tests. A variety of shape and size of specimens may be used such as prismatic, trapezoidal and cylindrical specimens. Asphalt specimens are relatively easy to fabricate in the laboratory but they are very difficult or even impossible to obtain from existing bituminous layers. The shortcoming of laboratory fabricated specimens is that they are not entirely representative of the bituminous road layer. Therefore, highway engineers are mostly interested in checking out the bituminous mixes using cores from road layers.

The purpose of this work is to determine the stiffness and fatigue properties of the bituminous base course layer in the laboratory and to find out the applicability

of indirect tensile test (ITT) in routine measurements.

2

Materials

About 20 cores per section with 100 mm in diameter have been taken from 13

sec-tions chosen from new constructed roads for laboratory studies [1]. Tests included

are determination of air void content, aggregate grading, binder content and type, layer thicknesses, resilient (stiffness) modulus and fatigue strength. The thickness of tested specimens sawed from field cores were varied from 30 mm up to 67 mm.

The recipe of the mix from base course layers should meet the specifications and guidelines for road construction [2]. The bitumen type is B180 (pen at 25°C, 145-210 mm/ 10) and the bitumen content is 4.5 i 0.5 percent by weight. The aggregate size limits of the grading curve type AG25 with the grading curves of test sections are presented in Figure l. The maximum aggregate size is 25 mm. The individual values of air void content should be between 4 and 11 per cent (this variation has been decreased to 3 9 according to the latest specifications

Pe

rc

en

ta

ge

Pa

ss

in

g

100

a I.

90

Zi

80 Size limits of ?. 70 mix AG 25 /Å//' 60 \ M 50 \ V/ 40 / //f§,///

10 -

////_/

//"

o

,

' |

.

,

|

l I

I l ]

6 Size (mm) FFigure ] Grading curves from test sections with size limits of the base course mix AG25.

Within and between variations in the mix composition from roadbase layers are illustrated in Figure 2 by frequency distribution diagrams. These variations are high and outside the specification limits. Mix variables have been shown to

significantly in uence the properties of bituminous mixes [3]. The effects of mix

variables have been a subject of many of the research work presented in the state of the art reports, references 4 and 5. Therefore, the influence of the variables (Figure 2) must be significant on the stiffness and fatigue properties of the base course mix and the measurements should be analyzed carefully with respect to the

variations.

30 V' __ * 20 l _ >. 8 10 -cu (3:- Std. Dev = 10.79 9 Mean=65.0 LL o _ _, _ _ _ _ _ _ _ _ _ N=295.00

0 7 7 & 6 6 6 ) ) <9 & &

go 9 0 år 9-0 If 9-6 at? °~o~ )-\5 9-0 r 9-0 VFB (Void filled with bitumen)

60 50 l 40 - ; \ 30 - \ 5 c: 20 I \._... 2 CJ' 10 . \ Std. Dev=2.47 9 . Mean=6 U-0____________ .N=295.00 1 3 5 7 9 11 13 2 4 6 8 10 12 14 Void content % 40 30 I 20 I I, > _ o c: (D 10 I å- Std. Dev = 2.42 93 Mean=16 Ll-0__________ N=283.00 I, 7.9 76, 77 76 76 I) 76, 19 6 0 9, {99 QL? é?

VMA-% (Voids in mineral aggregate)

8 _

6'

z

4 I />

/

O C 0) 2 g- / Std.Dev=.44 & . . Mean=4.5 u- o _ _ _ _ _ _ _ _ _ N=36.00 3.6 3.8 4.1 4.3 4.5 4.7 4.9 5.2 5.4Binder content weight-%

10 8 . 6 . /-\ >, 4 I // 0 C (D 8- 2 ' Std. Dev=21s.32 (D \Mean=716 LT. 0 N=19.00 Figure 2 Freq VTI\S.F.Said 200' 400" 600" 800' 1000' 1200"

Viscosity at 135 C, recovered bit.

3

Test methods

The indirect tensile test, ITT, has been used in this study for evaluating the resi-lient modulus and fatigue properties of basecourse layers. The validity of the ITT

and description of test methods are discussed elsewhere [6 and 7]. The loading

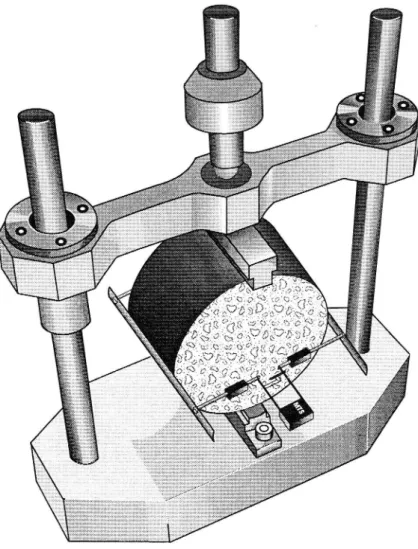

de-vice for ITT is shown in Figure 3.

Figure 3 Specimen with extensometers in the loading device for indirect tensile

test, ITT.

The VTIs Material Testing System (VMS) is a servohydraulic system with closed loop control. ATS software is used for the control of the testing machine and acquisition of data.

4

Resilient modulus (MR)

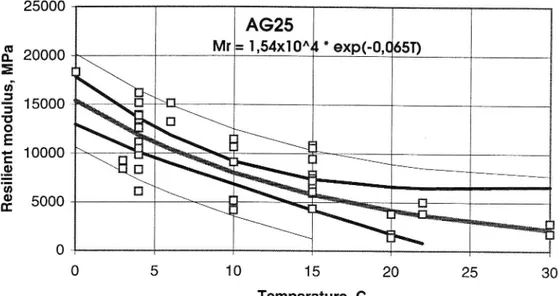

Resilient (stiffness) modulus were performed on cored specimen at different temperatures. Figure 4 presents the average of the resilient modulus of each test section at various temperatures. This variation in MR values is relatively very high with respect to pavement performance. It is believed to depend on the wide limits in the mix specification and the variation between road sections. The variations in the asphalt concrete characters have an influence on the variation in pavement life. Consequently, it should be taken into consideration when analyzing pavement per formance [8]. Figure 5 presents the regression relationship between resilient mo

dulus and temperature for the base course mix, AG25. The 90 % confidence and

prognosis bands are also illustrated. Knowledge of the variations in the stiffness of pavement layers is usable information for quality assurance and evaluation of pavement performance.

20000

18000 -- AG25, roadbase cores

16000 & CU % 14000 * w" 3 12000 4 3 "U 0 10000 4 E 4.1 c 8000 «-£2 * = -- . . 3 6000 - n... (I 4000 - ' 2000 9 0 , . _ o 5 10 15 20 25 Temperature, C + L252 + LS Ar RV23 w- Eeim RV62 + RV41 Ö + RV41 U

- l- RVBO -- AV --- RV67 O - L117 _D E66 A Norsholm

)( Gävle + RVBZÖ ® Rv32u l Rv34ö - - Rv34u

Figure4 Relationship between resilient modulus and temperature from test

sections.

VTI\S.F.Said

25000

AG25

20000 \D\ Mr: 1,54x10A4 * exp(-0,0651)15000 z

10000 Re si li en t mo dulu s, M P a 5000 Temperature, CFigure 5 Regression relationship between resilient modulus and temperature with 90 % eonfidence and prognosis bandfor base course mix AG25.

5

Fatigue strength

Fatigue strength tests were done on cored specimen from base course layers. Constant stress mode has been conducted using ITT illustrated in Figure 3. The fatigue test procedure is described in details in reference 9. A cylindrical specimen is subjected to a periodically repeated load with 0.1 sec loading time and 1.4 sec unloading time. The fatigue life is defined as the total number of load applications that cause a fracture of the specimen. Cores from ten sections were tested at two temperatures Viz +4°C and +15°C. Cores from three other sections have been tested at +10°C.

The strain at the centre of the specimen (so) is calculated by the following formula:

80 = 2.13111?

D

where AH : total horizontal deformation

D = specimen diameter

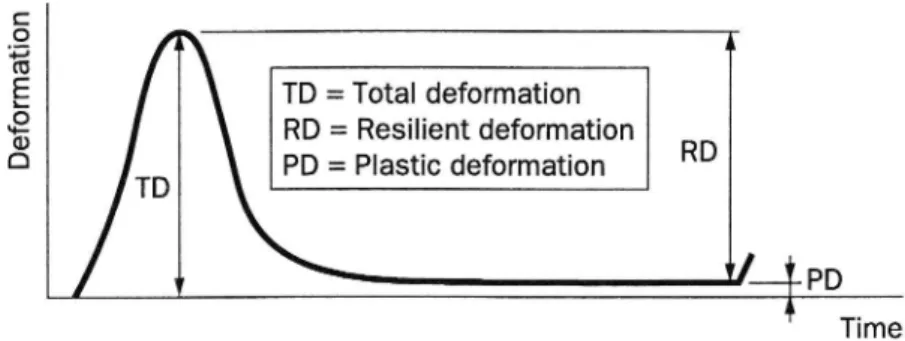

The total horizontal deformation (AH) is the maximum deformation under the

loading period which is in fact composed of the resilient and plastic deformations and illustrated in Figure 6.

TD = Total deformation RD = Resilient deformation PD = Plastic deformation De fo rm at io n RD TD V/___Y_ PD Time

Figure 6 Definition of total horizontal deformation.

Djärf [10] reported that the tensile strain at the bottom of base course layers from the test sections varies between 100 to 350 ue calculated from deflection measurements. Therefore, the initial strain during the fatigue tests was planned to be in the range of 100 to 400 ue. The influence of temperature on the fatigue characteristic of the base course mix, AG25 is discussed in reference 1.

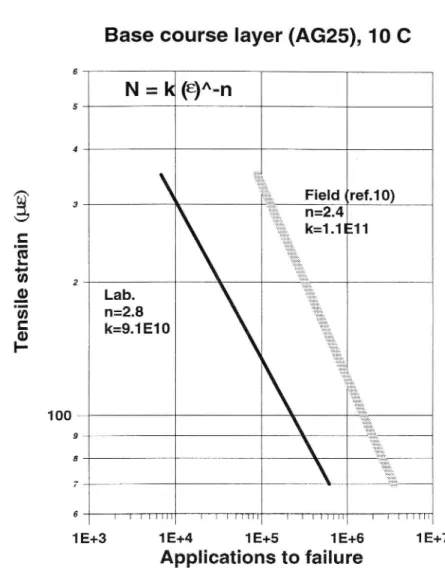

The calculated fatigue criterion at +10°C based on the laboratory measurements at +4°C and +15°C is compared with the field fatigue criterion in Figure 7. The field fatigue criterion, developed by Djärf [10], is based on field measurements on the same test sections where the cores are taken. The strains are calculated from

de ection bowls measured by FWD in the autumn, which are representative of a

temperature of +lO°C in the base course layer. The slope of the field and labora-tory based relations are 2.4 resp. 2.8 with a shift factor about 9 depending on the level of strain. The fatigue life produced in the laboratory is in agreement with the fatigue life predicted by the field based criterion.

Figure 7 Laboratory and field based criteria between no. of applications to failure and initial strain (Number of equivlent 100 kN single axle

loads for the field relation).

6

Te ns il e st ra in (pi -:)Base course layer (AGZS), 10 C

N = k (8)"-n

5 4 3 \ Field (ref.10) n=2.4 k=1.1| 2 Lab. n=2.8 k=9.1 E10 100 9 86 l llTTlli liliTTll I Illllll l lilllll

1E+3 1E+4 1E+5 1E+6

mix evaluation.

A good agreement is found between laboratory and field fatigue criteria.

The indirect tensile test which is relatively simple, rapid to conduct and make use of cylindrical specimen, is also sufficiently accurate for routine

measure-ments.

VTI\S.F.Said

Applications to failure

Conclusions

There are a lot of variations in the composition of the base course mix, AG25,

which give rise to variations in the mix properties such as stiffness modulus and fatigue strength. These variations should be taken into consideration for

[1]

[2]

[3]

[4]

[5]

[6]

[7]

[8]

[9]

[10]

VTI\S.F.SaidReferences

Djärf, L. and Said, SF; Laboratory Fatigue Properties Compared with Field Performance , 5th Eurobitume Congress vol 1B, Stockholm 1993.

; Speci cations and Guidelines for Road Construction,

1984 . Swedish National Road Administration (in Swedish).

Brown, S.F; Mix Design of Base Courses , Course on Bituminous Pavement: Material, Design and Evaluation. Univ. of Oulu, Oulu, Finland 1995.

Judycki, ] ; Fatigue of Asphalt Mixes , Univ. of Oulu, Oulu, Finland 1991.

Said, S.F; Fatigue characteristics of Asphalt Concrete Mixtures ,

VTI Meddelande no. 583 A, Linköping 1988.

; FAS method 454: Determination of Resilient Modulus

of Asphalt Concrete by Indirect Tension Test (in Swedish).

Said, S.F; Test and Design Parameters of Elastic Stiffness and Permanent Deformation . Course on Bituminous Pavement: Material, Design and Evaluation. Univ. of Oulu, Oulu, Finland 1995. Molenaar, A.A.A; Variability in Pavement Structures and Its

Signi cant to Performance of Pavements . Course on Bituminous

Pavement: Material, Design and Evaluation, Univ. of Oulu, Oulu, Finland 1995.

Said, S.F; Determination of Fatigue Strength of Asphalt Concrete by Indirect Tensile Test . VTI Notat no. 38-1995, Linköping (in

Swedish).

Djärf, L; Asphalt strain criterion based on eld studies . VTI