1978 -: ___ ] - Statens väg- och trafikinstitut (VTI) : Fack - 58101 Linköping ISSN 0347-6049 , National Road & Traffic Research Institute - Fack : S-58101 Linköping : Sweden

il Suggestions to the International Standardization -- äv of Test Methods for Aggregate Strength _

Nr 102 ' 1978 Statens väg- och trafikinstitut (VTI) - :Fack - 581 01 Linköping

ISSN 0347-6049 National Road & Traffic Research Institute * Fack - S-58101 Linköping ' Sweden

Suggestions t0 the International Standardization

of Test Methcds for Aggregate Strength

PREFACE

The RILEM committee GM 26 is working at recommendations

for test methods for aggregates and fillers. The-committee is arranging the International Symposium on Aggregates and Fillers in Budapest on October 9th till

12th, 1978. At the meeting of the committee in London

on May 12th, 1977 the National Swedish Road.and Traffic Research Institute was commissioned to obtain a basis for an international standardization of test.methods for aggregate strength. This work has been financed by

the institute.

Suggestions to the International Standardization of Test Methods for Aggregate Strength

by Peet Höbeda Å .

Statens Väg- och trafikinstitut

Fack

581 01' LINKÖPING

SUMMARY

. It is suggested that the Los Angeles method according

to ASTM C 131 is recommended by the RILEM-committee as

the main test method. As a single standard fraction

grading B appears to be the most suitable one. Tests 'on other fraCtions should be avoided. If the committee

consider it necessary, some supplementary tests (crushing and impact type) may be included in the

recommendation.

In order to make it possible to test "local materials" the French "Micro Deval" method should be adOpted for dry and wet samples. The wet abrasion is the most_

important procedure.

There is, for the time being, no accepted method for

the testing of aggregate_homogeneity. The brass rod scratch test (ASTM C 235) appears to be a suitable method for determining the content of very soft pieces

TABLE Table Table Table Table Figur Figur Appen OF CONTENTS :Page SUMMARY

Methods used for testing aggregate strength l

Pre-treatment of samples . 4

'Aggregate size 5

-Particle shape 6

Measurement of degradation 8

Test methods for a RILEM recommendation 9

Methods for testing "local materials" 12

Methods for determining the content of "soft" '13

particles

I

'

1. Data for Los Angeles test

Data for aggregate crushing tests 2.

3. Data for impact tests

4. Micro-Deval

es 1-7. Results from tests performed by the RILEM committee GM 26

es 8-22. Results from previous investigations

dix. The repeatability and reproducibility of methods for the determination of aggregate

strength

1,

METHODS USED FOR TESTING AGGREGATE STRENGTH

A number Of different methods are internationally used for classifying aggregates according to their mechanical properties. There is, unfortunately, a great confusion in this field and though several countries sometimes

use the same test mehtod, the test is often carried out

in different ways. This is partly due to the fact that the sizes of the test sieves differ in national

specifica-tions. The recommendations of the RILEM-committee GM 26

should be baSed on only one method of aggregate strength.

Based on more than one method, methods used in as many

countries as possible should be chosen. The aggregate size should be selected according to ISO 565. The methods should have a good repeatability and reproducibility.

The various test methods can be classified as "static" crushing and impact tests or as "abrasion" tests. "Pure" wear tests performed on a grinding wheel, e 9 the

British Abrasion Test, are not discussed. The well-known

Los Angeles Test is, although it is called "abrasion test" .in the USA ("attrition test" in Great Britain), primarily

an impact test as the main stress is produced by falling steel shots. The most efficient impact action is obtained

if a Small aggregate size is tested.

A great deal of work has been put in on Studies of test

methods in laboratories, but few investigations have been

made to study the relation between test results and the applicability of aggregates to practice. Decades ago the methods for macadam with an uniform gradation were develOped.

Nowadays, however, well-graded mixtures low in voids

con-tent are mainly used in road work. Some hesitation in in-troducing fixed limits for aggregate strength in road building specifications can be noticed in some countries, as in practice some suitable aggregates can be eliminated. In concrete work the relation to suitability seems to be

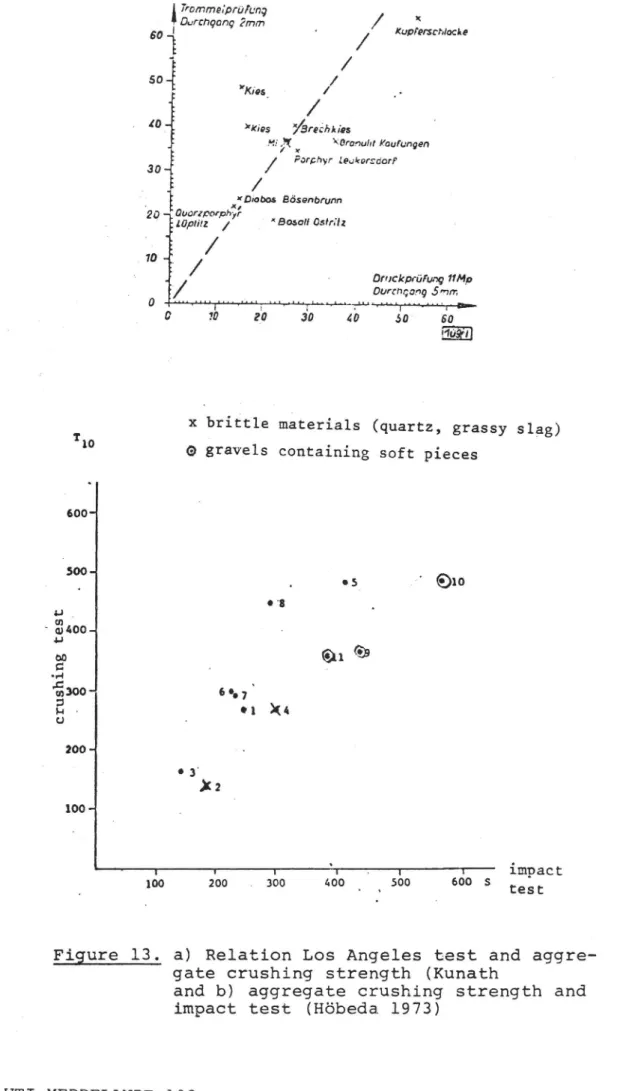

In some investigations of different test methods of

strength it has been found that the relation between

the methods is often quite good. It is not possible

exact-ly to transfer the result from one method to another,

but in spite of this the same material properties are tested. Rather good correlations can be observed in the investigation that was made by the committee 26 of ,RILEM (see figure l-7). As a comparison the results

of several previous studes are summariáed in figuresr8-l4.

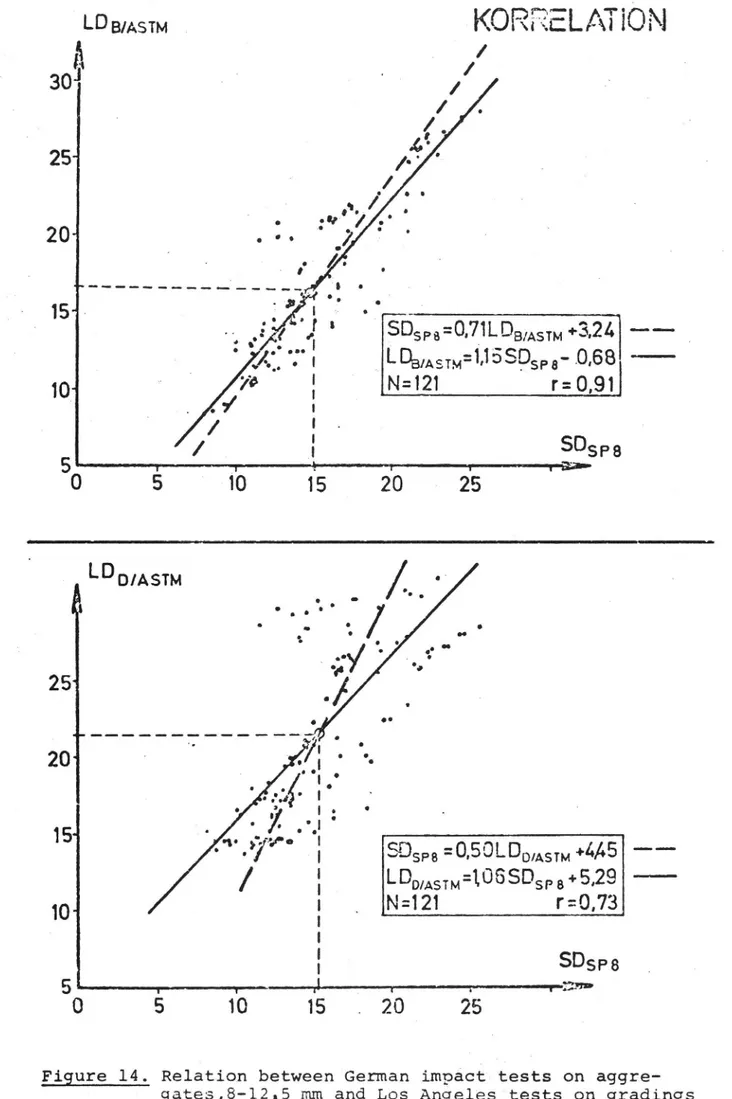

The condition.of a good correlation is, however, that the test fractions do not differ too much (figure 14).

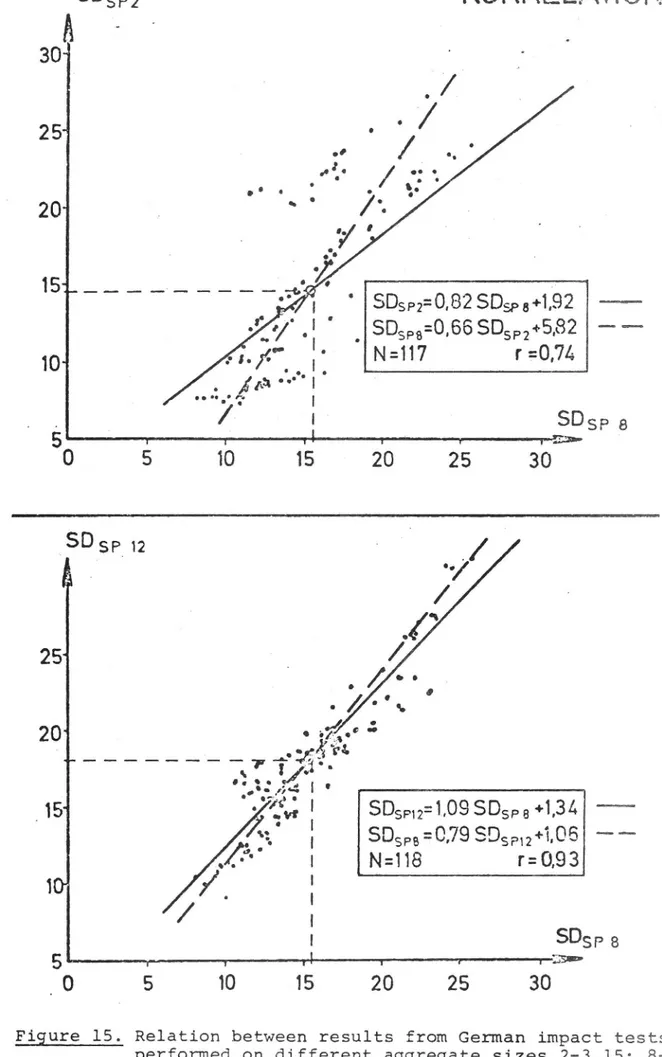

If that is the case, differences in particle shape and maybe also in petrography are to be considered, too. A poor relationship is obtained by the same test method

if the aggregate size differs (figure 15). The best

correlatiOn is also obtained if the aggregates do not differ too much in regard to physical properties. This

is, however, not true of the aggregates used in the RILEM

investigation.

Consequently, there is no reason for carrying out both static crushing tests and impact tests (the Los Angeles test included). The method that is the most widespread one, not too complicated and that perhaps produces the most reproducible results should be chosen. Other properties that are related to the strength, such as wear and polishing resistance, moisture susceptibility, frost durability and so on, should be investigated in-stead if necessary.

During the last few years a tendency to complete or

even sometimes to replace the "established" test methods previously discussed by new ones, which are considered to better reflect the applicability of the aggregates to practice under the preSent geological and climatological

Californian specifications, accordingly, the Los

Angeles method has been replaced by a wet degradation test, the so called "Durability Index", which also has been adopted by AASHTO (T 210). This test is considered

to bear a better relation to the aggregate quality in

road constructions. In France a wet abrasion mehtod, "Micro Deval", has been developed from the old Deval test as a complement to the.Los Angeles method. It is important that also some of the "new" methods are adopted by the committee to make tests on aggregates. of a low quality ("local materials" and weak materials in the developing countries, see 6.1 and 6.2) more

re-levant, too.

According to experience in Sweden the "established" methods, such as impact and Los Angeles tests, are

primarily suited for tests on ingeous and metamorphic

rocks, provided that they are not too rich in mica and not too weathered. Such aggregates and also aggregates of sedimentary rocks require special investigations. The Swedish impact test may be as misleading as other

"old" standard tests (figure 21 and 22). It seems to

be advisable to use a Classification specially adapted to road problems before the test is performed in order to avoid unnecessary laboratory work. In Sweden a very simple Classification has been suggested. Most aggregates will belong to group 1 and may be tested by the standardized impact test, or, if necessary, by a grinding test

(related to the British Abrasion Test).

The Classification is:

Artificial aggregates, non-porous

l. "Primary" rocks (granite, gneiss, greenstone etc) 2. "Primary" rocks, rich in mica

3. "Primary" rocks, weathered 4. Limestone

5. Shale 6. SandstOne 7.

It is more complicated to classify gravel aggregates

and the result from standardized tests are sometimes

misleading (6.1 and 6.2).

Before the suitability of test methods is further

dis-cussed the effect of different factors, such as pre-treatment of the sample, the size of the test fraction, the particle shape and the estimation of the degradation,

is dealt with.

2.

PRE-TREATMENT OF SAMPLES

A purposeful test of aggregates implies a correct and representive sampling. Specifications of samplings have been made in several countries. In the prospecting work it may be necessary to test different aggregate Samples, for instance stone lumps or cores obtained from diamond drillings. When rock lumps are crushed in a laboratory crusher they may get other particle shapes and strength prOperties than the ones that are produced later on in a crushing and sieving plant. The test on aggregates

crushed from core samples - with rounded, abraded

sur-faces - involves problems, too. General outlines of the pre-treatment should be laid down.

The strength of some aggregates has turned out to be in-fluenced by moisture. The hygrosc0pic moisture has

al-ready an effect. First of all, as a matter of fact, the

aggregates should be tested in a moist condition, when they are the weakest and not after the drying in a heating cabinet. This procedure will probably be met

with opposition as the order between some of the aggregates known may even be inverted. For this reason it is

ad-visable to retain the testing of dried samples, but the length of time and the temperature in the heating cabinet and also the cooling time at the room temperature before the testing should be standardized.

If the aggregates are classified as mentioned above

and, when necessary, special tests are carried out (6.1),

it should be possible to distinguish aggregates that are very susceptible to moisture.

3.-

AGGREGATE SIZE

In the Los Angeles method,for instance,tests on aggregates of different sizes are permitted and the stress (number of

steel shots, number of revolutions, sample size) has been adjusted to produce the same values. This is not, however,

applicable to aggregates of different characters and may in.fact be confusing. Thus it is advisable to test only one single standardized aggregate size in road connections. Within certain limits this size should be considered repre-sentative of both fine and coarse aggregabes; As mentioned before,thewrelation betWeen test results and road perfor-mance is questionable. Thus it is not necessary to obtain strength values on each aggregate size. Instead only one standardized size is tested for "aggregate strength", which can be considered to be a strength parameter like

the compressive strength on cylindric or cubical pieces. If very coarse aggregates, e g railway ballast, are to

be examined, a coarser size must be used, but then it is

a question of a new test method.

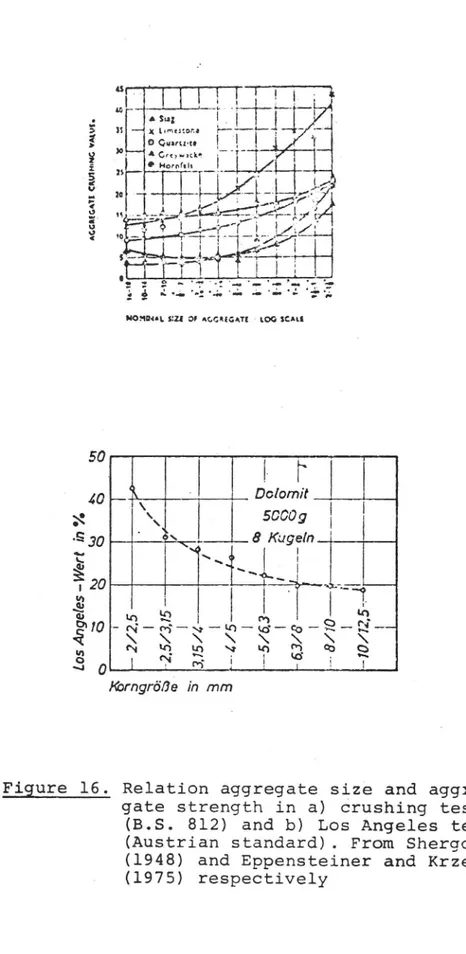

There is a fundamental difference between results ob-tained in the Los Angeles drum and tests that are made with the aggregates confined in rigid cylinders (e g as

in impact and crushing type tests). In the first case coarse aggregates are the strongest, in the latter the fine ones (figure 16).

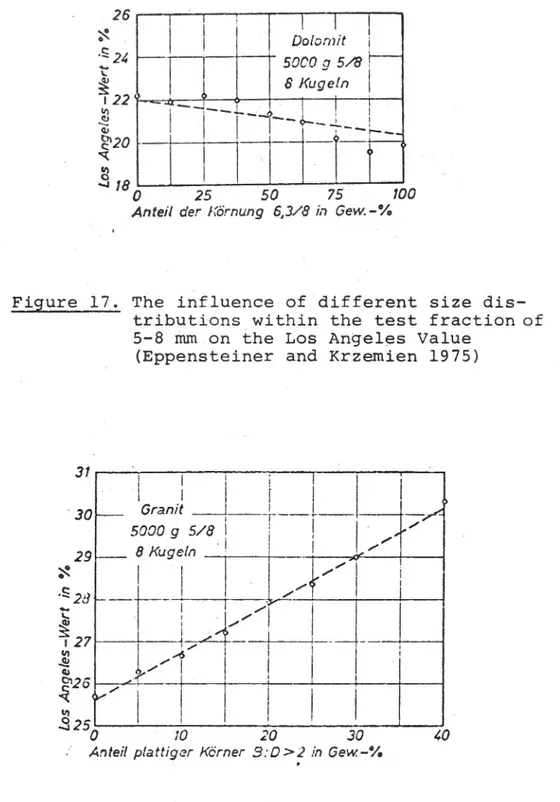

In testing aggregates confined in rigid cylinders it is important, in order to obtain.reliable;results, that the test_gradation is narrow. When wide gradations with small voids contents are being tested the order between the

results decreases, hOwever, and so do the reproducibility

and repeatability of the test. An intermediate sieve

should be used in preparing the test gradation in order that it can be correctly composed (figure 17). In the Los Angeles Test the wideness of the test gradation is not probably so important as in the aboveêdescribed tests.

The properties of the fine material in a well-graded

road aggregate are of importance, but tests of an en-tirely different type are needed, e g sand equivalent tests for plastic fines. In France a "friability test" has been developed for sand, which appears to be of 'interest. These methods should be included in another

RILEM-recommendation for the testing of fine materials.

4. PARTICLE SHAPE

For a long time it has been well-known that, in

addi-'tion to petrographical factors, the strength of aggregates is also influencedwby the particle shape, espeCially;the flakiness (figures 18 and 19).'The particle angularity

exerts a great influence, too, and from the strength

consideration spheres are the strongest - the particle shape and the stability of aggregates are concepts that,

to a certain degree, form a contrast to eachother.

Opinions differ as to the particle shape ianOnnection with strength tests. Some researchers claim that the influence of the particle shape should be included in the test re-sults as an unknown variable, flakiness will have a negative influence on strength. Others have recommended tests with a standard particle shape. Different aggregates could then be better compared with eachother regarding "material

properties" that depend on petrology.

According to standard specifications the aggregates are tested when the particle shape is "normal", that is

as it is produced in the crushers. In this respect the particle shape may be determined separately according to some method. In Sweden the particle shape has been determined in standard diagramsiand in that connection the strength is assumed.to bera funCtion of the flakiness index. The difficult point is that different aggregates have

different relations between particle shape and strength

(figure 19).

The influence of the particle shape depends also on_ how the degradation is estimated in the test (see 5). If the sample is sieved through a small sieve (as in the Los Angeles Test or the BS 812 Tests) the influence is low because a small amount of fines is produced when a flaky aggregate is splitted into a few pieces. It is high if the loss of weight of the test fraction is taken into consideration as it is in the Swedish specifications. If a particle is splitted into only two pieces,for in-stance, it still exerts a maximum influence to the same extent as when a particle is degraded into fines

(figure 20).

It is suggested that the committee recommends a test of aggregates also on a standard particle shape as a

complement to investigations on "normal" particle shapes. This would simplify the comparisons between different aggregates. According to a standard particle shape that is based on statistical considerations

(averages of a great number of tests on the particle shape of aggregates produced) the test fraction could be proportioned. It is also possible to test only one particle shape, for instance cubic particles, but the result will be considerably better than that of the aggregate that is produced. A disadvantage is that the sample size must be larger because a single particle size will be separated.

5. - MEASUREMENT OF DEGRADATION

The degradation of aggregates can be evaluated in

different Ways. The simplest way is to sieve the sample

through only one sieve and to determine the amount

passing. Methods for measuring the change of the finess modulus of the grading or even for determining the change

in the surface area of the sample are more complicated.

It has been pOinted out that the degradation can be determined by almost any sieve; Figure 20 a shows the

correlation between materials paSSing the 2.0 mm sieve and the sum of materials passing the 0.074-ll.2 mm Sieves. When a wider sieve opening is used, as in the Swedish standard impact test, the content of soft particles involves complications (see below).

The particles may degrade in two in principle different ways. If the petrological quality is low; the particles Will be crushed into fines to a large extent. This type of degradation is the most deleterious one. If the

particles are flaky or if there are weaknesses in the form of micro-cracks or schistosity, the particles will often be split into a few parts. If the degradation is determined by a small single sized teSt sieve, the

result is very much affected in the crushing into fines. Particles split into a few fragments are affected to a minor extent, because they remain on the test sieve. The relation will be the opposite if a coarse sieve, in

extreme cases the lower size of the test fractions, is

used. Figure 20 b shows how fines produced from "soft pieces" in the 8.0-ll.2 mm fraction have an influence on the test result (8 = sum of materials passing all

the 0.074-8.0 mm sieves, s = materials passing the 8.0 mm sieve).

' The determination of the degradation by several sieves (for instance determination of the change of finess modulus as performed in Switzerland or averages of ma-terials passing several sieves sizes as performed in

'Federal Germany) has the advantage that possible defects .in sieve sizes probably eliminate eachother. When only

one sieve is used the result may systematically be

dis-torted in unfortunate cases.

In some internationally known methods (Los Angeles, 'tests according to BS 812) the Crushing is determinedp

by using a single, small sieve size (tables l-2). It

is probably difficult to modify the test procedure

when completely.new values are obtained. For that-reason the method of measuring the degradation should

be retained, but a strict control of the quality of the test sieve should be prescribed.

6. TEST METHODS FOR A RILEM RECOMMENDATION

No Other method is as internationally spread as the Los

Angeles Test and for that reason it is to be preferred.

Table l summarizes some data of the test as it is

per-formed in some countries. The test is also characterized by some advantages. The repeatability is known to be good

(see Appendix). Weak aggregates can be tested, too, but

.complementary tests should, however, be carried out (6.1

.and 6.2).

The sieve sizes specified in ASTM C 131 and C 535 corre-spond to ISO 535. Different aggregates sizes can be tested but it is suggested that the B grading is recommended as a standard for reasons mentioned earlier.(3). This fraction is comparatively wide and should, in most cases, be suited for aggregates.that are to be used in road surfacings, base

courses and also.in concrete.Jl:is already used as a single

standard fraction in Finland.

The sample size for grading B is 5000 g but it is recommen-ded that it is corrected according to the aggregate compact density (as in German and Swedish impact tests) or is

measured by volume as in the British tests. Owing to the fact that the sample is quite large and that each particle

is subjected to the same impact by the steel shots the scattering of results tends to become lower than when such methods are used in which the particles are con-fined in rigid cylinders (see appendix)4 In the latter case primarily the upper particles in the cylinder are crushed and the sample is compacted into a dense mass, and in that way the degradation gradually decreases, which leads to difficulties in the testing of above all weak aggregates.

One disadvantage of the Los Angeles method is that the device is noisy and relatively bulky. It can, however, be built into an insulated cover. The stress is also somewhat undefined; it consists mainly of impacts by

steel shots, but to a certain degree also of abrasion.

The British methods (B.S. 812) are internationally wellá

known, too. The "Aggregate Crushing Value", which is

simi-lar to the ?staticv compression tests<that are performed

in certain other countries, has been completed by the

"lO_% Fines Value"..The latter was developed in order that weaker aggregates could be tested, too and that the load that is required to form lO % fines could be

determined.

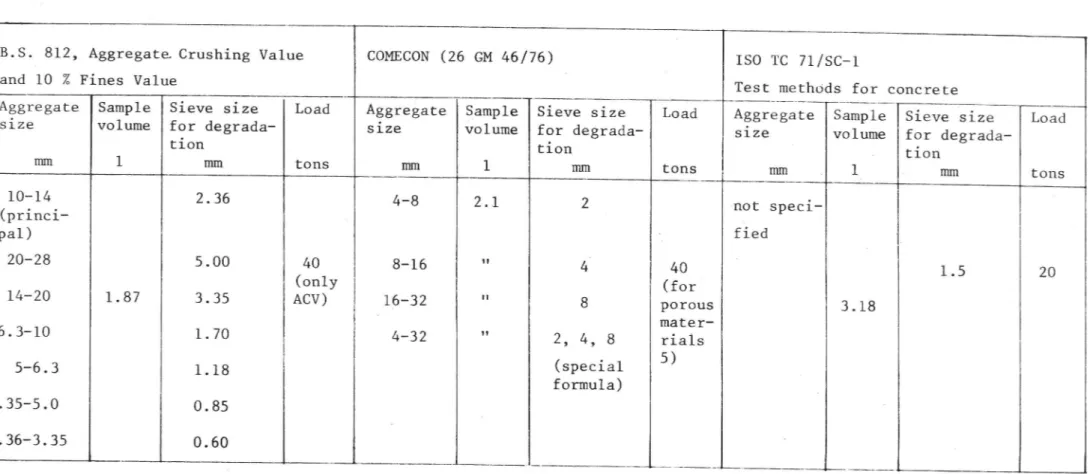

According to the COMECON recommendation another crushing test for the testing of aggregates has been suggested by the cOmmittee (26 GM 46/7). This test seems to be used in Hungary and-isprobably as well suited as the B.S.-test if a standard fraction is recommended. The load is 40 tons, but for porous aggregates 5 tons. The latter test corre-sponds to some extent to the British "lO % Fines Test". Table 2 gives some important data about these crushing tests. A static compression test is also performed in Switzerland. Theaggregate size and the evaluation of degradation correspond to the Swiss impact test (see below). The test sample, which is unusually large, is loaded to 50 tons. The advantage of these methods is that they do not require an expensive special equipment.

.LL

The British compression tests are completed by the'

B.S. 812 "Aggregate Impact Test". The tester is so

'small that it can be considered to be portable, the

sample is about 350 g. As distinguished from the

British test an expensive and bulky impact tester is

used in determining the German "Schlagfestigkeit".

After very comprehensive investigations the equipment was recently standardiZed, and its reproduCibility must be considered to be remarkably good (figure 4).

The degradation is determined as an average of

aggregates passing five sieve sizes, which must be

regarded as an advantage in comparison with the previous methods. A still bigger impact tester is used in

'SwitZerland. The evaluation is made by determining the

change of the finess modulus of the grading after the testing. It is probably difficult to spread these ex-pensive special pieces of equipment internationally. Data of these tests are presented in table 3.

Another difficult problem is the fact that different testers (particularly the "dymanic" ones) may produce varying results for one and the same method because of differences in design (see appendix). These diffe-rences have been eliminated to a large extent in the

German test, but similar standardization work is ned

cessary also for other methods, e g the Los Angeles

Test. A rather simple calibration can be made by using

several internationally accepted standard aggregates of different strength and which are as homogeneous as possible. Several aggregates should be used in order that variations that are due to unevitable inhomogeneity

can eliminate eachother.

It is suggested that the committee recommends the Los Angeles method as the first alternative. The other methods might be recommended as secondary ones. Owing

to the correlation between the test methods it is, on the whole, possible to transfer test values from one method to another if regard is payed to the aggre-gate size and the shape but also to the petrographical

composition. A Classification as broad as the one earlier mentioned is enough.

6.1 Methods for testing "local materials"

As earlier mentioned, a certain tendency, above all in _

the USA, to get rid of methods that have shown a doubt-ful correlation with the suitability of the aggregates in roads has been noticed. AccOrdingly the Deval method was recently removed from the ASTM-standard. Instead wet degradation tests have been developed at several state

road departments. The Californian method, "Durability

Test", has been adopted by the AASHTO (TZlO). When such

American tests are made the sieve analysis is not

primarily carried out to determine the degradation. In-stead, by flocculation tests (in principle determinatiOn of sand equivalent) attempts are made to measure

whether any plastic fines have been formed. It has even been maintained that durability tests (salt crystalliza-tion) do not have to be made if wet abrasion tests are performed when aggregates with a tendency to degrade are influenced in the same way in both cases. This is correct to a certain extent according to limited Swedish investiga-tions.

In France a wet abrasion method, "Micro Deval" (table 4),

has been developed as a complement to the Los Angeles

Test, while the old Deval Test does not seem to be much

used any more. In this method the degradation is deter-mined by a sieve analysis after the abrasion. In Great Britain attempts have also been made to adapt the routine methods according to B.S. 812 in such a way that the

"local materials" can be tested in a moist condition; but the procedure has not been standardized. In the USA an attempt to carry out the Los Angeles method on a moist sample and to evaluate the degradation by a flocculation

test was made. In a standardized condition the tester

.LJ

The committee is recommended to adopt a wet abrasion test that also admits of testings of weak aggregates.

Figures 21 and 22 show that "normal" test methods,

like the Los Angeles test and "pure" impact teSts, do nOt always eliminate aggregates_that are considered to be unsuitable in road constructions. In this connec--tion the "Micro Deval" method seems to be preferred. When

measuring the degradation by flocculation as in the

American tests the results may be doubtful in some cases.

Aggregates of different petrology can be difficult to

compare.

6.2 Methods for determining the content of "soft" particles

It is of interest to know how homogeneuos an aggregate (especially gravel) is as e g rather small contents of "soft" particles may be of importance in a road construc-' tion. The various strength tests give only an average value regardless of the petroglogical composition and homogeneity of the aggregate. AcCording to the ASTM

*specifications (C 131) of the Los Angeles Test the

crushing can be determined after lOO revolutions as a complement to the standardized 500 revolutions. The'

guotient between the results indicates the homogeneity

of the aggregates tested. Primarily the "soft" particles .are crushed. In Norway an additional impact test is

made on aggregates that have been obtained by sieving a new sample from two or more part samples previously tested. If the new result is considerably better, it indicates that the aggregate contains weak particles, which were degraded in the previous test, and that the

strong particles were Concentrated in the remaining sample. Such unhomogeneous aggregates can also be improved to

a certain extent in practice by a more intensive crushing in the plant.

The best thing to do is, however, to test the contents

14

of soft particles directly. In the American

specifica-tions there is a scratch test (ASTM c 235) in which

the separate particles are tested under a suspended brass rod. Particles that are scratched are

classi-fied as soft and the contents are determined. The

hardness of the rod is adjusted in such a way that limestone of a good quality cannot be scratched, which is, on the one hand, the case with deleterious porous limestone and shale. This method seems to be better suited than certain other tests in which separate particles are either statically crushed cr tested in a speCial small impact tester. Fine aggregaets are

difficult to test by a scratch test; the micro-hardness test is, however, applicable to the separate particles embedded in resin, and the contents of particles softer

than a certain hardness value can be determined.

It is suggested that the RILEM committee recommends the brass rod scratch test for the testing of the amount of

"soft" particles in aggregates. It may be possible to develop some rods with different hardness to increase 'the applicability of the test method. The suitability

of that method has been confirmed by comprehensive investigations made by Woolf (1951).

ISO/TC71/SC-I not specified

.Table 1. Important data for Los Angeles test as performed in various countries Country Grains size Number Sample Number Sieve size Remarks

mm of size of revolu- used for

complementary steel g tions evaluation

sizes not in- shots of crushing

cluded . '

Ausria 2/5 5 2500 500 1.6 5-8 mm mostly uSed?

u 5/8 8 5000 " " O norm B B128 8/12 11 5000 " H 8/18 11 5000 9 " 2/35 10 5000 v " 5/35 12 5000 ' " " 2/55 10 5000 " " 5/55 12 5000 " "

;Finland as ASTM but as ASTM as ASTM as ASTM 1 68

B only grad B grad B grad B °

EFrance see PIARC Information not

available at time of writing

GDR n,

W-Germany as ASTM as ASTM as ASTM as ASTM as ASTM Seldom performed Hungary 3-5 6 5000 500 1.6 Static crushing

5-10 7 5000 500 " test also performed

5-15 8 5000 500 " 10-15 9 5000 500 " 10-25 11 5000 500 " 10-45 12 5000 1000 " 25-45 12 10000 1000 " 30-60 12 10000 1000 " 45-90 12 10000 1000 " 60-100 12 10000 1000 "

Switzerland 16-25 11 5000 500 2.0 Impact test SNV

SNV 6708350 10-16 10 " " " main method (?) 8 H H U 3_6 6 ll N N USA (1) 37.5-50 12 10000 1000 1.68 ASTM C 535 (2) 25 -50 12 10000 1000 " (3) 19 -37.5 12 10000 1000 "

(A) 9.5-38.1

12

5000

500

"

(B) 9.5-19.1 11 5000 500 " ASTM C 131 (C) 4.8- 9.5 11 5000 500 " (D) 2.4- 4.8 11 5000 500 "USSR 5-10 8 5000 500 1.25 Static crushing test

GOST 8269 5-15 9 5000 500 " also performed

0-20 11 5000 500 "

L 20-40 12 5000 1000 "

1.25

Table 2. Some important data for aggregate crushing tests V T I M E D D E L A N D E 1 0 2

8.8. 812, Aggregate.Crushing Value COMECON (26 GM 46/76) 180 TC 71/SC-l

and 10 Z Fines Value Test methods for concrete

Aggregate Sample Sieve size Load Aggregate Sample Sieve size Load Aggregate Sample Sieve size Load

size volume for degrada-tion size Volume for degrada- size volume for

degrada-tion . tion

mm 1 mm tons mm 1 mm tons mm V 1_ - mm tons

10-14 2.36 4-8 2.1 2 4 <not speci- (princi-pal) 20-28 5.00 40 8-16 " 4' 40 A 1.5 20 (only (for-14-20 1.87 3.35 ACV) 16-32 " 8 porous 3.18 ' mater-6.3-10 1.70 4-32 " 2, 4, 8 rials 5) fied _ (special 5 6.3 1.18 formula) 3.35-5.0 0.85 2.36-3.35 0.60

V T I M E D D E L A N D E ! 1 0 7

Eable 3. Some important data for aggregate impact tests B.S. 812 Aggregate Impact Test Swedish Swiss Impact Test German "Schotterschlag" German "Splittschlag" 1975 Impact Test SNV 670830 10-14 mm smaller sizes in table 2

Aggregate-size, (principal) 8-11.2-12.5 '35.5-45.0 8.0-11.2, also 11.2-16.0 and '5.6-8.0 mm 10-16 45-58 Weight of hammer 13.5-14

50

50

-

14

_

50

Height of fall, cm 3837

42,

25

.

200

Number of impacts 1510

20

'

"

20

A

20

Sample size, kg 0.232 1 0.25 x comp.dens. 1.05 x comp.dens. 0.5 x comp.dens,kg 15

kg kg ' 2.66

Plunger, kg not used 23 23 3.6 24

Evaluation of 2.36 for smaller sizes, see

table 2

degradation

.--1,l_ri_lemwi_ _M 111

average of passing passing 10 mm

8, 5, 2, 0, 6 and

10.2 mm

8.0, 11.2 or 5L6 mm (weight

0.4-16 mm round Opening (graphical

loss of test determination)

Table 4. Micro-Deval (according to C Tourenq, Bull. Liai.

Labo Pet C 54, 1971)

Grain size

Steel shots Wearing time;

Coeff, Micro Deval

10 mm 2h, 12000 rev 2,0 mm

4/6

2 kg

"

'

n'

4 " n

10/14

5 kg 1

- _ "

' '

"

Cylinder size: 20 cm in diameter; 30 cm vin_length

är 30'* 5 ELos Angeles; Budapest' x - " - _ , Liege ' ' 0 x m - " - , Paris 0 1 x . :2 CD N _ ;CJ

5 20 --

-

x

0

3 C) 0 )( 2. *2/3 Iqu % % t? 10 _ 20 30 Los Angeles EPBOå . Los Angeles, Budapest

5-1 i: - - , Lie e 0 >< z >< g >< . å'4 O - " - , Paris N

204.

in X' 0 I; .LJ O . X '5 ?i U: *310a-?

i

e

10 _ 20 30 Los Angeles' Figures 1-2. Correlation between methods for aggregate strength according to RILEM GM 26

å . 0 Los Angeles, Budapest Ci 30db c M N _ . V_ X' - , Llege ' ä) 0 - " - , Paris'

§3

0 x

0

E .åä'

1

x

,

3

N 20*' .xU3

C X . 0 O >< 10 K 1 l I I I I 10 20 30 Los Angeles 9 304f CD N 0 á >(5

x

.2 U U) .LJ 4.) 'H r--I a.20+

0

X 0 X2

104" o Splittschlag, Bensberg O * " - , Nürnberg l- l 1 F I I 10 20 30 DruchzertrümmerungFigures 3-4. Correlation between methods for aggregate VTI MEDDELANDE 102

^ 4

o

._

8<

m 30s 0 ...-4 m> CD m r-i?0

5 X 4<.C8

"

0 0

A 20 x 0 0 X'10

+-oLos Angeles, Budapest

X - " -> , Liege 0 i- " - , Paris

L 4 1 ' L I A 4

1 T I I I j 1

10 20 30 ' 40 50 60 70

' Swedish impact value

3.0

4-53*

..

N

6

om a3 L.:å

.Hs 20-0- 0. H3

9

9

10 *L

0 Zsp, Nürnberg O Zsp, Bensberg 1 I 1 L l I I I I I _ I f 10 20 30 40 50 60Swedish impact value

Figures 5-6. Correlation between methods for aggregate

VTI MEDDELANDE 102

o

._.

ø

m 30 0 : r-'l m> CO m ,..q?0

5 X <8

4_

.0

Å 20 X *0 0 X'10+-oLos Angeles, Budapest

X - " - , Liege

o 1- " - , Paris

L 4 1 ' 1 1_ 4 A

' T I I I 1 1

10 _ 20 30.' 40 50 60 70

Swedish impact value

3.0*L

Ofå'

.,

N

6

00 c: LJå

'1-4 -1'- 0s 20

LJ.

g

9

9

10*L

0 Zsp, Nürnberg 0 Zsp, Bensberg L 1 1 L 4 1 I I T T . I I 10 20 30 40 50 . 60Swedish impact value

Figures 5-6. Correlation between methods for aggregate

strength according to RILEM GM 26

U) 0 1 ' I D r uc k ze r trüm m e r un g ' < 0 , 2 m m N <3 1 U 0

10+

_ n -. A b 10 20 30 40 50 60Swedish impact value

Figure 7. Correlation between methods for aggregate strength according to RILEM GM 26

'° no « 0' i v ,4 A 7 GO o . ä

ä

;

I ' _. 'i 0 4-. 2 m 0 g 0 ' 08

1

1'

i

in..°

____.

A '. _/M:

i .2 '1 .A 5' m.. . 3 M . _ 5' 0 N O O 'O .. få i.. ;a 0 . . . g 1,, 9 :Åh-fr a' . i . ' c J 3° .0 4 '37*64'? { Ord'th . i '0 0L

\

i A

'° c az :a 24 :o - 0 20 40 60 se .00ms Luca-Les Amaszm -VALu-:t LO! ANGELES AMASDN VALUE

a

'

b

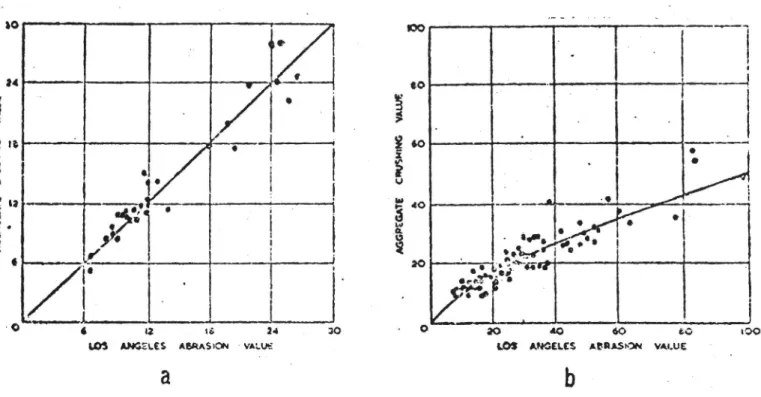

Figure 8. Relation British crushing value and Los Angeles test

. a) British b) Australian results (from Shergold 1948)

_ _ O FIISI;M\:7:N (1,30 0 Hmçhemul 1,s.o I Ei '* - <' I) § 'Magnusson .30 0.5.1 0 / g. ' l

n

t; (8i

..

'.

/ I. .o I

f'

^/

'

I ;i . 01° . D \... 2" 9» / / i 4 '*é .,

/ )*

o .46.)°*°

° /'

M 0 a I 7 6.' 9.* L' i 0* q . ; V / o , AM, 541 :g . 3 - ' *7* n a 93 o i . J ' :3 L 3» G 'fn' 0 'U Ial'ø'uilOHCI!"cc IS ?C L-äncr'j'm'mvom3 30 ' 4,4 . 5 . I / .Husum menøm nu W _ 4 / ' :a 40 :0 :Mmmm s(humana-__0-a' .

.

'

b'

Figure 9. Relation Los Angeles test and impact test

(Swedish type), tests performed in a)

Fin-land, Kauranne (1967) and b) Selmer-Olsen

(1949). The latter has used aggregates of very different flakinesses.

Ols-Schåcgsersuch DgL-DTQCKiefSUCh Uu- Los Argeles-VUSIJCh I 'GH-.lol 0. 20-1 - / 9- " 5 \ .. _ 05 0.=20&06n04,5 I ' 1.0 3. . 0- I J B., = V. "2 '1 '°'445f :, L ozpzocw-zg 5 *E å å ä* rozstoøw-wu S 20.1

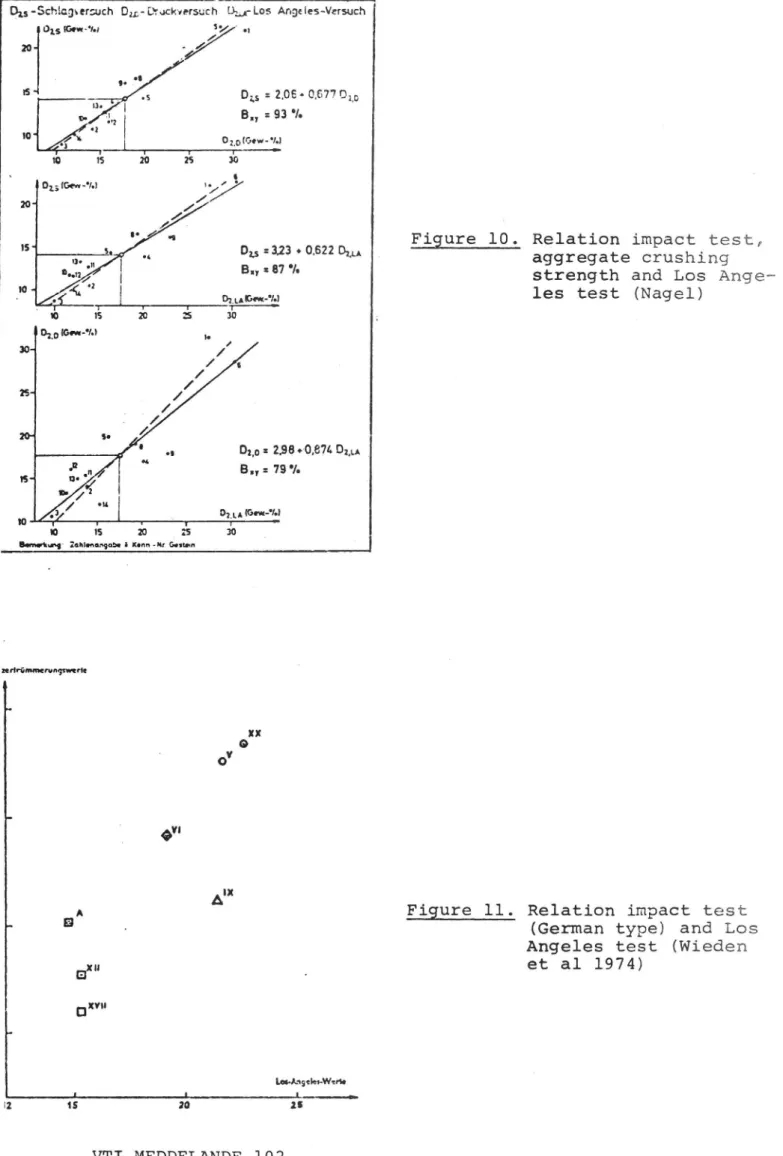

Figure lO. Relation impact testp

'5. Du :3,23 9 DILA A .

m ' - aggregate crushing

. m3"' B = 87 °/.-1 strength and Los Angem

i ,(4

Mumww

les test (Nagel)

_AI T T Y T'W A; n m x 5 m humana R I 30-* / / s // 25-4 _ / _ / / 20-1 se / r ' DL0=238+037LDLU 3.", eu=7sm '5-1 130 / h / 2 016

to åy/ r

m m m1

'- r

.307+ 'omid

mWang' Zahlmcngobc i Kahn -Nz Gatan

ndrümrunçsvnne W XX 0 av - ÖV' AIX

. Figure ll. Relation impact test

"

E

-

(German type) and Los

Angeles test (Wieden

n: et al 1974) B 0 KV" let-AngeksaW2m :2 i; 23 1; J_ VTI MEDDELANDE 102

ST maww .LJ U) (D 4.) .p . U . m Ragressionsgle'schmg '

(U v0 å ;m 0 I (auf Essä: det Origindwru)

2*

m

?aAa

////

-mxn Linn

.H I en \ ,.qu .6.33-:

' .mcååa

få

.

" \a:=

E

| " l

O'

O) . g. 96 C) å xn . m DM: ; '2 0 50 130 LA?" 9,5 40,.:Sprödhetstal

80 «

O O C ) L 1 1 O O O O 0 .k b O S we d i sh i mp a ct t es t I I . I T 710 ' 20

30

40

50

65

70

Los Angelestal

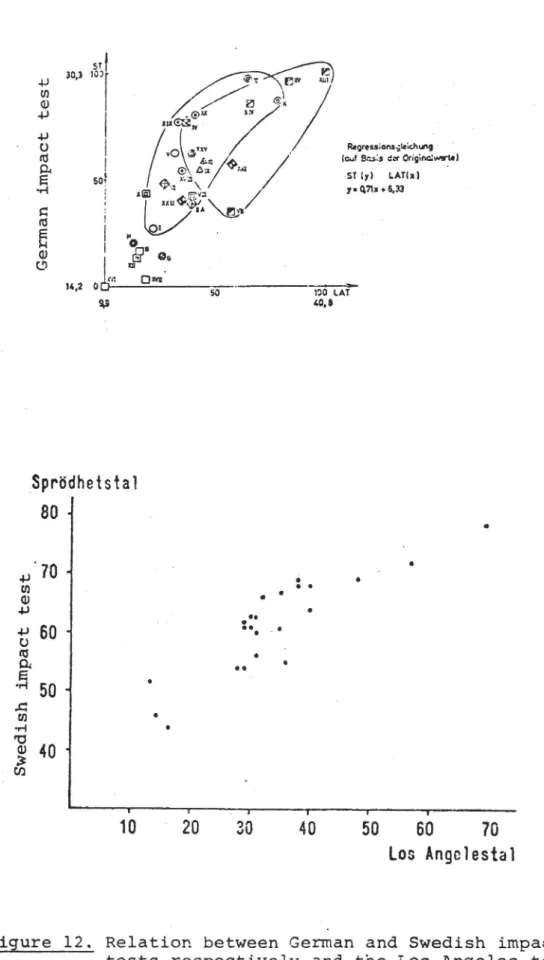

Figure 12. Relation between German and Swedish impact tests respectively and the Los Angeles test

a) Wieden and Kappel (1973) b) Höbeda (1969).

In the latter case petrologically more simi-lar aggregates have been used.

1

50-1: 1 p b '20 -: aaorzporphyz'-' Ewpmz / L P 7. q 7mmmeiprüfung Durchganç ?mm //

/ / 'Kiosü - ///

*kios yâreáhkiøs H! 71X X'Granum kaufungen / Far/:hyr :eukorsdorf/

X Diabas Bösenbrunn X X Kap/'erschlocke ' " Basal! Osfrüz/

j / Dmckprüfmq "Mp I'/ Darthçang .Smm 0 ' A LL ;6.4.1.14124Å173L ATHLFÄÄL .111%LILALAfu. ' b 0 10 20 30 40 50' 60 Månx brittle materials (quartz, grassy slag)

r . 4

10 G gravels contalnlng soft pieces

600-sm» .Sg V, CNG 03 H .

* 3400_

;J w ©U Q; c . .H \ 6..7 3 01 X4 U 200-_ .y X: 100-, , 1 H . . r impact 100 200 . 300 40° . . 5°° 600 s testFigure 13. a) Relation Los Angeles test and aggre-gate crushing strength (Kunath

and b) aggregate crushing strength and impact test (Höbeda 1973)

Loa/ASTM .

KORRELATiON

'a

.

/

L.

.

30.25'

204

o 30

I J . . _ _ _ _ _ _ _ - _ _---1 .'a 154.

.

V

.. .: ,O ,.'f '

,21'

'

a

SDspa=0a71LDBIASTL1 *324 nl'* .

. . .' ...LDB/ASTMAJSSDSPB-.0.68 """'"1074

:

N=121

r=0,91

i

5

{

§E§Pe

o

15 I 20 I 25

LDB/ASTM

25*

20'

S.1

sam :0.931.00,ASTM +445

--LDD/ASTM:1'OSSDSP a *' 529

__-0 on 0 . l L -_ -_ -_ _ _ _ -_ _ 0010.

N=121

I'=O,73

SDSPe

5

1

T

.

.

r

:2.12:-0

5

10

15 . 20

25

Figure 14. Relation between German impact-tests on aggre-\ gates,8-12.5 mm and Los Angeles tests on gradings

?gâzd D (9,5-19,0 mm and 2,4e4,8 mm), Leins et al

505,32

KUHH'CLAHON

30.* 5 . .

. /

254

20'

151._____ ______,,.

C

'

_.

f.. l QDSP2=O.82 SD5p3+1,92 m. 5098:055 SDSP2+5,82

--10*

l'

N=117

r :0,74

.

.

"I'

-nu,:

|

'

/I

'I

SDSPB

5

r

,

"är

1 .

r

1 m_ _

0

5

10

5

20

25

30

SHJSP12

SDSP12= SDSP 8 *1,34 m SDSPB=O,79 SDSP12+105

__-N=H8

r=093

_15*

10'

*SDSP8

20

25

30

5

0 0

5

10

15

Figure 15. Relation between results from German impact tests performed on different aggregate sizes 2-3,15; 8»

12.5; 12.5-20 mm, Leins et al 1974

;sw- If,..;.

w

i

I

35 M x lomutor.: Pai*'L'-'d ,Är-.- ' 0 Guru-tg I ,o 4 Gren-ud... .o 7 pl 9 Hornhh ) L / ac ca gc au ca mn mc na m.0403:20; 5:2: 0! AçclEGATE : Loa SCAu

40 __'K\ Dolomit x \\.1 V 50009 .5 30 MY. 8 Kuga/n t \\% i. I

å'

[20 '\ 2

'L .\_W'*'--<;0 m

! ,L 1 1 us

um-N-s-wemub-w-escm-

\i i E: *3. 3.' ? Ts- °? å

s] 0 1 1 m 1 L 1 Korngrö/?e in mmFigure 16. Relation aggregate size and aggre-gate strength in a) Crushing tests

(B.S. 812) and b) Los Angeles tests (Austrian standard). From Shergold

(1948) and Eppensteiner and Krzemien

(1975) respectively

N N N N 0 N Å ' O) Lo s An ge le s -W er t in% ' N Q

1

l

Dolomit 5000 9 5/8 6 Kugeln ( 1sw-l;. -

_ äjk'* åh.. ;gåI

o 0 25 50 75 100 Ante/l der Körhung 6,3/8 in Gew.-%Figure 17. The influence-of different size

dis-_tributions within the test fractioncxf

5-8 mm on the Los Angeles Value (Eppensteiner and Krzemien 1975)

(0 i. . .i l i l 0 -30 Gran/t 744 5000 9 5/8 A/ 29 8 Kugeln ' Å Ä, / . 3 5 'L// / .E 23 h_ /"

:i:

. 27

:71

3 101/

-4-0

q; 0,M

5 5x/

l8250

10

20

30

40

Antei! platt/'ger Körner .9:D>2 in Gew-V.

Figure 18.

VTI MEDDELANDE l 0 2

Relation between the content of flaky

particles and the aggregate strength _in the Los Angeles test (Eppensteiner

AL

SDSp8

28" ©<alkstein Granit V ®Gmnit I ®Ouarzit 13 Quarzporphyrit ranitl ®Melaphyr 196ronijporphyr 4 Diabas ' Quorzporphyr®Grauwccke . G) Basal: _ üg>2

20

30

40 [Gew.°/o]

un 5Figure 19. Relation flakiness - German impact

test for different aggregates (Leins

et al 1974)

82 35"

30

4

°

20 v

.15' -4 i

.

10" I. &54

a'o

10'0

1å0

ng fån

nio_ 260' 2205

5 ' GW A652/ ord 600 -* 0 berg- och konstmaterialx naturgrus 5 hal/,Cw'áwiuüåüo-?Vpå ;cm ' . I

saa'

_

'_

/ '

4/

100 -T W ' ' r ' 10 20 m Am '50 60 s'Figure 20. Relation between different methods of measuring the degradation of the

8.0-ll.2 mm aggregates a) materials passing the 2.0 mm sieve, sz, and the amount of materials passing the

0.074-8.0 mm sieves, S b) Swedish

im-pact value s (weight loss of test frac-tion) and S. Gravel containing soft particles is crushed into fines and has a small influence on 5

(Höbeda 1969 and 1973).

TT*W

1,'t* T* *' -t'

'i

__

J

LART-'á-Lms :1 500 Revolutions

' Lux Du'cbh

Figure.21. Relation Los Angeles test

. ' dex (Hveem 1964) b) Micro

Lorrain 1977) MD ! -m ar

-O Roche: grenues á grcs grain:

Nungc gbofechniqu. O Colcoire de moyonn. "- ' 40 . [I] §\\ ' as quau'l . 1 i: \ ," i Nuagc. gêo'echniqu. 1' \\ '\__z Colc'aore médiocrø

: I .g (00 dun: »vagn conespmdem

. I 8 ' x I c. unc locahsoøio.

35 .. .| x : ge'oqrcphiquo bien individuoi ;.3.

l \\ 3 I0 I \\ 'I' \ \§_oll . 30 . at 35 , 20. I I 15 t m 1 1 1 1 1 1 > . m 15 20 25 30 35 40 Fd

Figure 22. Relation impact strength, Fd,

(BS 812) and Micro Deval, wet (Aubert and Lorrain 1977)

VTI MEDDELANDE l 0 2

. . Lzosuo f

3 0 0: man: ljflufcâTE (i. 0a): i 'U '4' -' 0 D. Mt: :srmgcvu'é n :005: - M i i i I. J . I ' V . i i I Q 3.' 9 1 i g 1 a 9. .i 3 I A __.AJ - -..4-_-. .n .g 0 -- - - - L_-

.-35Q°|

-.1* 4 i i.

1 ..

'.

5*j

.um:

r e

.. _- °.11.51z a

3: - eb -' --n fn A -»- o----3

L

-0

I: '-41 H '1 '.91 T ' : F 1 26h 3 l :A i! ..- Q - lh-.. cor; -«« 7:- --4 I??

: 'L-mar-Ju*

1 Q I22_ -

'0i '.J 1 i. *

_Hem-ra-

?I Iv t; m 18 -,

,t,6 . :J I I Å r | J | I 0 [0.. 1 \\ I' O 0 1 A i l ' :i a a \00 \ ' I 4 0; ' 14 I | \ I I c: .D °° 'T- .Iä

.4 '"g

'_T3'

0 'L12..

A I

I ha1 \

v \

\. l <q. '

i°

P

.1

4,

;tt-- --

av -

. o

w _- .l 0 ,en

. x-xx

'-ts o \ . 5

x x °o

" ,/

i -I ,' l 1 \*',a

nr

»r 2.*

:wa-e

.

8- m.

6_ 3.. d ,

wei---?

.

i :I ' '9 " o I A 1' a. l 4 f ?1. ' 4 *- '- / q I 1" -v 0 - _I I U L ä 9 . 2 \. \\s I, . UNACCEPTABLE av d 6 ls* _ _' 0 | . 0 l l 1 t 1 r .e . , .L Å - 5 10 15 20 25 30 35 . I' : 1 ' D Roche: gotcaniquesLib, UME'FHY 75,57 2 I' 1 I Roche: hypowlcaniques des Vosg-:s septentrionales

CD .0 ;15 _ se ;U 5:, _ A Roche: hypovoiçamuues des Vosges moyennes

0 Roche: olutqniquçs G! m'étamorphuqucs

and.a) durability in-Deval, wet (Aubert and

Appendix

The repeatability and reproducibility of methods for the

determination of aggregate strength

Values for standard deviation have been stated for most

test methods, but they have to be compared Cautiously

as they may have been obtained in different ways andon aggregates of a varying homogeneity. A distinction must be made between repeatability, which is applicable to repetition of the test in the same laboratory, and re-producibility, which indicates the distribution of the test results among different laboratories.

The results of some studies of repeatability and repro-ducibility are presented below. The results are treated 'in relative terms and the coefficient of variation is

given to facilitate comparisons. In the first case only

results obtained on the same sample of one test aggregate

are included, whereas results from continous production

controls not are included. In the second case petrographic variations hav a great influence on the repeatability.

Repeatability

A summary of the results of different investigators is shown in table l:l. In one case (Leins and Nagel, 1965) the coefficient of Variation was calculated from a diagram in their paper.

Some investigators have studied the repeatability of test

methods, but without presenting comparable values. Hanks

(1962) has thus studied the Los Angeles method in Australia following the ASTM specifications. He points out that a repeatability of i 1 (the absolute value as the mean value is not given) is possible provided that the testing

procedure is well standardized. It is, among other things, of importance to standardize the drying procedure and the following cooling procedure carefully. The aggregates in question

Table 1:1

Method Particle Size Coefficient of Source

Variation %

Los Angeles 1.8 Woolf, 1936

Test

1;6_,

Shergold, 1948

B 1.5 Kauranne, 1962

B :1.6 ' Kauranne, 1970

8-12

1.8 (l.6-2.0)

Nagel, 1970

5-8 1.0 (O,1-2.0) .Wieden and Kappel, 1974

1.0 Benson and Ames, 1975

Swiss Impact Max. 8.4 Haller, 1974

Test

Impact Test 8-12 2.5 (2.0-3.2) Nagel, 1970

FDR 8-12 Leinz and Nagel, 1965

8-12 2.6 (0.9-5.3) Wieden and Kappel, 1974

8-12 (cubical) (3.4-5.1) Paulmann, 1964

Aggregate 4.4 Cox, 1973

Impact Test

'

Swedish Impact 8-11.2 gravel 5.5 Kauranne, 1962

Test 8-ll.2 macadam 2.5 Kauranne, 1962

_8-11.2 gravel 4.7 Kauranne, 1970

.8-11.2 macadam 2.6 Kauranne, 1970

'8-1l.2

4.7 (2.8-6.5)

Höbeda, 1971

Aggregate l. _Shergold, 1948

Crushing Cox, 1973 (via TRRL)

BS. 812

10 % Fines Test 5.6 Cox, 1973

Druckzertrümme- 8-12.5 5.1 (2.9-8.6) Dao and Feller, 1969

rung, DDR 3 MPa

D question (partly weathered basalts) Were obviously

sensitive to the hygrosc0pic moisture. Leins et al

(1974) have compared some internatiOnal methods. It is

claimed that in the Los Angeles method and in the German impact test the repeatability is satisfactory, whereas

the British impact test is inferior in that respect.

Reproducibility

Woolf (1936) has studied the reproducibility of the Los Angeles method by a ring test with 18 participating

laboratories and has found a coefficient of variation of 5.6 %. Shook and Fang (1961) present a ring analysis,' made by 19 laboratories, on base course gravel from the AASHO Road Test in which a coefficient of variation of .8.1 % was obtained. Benson and Ames (1975) present the

coefficients of variation of 1.0 and 1.88 6 for the

re-peatability and the reproducibility respectively.

Kohler and Nagel (1972) have made a ring analysis of the

Los Angeles Test with 16 participating Eur0pean road

laboratories and have found very great deviations (20-30 %). In the different countries of Europe the method is obviously performed in a less uniform way than in the USA and the

' design of the devices probably vary more than in the USA.

In "Merkblatt für der Slagversuch an Splitt 8/12" of 1966

a ring analysis, made by 12 laboratories, with the German impact tester is described. In 5 aggregates the coefficient of variation was between 12 and 21 %. Nagel (1970) presents a coefficient of variation of i 11.1 % for the "Splittzer-trümmerungswert" in a ring analysis made by different 1a-boratories. Later on comprehensive investigations to improve the reproducibility of the method were made in Germany and the impact tester type was more carefully standardized.

There are, however, no known results from later ring analyses.

Except for Sweden the Swedish impact tester is only

used in Norway and to some extent in Finland. The methods

do not, however, completely correspond. A ring analysis made by theSe laboratories showed also a very poor

correspondence (ThurmanêMoe, 1964). A ring analysis made

by three laboratories in Norway did also reveal poor results (Noteby, 1972). A comparison between two labora-tories in Sweden (Höbeda, l97l) revealed, however, a good correspOndence. The latter investigations were too

limited for a determination of the coefficient of variation

to be made.

Conclusion

The presented data show that the Los Angeles method gives

the best repeatability and according to American ring

analyses it also seems to give a good reproducibility. Obviously the method is, however, carried out in very different ways in European countries and a better adap-tion to American specificaadap-tions is desired.

The experience from other methods is more limited, but the repeatability seems to be decidedly poorer than in the Los Angeles test. Except for the Swiss impact tester the sample amounts are smaller than in the Los Angeles method..The greatest crushing also occurs in the upper part of the sample.

BIBLEOGRAPHY

"Benson, P.E., Ames, H. The Precision of Selected Aggregate Test Methods. Transport Research Record 539, 1975.

Cox, E.A., Roadstone Assessment - on Art or Science. The Quarry Managers Journal, maj 1973.

Dao, N.X., Feller, M. Festigkeitsprüfung von Gesteinsplitten für Strassenbau, Die Strasse, Heft 9, 1969.

Eppensteiner, W., Krzemien, R. Die Prüfung von Körnungen und Korngemischen in der Los Angelestrommelmühle. Bundes-ministerium für Bauten und Technik, Strassenforschung.

Heft 16, 1975.

'

ForschungsgesellSChaft für das Strassenwesen. Vorläufiges Merkblatt für den SchlagverSuch an Splitt, 8/12, 1966. Haller, P. Die Prüfung von verschieden gekörntem Gesteins-material aus Gruben und Steinbrüchen. Eidgenössische

Materialprüfungs- und VerSuchsanstalt für Industrie,

Bau-wesen und Gewerbe. Forschungsauftrag 14/64.

Hanks, J.N. The Effect of Simple Factors on the Reproduci-bility of the Los Angeles Test. Australian Highway Research

Board, Proceedings, Volume I, 1962. ,

Höbeda, P. Stenmaterials tryck- och slaghållfasthet - en

jämförande undersökning. Rapport nr 39, 1973; Höbeda, P. 1970. Unpublished Tests.

Kauranne, K. Comparison of Some Methods used in the Testing of Road Surfacing Aggregates. Valtion Teknillinen Tutkimus-laitas Tielaboratorio, Tiedonanto no 3, 1970. '

Kauranne, K., Markkula, V. Rakennustekniika nr 7 och 8, 1967.

Kauranne, K. Undersökningar av laboratoriebestämningarna

1961-1962, Unpublished Statistics.

Kohler, G., Nagel, J. Comparative Investigations of Inter-national Test Methods for Small-Sized Coarse Aggregates. Highway Research Record 412, 1972.

Leins, W., Kohler, G., Meyer, G., Berg, von, P.

Beant-spruchung und Prüfung von "Gesteinssplitten". Internatio-nale Splittprüfverfahren deren Aussagekraft und die Beein-flussung der Prüfwerte durch die Kornform. Strassenbau und Strassenverkehrstechnik, Heft 156, 1974.

Leins, W., Nagel, J. Stand und Entwicklung der

Naturstein-prüfungen in BRD unter besonderer Berücksichtigung des Strassenbaues. Der Naturstein im StraSsenbau 40 1965/2.

Nagel, J. Beantspruchung und Prüfung von Geste.nsspliften.

Diss Fakultät Bauwesen der RheiniSch-Westfälischen Tech-nische Hochschule Aachen, 1969.

Nagel, J. Problematik bei der Beurteilung von Gesteins-vorkommen über den Schlagzertrümmerungswert an Splitt 9/12.

Die Natursteinindustrie nr 5/1970.

Noteby. Korrelasionsforsøk NTH - Veglaboratoriet - Noteby. Intern Opdrag. 25.11.1972.

Paulmann, GQ Auswertung von Prüfergebnissen bei der Prüfung von Naturstein mit Hilfe der matematischen Statistik. Der

Naturstein im Strassenbau 36/1964.

Selmer-Olsen, R. Prøvning av steinmaterialet till vegdekker.

Meddelelser fra Vegdirektøren nr 12, 1949.

Shergold, F.A. A Review of Available Information on the Significance of Roadstone Tests. Road Research Laboratory,

Technical Paper, No 10, 1948.

Shook, J.F., Fang, Y. C00perative Materials Testing Program at the AASHO Road Test. Highway Research Board, Special

Report 66, 1961. '

Thurman-Moe, T. Diskussionsinlägg, Nordisk Vegteknisk For-bund. Utvalg 3l, Oslo 21-22 aug, 1964. Statens Vegvesen, ' Veglaboratoriet, Meddelelse 21, 1964.

.Tons, E., Goetz, W.H. Packing Volume Concept for Aggregates. Highway Research Record 236, 1968.

Wieden, P., Kappel, F. Untersuchungen an Gesteinmaterialen

hinsichtlich Abriebverhalten und Widerstandeähigkeit gegen

Polieren. Bundesministerium für Bauten und Technik,

Strassen-forschung, Heft 2, 1973. '

Wieden, P., Kappel, F., Zieger, M. Vergleichende Unter-suchungen mittels Los Angeles-Test, Deval-Abrieb-Test und Schlagzertrümmerungstest an für den Strassenbau verwendeten

Gesteinen. Bundesministerium für Bauten und Technik, Strassen-forschung, Heft 32, 1974.

Woolf, D.O. Methods for the determination of soft pieces in

aggregate. Public Roads, april, l951.

Woolf, D.O. Results of cooperative tests using the Los

Angeles abrasion machines. Highway Research Board, Proceedings,