DOI: 10.4018/IJORIS.2019100102

Copyright©2019,IGIGlobal.CopyingordistributinginprintorelectronicformswithoutwrittenpermissionofIGIGlobalisprohibited.

System Architectures for Sensor-Based

Dynamic Remaining Shelf-life Prediction

Åse Jevinger, Malmö University, Malmö, Sweden Paul Davidsson, Malmö University, Malmö, Sweden

ABSTRACT Differentstorageandhandlingconditionsincoldsupplychainsoftencausevariationsintheremaining shelflifeofperishablefoods.Inparticular,theactualshelflifemaydifferfromtheexpirationdate printedontheprimarypackage.Basedontemperaturesensorsplacedonorclosetothefoodproducts, aremainingshelf-lifeprediction(RSLP)servicecanbedeveloped,whichestimatestheremaining shelflifeofindividualproducts,inreal-time.Thistypeofservicemayleadtodecreasedfoodwaste andisusedfordiscoveringsupplychaininefficienciesandensuringfoodquality.Dependingonthe systemarchitecture,differentservicequalitiescanbeobtainedintermsofusability,accuracy,security, etc.Thisarticlepresentsanovelapproachforhowtoidentifyandselectthemostsuitablesystem architecturesforRSLPservices.Theapproachisillustratedbyrankingdifferentarchitecturesfora RSLPservicedirectedtowardsthesupplychainmanagers.Asaproofofconcept,someofthemost highlyrankedarchitectureshavebeenimplementedandtestedinfoodcoldsupplychains. KeywORDS

AHP, Cold Supply Chain, Implementation, Information System Architecture, Perishable Food, Remaining Shelf-life Prediction, Sensor-based System, Temperature Sensor

INTRODUCTION Studiesshowthattemperatureinfoodsupplychains(FSCs)oftendifferfromtheonesrecommended bytheproducer(Hafliðasonetal.,2012;LikarandJevšnik,2006).Thismightleadtoshortershelf lifeforperishables,suchasdairyproducts,freshmeatandfish,andthattheexpirydatesprintedon theprimarypackagesnolongerrepresentgoodestimatesoftheactualshelflife.Ontheotherhand, foodthathasbeenwelltreatedcanoftenbesafelyconsumedaftertheprintedexpirydatehaspassed. Ithasbeenestimatedthatonethirdofallfoodproducedgloballyforhumanconsumptionislostor wastedandthatmorethan40%ofthisfoodlossoccuratretailandconsumerlevels,inindustrialized countries(Gustavssonetal.,2011).Withinformationabouttheactualshelflifeoftheproducts,this foodwastecanbereduced.Onewaytogetanestimateclosertotheactualshelflifethantheprinted expirydateistouseproductconditionmonitoring.Thatis,tocontinuouslymeasurerelevantconditions oftheproducts,suchastemperature,andusethesemeasurementstoestimatetheproductshelflife. AmongenvironmentalparametersinFSCs,temperaturehasthemostsignificantinfluenceonthe qualityofperishablefoodproducts(Jedermannetal.,2009).Asaconsequence,temperatureabuse andfluctuationsarethemainreasonsforproductreturns,foodwasteandfinanciallosses(Raabet al.,2008).Scheer(2006)reportsthatmismanagedtemperatureduringperishableFSCdistribution cancauseupto35%inproductloss.Moreover,Göranssonetal.(2018a)havefoundsignificant differencesinestimatedproductshelflifewhencomparingdifferentFSCsforthesameproducttypes

andtemperaturerequirements,infieldtests.Thismeansthatthecorrespondingdifferencesbetween actualshelflifeandtheshelflifeprintedonthepackages,alsovaried.Byusinglocalsensorsto measurethetemperatureinFSCs,theactualqualityofthefoodproductscanbeestimated.These sensorsmustbepresentthroughoutthetransportchain,andtheclosertotheproductstheyareplaced, themoreaccurateestimationscanbemade.Basedontheestimatedquality,theremainingshelf lifecanbedynamicallyupdatedinrealtime,enablingproductowners,actorswithinsupplychain managementandfinalconsumers,tomakemoreinformeddecisionsabouthowtohandlethefood andwhentodiscardit.Furthermore,aserviceprovidingaremainingshelf-lifeprediction(RSLP) basedontemperaturesensorsmightbecolligatedwithotherservicessuchastrackingandtracing, productinformation(forinstanceoriginandhandlinginstructions),carbondioxidelabeling,and dynamicpricing(Bartelsetal.,2010). AnRSLPservicecanbeimplementedinmanydifferentways,usingdifferentsystemarchitectures. Forinstance,theremainingshelflifecanbecalculatedontheproductorbyremoteservers(inthe cloud),andthetemperaturecanbemeasuredbyasensorattachedtotheproductorbyfixedclose-by device.Thesedifferentoptionsneedtobeevaluatedbeforeaninformeddecisionaboutthesystem architecturecanbetaken.Tothebestofourknowledge,therearenopreviousstudiesonhowthis canbedoneinasystematicmannerforthistypeofservice.Inhispaper,wepresentandapplya novelapproachtoidentifyandevaluatethemostsuitablesystemarchitectureforanRSLPservicefor perishablefood.Weillustratetheapproachbyrankingallarchitecturessatisfyingtherequirements oftwoparticularusergroups:thesupplychainmanagersandproductowners.Asaproofofconcept, wehavealsoimplementedandtestedsomeofthemosthighlyrankedarchitecturesinacoldFSC.In summary,theaimsofthispaperisto: • Presentandapplyanovelapproachtoidentifyandevaluatethemostsuitablesystemarchitecture foranRSLPservice, • PresentexperiencesgainedfromimplementingandtestingsomeofthemostsuitableRSLP architecturesinacoldFSC, • Provethatthistypeofservicecanbeimplementedusingthetechnologyavailabletoday. Theremainderofthispaperisstructuredasfollows.Thenexttwosectionsdescribeprevious studiesrelatedtoproductconditionmonitoring,andthemethodologyappliedinthispaper.Thereafter, wepresenttheresultsintermsofanewmodelforrepresentingthesystemarchitectures,afiltering processleadingtoasetofarchitecturessubjectforevaluation,thefinalrankingofthesearchitectures, andtheexperiencesgainedfromFSCimplementationandtests(asproofofconcept).Thepaperends withashortdiscussionandsummaryofconclusions.

PRODUCT CONDITION MONITORING: STATe-OF-THe-ART

ProductsaccompaniedbyahigherlevelofintelligencethanonlypossessinganassociatedID(e.g. thesimplestformofRFID),areoftenreferredtoas“smart”or“intelligent”(Meyeretal.,2009).For instance,theseproductsmaybecapableofcommunicatingwiththeirenvironments,storingdata, processingdata,andevenmakingautonomousdecisions.Dependingonthelevelofintelligence, suchproductsmaybecapableofmonitoringthelocalconditionsduringtransportation(Lópezetal., 2011),andmaybealsoofcalculatingtheremainingshelflife.Theintelligencerelatedtoaproduct mayormaynotbelocatedontheproductitself(Meyeretal.,2009).However,fortheRSLPservice, localintelligence,forinstanceimplementedontheproduct,apalletorinthevehicle,abletoperform conditionmonitoringisrequired. Withintheareaofcommunicativepackaging,potentialmeanstomonitortheconditionof packagedcontentsbyenhancingtheintelligenceofthepackageitselfhavebeeninvestigated(Heising

etal.,2014).Thesolutionsconsistofacombinationofpackagingtechnologiesandcommunicative signals(e.g.changingcolors,diagrams,displays)(Dobonetal.,2011).Communicativepackaging isseenasaspecifictypeofsmartpackaging,whichusesdifferenttechnologiestoaddextrafeatures topackaging(e.g.informationaboutremainingshelflife,identificationaboutthetype/originofthe productandprotectionagainstcounterfeiting).Alifecycleassessmentstudyontheuseofaflexible best-before-datecommunicativedevice(FBBD,withatemperatureloggerandadisplay)onpackaging consumerunits,showsthattheuseofFBBDdevicesdecreasesenvironmentalburdensassociated totheproduction,packaginganddeliverytothepointofsale,thankstoreductioninfoodlosses (Dobonetal.,2011).Othercasestudiesshowpotentialbenefitsofradio-frequencyidentification (RFID)basedcold-chainmonitoringinincreasedsalesduetoreducedout-of-stock,reductionin inventoryduetolowersafetystock,improvementofvisibilityandtransparencyinthesupplychain etc.(Joletal.,2006).BenefitsfromusingTTIs(Sahinetal.,2007;BhushanandGummaraju,2002) andwirelesssensornetworks(Qietal.,2014)havealsobeeninvestigated.Inparticular,Bijwaardet al.(2011)havestudiedthecommunicationlinksinawirelesssensornetworkcapableofmonitoring environmentalconditions,calculatingtheremainingproductshelflife,andtransmitthisdatatoa back-endserver.Inrecentyears,FSCmonitoringbasedontheInternetofThings(IoT)umbrella concepthaveemerged(WangandYue,2017).Forinstance,datacollectedbymeansofIoTcanbe representedinvirtualobjects,toallowformonitoring,controlling,planningandoptimizingremotely andinrealtime(Verdouwetal.,2016). Analternativetoenhancingthepackageofaproductitselfistoplacethelocalintelligence, includingtemperaturesensors,onahigherlevel,suchasoncontainersorinvehicles(Ruiz-Garcia etal.,2007;Jedermannetal.,2014).Forinstance,Sciortinoetal.(2016)havedevelopedasmart logisticsunit(SLU)mountedonpallets,thatmeasureshumidity,temperatureanddifferenttypesof gases,andcommunicatesthesemeasurements,togetherwithGPSinformation,toaserver. Placingintelligenceondifferentlevelsinatransportsystemresultsindifferentprocessing, informationandcommunicationrequirementsaswellasenablesdifferentservicequalitiesand functionalities.Dependingonthepurposeoflocalconditionmonitoringandshelf-lifeestimations, differentsolutionsbasedondifferentsystemarchitecturesmighttherebybepreferred-inparticular bydifferenttargetusergroups.Asshownabove,severalpreviousstudieshaveinvestigatedhowto monitorfoodproducts.Someofthemhavealsousedthecollectedsensordatatocalculateproduct shelflife.Althoughdifferentsystemarchitecturescanbedistinguishedinthepreviousstudies,none ofthestudiesaddressestheproblemofhowtoidentifythedifferentarchitecturealternativesandhow todeterminewhichonetochoose.Thispaperaimsatfillingthisresearchgap. MeTHODOLOGy Theresearchmethodologyappliedinthispaperisbasedondesignscience(DS)researchininformation systems(IS)(Hevneretal.,2004).Thisdisciplineisdirectedtowardscreatingapplicablesolutions toproblems,bydevelopingartifacts,attheintersectionofITandorganizations(Peffersetal.,2007). Accordingtothisterminology,theartifactdevelopedwithinourstudyisamethodforidentifying andevaluatingappropriatesystemarchitectures.Hevneretal.(2004)presentaframeworkfor understanding,executing,andevaluatinginformationsystems(IS)research.Theframeworkincludes theenvironment,whichdefinestheproblemspaceandthebusinessneeds,andtheknowledgebase, whichprovidestherawmaterialstotheISresearch(theories,frameworks,etc.).Thebusinessneeds andtheknowledgebaseformtheinputtotheISresearchprocess.Theprincipalbusinessneedsfor ourresearchhavebeendescribedintheintroduction.Theknowledgebaseiscomposedofconceptual modellingandexistingexpertiseconcerningfieldtestsandquestionnaires. InordertodeterminenecessaryrequirementsfortheRSLPserviceandthecorrespondingsystem architecture,weusedtheresultsfromapreviousstudy,inwhichweinterviewed11differentFSC actors(Jevingeretal.,2014).Additionally,weconductedliteraturestudiestoidentifyrelevantcriteria.

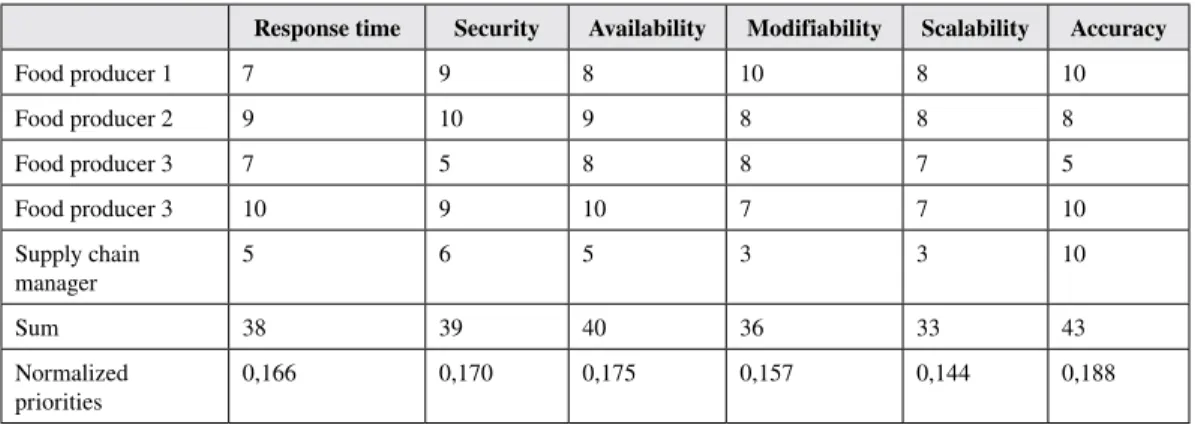

Inordertovaluetheidentifiedcriteria,wethenaskedfiveactorswithintheFSC,fourdifferent perishablefoodproducersandonesupplychainmanager,tofillinaquestionnaire.Theseactorswere selectedtoreflecttheusergroupsinfocusinthispaper.Thequestionnaireaskedeachrespondentto setavalue(between1and10)toeachoftheidentifiedcriteria(seeAppendix1). Asmentionedabove,wehavedevelopedanovelapproachtoidentifyandevaluatethemost suitablesystemarchitectureforanRSLPservice.Theinformationcollectedfromtheinterviews, questionnaireandliteraturereviewwasusedtospecifythetargetusergrouprequirements,inthis approach.Wealsodevelopedasystemarchitecturerepresentationmodel,aspartoftheapproach.The modelcharacterizesarchitecturesbasedonwhere(e.g.,directlyattheproductorataremoteserver)the differentactivitiesinvolvedintheRSLPservice(e.g.,readingandstoringsensordata,andcomputing theRSLP)areperformed.Themodelisusedtoidentifythesetofallpossiblesystemarchitectures. Thereafter,thecandidatesthatdonotmeetthetargetusergrouprequirementsareremovedfromthe set.Moreover,weuseconceptualfilteringprinciplestoremovearchitecturecandidatesthatdonot seemreasonablefromapracticalperspective.Theremainingsystemarchitecturesarethenevaluated usinganAnalyticalHierarchicalProcess(AHP),whichisamethodforanalyzingcomplexdecision problemswithmultiplecriteria(Saaty,1980).Thecriteriaareusedinpairwisecomparisonsofthe consideredalternativesandshouldreflectallimportantaspectsofeachofthealternatives(Saaty,1987). Weillustratethenovelapproachtoidentifythemostsuitablesystemarchitectures,byapplying ittotwoparticularusergroups,thesupplychainmanagersandproductowners.Someofthemost highlyrankedsystemarchitectureswerethenimplementedandtestedinrealcoldFSCs,involving foodproducers,logisticsserviceproviders,wholesalers,distributors,andretailers.Someofthesystem requirementsfromthepreviousstudyalsoaffectedtheimplementationofthisarchitecture(Jevinger etal.,2014).Thereby,theseservedasrequirementsduringtheimplementingphase,aswell. Inthisstudy,theRSLPisbasedontemperaturemeasurements.Thus,sensorsareneededto recordthelocalconditionsaccordingtosometimeinterval.Theoretically,theservicecouldhave beenbasedonmeasuringthecurrentbacterialevelonly.However,giventhecurrentstatusofsensor technology,directmeasurementofthecurrentbacterialevelinaproductisnotaviableapproach. ReSULTS InordertobeabletocomparedifferentsystemarchitecturesofanRSLPservice,theymustfirstbe identifiedandcharacterized.Wehavedevelopedanewsystemarchitecturerepresentationmodel, thatcharacterizesthearchitecturesbasedonwherethedifferentactivitiesinvolvedintheserviceare performed.Themodelwasdevelopedbyfirstspecifyingallactivities(A)thatmustbeperformed,as wellasthedifferentlocations(L)whereeachoftheseactivitiescouldbeperformed.Bycombiningthe activitieswiththelocations,wegotthesetofallpotentialarchitectures(i.e.,theCartesianproductL\A\). Thesetofpotentialarchitectureswasthenreducedbyremovingunfeasibleandobviously impracticalarchitectures.Fromtheremainingsetofarchitectures,themostsuitableones,withrespect tothefunctionalandqualityrequirementsofeachtargetusergroup,shouldbefound.Ideally,every identifiedarchitectureshouldbeevaluatedandcompared.However,duetotheamountofworkthis processwouldrequire,theleastsuitableoneswerefilteredoutintwosteps.Inthefirstfilteringstep,we appliedtargetusergrouprequirementsspecifyingwheretheRSLPshouldbepresented.Forinstance, someusergroupsmightwanttoreachtheRSLPviaamobileterminal(e.g.terminalworkers)whereas othersmightwanttoreaditontheproductitself(e.g.consumers).Inthispaper,weonlyfocusonthe architecturessatisfyingtherequirementsofthesupplychainmanagersandproductowners,whichare bothassumedtorequiretheRSLPdisplayedinaremotedevice,forinstanceastationarycomputer runninganERPsystem.Inthesecondfilteringstep,twoconceptualfilteringprinciplesderivedfrom generalrequirementsonthearchitecturewereappliedtodistinguishthemostpromisingcandidates. Finally,AHPanalysiswasperformedontheresultingsetofarchitectures,prioritizingthemost suitableonesaccordingtoasetofquality-basedcriteria.Asmentionedabove,thecriteriausedshould

reflectalltheimportantaspectsofeachoftheconsideredalternatives.Inourcase,weidentifieda partofthesecriteriabyanalyzingtheservicerequirementsexpressedbyFSCactors.Interviewsfrom apreviousstudyidentifiedfollowingsystemrequirements(Jevingeretal.,2014): 1. Thesolutionmustbeaffordable. 2. ThesolutionshouldbeseamlesslyintegratedintheFSC. 3. ThegeneratedinformationshouldbereporteddirectlyintotheEnterpriseResourcePlanning (ERP)systems. 4. Temperaturemustbemeasuredclosetotheproducts. 5. Generatedinformationmustbeprotectedfromunauthorizedaccess(e.g.fromcompetitors) 6. Generatedinformationmustbeprotectedfromdatatampering. Systemrequirementsno.2and3,affecttheimplementationofanarchitecture.Requirements no.4-6influencethechoiceofarchitecture.Theserequirementswerethereforeused,incombination withqualityattributesgatheredfromliterature(Offutt,2002;Barbaccietal.,1995;O’Brienetal., 2007;Larsson,2004;Clements,2001),todeterminethecriteriafortheAHP.Inordertovaluethe identifiedcriteria,wecollecteddatafromthequestionnaire.Theresultsfromthisquestionnaire servedasinputtotheAHP. Requirement1naturallyalsoinfluencesthefinalchoiceofarchitecture.However,sincecosts aredependentoncurrentpricesandtechnologicalachievements,costaspectsarenotincludedinthe AHP.Instead,thearchitecturesareprioritizedfromafunctionalandqualityperspective.Costaspects aretakenintoconsiderationaftertheAHP. Figure1illustratesthedifferentstepsinthenovelapproachusedforidentifyingpossiblesystem architecturesforRSLPservicesandevaluatingthemostsuitableones. Inthefollowingsubsectionswefirstpresentandapplythesystemarchitecturerepresentation model(step1inFigure1).Wethendescribethetargetusergrouprequirementsaswellasthe conceptualfilteringprinciplesused(step2and3inFigure1).Thisisfollowedbytheapplication oftheAnalyticalHierarchicalProcesstoevaluatetheremainingsystemarchitectures(step4in Figure1).Thesectionendswithaproofofconcept,presentingtheexperiencesgainedfromour FSCimplementationsandtestsofsomeofthemosthighlyrankedarchitecturesresultingfromthe precedingapplicationofsteps1-4.

System Architecture Representation Model

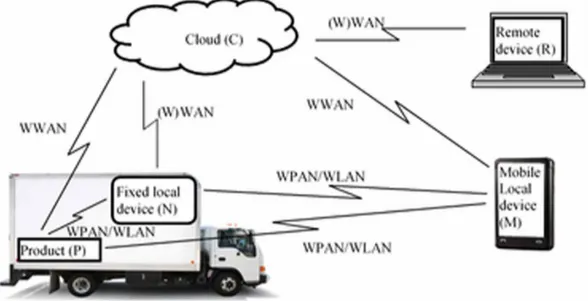

TheRSLPservicerequirestheexecutionoffourmainactivities:(a1)thelocaltemperatureofthe producthavetobemeasured,(a2)therecordedtemperaturedatamustbestored,(a3)theRSLPmust becalculatedbasedonthestoredtemperaturedata,and(a4)theresultmustbepresentedtotheuser oftheservice.Theseactivities(A={a1,a2,a3,a4})canbeperformedatdifferentlocations:atproduct level(P),onafixedlocaldevice(N),onamobilelocaldevice(M),inaremotedevice(R)orinthe Figure 1. Approach to identify and evaluate the most suitable system architectures for RSLP services

cloud(C),i.e.L={P,N,M,R,C}.Below,amoredetailedexplanationofthedifferentlocationsis given.Figure2illustratesthecorrespondingpossiblecommunicationlinksbetweentheselocations. Inthisstudy,weassumethatbothRandMareconnectedwiththecloud(whenthereiscoverage) andthatNisavailablewheneverneededinaccordancewiththerequirementsofthearchitecture. TheentitiesinsetLcanbeexplainedasfollows: P:Entityatproductlevel,i.e.,attachedtotheprimarypackage.Thisentityfollowstheproduct throughoutthetransport. N:Localdeviceneartheproducts,locatedforinstanceonthesecondarypackage,pallet,orinsidea vehicle,terminalorrefrigerator.TheNusedbytheserviceonbehalfofaproductmaychange duringtransport. M:Mobilelocaldevicewithincommunicationrangeoftheproductorlocaldevice.Thiscouldbea smartphoneusedbyconsumersorlocalsupplychainpersonnel,e.g.truckdriversandterminal workers.MmaycommunicatedirectlywithNandP. R:Remotedevice,forinstanceastationarycomputerrunninganERPsystem.Risunableto communicatedirectlywithNandP. C:Cloudentities,forinstancenetworkservers,accessiblefromanydevicewithInternetaccess. Giventhenumberofactivitiesandthenumberofpossiblelocationsabove,thesetofpotential architectures,L\A\,consistsof625elements(5*5*5*5=625).However,someofthesecorrespondto unfeasibleorobviouslyimpracticalsolutions.MeasuringthelocalconditionsinCorRisimpossible, andtodoitonMisimpracticalsinceMmaybemovedaround.Also,tostorethesensordataonM orNisimpracticalsincetheserviceshouldnotbedependentonMbeingpresent(receivingsensor dataviaWPAN/RFID)andsincestoringsensordataonNwouldrequireadatatransferwhenever Nchangesandthatmightnotbepossible(ordesirableforsecurityreasons).Finally,topresentthe expirationdateinCisnotmeaningful.Tosumup,inrealitytheactivitiesmayonlybeexecutedin thefollowinglocationsinthesystem:

Figure 2. Possible communication links between different parts of the service system, (W)WAN: (Wireless) Wide Area Network, WLAN: Wireless Local Area Network WPAN: Wireless Personal Area Network.

1. Measurementoflocalconditions:PorN 2. Sensordatastorage:P,CorR 3. RSLPcalculation:P,N,M,RorC 4. RSLPpresentation:P,N,M,orR TheresultingRSLPsareassumedtobestoredeitherwheretheyarecalculatedorwheretheyare tobepresentedinthesystem(ornotatall).TheRSLPcalculationisbasedoncurrentandhistorical sensordataandthissensordatamight,ontheotherhand,bestoredsomewhereapartfromwhereit iscollectedorused.Thereasonforstoringthisdatainathirdplacemightbetoavoidoverloading theproductlevelortoallowforthefixedlocaldevicetobechangedduringtransport.Depending onwherethesensordataisstored,ahigherlevelofintelligencemightberequiredbytheinvolved entities,aswellasadditionalcommunication. Theoptionslistedaboveresultsin120differentalternativearchitectures(2*5*4*3=120).We haveinvestigatedeachoneofthemwithrespecttoindividualcharacteristics,usefulnessfordifferent targetusergroups,communicationpathsandrequiredcapabilities(accordingtoJevingeretal.,2011). Thearchitecturescanbegroupedbasedonwheremeasurement,storageandcalculationare located.AllarchitectureswiththesamelocationsoftheseactivitiesonlydifferinwheretheRSLP ispresented,andtheymaythereforebecombinedtoprovideseveralmeansofaccessingtheRSLP. Forinstance,asolutionshowingtheRSLPinboththeRandMmightberequired(e.g.tosatisfy requirementsfromdriversandterminalworkersaswellascentralizedsupplychainmanagers), basedonarchitectureswiththesamelocationsoftheotherserviceactivities(measurement,storage andcalculation).Inthisstudy,weshowanapproachtohowtoprioritizethemostsuitablesolutions foroneofthetargetusergroups;however,thisapproachcanbeusedtoprioritizethesolutionsfor otherusergroupsaswell.Ifacombinationisrequiredasdescribed,thetopmostarchitectureswith thesamelocationsofmeasurement,storageandcalculationshouldbeselectedfromtheresulting prioritizedlistsofarchitectures.

Target User Group Requirements and Conceptual Filtering Principles

Differentusergroups,e.g.consumers,terminalworkers,truckdrivers,supplychainmanagers,product owners,etc.,requiredifferentalternativesforhowtheRSLPshouldbeaccessed.Thispaperfocuseson thesupplychainmanagersandproductowners,whichweassumeonlyhaveonerequirementonhow theywanttoreadtheRSLP,namelyinaremotedevice(R).Forinstance,theymightwanttheRSLP serviceintegratedwiththeirERPsystem.Ideally,allarchitecturesfulfillingthisrequirementshould beevaluatedwithrespecttothefunctionalandqualitypreferencesofthesupplychainmanagers/ productowners.Thiswouldmeanevaluating48architectures.Forotherusergroupsidentified,the setofarchitecturestoevaluatehasbeenshowntobe138andperforminganAHPonallofthese wouldrequireahugeamountofwork.Moreover,manyofthearchitecturesthatarepossiblefrom atheoreticalperspectivereflectsolutionsthatdonotseemreasonablefromapracticalperspective, suchascalculatingtheRSLPinMandshowingtheresultonP.Therefore,wehavedevelopedtwo principlesforfilteringouttheleastpromisingarchitectures,fromtheperspectiveofthesupplychain managers/productowners.Thelistofprinciplesmayhavetobeextendedforotherusergroups,though theprinciplesbelowshouldbeappliedforthoseaswell.

Conceptual Filtering Principle 1: If sensor data is stored on C/R and the RSLP is presented on R, the calculation should be co-located with the storage or the presentation.Thepurposeofthis

principleistoprioritizethesimplestsolutionsthatdonotinvolvesendinginformationbackandforth, inparticularfromthecentrallevel,tothelocallevel,andbackagain.Forinstance,architecturesstoring sensordatainR,usingP/Nforcalculation,andshowingtheresultingRSLPinR,areremoved.This principlefiltersoutthefollowingarchitectures(Measurement-Storage-Calculation-Presentation): P-C-P-R,N-C-P-R,P-C-N-R,N-C-N-R,P-C-M-R,N-C-M-R,P-R-M-R,N-R-M-R,P-R-C-R,N-R-C-R,P-R-N-R,N-R-N-R,P-R-P-R,N-R-P-R.

ConceptualFilteringPrinciple2:ArchitecturesshowingtheRSLPonRshallnotuseMfor calculation.Thesupplychainmanagers/productownersshouldnotbedependentonMforreceiving theRSLPsinceMismobileandisthereforenotguaranteedtoalwaysbepresent.Thisprinciplefilters outthefollowingarchitectures:P-P-M-R,N-P-M-R. Asaresult,14architecturecandidatesremainthathavenotbeenrejectedbytheprinciples.Thus, thefollowingAHPwillbebasedonthese.

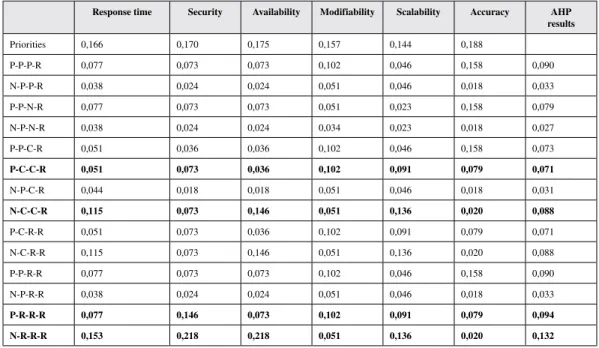

Analytical Hierarchical Process

AHPisanapproachtoevaluatinganumberofdifferentalternativeswithrespecttoseveralcriteria, andbasedonthis,selectthebestoption.Pairwisecomparisonsareusedtodevelopoverallpriorities reflectingtheimportanceofeachcriterion,relativetothegoaloftheselectionproblem.The performanceofeachalternativeoneachcriterionmustalsobedetermined,andtogetherwiththe prioritiesofthecriteria,arankingofthealternativescanbeproduced.Inthispaper,weuseAHPto ranktheremainingarchitecturecandidates.AHPhaspreviouslybeensuccessfullyusedforevaluating architecturecandidates(Svahnbergetal.,2003;Davidssonetal.,2006).Asafirststep,thesetof criteriamustbeidentified.Basedonalargesetofqualityattributesfoundinliterature(Offutt,2002; Barbaccietal.,1995;O’Brienetal.,2007;Larsson,2004;Clements,2001),incombinationwitha numberofRSLPservicerequirementsfromapreviousstudy(Jevingeretal.,2014),wehaveidentified thecriterialistedinTable1asrelevantfortheRSLPservice. ThesecondstepofAHPinvolvesprioritizingthecriteriaaccordingtheimportanceofeach criterion,inrelationtothegoaloftheselectionproblem.Eachcriterionispairwisecompared toallothercriteriawithrespecttohowdesiredtheyaretotheservicesystem.Inourcase,these comparisonswerebasedonthequestionnairesgiventoactorsoperatingindifferentpartsoftheFSC (seemethodologysection).Weonlyusedconsistentpriorities,andafterthepairwisecomparisons,the prioritieswerenormalizedtosumuptoone.ThequestionnaireresponsescanbefoundinAppendix 2,andtheresultingnormalizedprioritiesarelistedinthefirstrowofTable2. InthethirdstepofAHP,thearchitecturecandidatesarecomparedwithallothercandidates, withrespecttothecriteria.Thesecomparisonsarebasedonpairwiseassessmentsandasbefore, weusedconsistentpriorities,normalizedtosumuptoone.TheresultingsetsareshowninTable2, belowfirstrow. Inthefourthstep,therelativeimportanceofeachcriterioniscombinedwithhowwelleach architecturecandidatesatisfythecriteria,bymultiplyingthenormalizedprioritiesrelatedtothe architecturecandidateswiththenormalizedprioritiesofthecriteria.Theresultingproductsare thereaftersummedforeacharchitecturecandidateandthevaluesofthesesumsreflectthesuitability ofeachcandidate,inrelationtotheothercandidates.Thefinalvaluesforeacharchitecturecandidate arepresentedinthelastcolumnofTable2. Table2showsthat,withthisapproach,architectureN-R-R-RreceivesthehighestAHPscorefor thesupplychainmanagers/productowners,withrespecttoqualityandfunctionalityrequirements. ArchitectureP-R-R-Rissecondbest,whereasthetwosimilararchitecturesP-P-P-RandP-P-R-Rare regardedasthirdbest.Eventhoughtheaccuracyisconsideredasmostimportantandmeasurements onPhaveamuchhigheraccuracythanmeasurementsonN,architectureN-R-R-Rstillreceiveshigher priorityduetoitsotheradvantages,primarilyinresponsetime,securityandavailability.Hadthe accuracybeenconsideredasevenmoreimportantbythequestionnairerespondents,theprioritiesof thetwoarchitecturesmighthavebeenreversed. TakingintoconsiderationthecostsofeachsolutionaswellnaturallywouldchangetheAHP scores.Forinstance,architectureP-R-R-Rmostprobablyentailsahighercostthanarchitecture N-P-R-R,sincearchitectureP-R-R-RrequiressensorcapabilityonPwhereasarchitectureN-P-R-R maybeimplementedusingasimpleread/writepassiveRFIDtagonP.Implementingahighlevel ofintelligenceinproduct-leveldevicesisusuallyrelativelycostlysincethenumberofproductsis highinrelationtotheotherpotentiallocations,forinstancevehicles.Thus,theapproachpresented

Table 1. Criteria for AHP analysis

Criteria Meaning

Response

time Howlongittakestoprocessarequest(O’Brienetal.,2007).WedefineitasthetimeittakesfromaskingfortheRSLP,untilitisavailablefortheuser.SituationsinwhichtheRSLPcannotbeprovided atallarecoveredbyAvailability. Security Weconsiderintegrityandconfidentialityasthemostrelevantaspectsofsecurity.Integrityguarantees thatinformationisnotcorruptedandconfidentialityensuresthataccesstotheinformation/serviceis grantedonlytoauthorizedsubjects(O’Brienetal.,2007).Inourcontextintegritycorrespondstohow difficultitistomanipulatethesystemintoproducingnoorerroneousRSLPs,andconfidentialityto howdifficultitisforunauthorizeduserstoaccesstheRSLP. Availability Theproportionoftimeasystemorcomponentisoperationalandaccessible(O’Brienetal.,2007).In ourcontext,itismeasuredastheproportionofthetimetheserviceisoperationalduringitslifetime.We donotaddressphysicaldamageofequipment. Modifiability Theabilitytomakechangestoasystemquicklyandcost-effectively(Clementsetal.,2001).Inour context,itisameasureofhoweasyandcost-effectivelythesoftware(dateestimationalgorithms, softwarefunctionalityetc.)andthehardwarecomponents(tags,readers,displaysetc.)oftheservicecan beexchanged. Scalability Theabilityofthesystemtofunctionwellwhenthesystemischangedinsizeorinvolumeinorderto meetusers’needs(O’Brienetal.,2007).Inourcontext,itconcernshowwelltheservicesystemisable tohandleagrowingnumberofproductsorlongertransportdistances. Accuracy Theprecisionofcomputationsandcontrol(Larsson,2004).Inourcontext,itconcernshowwellthe RSLPapproximatestheactualremainingshelflife,includingthereliabilityofthesensordata.

Table 2. Priorities derived from questionnaires and comparisons between the architecture candidates with respect to the criteria as well as the final results of the AHP analysis

Response time Security Availability Modifiability Scalability Accuracy AHP results Priorities 0,166 0,170 0,175 0,157 0,144 0,188 P-P-P-R 0,077 0,073 0,073 0,102 0,046 0,158 0,090 N-P-P-R 0,038 0,024 0,024 0,051 0,046 0,018 0,033 P-P-N-R 0,077 0,073 0,073 0,051 0,023 0,158 0,079 N-P-N-R 0,038 0,024 0,024 0,034 0,023 0,018 0,027 P-P-C-R 0,051 0,036 0,036 0,102 0,046 0,158 0,073 P-C-C-R 0,051 0,073 0,036 0,102 0,091 0,079 0,071 N-P-C-R 0,044 0,018 0,018 0,051 0,046 0,018 0,031 N-C-C-R 0,115 0,073 0,146 0,051 0,136 0,020 0,088 P-C-R-R 0,051 0,073 0,036 0,102 0,091 0,079 0,071 N-C-R-R 0,115 0,073 0,146 0,051 0,136 0,020 0,088 P-P-R-R 0,077 0,073 0,073 0,102 0,046 0,158 0,090 N-P-R-R 0,038 0,024 0,024 0,051 0,046 0,018 0,033 P-R-R-R 0,077 0,146 0,073 0,102 0,091 0,079 0,094 N-R-R-R 0,153 0,218 0,218 0,051 0,136 0,020 0,132

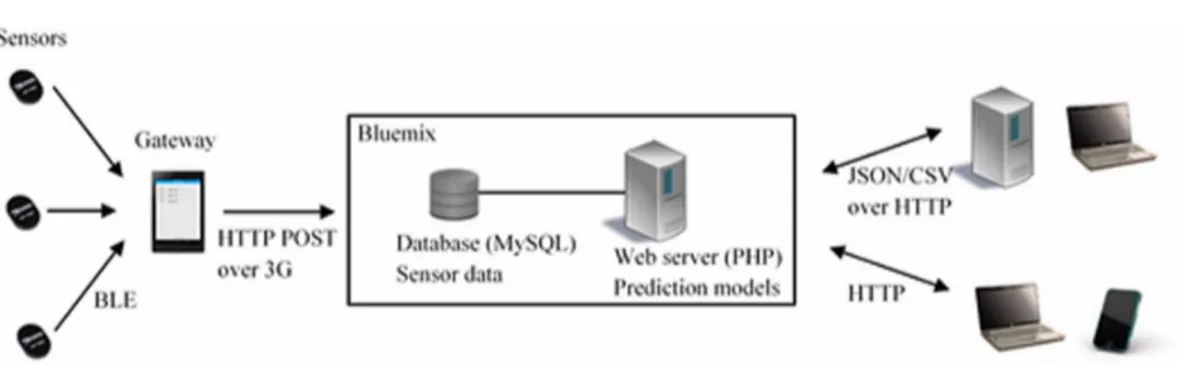

inthispapershouldprimarilybeusedforprioritizingthearchitecturesfromafunctionalandquality perspectiveandbasedontheseresults,incombinationwiththecostsofeacharchitecturecandidate, themostsuitablesolutioncanfinallybeselected. Proof of Concept AccordingtoTable2,thefollowingarchitecturesreceivedthehighestAHPscores:P-P-P-R,P-P-N-R,P-P-C-R,P-C-C-R,N-C-C-R,P-C-R-R,N-C-R-R,P-P-R-R,P-R-R-R,N-R-R-R.However,as mentionedabove,costshavenotyetbeenconsidered.Afterhavingsearchedthemarketforavailable sensorsandcorrespondingreaders,weconcludedthattemperaturesensorsusingBluetoothLow Energy(BLE)technologywouldincurthelowestcosts.Forinstance,RFIDreadersbothcovera smallerareaandaremoreexpensive.ThechoiceofusingBLEcausedsomerestrictionsonthe architectures,though.Ofthearchitectureswithhighestpriorities,P-P-P-R,P-P-N-R,P-P-C-R,P-P-R-R,P-C-R-RandN-C-R-R(writteninitalicsinTable2)werenotincludedinthecoldFSCtests, forthefollowingreasons: • Lettingtheproductlevelberesponsibleforbothmeasuringthetemperatureandstoringthedata, requiresasensorwithloggingcapabilities.However,wewereunabletofindBLEtemperature sensorswithloggingcapabilitiesonthemarket(withoutadditionaldevelopmentcostsincluded intheprize).Therefore,architecturesP-P-P-R,P-P-N-R,P-P-C-R,P-P-R-Rwereexcluded. • Ascanbeseen,thearchitecturesP-C-R-RandP-C-C-RreceivethesameAHPscoreinTable 2.Thus,fromafunctionalandqualityperspective,theseareequallywellsuited.Thesamegoes forarchitecturesN-C-R-RandN-C-C-R.Forpracticalreasons,wechoseonlytoimplement P-C-C-RandN-C-C-R. Insummary,thecoldFSCtestsincludedthearchitecturesP-C-C-R,N-C-C-R,P-R-R-R,N-R-R-R(writteninboldfaceinTable2). TheimplementationincludedBluetoothLowEnergytemperaturesensors(nRF51822,Nordic Semiconductor)measuringfoodproducttemperatures,smartphones(SonyXperia)actingasgateways, arelationaldatabasestoringalltemperaturedataandawebserverwithPHPsupport,whichcalculated anddistributedallresults.Thegatewayswereresponsibleforcollectingtemperaturesensordataand transmittingittothedatabase.Thedatawasthenusedbythewebservertocalculatetheremaining shelflivesoftheproductsinvolved,atanygiventime.ThecoldFSCtestsincludedthreedifferent producttypes:freshcod,smokedhamandcottagecheese.Differentproduct-specificmicrobiological predictionmodelswereimplementedforeachoftheproducttypes:Mataragasetal.(2006)forsmoked ham,Dalgaardetal.(1997)forfreshcodandØstergaardetal.(2014)forcottagecheese.Theselection ofthesemodelswasbasedonpreviousmicrobiologicalstudieswithintheprojectDynahmat(Dynamic shelflifeforminimisedfoodwaste(Dynahmat,2016)),aimingatidentifyingmodelswiththesmallest biasandhighestaccuracyfactor,inrelationtomeasuredbacterialevels.AllFSCteststookplacein thesouthernandmiddlepartsofSweden,andwerecarriedoutbetween2014and2016,aspartofthe Dynahmatproject.BoththedatabaseandthewebserverweredeployedatanIBMplatformcalled Bluemix.Figure3showsthesystemsetup. ThecommunicationbetweenthegatewayandthedatabasewasbasedontheHTTPPOST protocol,over3G.Theinformationprotocolwasdefinedaspartofthestudy,anditprimarilyincluded thefollowinginformation:IDofthesensor,IDofthegateway,measuredtemperature,timeofthe measurement,andlocationofthegatewayatthetimeofmeasurement.Thelastinformationentitywas usedfortrackandtracepurposes,e.g.whentemperaturewasbeloworaboverecommendedlimits. TheapplicationformedbythedatabaseandthePHPscriptsenablesuserstocreaterepresentations ofcoldFSCs.Theproducttypeconnectedtoasensorisspecifiedintheuserinterface,whenthe sensorisassociatedwithaspecifictest.Theproducttypedetermineswhichpredictionmodelis used.Moreover,sincetheinitialconcentrationoftargetbacteriahasastronginfluenceontheshelf

lifeofaproduct,thisalsohastobespecifiedbytheuser.Sincewehavenoinformationaboutfuture temperatures,twodifferentversionsoftheRSLParepresentedbythesystem:onebasedonthe assumptionthattheproducttemperatureiskeptatthehighestrecommendedtemperatureinthe future,andonebasedontheassumptionthattheproducttemperatureremainsthesameasthecurrent temperature. AnimportantinsightgainedfromthecoldFSCtestswasthatthesensorsacquiredfromretailers wererarelycorrectlycalibrated,whichcauseddiscrepanciesbetweentheactualtemperaturesandthe measuredtemperatures.Therefore,weinvestigatedthecalibrationofeachofthesensorsinathermal incubator.Asaresult,alinearequation(y kx m= + ,whereyrepresentstheactualtemperatureand xrepresentsthemeasuredtemperature),hadtobeusedtocompensatefortheerror.Thecoefficient (k)andtheconstant(m)foreachsensorwereidentifiedbythethermalincubatortests,andthen insertedintothesystemviatheuserinterface.Weinvestigatedthecalibrationofmorethan100 sensors.However,foracommercialsolution,thiswillmostprobablynotbeaviableapproach. AccordingtotherequirementsonanRSLPservice,thegeneratedinformationshouldbereported directlyintotheERPsystems.Tosatisfythisrequirement,theimplementedsystemallowsfordata retrievalviaanAPI.ThedefaultresponseformatisJSONoverHTTPbutthedatacanalsobefetched asCSVoverHTTP(seeFigure3).Thefollowingdatamayberetrieved: • Sensordataasreceivedfromthegateways(rawdata) • Actualtemperaturedata(calibratedasdescribedabove) • Predictiondata Thepredictionmodelsusedinthetests(forfreshcod,smokedhamandcottagecheese)share somesimilarities,whichledtoanimplementationwherethepredictionmodelsinheritfromageneric predictionmodel.Thesharedfunctionalitywasdefinedinthegenericmodel,whereasspecificsand differenceswerehandledbyextendingandoverridingthegenericmodel,inthespecificmodel. However,initspresentform,whenevernewpredictionmodelsneedtobeadded,thesoftwaremust bealtered.Toovercomethisproblem,themicrobiologicalmodelsshouldbeparameterized,sothat whenperishableswithnewpredictionmodelsaretobeaddedtothesystem,thesemodelscanbe specifiedviatheuserinterface. Theimplementedarchitectures,i.e.P-C-C-R,N-C-C-R,P-R-R-RandN-R-R-R,differinsensor locationaswelldatastorageandcalculationlocation.Thedifferencesinsensorlocationhadno effectonourimplementation,exceptforthenumberofsensorsrequired.Moreover,asshownby Göranssonetal.(2018b),thedifferentsensorlocationsprobablyhavelittleeffectontheaccuracyof theshelf-lifepredictions.Thedifferencesindatastorageandcalculationlocationprimarilyaffected thesecurity.WhenimplementedinC,wehadlesscontroloverthesecurity,buthadtorelyonsome oftheservicesprovidedbyBluemix.

DISCUSSION AND CONCLUSION WehaveshownanovelapproachtohowtoidentifythemostsuitablesystemarchitecturesofanRSLP service.Aspartofthisapproach,wehavedevelopedasystemarchitecturerepresentationmodel, whichcharacterizesarchitecturesbasedonwherethedifferentactivitiesinvolvedintheserviceare performed.Theprimaryadvantagewiththismodelisthatallpossiblearchitecturescanbeidentified andevaluated.Thereafter,wehaveusedusergroupspecificrequirementsandtwoconceptualfiltering principlestoidentifyandremovearchitecturecandidatesthatdonotfulfillthegeneralrequirementson thefinalsolution.TheremainingsetofcandidateshasbeenevaluatedinanAHPbasedonanumber ofqualitycriteria,andtheresultsarepresentedasalistofprioritiesofthecandidates. Furthermore,wehaveillustratedthenovelapproachtoidentifythemostsuitablesystem architectures,byapplyingitfortwoparticularusergroups,thesupplychainmanagersandproduct owners.Thisworkresultedinalistofthemosthighlyrankedarchitectures.Someofthesewerethen implementedandtestedincoldFSCs.Thesetestsprovedthataworkingsolutionofthistypeofservice canbeimplementedusingthetechnologyavailabletoday.Thetestsalsovalidatedthatthemethod developedcanbeusedtofindasolutionthatcanbeimplementedandused.Theimplementedsolution isgenericinthesensethatitworksfordifferenttypesofsensorsandfoodproducts. Thesetestsincludedsoftwarethatprovidedshelf-lifedatabasedonproduct-specificprediction models.Inourimplementation,thesemodelswereincorporatedwiththesystem.However,depending onthebusinessmodelbehindtheRSLPservice,theremaybeotheralternativestothis.Forinstance, thepredictionmodelsmayresidewithineachFSCactor’sowninformationsystem.Thismeansthat theactorwouldberesponsibleforproducingthepredictiondatabasedonthesensordata,whichis retrievedfromthesystemviatheAPIs.AnotheralternativewouldbetolettheFSCactorsdefineand formalizethepredictionmodelswithineachactor’sdomain,andthencommunicatetheminawaythat allowsthesystemtousethem.Thiswouldrequireadefinedamessagingformatforcommunications betweenthesystemandtheactors.AconventionalformatforsuchtasksisXML. Ourimplementationincludedagatewaycommunicatingsensordatafromtheproducts,tothe centraldatabase.Onealternativetothiswouldbetolettheproductscommunicatedirectlywiththe database,byusingalow-powerwide-areanetworkprotocol,e.g.NB-IoTorLoRa.Naturally,these communicationtechnologiescanalsobeusedforanyfixedlocaldevices. Accordingtothesystemrequirementsidentifiedinapreviousstudy(Jevingeretal.,2014),the solutionshouldpreferablebeintegratedwiththefoodproducersystemsusedtoday.Thismeansthat theRSLPserviceshouldaddaslittleextraworkaspossible,forinstance,aroundsensorinstallations. Thereisnoneedforhavingsensorsateveryfoodproduct,though.Göranssonetal.(2018b)emphasize theimportanceofcontinuoustemperaturemonitoringalongtheentirecoldfoodsupplychains. However,theyshowthattemperaturesensorsusedforcalculatingthepredictedshelflifeofaproduct, canbeplacedrelativelyfarfromtheproductitself(e.g.onthesecondarypackageorevenonthe pallet)withoutjeopardizingthereliabilityoftheresultingshelf-lifeprediction. BuildingupaninfrastructureforanRSLPservicemayenableotherservicesaswell,e.g. temperaturecontrol,dynamicpricing,andtrackandtrace.Inparticular,theactorsparticipatinginour studieshaveexpressedspecificinterestsforacommonandreliablewayoftemperaturemeasurements alongtheFSC.However,anRSLPservicealsoraisesmanyquestionsintermsofthebusinessmodel. Forasuccessfulimplementation,sensordataisrequiredfromtheentireFSC,whichmeansthatmany actorsmustbeinvolved.Someofthesegainmorefromtheservicethanothers.Whoshouldpayfor whatinvestments,andwhoownsthegenerateddata?Theseandmanyotherassociatedquestions needtobesortedout. FutureworkinvolvesimplementationoftheothersystemarchitecturesthatreceivedhighAHP scores,whichwouldenablefurthervalidation.Inparticular,quantitativeevaluationofdifferent architecturesinpracticalimplementationswouldbeuseful.Moreover,furtherstudiesonhowan RSLPservicewouldaffectthebehaviorsofconsumersandsupplychainactorsareneeded,aswell asinvestigationsrelatedtotheuserinterfacedesign.

ACKNOwLeDGMeNT

Partsoftheworkpresentedinthispaperhasbeenconductedwithintheinterdisciplinaryproject Dynahmat,fundedbytheTvärLivsprogrammemanagedbyVINNOVA(SwedishGovernmental AgencyforInnovationSystems).

ReFeReNCeS

Barbacci,M.,Longstaff,T.A.,&Weinstock,C.B.(1995).Quality Attributes.CarnegieMellonUniversity. Bartels,P.V.,Tromp,S.O.,Rijgersberg,H.,&Kreft,F.(2010).Improvementofsustainabilityintheperishable foodsupplychainbyusingcommunicativepackagingdevices.InTowards Effective Food Chains: Models and

Applications(pp.275-291).

Bhushan,N.,&Gummaraju,K.(2002).APetrinetbasedsimulationapproachforevaluatingbenefitsof timetemperatureindicatorandwirelesstechnologiesinperishablegoodsretailmanagement.InThe Second

International Conference on Simulation and Modeling in the Food and Bio-Industry (FOODSIM’2002).

Bijwaard,D.J.,vanKleunen,W.A.,Havinga,P.J.,Kleiboer,L.,&Bijl,M.J.(2011).Industry:Usingdynamic WSNsinsmartlogisticsforfruitsandpharmacy.InThe 9th ACM Conference on Embedded Networked Sensor

Systems.

Clements,P.,Kazman,R.,&Klein,M.(2003).Evaluating software architectures.Beijing:TsinghuaUniversity Press.

Dalgaard,P.,Mejlholm,O.,&Huss,H.H.(1997).Applicationofaniterativeapproachfordevelopmentofa microbialmodelpredictingtheshelf-lifeofpackedfish.International Journal of Food Microbiology,38(2), 169–179.doi:10.1016/S0168-1605(97)00101-3PMID:9506282 Davidsson,P.,Johansson,S.,&Svahnberg,M.(2006).UsingtheAnalyticHierarchyProcessforEvaluating Multi-AgentSystemArchitectureCandidates.InJ.Müller&F.Zambonelli(Eds.),Agent-Oriented Software Engineering VI(pp.205–217).Berlin,Germany:Springer.doi:10.1007/11752660_16 Dobon,A.,Cordero,P.,Kreft,F.,Østergaard,S.R.,Robertsson,M.,Smolander,M.,&Hortal,M.(2011).The sustainabilityofcommunicativepackagingconceptsinthefoodsupplychain.Acasestudy:Part1.Lifecycle assessment.The International Journal of Life Cycle Assessment,16(2),168–177.doi:10.1007/s11367-011-0257-y Dynahmat.(2016).Report:Insightsandlearningsfromthechallenge-driveninnovationprojectDynahMat. Retrievedfromhttp://dynahmat.com Göransson,M.,Jevinger,A.,&Nilsson,J.(2018b).Shelf-lifevariationsinpalletunitloadsduringperishable foodsupplychaindistribution.Food Control,84,554–560.doi:10.1016/j.foodcont.2017.08.027 Göransson,M.,Nilsson,F.,&Jevinger,Å.(2018a).Temperatureperformanceandfoodshelf-lifeaccuracy incoldfoodsupplychains–Insightsfrommultiplefieldstudies.Food Control,86,332–341.doi:10.1016/j. foodcont.2017.10.029 Gustavsson,J.,Cederberg,C.,Sonesson,U.,vanOtterdijk,R.,&Meybeck,A.(2011).Globalfoodlossesand foodwaste.Foodandagricultureorganizationoftheunitednations,Rome. Hafliðason,T.,Ólafsdóttir,G.,Bogason,S.,&Stefánsson,G.(2012).Criteriafortemperaturealertsincod supplychains.International Journal of Physical Distribution & Logistics Management,42(4),355–371. doi:10.1108/09600031211231335

Heising,J.K.,Dekker,M.,Bartels,P.V.,&vanBoekel,M.A.J.S.(2014).Monitoringthequalityofperishable foods:Opportunitiesforintelligentpackaging.Critical Reviews in Food Science and Nutrition,54(5),645–654. doi:10.1080/10408398.2011.600477PMID:24261537

Hevner,A.R.,March,S.T.,Park,J.,&Ram,S.(2004).DesignScienceinInformationSystemsResearch.

Management Information Systems Quarterly,28(1),75–105.doi:10.2307/25148625

Jedermann,R.,Poetsch,T.,&Lang,W.(2014).Smartsensorsfortheintelligentcontainer.InIEEE 2014 European

Conference on Smart Objects, Systems and Technologies (Smart SysTech).IEEE.

Jedermann,R.,Ruiz-Garcia,L.,&Lang,W.(2009).Spatialtemperatureprofilingbysemi-passiveRFIDloggers forperishablefoodtransportation.Computers and Electronics in Agriculture,65(2),145–154.doi:10.1016/j. compag.2008.08.006

Jevinger,Å.,Davidsson,P.,&Persson,J.A.(2011).Aframeworkforagent-basedmodelingofintelligentgoods. InAgents in Principle, Agents in Practice(pp.97-112).Berlin,Germany:Springer.

Jevinger,Å.,Göransson,M.,&Båth,K.(2014).Afieldteststudyonadynamicshelflifeserviceforperishables. In26th Conference of the Nordic Logistics Research Network (NOFOMA).

Jol,S.,Kassianenko,A.,Wszol,K.,&Oggel,J.(2006).IssuesinTimeandTemperatureAbuseofRefrigerated Foods.Food Safety,11(6),30–32.

Larsson,M.(2004).Predicting quality attributes in component-based software systems[Dissertation].Mälardalen University.

Likar,K.,&Jevšnik,M.(2006).Coldchainmaintaininginfoodtrade.Food Control,17(2),108–113. doi:10.1016/j.foodcont.2004.09.009

López,T.S.,Ranasinghe,D.C.,Patkai,B.,&McFarlane,D.(2011).Taxonomy,technologyandapplications ofsmartobjects.Information Systems Frontiers,13(2),281–300.doi:10.1007/s10796-009-9218-4

Mataragas,M.,Drosinos,E.H.,Vaidanis,A.,&Metaxopoulos,I.(2006).Developmentofapredictivemodel forspoilageofcookedcuredmeatproductsanditsvalidationunderconstantanddynamictemperaturestorage conditions.Journal of Food Science,71(6),157–167.doi:10.1111/j.1750-3841.2006.00058.x

Meyer,G.G.,Främling,K.,&Holmström,J.(2009).Intelligentproducts–asurvey.Computers in Industry,

60(3),137–148.doi:10.1016/j.compind.2008.12.005

O’Brien,L.,Merson,P.,&Bass,L.(2007).Qualityattributesforservice-orientedarchitectures.InInternational

Workshop on Systems Development in SOA Environments.IEEEComputerSociety.

Offutt, J. (2002). Quality attributes of web software applications. IEEE Software, 19(2), 25–32. doi:10.1109/52.991329

Østergaard,N.B.,Eklöw,A.,&Dalgaard,P.(2014).Modellingtheeffectoflacticacidbacteriafromstarter-and aromacultureongrowthofListeriamonocytogenesincottagecheese.International Journal of Food Microbiology,

188,15–25.doi:10.1016/j.ijfoodmicro.2014.07.012PMID:25086348

Peffers,K.,Tuunanen,T.,Rothenberger,M.A.,&Chatterjee,S.(2007).Adesignscienceresearchmethodology forinformationsystemsresearch.Journal of Management Information Systems,24(3),45–77.doi:10.2753/ MIS0742-1222240302 Qi,L.,Xu,M.,Fu,Z.,Mira,T.,&Zhang,X.(2014).C2SLDS:AWSN-basedperishablefoodshelf-lifeprediction andLSFOstrategydecisionsupportsystemincoldchainlogistics.Food Control,38,19–29.doi:10.1016/j. foodcont.2013.09.023 Raab,V.,Bruckner,S.,Beierle,E.,Kampmann,Y.,Petersen,B.,&Kreyenschmidt,J.(2008).Genericmodelfor thepredictionofremainingshelflifeinsupportofcoldchainmanagementinporkandpoultrysupplychains.

Journal on Chain and Network Science,8(1),59–73.doi:10.3920/JCNS2008.x089

Ruiz-Garcia,L.,Barreiro,P.,Rodríguez-Bermejo,J.,&Robla,J.(2007).ReviewMonitoringtheintermodal, refrigeratedtransportoffruitusingsensornetworks.Spanish Journal of Agricultural Research,5(2),142–156. doi:10.5424/sjar/2007052-234

Saaty,R.W.(1987).Theanalytichierarchyprocess—whatitisandhowitisused.Mathematical Modelling,

9(3-5),161–176.doi:10.1016/0270-0255(87)90473-8

Saaty,T.L.(1980).The Analytic Hierarchy Process.NewYork:McGrawHill.

Sahin,E.,Babaï,M.Z.,Dallery,Y.,&Vaillant,R.(2007).Ensuringsupplychainsafetythroughtimetemperature integrators.International Journal of Logistics Management,18(1),102–124.doi:10.1108/09574090710748199 Scheer, F. P. (2006). Optimising supply chains using traceability systems. In I. Smith & A. Furness (Eds.), Improving traceability in food processing and distribution (pp. 52–64). Woodhead Publishing. doi:10.1533/9781845691233.1.52

Sciortino,R.,Micale,R.,Enea,M.,&LaScalia,G.(2016).AwebGIS-basedsystemforrealtimeshelflife prediction.Computers and Electronics in Agriculture,127,451–459.doi:10.1016/j.compag.2016.07.004

Svahnberg,M.,Wohlin,C.,Lundberg,L.,&Mattsson,M.(2003).Aquality-drivendecision-supportmethod foridentifyingsoftwarearchitecturecandidates.International Journal of Software Engineering and Knowledge

Engineering,13(05),547–573.doi:10.1142/S0218194003001421

Verdouw,C.N.,Wolfert,J.,Beulens,A.J.M.,&Rialland,A.(2016).Virtualizationoffoodsupplychainswith theinternetofthings.Journal of Food Engineering,176,128–136.doi:10.1016/j.jfoodeng.2015.11.009 Wang,J.,&Yue,H.(2017).Foodsafetypre-warningsystembasedondataminingforasustainablefoodsupply chain.Food Control,73,223–229.doi:10.1016/j.foodcont.2016.09.048

APPeNDIX 1 Pleaseprovidescoresfrom1to10,basedonimportance(10correspondingtoextremelyimportant and1notatallimportant) Responsetime:Wedefinetheresponsetimeasthetimeittakesfromaskingfortheexpirydate,till itisavailablefortheaskinguserorsystem.Longresponsetimescanbecausedby,forinstance,poor wirelesscoverage,overloads,ormanyandlongcommunicationpaths.Situationswheretheexpiry datecannotbetransmittedatallduetolackofwirelesscoverageareencompassedbytheAvailability criteria. Security:Securitycorrespondstohowdifficultitistomanipulatethesystemintoproducingnoor erroneousexpirydates,orhowdifficultitisforunauthorizeduserstoaccesstheexpirydate.Bad securitycanbecausedby,forinstance,communicationthroughnetworkscontrolledbyunauthorized actors,maliciousdisturbanceofwirelesscommunicationandbadlyprotectedlocalinformation,e.g. inRFIDtags. Availability:Availabilityismeasuredastheproportionoftotaltimetheserviceisoperationalin relationtotherequiredlifetimeoftheservice.Wearenotfocusedonimplementation-specificdetails like,forinstance,compatibilityissuesbetweenareaderandatagordevicesofpoorquality.Nordo weaddresstheriskofphysicaldamagelocallyplaceddevices(forinstanceRFIDtagsandsensors) areexposed.Lowavailabilitycanbecausedby,forinstance,lackofwirelesscoverage,overloads, architecturedesignorbatteriesrunningoutofpower. Modifiability:Modifiabilityisameasureofhoweasyandcost-effectivelythesoftware(dateestimation algorithms,softwarefunctionalityetc.)andthehardwarecomponents(tags,readers,displaysetc.) oftheservicecanbeexchanged.Badmodifiabilitycanbecausedby,forinstance,reusabletagsand sensorsthatmaybenecessarytoupdate,especiallyiftheylackconnectiontoacentralinformation system. Scalability:Scalabilityconcernshowwelltheservicesystemisabletohandleagrowingnumber ofproductsorlongertransportdistances.Asolutionmighthavelowscalabilitydueto,forinstance, localentitiesresponsibleforwirelesscommunicationorprocessingfromseveralproducts,orlocal entitiesstoringsensordataduringlong-distancetransports. Accuracy:Theaccuracyconcernshowwelltheestimatedexpirydateapproximatestheactualexpiry date.Forinstance,theclosertotheproductsthesensorisplaced,andthemoreoftenasensormeasures, themoreaccurateexpirydatecanbeobtained. APPeNDIX 2

Table 3. Questionnaire responses

Response time Security Availability Modifiability Scalability Accuracy

Foodproducer1 7 9 8 10 8 10 Foodproducer2 9 10 9 8 8 8 Foodproducer3 7 5 8 8 7 5 Foodproducer3 10 9 10 7 7 10 Supplychain manager 5 6 5 3 3 10 Sum 38 39 40 36 33 43 Normalized priorities 0,166 0,170 0,175 0,157 0,144 0,188

Åse Jevinger is a senior lecturer in Computer Science at Malmö University, Sweden. She received her PhD from Malmö University, in 2014. Her research is focused on different applications of the Internet of Things (IoT), mainly within healthcare, logistics and public transports. In particular, she is interested in system architectures, information flow and information needs in IoT-based systems. In 2015, Åse Jevinger was awarded “Thesis of the year” (2014) for her PhD thesis, at Malmö University. In addition to her research work, she is the director of research studies in computer science at Malmö University.

Paul Davidsson is Professor of Computer Science at Malmö University, Sweden. He received his Ph.D. in 1996 from Lund University, Sweden. Davidsson is currently the Director of the Internet of Things and People Research Centre. His research interests include agent technology, simulation, information systems, and artificial intelligence. Major application areas are transport systems, building automation, and energy systems. The results of this work have been reported in more than 200 peer-reviewed scientific articles published in international journals, conference proceedings, and books.