Relationships between Life Cycle

Assessment and Risk Assessment

– Potentials and Obstacles

Relationships between Life Cycle

Assessment and Risk Assessment

– Potentials and Obstacles

Karolina Flemström Raul Carlson Maria Erixon

Industrial Environmental Informatics (IMI), Chalmers University of Technology

E-post: natur@cm.se Postadress: CM Gruppen Box 110 93 161 11 Bromma Internet: www.naturvardsverket.se/bokhandeln NATURVÅRDSVERKET Tel: 08-698 10 00 (växel) Internet: www.naturvardsverket.se

Postadress: Naturvårdsverket,106 48 Stockholm ISBN 91-620-5379-5.pdf

ISSN 0282-7298

Elektronisk publikation

Foreword

There is a need for a collected and better knowledge of the environmental impacts of products. Access to credible, lifecycle-based knowledge and information is a key issue when deciding how products should be designed, used and handled when becoming waste. Relevant information is also important for purchasers, professionals as well as individuals. In order to obtain information, generating relevant data is crucial. However a more holistic view is needed in order to improve knowledge of the environmental impact from products, and to improve the dissemination of this knowledge.

A starting point with this report has been the fact that Life Cycle Assessment to a high degree lacks a chemical perspective. This report aims at giving support for the process of choosing an approach for combining Life Cycle Assessment (LCA) and Risk Assessment (RA). The authors’ perspective of the status of combining LCA and RA is therefore presented. Furthermore, the report intends to give basic information about the different methods of LCA and RA, identify related analysis methods and legal requirements that should be used etc. The reader of this report may either be LCA experts, RA experts or people working with environmental decision-making.

The report has been compiled by Karolina Flemström, IMI, Chalmers University of Technology, Maria Erixon, IMI, Chalmers University of Technology and

Raul Carlson, IMI, Chalmers University of Technology on behalf of the Swedish

Environmental Protection Agency. The authors have sole responsibility for the content of the report and it can therefore not be taken as the view of the Swedish Environmental Protection Agency.

The authors want to especially thank the persons who have contributed to the result of this study; Stellan Fischer, Swedish Chemicals Inspectorate, Klas Hallberg, Akzo Nobel Surface Chemistry, Sandra Häggström, IMI, Chalmers University of Technology, Ida Johansson, Henkel Technologies Norden AB (former Loctite Sweden AB), Ylva Larsson, Bombardier Transportation, Sverker Molander, ESA, Chalmers University of Technology Bo Nyström, Swedish Chemicals Inspectorate, Ylva Reinhard, Swedish Environmental Protection Agency, Karin Sanne, Akzo Nobel Surface Chemistry, Guido Sonnemann, UN Environment Programme (former URV Tarragona, Spain), and Johan Tivander, IMI, Chalmers University of Technology.

Stockholm, February 2004

Contents

Foreword... 3

Summary... 7

1. Introduction ... 9

1.1 The goal and scope of the study, and method used... 9

1.2 Reading instructions... 10

2 Abbreviations and explanations of concepts... 11

3 Introduction to the area ... 15

3.1 Introduction to Risk Assessment... 15

3.1.1 General description ... 15

3.1.2 Goal and scope... 16

3.1.3 Concepts... 17

3.2 Introduction to Life Cycle Assessment ... 19

3.2.1 General description ... 19

3.2.2 Goal and scope... 20

3.2.3 Concepts... 21

3.3 Relation between Risk Assessment and Life Cycle Assessment ... 23

3.3.1 Similarities between Life Cycle Assessment and Risk Assessment ... 25

3.3.2 Differences between Life Cycle Assessment and Risk Assessment ... 26

3.3.3 Conflicting results of Life Cycle Assessment and Environmental Risk Assessment... 27

3.3.4 Potential difference in data quality and data acquisition... 28

3.3.5 Interface between Life Cycle Assessment and Risk Assessment ... 29

4 Methods used in Risk Assessment and Life Cycle Assessment... 33

4.1 Analysis methods ... 33

4.1.1 Analysis methods for Life Cycle Assessment... 33

4.1.2 Life Cycle Impact Assessment models ... 33

4.1.3 Comparison of different methodologies for toxicological characterization used in Life Cycle Assessment... 36

4.1.4 Analysis methods for Risk Assessment ... 44

4.1.5 Analysis methods for Life Cycle Assessment/Risk Assessment ... 47

4.2 Reporting formats ... 48

4.2.1 Reporting formats used in Life Cycle Assessment ... 48

4.2.2 Reporting formats used in Risk Assessment... 48

4.2.3 Reporting formats used for Life Cycle Assessment/Risk Assessment ... 50

4.2.4 Legal reporting requirements ... 50

4.3 International and industrial standards for Life Cycle Assessment and Risk Assessment... 50

4.3.1 International and industrial standards for LCA... 50

4.3.3 International and industrial standards for a combination of

Life Cycle Assessment and Risk Assessment... 51

5 Advantages with a combination of Risk Assessment and Life Cycle Assessment... 53

5.1 Practical use of Life Cycle Assessment and Risk Assessment ... 53

5.2 Need for a combination of Life Cycle Assessment and Risk Assessment... 54

5.3 Practical and economical advantages with a combination of Life Cycle Assessment and Risk Assessment... 56

5.4 Relation to Registration, Evaluation and Authorization of Chemicals (REACH) ... 56

6 Organizational perspective of Life cycle assessment and Risk assessment ... 57

6.1 Organisational requirements ... 57

6.1.1 Legal requirements... 57

6.1.2 Life Cycle Assessment and Risk Assessment within OECD... 58

6.1.3 Life Cycle Assessment and Risk Assessment within UNEP ... 58

6.1.4 Life Cycle Assessment and Risk Assessment in EU chemical regulation... 59

6.1.5 Communication requirements ... 61

6.1.6 Reporting requirements... 61

6.1.7 Review requirements... 61

7 Ongoing work in the Life Cycle Assessment and Risk Assessment area ... 63

7.1 Organizations with Life Cycle Assessment and Risk Assessment issues on their agenda today ... 63

7.2 New and ongoing projects in the area ... 63

7.2.1 The OMNIITOX project ... 64

7.2.2 The DANTES project... 67

7.2.3 The ExternE project ... 67

7.2.4 The book ‘Integrated Life-Cycle and risk assessment for industrial processes’.. 68

8 Discussion and conclusions ... 71

8.1 Recommendations for future work in this area ... 73

Summary

The aim of this report has been to describe and clarify the roles and information from each of the tools Life Cycle Assessment (LCA) and Risk Assessment (RA) to find possible alternative ways for combining them. The information of the two tools is compiled from literature studies and interviews with companies having LCA, RA or both on their agenda. The term risk assessment is mainly referred to environmental and human risk assessment as defined in the Technical Guidance Document for RA (TGD) within the European Union. LCA is mainly referred to life cycle assessment as described in the international standards ISO 14040 series.

LCA and RA are two approaches often used separately for quantifying potential effects of products. Recent studies have however revealed inconsistencies between the results from the two methods. These differences need to be understood, explained and methods eventually improved.

The most common approach of combining LCA and RA is to include ecotoxicological and toxicological parameters in life cycle impact assessment (LCIA) used in a LCA, which has been performed in a number of well known impact assessment methods. However, there are other alternative approaches but there is also a gap of knowledge, information and coordination identified in the study resulting in this report.

Advantages and difficulties of the different approaches of combining them have also been discussed. There are many advantages with an integrated approach both environ-mentally, practically and economically e.g. regulatory risk assessment and the impact assessment part of LCA, use the same type of inherent properties data for the assessment of toxic impacts.

For the purpose of chemical risk management and decision-making, risk assessment and life cycle assessment of products are indispensable tools. However, a more holistic approach for chemical management and a harmonisation of the approach of LCA and RA is needed. A common approach where neither tool is excluded and without the loss of their individual advantages is proposed.

This report has been funded by the Swedish Environmental Protection Agency (EPA) and written by Industrial Environmental Informatics (IMI), a unit at Chalmers University of Technology.

1 Introduction

To handle the environmental impact of products and chemicals in the society i.e. to reduce the environmental impact of products during their whole life cycle and to avoid and reduce hazardous effects of different chemical substances on human health and the environment, the following well-known methods are needed: Life Cycle Assessment (LCA) and Risk Assessment (RA).

LCA focuses on the product area and RA on the chemical area in terms of toxicology and ecotoxicology. Current risk assessment methodology of chemicals for regulatory use, focus on exposure as well as ecotoxicological and toxicological effects of the specific compound under study, while impacts such as energy consumption, use of natural resources etc. covered by the LCA-approach are not taken into account. Furthermore, toxicology and ecotoxicology is often not used as impact categories1 when performing an

LCA study.

1.1 The goal and scope of the study, and method used

The aim of this report has been to describe and clarify the roles and information from each of the tools Life Cycle Assessment (LCA) and Risk Assessment (RA) to find the possible or probable alternative ways for combining them. Advantages and difficulties of the different approaches of combining them have also been discussed.The definition of risk assessment used in the European Union is considered in this report i.e. regulatory risk assessment described in the Technical Guidance Document, based on the Directive 93/67/EEC and the Regulation 1488/94.

This report considers risk assessment and LCA in the European Union in particular. However, OECD guidelines are also included but focus has been on Europe. United States, Asia and other possible relevant geographical, economical and political areas are not included. It should be noted that the use of RA in the United States differ from the use and regulations in Europe. A comparison can be found in a master thesis work made by Suleiman M. Mohamoud, Chalmers University of Technology, Ecological (Environ-mental) Risk assessment in the United States and the European Union, 1997.

The focus of this report for risk assessment, are RA of voluntarily produced chemicals and therefore voluntary emissions due to industrial processes like incinerators, transports etc are not emphasized in the discussions. Furthermore, the aspect of risk related to accidents is not included in this report.

The term LCA is referring to Life Cycle Assessment as described in the international standard ISO 14040 series. However, while considering the relationships between the tools of LCA and RA, LCA has sometimes been viewed from a broader perspective than what is described in these ISO-texts.

1 An impact category is according to ISO 14042:2000 a class representing environmental issues of concern to

The main methods used to meet the goals of this report have been literature studies and interviews of persons from manufacturing companies, academia and authorities. The companies represented different industries like chemical manufacturing, transportation and consumer products manufacturing. The name of all interviewed persons can be found in the foreword of the report.

1.2 Reading instructions

This report should be read as an introduction to the area of combining life cycle

assessment and risk assessment. The intended readers of the report are persons working with LCA and/or RA and also decision-makers interested in a potential integrated approach of using LCA and RA. It is provided that the reader has basic knowledge about the two methods/tools LCA and RA. The first section of the report gives a general description and for further reading, the reader is referred to the literature.

All abbreviations used in the report are summarised in a separate list to facilitate for the user. Crucial concepts described and discussed in the report are also included in the list to give the reader an overview. When a thorough description of a concept is out of the scope of the report the reader is referred to a literature reference where more information can be found.

This report is divided into five major sections:

1. Introduction of the area with description of LCA and RA and the relationship between them including description of basis concepts, discussion about differ-ences, similarities and interface between LCA and RA.

2. Method used in RA and LCA, including description of the used reporting for-mats, measuring methods and also different methods used in the LCA/RA ap-proach: toxicological characterisation used in LCA.

3. Advantages with a combination of RA and LCA based on interviews and litera-ture studies.

4. The organisational perspective is also presented including the connection to chemical legislation in EU, work performed within UNEP and OECD as well as legal requirements, reporting and review requirements of LCA and RA.

5. The ongoing work in the area of LCA and RA is described in terms of companies working with an integrated LCA/RA approach and ongoing projects in the area.

2 Abbreviations and

explanations of concepts

Characterization factor is a factor derived from a characterization model which isapplied to convert the assigned LCI results to the common unit of the category indicator. The common unit allows aggregation into category indicator result.

CPM Centre for Environmental Assessment of Product and Material Systems, a

competence centre at Chalmers University of Technology

CPP Chemical Product Policy

DALY Disability Adjusted Life Years, a category indictor used in life cycle impact

assessment

DANTES project Demonstrate and assess new tools for environmental sustainability,

project within the EU life programme.

Eco-indicator’99 a life cycle impact assessment method

EDIP Environmental Design of Industrial Products, a life cycle impact assessment

method.

EMS Environmental management system EPR Extended Producer responsibility

EPS Environmental priority strategies, a life cycle impact assessment method ERA Environmental risk assessment

ESD Emission scenario documents,

EUSES European Union system for the evaluation of substances

FU Functional unit, quantified performance of a product system for use as a

reference unit in a life cycle assessment

GPSD General Product Safety Directive

IA Inventory analysis

IMPACT 2002 IMPact Assessment of Chemical Toxics, version 2002, a life cycle

impact assessment method.

IPP Integrated product policy

IPPC Integrated Pollution Prevention and Control IRIS Integrated risk information system

IUCLID the International Uniform Chemical Information Database, Joint Research

Centre, European Chemicals Bureau, European Commission

LCA Life cycle assessment LCI Life cycle inventory

LCIA Life cycle impact assessment LCM life cycle management

LOEL Lowest observed effect level MC Monte Carlo, a simulation method NOAEL no observed adverse effect level NOEC no effect concentration

NOEL no observable effect level

ODP ozone depletion potential, a characterisation factor used in LCA

OMNIITOX project Operational Models aNd Information tools for Industrial

applica-tions of eco/TOXicological impact assessments, an EU-project within the Competitive Sustainable Growth Programme.

PAF Potentially Affected Fraction, a category indictor used in life cycle impact

assessment

PEC predicted environment concentration PM particulate matter

PNEC predicted no effect concentration

QSAR quantitative structure activity relationship, computer modelling to obtain data

about chemical substances

RA Risk assessment

REACH Registration, Evaluation and Authorisation of Chemicals SETAC Society of Environmental Toxicology and Chemistry SEA Socio-Economic Analysis

SPINE Sustainable Product Information Network for the Environment SPOLD Society for the Promotion of LCA Development

TGD Technical Guidance Document, risk assessment procedure described according to

EC regulation

UNEP United Nations Environmental Program

US-EPA United States Environmental Protection Agency WBCSD World Business Council of Sustainable Development WSSD World Summit on Sustainable Development

3 Introduction to the area

3.1 Introduction to Risk Assessment

3.1.1 General descriptionRisk assessment (RA) emerged in the US in the 1970s to address the concern for human health, and cancer in particular, and has since then evolved to include non-cancer concerns and also more general environmental concerns. Risk assessment has been adopted by other national governments and by e.g. EU and OECD.2 However, a number

of different subdivisions within risk assessment have been developed since the nineteen seventies. In this report, environmental risk assessment (ERA), also named ecological risk assessment and human (health) risk assessment (HRA) is considered. The definitions of ERA and HRA differ substantially from one source to another, mainly due to the wide range of approaches and meanings of terms used by different groups of experts and practitioners.

Other aspects of risk assessment like for example risk assessment for occupational health, civil protection and rescue services, illustrate the wide definition of the term. In many European countries the usefulness of the risk assessment procedures in developing e.g. the emergency preparedness at a local level is clearly recognised. In practice, though, most weight is given to the risk assessment work done in the field of industry, based on legislative obligations.3

Risk is commonly defined as ‘the combination of the probability, or frequency, of

occurrence of a defined hazard and the magnitude of the consequences of the occurrence.

Hazard is defined as “the potential to cause harm”4 The distinction between risk and

hazard can be illustrated by the following example: A large number of chemicals have hazardous properties and acids are one of them. Acids may be corrosive and/or irritant to humans. However an acid is only a risk to human health if humans are exposed to it. The degree of harm caused by the exposure depends on the specific exposure scenario.4

Therefore, if a human comes into contact with the diluted acid, the risk of harm may be minimal but the hazardous property of the acid will remain unchanged.5

Risk assessment is commonly defined as the scientific process in which the risks posed

by inherent hazards involved in the process or situations are estimated either quantita-tively or qualitaquantita-tively.4

2 Bruce Vigon, LCA News, vol.17, no. 5, 1997, Society of Environmental Toxicology and Chemistry

(SETAC), www.setac.org/septlca.html

3 Communication with Sverker Molander, Environmental System Analysis, Chalmers University of

Technology, 2003-12-09

4 Fairman, R., Mead C.D., Williams W.P., Environmental Risk Assessment: Approaches, Experiences and

Information Sources. Environmental Issues Series No. 4 – Copenhagen, European Environment Agency, 1998

5 Manuilova, A., Svensson, H., Methods and tools for Assessment of Environmental Risk, Akzo Nobel

Ecological risk assessment (ERA) evaluates the potential adverse effects that human

activities have on plants, lakes and animals etc, that make up ecosystems, and implicitly the co-operation and function of the eco-system itself. The risk assessment process provides a way to develop, organise, and present scientific information making it relevant for environmental decisions. Risk assessment results may also provide a basis for

comparing different management options, enabling decision-makers and the public to make better informed decisions about the management of ecological resources. ERA has become more commonly used in the industry as a result of the use of ERA in regulations. The uses of ERA in the industry are for example in compliance with legislation, product safety, site-specific decision making, prioritisation and evaluation of risk reduction measurements and financial planning.6

Human (health) risk assessment (HRA) evaluates the potential human health risks to

people that may now, or at some time in the future, be exposed to a certain chemical substance. HRA is a tiered process that progresses from the use of short-term tests (acute oral and dermal toxicity, skin and eye irritation, mutagenicity, sensitisation potential) and conservative assumptions to longer-term (chronic) tests paired with more realistic

assumptions.

Risk assessment is a system analytical tool to organise, structure and compile scientific information in order to help identify existing hazardous situations, anticipate potential problems, establish priorities and provide a basis for regulatory controls and/or corrective actions. It may also be used to help gauge the effectiveness of corrective measures or remedial actions. A key underlying principle of risk assessment is that some risks are tolerable – a reasonable and even sensible view, considering the fact that nothing is wholly safe. After a risk assessment study follows usually a risk management exercise study, in which decision are made on the allocation of limited resources. The risk assessment allows decision makers to receive relevant information about consequences of management activities, facilitates explicit identification of human health and

environmental values of concern and also identifies critical knowledge gaps, thereby helping to prioritise future research.7

In the European Union, the Council Regulation 793/93/EC foresees that the evaluation and control of the risks posed by existing chemicals will be carried out in four steps: Data collection, Priority setting, Risk assessment and finally, if there is a risk associated, the last step Risk reduction is applied. Risk assessment studies are prepared due to legal requirements and the results as well as data sources are reported to authorities.

3.1.2 Goal and scope

The purpose or goal of performing a risk assessment is to determine the risk posed by a chemical or a chemical product. The scope of the risk assessment described in this report, includes emissions and consequent environmental impact and human exposure at each

6 Fairman, R., C.D. Mead & W.P. Williams Environmental Risk Assessment: Approaches, Experiences and

Information Sources. Environmental Issues Series No. 4 – Copenhagen, European Environment Agency, 1998

7 Society of Environmental Toxicology and Chemistry (SETAC), Ecological Risk Assessment Technical

stage of the life cycle of a chemical substance. In risk assessment the life cycle for a chemical is defined as from production, through processing, formulation and use to recycling and final disposal. The term “life cycle” is not defined in the same way in RA and LCA, see section 3.2. The atmosphere, sediment and soil-dwelling organisms, aquatic organisms, micro-organisms in waste water treatment plants and birds and mammals exposed via accumulation in the food chain are included in the protection goals for the environment. For humans, exposure for all relevant sources are considered e.g. from consumer products, air, food, drinking water, exposure at the workplace etc. Ecological risks can be local, e.g. the risks from a hazardous waste site, but the risk may also be

regional or global e.g. atmospheric transport of chemicals. The aspects of risks due to

accidents are not included in this report and the risk on the local level due to emissions from industrial processes like refineries or incinerators are only briefly discussed.

The system scope of RA described here should be compared to the system scope of LCA, described in section 3.2, this is crucial for the comparison of the two methods.

3.1.3 Concepts

The risk assessment carried out under Regulation 793/938 is conducted following the

principles of the Regulation 1488/949 and following the detailed methodology laid down

in the Technical Guidance Document (TGD) on Risk Assessment for New and Existing Substances. The following actions are included in a risk assessment process to be used for both human (health) and environmental risk assessment, according to the above given regulations:

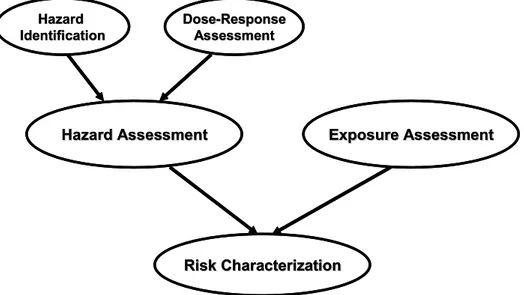

1. Assessments of effects (also called hazard assessment), comprising

a) Hazard identification: identification of the adverse effects which a substance has an inherent capacity to cause.

b) Dose (concentration) – response (effects) assessment: estimation of the rela-tionship between dose, or level of exposure to a substance, and the incidence and severity of an effect, where appropriate.

2. Exposure assessment, estimation of the concentrations or doses to which human populations or environmental compartments are or may be exposed.

8 Council Regulation (EEC) No 793/93 of 23 March 1993 on the evaluation and control of the risks of

existing substances.

9 Commission regulation (EC) No 1488/94 of 28 June 1994, laying down the principles for the assessment of

risks to man and the environment of existing substances in accordance with Council Regulation (EEC) No793/93

3.

Risk characterisation, estimations of the incidence and severity of the adverseeffects likely to occur in a human population or environmental compartment due to actual or predicted exposure of a substance, and may include “risk estima-tions”, i.e. the quantification of that probability.10 In the risk characterisation

haz-ard evaluation and the exposure assessment is combined to estimate the likeli-hood whether exposure will be sufficient for an effect or impact to occur.

Hazard Assessment

Hazard Assessment Exposure AssessmentExposure Assessment

Risk Characterization Risk Characterization Hazard Hazard Identification Identification Dose

Dose--ResponseResponse

Assessment

Assessment

Hazard Assessment

Hazard Assessment Exposure AssessmentExposure Assessment

Risk Characterization Risk Characterization Hazard Hazard Identification Identification Dose

Dose--ResponseResponse

Assessment

Assessment

Figure 1. Illustration of the Risk Assessment paradigm

An effect or hazard assessment are integrated and compared to an exposure assessment in completing a risk characterisation to ensure that the concentration of a substance released to the environment, the Predicted Environmental Concentration (PEC) remains below harmful concentration i.e. the Predicted No Effect Concentration (PNEC). The risk characterisation or risk quotient is therefore defined as the ratio between PEC and PNEC (PEC/PNEC).

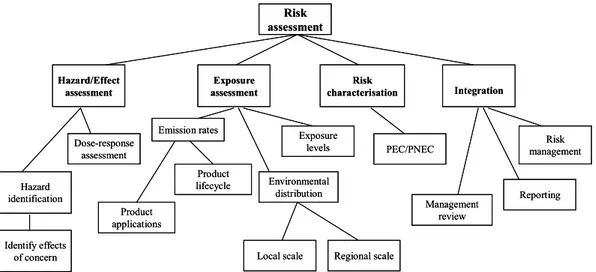

A more detailed picture of risk assessment can be given using a logic structure i.e. a breakdown of a method into conditions or parts that need to be fulfilled in order to complete the assessment. This figure can be compared to figure 5 illustrating a logical breakdown of LCA.

10 Technical Guidance Document in support of Commission Directive 93/67/EEC on Risk Assessment for

new notified substances, Commission Regulation (EC) No 1488/94 on Risk Assessment for existing substances and Directive 98/8/EC of the European Parliament and of the Council concerning the placing of biocidal products on the market. European Chemical Bureau, 2003:

Risk assessment Exposure assessment Hazard/Effect assessment Risk characterisation Hazard identification Dose-response assessment Emission rates Environmental distribution Exposure levels PEC/PNEC Identify effects of concern Reporting Risk management

Local scale Regional scale Product applications Product lifecycle Integration Management review Risk assessment Exposure assessment Hazard/Effect assessment Risk characterisation Hazard identification Dose-response assessment Emission rates Environmental distribution Exposure levels PEC/PNEC Identify effects of concern Reporting Risk management

Local scale Regional scale Product applications Product lifecycle Integration Management review

Figure 2. Example of Logic structure of risk assessment based on the framework set out in Commission Regulation (EC) 1488/94 and implemented in the detailed Technical Guidance Documents on Risk Assessment for New and Existing Substances.

The risk assessment procedure as described in the Technical Guidance Document (TGD)11, based on EU regulations aims at cover the whole life cycle of the considered

substance, the effects on all human populations and also fate and effects in all environ-mental compartments. The framework described in the TGD document is intended to assess the risks posed by one chemical substance to humans or the environment as required by Directive 92/32/EEC and Regulation 793/93. Risk Assessment according to the TGD regard one chemical substance over the whole life cycle i.e. in principle, all potential sources of emissions of the chemical substance are included throughout the life cycle. Synergistic effects or additive effects that may be caused by a combination of two or several substances are not considered. A risk assessment report should be made according to the guidelines in the TGD documents.

3.2 Introduction to Life Cycle Assessment

3.2.1 General descriptionLife Cycle Assessments were first made in the 1960s, aiming to optimise energy

consumption in a context where strong energy consumption represented a restraint for the industry i.e. costs. The scope of these energy analyses were then widen to include raw

11 Technical Guidance Document in support of Commission Directive 93/67/EEC on Risk Assessment for

new notified substances, Commission Regulation (EC) No 1488/94 on Risk Assessment for existing substances and Directive 98/8/EC of the European Parliament and of the Council concerning the placing of biocidal products on the market. European Chemical Bureau, 2003:

materials, emissions and waste. The development of LCA is described in the LCA literature where the history of LCA is frequently discussed.

The definition of LCA used in this report is based on the international standard ISO 14040 series where the ISO framework for LCA is presented. The definition of life cycle

assessment is “compilation and evaluation of the inputs, outputs, and the potential

environmental impact of a product system throughout its life cycle.”12

LCA is a method for analysing and assessing the environmental impact of a material, product or service throughout its entire life cycle. It is an environmental management tool which aims at identifying all resources used and also emissions and waste generated to air, ground and soil, over the whole life cycle of a specific service or product which is described in detail in section 3.2.2.

LCA can support decision making for future investments in e.g. a new product or production process development and understanding of where opportunities exist for overall system improvements. It can also be used to identify environmental “hot-spots” in the production process, to make policies and long term strategic planning for larger systems and also for product labelling in terms of environmental impact, identifying trade-offs across different operations or product/service options. Other potential uses of LCA could be in overall priority setting (including non-chemical products) of product groups within environmentally orientated integrated product policy and in standardization work related to products/processes releasing chemicals to the environment. Many LCA applications are often seen as part of the so-called Life Cycle Management toolbox.

3.2.2 Goal and scope

LCA have a system-wide or life-cycle stage perspective which differ form the life cycle perspective discussed for risk assessments, see section 3.1. In an LCA of a product, the products whole life cycle is considered i.e. upstream from raw material extraction and downstream to final waste disposal aspects are included. The life cycle phases in a technical system are raw material extraction, raw material production, transports,

manufacture of the product, use, recovery and/or scrapping of the product in the product’s end of life phase. For the emissions in the inventory analysis the focus for LCA is to take into account all emissions from “cradle to grave”. Furthermore, the emissions are related to a functional unit which usually is mass of product or associated to benefit and

performance of the technical system.

The effects of product or services considered in LCA are overall potential environ-mental impacts e.g. global warming, stratospheric ozone depletion, acidification, photochemical oxidant formation, toxicity and eutrophication, of all resources used and waste generated in a defined technical system.

The time perspective for LCA can be retrospective or prospective and the basis for comparison in LCA is the functional unit, which all inventory data is based on. A functional unit is according to the international standard ISO 14040:1997(E) defined as “quantified performance of a product system for use as a reference unit in a life cycle assessment”.

The goal and scope of each LCA analysis are often set and defined before the Life Cycle Inventory (LCI) is performed. However, they differ from case to case since there are no regulation that explicitly define what to include or exclude in an LCA analysis.

The system scope of LCA described here should be compared to the system scope of RA, described in section 3.1 because this is the basis for comparison between the two models.

3.2.3 Concepts

The ISO framework of LCA describes LCA as four compulsory phases. In the first phase, called the goal and scope definition (ISO 14041:1998), the purpose of the study and its scope is defined e.g. the system boundaries13 and functional unit is defined. The inventory

analysis (ISO 14041:1998) involves data collection and calculation procedures to

quantify relevant inputs and outputs of a product system. Furthermore, in the life cycle

impact assessment(LCIA) (ISO 14042:2000), the data that constitutes the results of the

inventory are associated with specific environmental impacts e.g. global warming, acidification and eutrophication, enabling evaluation of the significance of these potential impacts. Finally, in the life cycle interpretation (ISO 14043:2000) phase, the results from the inventory analysis and impact assessment are interpreted to meet the beforehand defined goals of the study. The overall principles and framework is described in the ISO 14040:1997 standard. Figure 3 illustrate the relationships between the different phases according to ISO 14040. Goal and scope definition Inventory analysis Impact assessment Interpretation Direct applications: - Product development and improvement - Strategic planning - Public policy making - Marketing

- Other

Copyright: ISO 1997, ISO 14040:1997(E)

Figure 3. Phases of an LCA according to ISO 14040:1997(E)

13 A system boundary is “a interface between a product system and the environment or other product

In the Life Cycle Inventory analyse, LCI data describes environmental relevant inputs and outputs of defined model of a technical system, see figure 4 below. The inputs and

outputs consist of matter and energy that is used in the technical system to fulfil a well-defined function of the system, expressed by the functional unit. For example, the technical system can be a production site where formaldehyde is produced. The function of the system can thus be defined as “production of formaldehyde”, and the functional unit as e.g. 1 kg formaldehyde. Examples of relevant inputs and outputs are raw

materials, natural resources, energyware, ancillary material, products, by-products, waste, emissions to water and air etc.14

Technical system Inputs Outputs Technical system Inputs Outputs

Figure 4. A model of a technical system (Flemström and Pålsson, 2003)14

The main steps made when performing a LCIA is classification – assignment of LCI results, characterization – calculation of category indicator results and finally, weighting which is an optional element defined as the process of converting indicator results of different impact categories by using numerical factors based on value-choices, it may also include aggregation of the weighted indicator results.15

The terms impact category, category indicator, characterisation factor and category

endpoint are central in life cycle impact assessments. An impact category e.g. global

warming is “a class representing environmental issues of concern to which LCI results may be assigned” and a category indictor e.g. Global Warming Potential (GWP) for each greenhouse gas (kg CO2-equivalent/kg gas), is “a quantifiable representation of an impact

category”. Furthermore, a characterization factor is “a factor derived from a characteriza-tion model which is applied to convert the assigned LCI results to the common unit of the category indicator. The common unit allows aggregation into category indicator result”. Finally, category endpoint e.g. forest, crops, coral reefs, is an “attribute or aspect of natural environment, human health or resources, identifying an environmental issue of

concern”

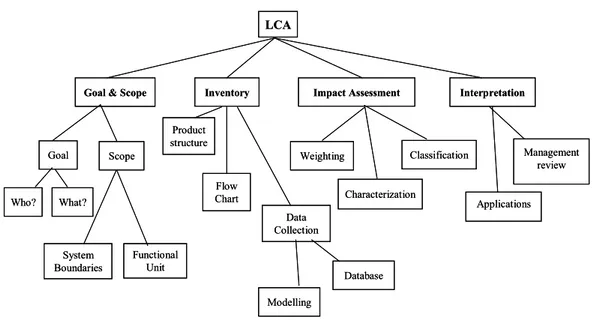

15Below a logic structuring of LCA, based on the framework structured in ISO 14001 and guidance in ISO 14004, is presented. A logic structure is a structured breakdown of a method or task into different parts or conditions required to fulfil the task. This figure can be compared to figure 2 illustrating a logical breakdown of RA.

14 Flemström K., Pålsson A-C., Introduction and guide to LCA data documentation using the CPM data

documentation criteria and the ISO/TS 14048 data documentation format, Chalmers University of Technology, CPM report 2003:3

LCA Inventory Who? Functional Unit Goal System Boundaries Database Data Collection Product structure Weighting Characterization Classification Scope What? Flow Chart Modelling Interpretation Goal & Scope Impact Assessment

Management review Applications LCA Inventory Who? Functional Unit Goal System Boundaries Database Data Collection Product structure Weighting Characterization Classification Scope What? Flow Chart Modelling Interpretation Goal & Scope Impact Assessment

Management review

Applications

Figure 5. Logical structure of LCA based on 14001 and 14004.

3.3 Relation between Risk Assessment and Life Cycle

Assessment

The similarities, differences and interfaces between the two methods LCA and RA are more complicated questions than what may intuitively be apprehended. Below is a comparison between the two methods focusing on the use of each method, scope and

results. This comparison is mainly based on literature studies and also the results from the

performed interviews. One conclusion is that there are different paths to go when

analysing the relation between LCA and RA, furthermore no explicit, clear conclusion of the ultimate combination or benefit between LCA and RA can be found in the literature.

Risk assessment and LCA are used to conduct inherently different types of analyses. Both purpose and perspective of the two methods are often different and the connections between them are not fully investigated in literature to date. When comparing risk assessment and LCA there are five different, alternative solutions or approaches; they could be seen as completely separated, overlapped i.e. there is an intersection between them, RA could be a subset of LCA, LCA could be a subset of RA and finally they could be seen as complementary tools where they both are needed to get the whole picture, illustrated with the dashed line in the figure below. When analysing the relationship between the two tools it is valuable to have a clear picture of these potential alternative ways of describing the relationship.

LCA LCA (E)RA LCA (E)RA (E)RA (E)RA LCA LCA (E)RA A Separated B Overlapped C (E)RA as a subset of LCA D LCA as a subset of (E)RA E Complementary tools

(©Flemström, Carlson, IMI, 2003)

16Figure 6. Alternative approaches of LCA and risk assessment in terms of simplified Venn diagrams.

Chemical substances can form part of a product’s life cycle in a number of different ways, for example the chemical substance can be the product itself, a by-product, a raw material, an emission formed during the production process, a sub-component of an inflow or outflow, waste etc. In figure 7 below this is illustrated. For each of the small arrows in the figure a risk assessment could be performed in terms of dose- response assessment and hazard identification for environmental and health effects, since these chemical substances may leach out from the identified system and reach humans in the surroundings and the environment.

End of life Disposal Identified system Chemical 1 Chemical 2 Chemical 3 Chemical 4 Chemical X

Raw materials Production Use

Product End of life Disposal Identified system Chemical 1 Chemical 2 Chemical 3 Chemical 4 Chemical X

Raw materials Production Use

Product

(©Flemström, Carlson, IMI, 2003)

16Figure 7. Illustration of a products life cycle in terms of chemicals.

3.3.1 Similarities between Life Cycle Assessment and Risk Assessment Both LCA and RA provide a way of structuring, presenting and evaluating information relevant to one or more environmental aspects of the decision making process. In

addition, both approaches, have a life cycle perspective; however they differ in the way of viewing the life cycle. The procedure of the RA covers the whole life cycle of a chemical product/substance since all potential sources of emissions of the product/substance should be included. However, if the chemical substance is formed to another substance during use it is not included and the life cycle chain stops. Another example is if the liberation of a bioaccumulative chemical to air is very slow, it is often not regarded. Even if it is two methods with life cycle perspective, it should be noted that RA according to the TGD focus on the total tonnage of one chemical substance, whereas LCA focus on the product and the systems functional unit.

It should be noted that chemical products/substances have the life cycle of production, use (often in other types of products) and disposal but there are also chemical substance that are not voluntarily produced as e.g. emissions of industrial processes like dioxins or particles, sometimes with heavy metals adsorbed. Their life cycle consist of emission, conversion i.e. no use at all, and disposal that then might cause impacts. This is usually called impact pathway and not life cycle.

The impact assessment part of LCA (LCIA) performs modelling of the potential impacts related to the provision of a product or service expressed in the functional unit of the technical system under study. RA on the other hand, according to the TGD and European methods, includes assessment of the risks related to emissions of single substances at local or regional scales. From these perspectives both methods make statements about potential or probability of effects.

One resemblance of the two methods is that risk assessment can assess local or re-gional effects on specific targets and LCA can consider both global and rere-gional impacts. Due to the weakness of LCA to assess local and regional effects and the strength of risk assessment to assess these impacts, different methods for site- or region-dependent impact assessments as part of LCIA have been proposed. These methods allow the assessment of actual impacts in LCA instead of potential impacts as usually done in LCIA.17

The difficulty with data availability and the high cost of acquiring data is also common for the two methods. The costs of performing both LCA and RA studies are also high according to the practitioners. Therefore systems should be established that allow easily use of the same data for both approaches. For instance, emission data for industrial processes can be used for risk assessment and in life cycle inventories. The same holds true for toxicity information usable in risk assessment and life cycle impact assessment.

3.3.2 Differences between Life Cycle Assessment and Risk Assessment There are two different systems in focus for LCA and RA respectively. From a systems

analysis perspective it is two different systems and two different ways of viewing them i.e. the systems analysis perspective differ for the methods. The scope and goal of the methods also differ as described in 3.1 and 3.2.

The raw data used in risk assessment comes from experiments or extrapolations. Experiments have well-defined surroundings e.g. in terms of measurement techniques, light, heat and type of fluid, and also well-defined inputs and outputs. The experiences form the laboratory is then approximated to a real environment. Regarding time, space and boundaries; time could be the same for LCA and RA, the definition of space is different since different systems are studied – the space for LCA is defined when the consequences are followed down or upstream and the space for RA is a downstream analysis until the consequences occur. The latter has not the problems with well defined system boundaries and limitations since all consequences should be found.

Both LCA and RA address distinct and different questions, compare the statement in Olsen et al 200118: “While the objective of an ERA is to guarantee the environmental

safety of a product by modelling the impact of the absolute quantities of an operation’s emission of toxic substances (more “receptor focused”), LCA address the objective to reduce the overall pressure on the environment of an entire product system from cradle to grave focusing on the product system’s total release of toxic substances (more “loading focus”)”. As described in 3.1 and 3.2, in LCA a products’ contribution to all types of environmental impacts are included, e.g. ozone-depletion, global warming, toxicity and eutrophication. However, in RA only toxicological and eco-toxicological impacts are regarded, which is one essential difference compared to LCA. A risk assessment does not cover all emissions from all processes involved in a specific technical system e.g.

transports and energy production, it only covers a part of the environmental impacts caused by a product. LCA on the contrary, attempt to cover all emissions (including intermediates), assess all potential environmental impacts and assess the average situation.19 In addition, LCAs are comparative in terms of e.g. alternative ways of

achieving a defined function, compared to risk assessments.

LCA focus on the emissions caused by the investigated product or service as specified in the defined functional unit, which usually is mass of product or associated to benefit and performance of the technical system. In RA on the contrary, emissions are expressed as concentrations e.g. mass of a product by volume in a specific environment. Further-more, LCA does not take into account the emissions caused by a specific substance due to other products or services, an assessment of the risks of the release of a specific chemical substance is therefore often not possible in LCA. However, site- or region-dependent

18 Olsen S.I., Christensen F. M., Hauschild, H., Pedersen, F., Larsen, H.F., Torslov, J., Life cycle impact

assessment and risk assessment of chemicals – a methodological comparison, Environmental Impact Assessment Review 21(2001) pp.385-404

19 Christensen F.M. and Olsen S.I., 2003, The potential role of Life Cycle Assessment in regulation of

chemicals in the European Union, abstract and presentation at SETAC Europe 13th Annual Meeting, April 2003, Hamburg, Germany

impact assessment, using in particular the category indicator Disability Adjusted Life Years (DALYs), allows quantifying risk for population since population density is part of the corresponding LCIA models used.

An important feature of LCA is the relative assessment caused by the use of a func-tional unit. Risk assessment on the other hand, requires very detailed and specific data and is an absolute assessment, which is able to predict the occurrences of adverse effects from chemicals. Furthermore RA is often performed as a “worst-case” analysis to ensure a safety distance to unwanted effect. Both tools are necessary because they fulfil different purposes and they can not substitute each other. Their role in the total environmental effort and decision making are complementary e.g. in reducing chemical pressure.

3.3.3 Conflicting results of Life Cycle Assessment and Environmental Risk Assessment

Analyzing the same product with LCA and ERA respectively, may in some cases give different or even contradictory results. At the Nordic workshop in Vedbaek, 1999 a LCA study and a parallel ERA study performed at Procter & Gamble on a detergent product was presented. The result of the studies indicated that the result from LCA and ERA differed. The focus for the ERA was release of detergents after waste water treatment and the focus for LCA was to take into account all emissions from “cradle to grave”. Of two products, the LCA study showed that for most of the inventory emission and impact categories, product A had a lower potential impact than product B. In the context of comparative analysis between A and B, the risk assessment indicated that product B was preferred due to higher level of comfort to risk manager. This study illustrated the need to use complementary tools in the context of environmental management of chemical products according to the authors E. Saouter and T. Feijtel.20

At other companies similar experiences exist. There have been attempts to combine LCA and ERA but difficulties have occurred when trying to link LCA and RA together. One reason for this has probably been the lack of functional unit in RA.

Sonnemann et al. 200321 present a comparison by the example of electricity generated

from coal and produced in the same way but in two different regions, in which obviously the combustion of coal is an important part of the life cycle:

• Case 1: In very populated and acidification-sensitive area next to the mining site. • Case 2: In purely populated and no acidification-sensitive area far away from the

mining site.

Probably the LCA will state the minimal total emissions and energy demand for case 1 due to the importance of the additional transport and the negligence of the specific region. By contrast, the risk assessment will state the minimal risk to the environment for case 2, because the focus is put only on the main process within the life cycle, but the extra

20 Saouter E., and Feijtel, T., Use of Life Cycle Analysis and Environmental Risk Assessment in a Integrated

Product Assessment, Risk Assessment and Life Cycle Assessment, Environmental Strategies, Nordic Workshop, Vedbaek, 1999, p 81, TemaNord 2000:545

21 Sonnemann G., Castells F Schuhmacher M. Integrated Life-Cycle and Risk Assessment for Industrial

transport is not considered. This example shows in a simple way the significance of the difference highlighted before. It demonstrates also clearly the need for a more coherent approach that does not allow so easily that two environmental impact assessment tools provide such contradictory and inconsistent results.

According to Olsen, 199922, and Sonnemann et al. 2003 there is a need to understand

and explain these differences in both academia and in industry to avoid misuse of the methods etc. Firstly, the functional unit in a LCA study needs to be defined in a way that allows for a more meaningful calculation of exposure concentrations taking into account the absolute mass of emissions etc. Both methods are flexible and therefore it may also be relevant to harmonize the choice of system boundaries for both methods, and also the choice to include or exclude different subsystems. A comparison will then probably be facilitated.

3.3.4 Potential difference in data quality and data acquisition

The difference in data quality between LCA and RA is based on the application of the methods. Risk assessments, compared to LCAs, are prepared due to legal requirements and the results as well as data sources are reported to authorities. Since data sources are reported and data quality requirements are high, the data acquisition for a RA study could be more extensive and costly than the data acquisition for a LCA study. The same

databases on inherent properties are sometimes used for RA and LCIA methods including toxicity, because data on for example use and exposure of chemicals are required for both methods. During data collection for RA and LCIA, in different internal and external databases, problems regarding data availability for specific toxicity and physico-chemical parameters are a common problem.

To date, most methodologies for acquiring and generating data conducting risk as-sessments and making risk management decisions have focused primarily on the production phase of the chemicals and chemical products e.g. a washing powder. The amount of information about the use phase of e.g. a washing powder is smaller since the producers of the raw material chemical are required to supply this information.

One aspect of data used in RA models and LCIA characterisation factors, is that it is important that they are based on data reviewed in a structured way to avoid variation or uncertainties in e.g. the calculated characterization factors. Comparative studies of different risk assessment and LCIA methods show that a lot of the differences in the results are due to different toxicological and epidemiological base data promoted by different authorities like WHO, US EPA and certain authorities of EU member coun-tries.23 The reliability of the results depends on these aspects and therefore also the use of the results.

22 Olsen S.I., 1999, Life Cycle Assessment versus Risk Assessment – An introduction, Risk Assessment and

Life Cycle Assessment, Environmental Strategies, Nordic Workshop, Vedbaek, 1999, p 81, TemaNord 2000:545

23 Hofstetter P., Perspectives in Life Cycle Impact Assessment - A Structured Approach to Combine Models

Another difference between LCA and RA regarding data, as stated in the SETAC annual conference in Hamburg, 2002, is that due to aggregation in time and space in the life cycle inventory (LCI) a simultaneous exposure is assumed, which in risk assessment often not is accepted. Removal of information on time and space in LCI results in limited possibilities to address actual exposure and background concentrations in LCIA which is a disadvantage for the impact assessment.24

3.3.5 Interface between Life Cycle Assessment and Risk Assessment The interface and relationships between and a combined use of LCA and RA can be divided in different alternatives as illustrated in the Venn diagrams in 3.3. In diagram A and B the tools are regarded as separated and as if there are a distinct overlap between them. When performing a LCA study of a product taking toxicity impact into considera-tion there is often an overlap concerning risk assessment related data etc. LCA as a subset of RA, approach D is not commonly used today because RA is limited to chemicals and therefore includes not LCA. A potential way forward is risk assessment for the chemical product and then when it becomes part of a ‘normal’ product the further impacts is dealt with by LCA.

Only one approach - to use LCA for assessing risks - has thoroughly been described in literature i.e. the impact assessment approach, other approaches have only been briefly discussed in literature to date. Two alternative approaches are presented below.

A first approach of combining LCA and RA, illustrated in Venn diagram C is to include toxicological and eco-toxicological models in life cycle impact assessments (LCIA). To include these aspects, RA methods and models as well as data used for risk assessments need to be included in LCA i.e. RA is here used as a subset of LCA. The models generate characterization factors which then have been used in the impact

assessment part of LCA. There are several examples of this approach and a comparison of a number of these impact assessment methods is presented in section 4.1, where they are described and compared in terms of how they handle toxicity.

Generally, a LCA reality model used for LCIA modelling is based on model extrapola-tion of more than one empiric laboratory experiment. In figure 8 this is illustrated. The addition of a toxic substance into a test sample is extrapolated into real potential

emissions from production or use of a substance (A). The laboratory conditions of the test sample are extrapolated into realistic natural environments, including temperature, Ph-level, impurities etc (B) and the test sample, typically some well-specified family of daphnia, are extrapolated into different types of biological life forms (C). In this

illustration epidemiological aspects i.e. study of the incidence and distribution of diseases and their control and prevention, are not included.

24 SETAC Europe 13th Annual meeting Hamburg, Germany, 27 april-1 may 2003, Understanding the

TOXICITY EXPERIMENT MODELING EXTRAPOLATION EMISSION TO ENVIRONMENT

EMPIRIC LABORATORY LCA REALITY MODEL

A B C TOXICITY EXPERIMENT MODELING EXTRAPOLATION EMISSION TO ENVIRONMENT

EMPIRIC LABORATORY LCA REALITY MODEL

A

B

C

(© Carlson, R., IMI, 2004)

Figure 8. RA empiric laboratory results extrapolated into LCA reality models

However, the problem is not to only to extrapolate experiments in terms of the effect analysis into LCIA characterisation factors, but also how to deal with fate and exposure due to the aggregation in time and space. Fate, exposure and effects are three central concepts in risk assessment and LCIA.

A toxic substance can be seen from two perspectives: as a product and as an emission. In the first perspective a LCI analysis of a production site producing the hazardous product Px containing the toxic substance x is made. An upstream, production related LCI

of Px may be performed to identify the input and output flows of the production site i.e.

the inventory profile. From the second perspective the hazardous emission Ex is an input

to a natural system. A characterization of emission Ex containing the hazardous substance

x is made to assess its toxicological impacts on the environment. It should be noted that in the LCI case, the emission of the hazardous substance x is often not identified and

therefore this information is not included or missing if an impact assessment is made on the emissions out from the technical system.

A second approach, illustrated in Venn diagram E, is to perform detailed risk assess-ments on every emission identified in LCA i.e. in the inventory through the life cycle chain of a product or service (see figure 9). Such an approach has been chosen within the ExternE project, in particular to assess the external costs of electricity production.25 Nigge, 200026 and Sonnemann et al., 200327 have made proposals for adequate trade-offs

between site-orientated assessments and life cycle orientated assessments that aggregate over time and space.

25 EC - European Commission, ExternE – Externalities of Energy. 6 volumes. EUR 16520-162525. DG XII

Science, Research and Development, Brussels, 1995

26 Nigge K.M., Life Cycle Assessment of Natural Gas Vehicles, Development and Application of

Site-Dependent Impact Indicators. Springer-Verlag, Berlin, 2000

27 Sonnemann G., Castells F Schuhmacher M. Integrated Life-Cycle and Risk Assessment for Industrial

End of life Disposal Identified system Chemical1 Chemical 2 Chemical3 Chemical4 ChemicalX

Raw materials Production Use

Product RA RA RA RA RA RA RA RA

RA =Risk Assessment report

End of life Disposal Identified system Chemical1 Chemical 2 Chemical3 Chemical4 ChemicalX

Raw materials Production Use

Product RA RA RA RA RA RA RA RA

RA =Risk Assessment report

(© Flemström, Carlson, IMI, 2003)16

Figure 9. Risk assessment performed at every stage of a products life cycle

The conceptual background and purpose of LCA and RA are different as stated earlier, but there are overlaps where they may benefit from each other and also complement each other in an environmental decision process. However, there are still questions to be solved and a thorough analysis of the interface between the two tools may be advanta-geous. For example questions that needs to be investigated further is which data that are exchangeable between the two tools, how to address mixture toxicity i.e. toxic effects of mixtures of chemicals, for comparison of products, and also how to integrate the methodical development of assessment of the use and disposal phases.28

28 Olsen S.I, Christensen, F.M., Hauschild, M., Pedersen, F., Larsen, H.F., Torslov, J., Life cycle assessment

and Risk assessment of chemicals – A methodological comparison, Environmental Impact Assessment Review 21(2001) pp. 385-404

4 Methods used in Risk

Assessment and Life Cycle

Assessment

4.1 Analysis methods

4.1.1 Analysis methods for Life Cycle Assessment

LCA include calculations in terms of structured measurement methods. Especially calculation methods for the life cycle inventory (LCI) part have been developed in detail. To be interpretable, LCI-data need to be documented according to a defined format. To date, there is no international standard for this but a technical specification within ISO for a LCI data documentation format. In the 1990s, SPINE - Sustainable Product Information Network for the Environment, was developed within the CPM – Centre for Environ-mental Assessment of Product and Material Systems, collaboration, at Chalmers University of Technology in Sweden. A data tool for LCI data documentation was developed and a national database was built up. In addition, there are other tools and formats developed and used within Europe e.g. SPOLD.

4.1.2 Life Cycle Impact Assessment models

Life cycle impact assessment, also include calculations, for which information has been collected from different methods. There exist many different impact assessment methods e.g. EPS, Eco-indictor 99, EDIP, Eco-Scarcity, Tellus, Impact 2002 and Environmental Theme. An impact assessment method is a description of a method applied for choosing characterisation and weighting factors. The method or models for characterisation and weighting contribute to the major difference among these methods. Different methods may lead to very different results, and therefore different methods can contribute with different kind of information to decision-making processes.29

Below is a short basic presentation of three of the existing models. It should be noted that there are many impact assessment models and this report does not aim at describing all existing methods. Therefore, a number of them where chosen by the authors mainly based on the availability of information.

4.1.2.1 Environmental Design of Industrial Products (EDIP)

The Environmental Design of Industrial Products (EDIP) method was developed in a Danish project aiming mainly at providing product developers with ready-to-use tools for environmental assessment. The method handles environmental impacts, resource

29 Bengtsson, M., Environmental Valuation and Life Cycle Assessment, Department of Environmental

consumption, and impacts on work environment as separate categories. In EDIP the impact category modelling approach is used.

The weighting principle used is separate weighting of emissions (political goals), resources (supply horizon) and work environment and it is based on a Danish policy targets. Therefore EDIP has a relatively even contribution to the overall weight from most regulated emissions etc.

This method belongs to a group known as distance-to-target. Several methods are relating the weighting factors to some sort of target. These methods are conveniently called distance-to-target-methods. There are a few critical issues in distance-to-target methods e.g. the target levels and how they are determined.

• The type of impact category indicator used is normalized impact potentials (person equivalent)

• Spatial extension: Global and national

• Weighting principle used is separate weighting of emissions, resources and work environment

4.1.2.2 Eco-indicator ’99

Eco-indicator ‘99 is a rebuild of the Eco-indicator ‘95 method which was a method developed in the Netherlands It is a top down model which begins by identifying three environmental damage end-points:

• Human health • Ecosystem quality • Resources

For example, damage models for human health were developed for respiratory and carcinogenic effects, the effects of climate change, ozone layer depletion and ionizing radiation.

These three impacts are based on the best available scientific knowledge, and the areas are then weighted against each other based on the distance-to-target principle. The model analyses the damage path from the inventory, through to the predicted damage.

Weighting factors in Eco-indicator ‘99 is based on a LCA interest groups answers on a number of questions concerning ranking of the three environmental damage end-point and also a number of questions regarding attitude and perspective on society. On the basis of this information some of the respondents could be distinguished as using a perspective that fits within one of the following archetypes: hierarchist, egalitarian, and individualist.

The Eco-indicator ‘99 uses a two step weighting procedure; the first step is made within each damage end-points (human health, ecosystem quality and resources) following a formal methodology and the second step is of panel type.

• The type of impact category indicator used is Damage. • Spatial extension: Europe

• Weighting principle used is two step weighting

4.1.2.3 Environmental Priority Strategies in product design (EPS)

The EPS method was developed in Sweden in the early 1990’s, and it uses economical values to weight up different impact categories.

There are five safeguard subjects within EPS: • Biological diversity

• Human health

• Capacity of biological production (i.e. fertility) • Resources (not renewable resources)

• Aesthetic and cultural values

These five safeguard subjects represent a definition of ‘environment’ within the EPS system. In the characterization step of LCA the impacts on each of these ‘safeguard subjects’ is determined and quantified. Monetary values have been calculated for each area using actual expenditure or contingent valuation (willingness to pay). An excess death is equal to one million ‘environmental load units’ (1ELU=1 European Currency Unit, ECU), a nuisance equals 100 ELU per person-year. For the loss of production of natural resources, actual commodity prices are used.

The EPS system is a top-down principle which means that issues important for the decision are dealt with before those giving the basic information and rough estimations are made first, the quality are then improved. The top-down principle is a way of dealing with complex systems since there will always be parts that are not known or impossible to include because of limited resources.

• The type of impact category indicator used is end point effects • Spatial extension: Global

• Weighting principle used is WTP- Willingness to pay - to avoid changes

4.1.2.4 General comparison of EDIP, Eco-indicator’99 and EPS

All models have been criticized in different ways. There is not one superior model and therefore it is important to know about the models limitations and what they are aimed to be used for. However, EDIP and Eco-indicator ‘99 could be seen as more scientific methods than for example the EPS method and also more complicated. EDIP is based on Danish conditions e.g. weighting targets are based on Danish political reduction targets and on the frequency of reported work-related injuries in Denmark. It is also a scientific method which is more or less inappropriate for making average values. There are a few critical issues in distance-to-target methods like EDIP and Eco-indicator ‘99 e.g. the target levels and how they are determined. These methods are based on the assumption that all targets are equally important. The distance-to-target method EDIP has a relatively