VTIsätryck

130

1.989

Use of unbound pavement materials in

Sweden and other Scandinavian countries

Peet Höbeda, Swedish Road and Traffic Research Institute (VTI),

Linköping

Håkan Thorén, National Road A dministration, Borlänge

Reprint from: International Symposium on Unbound Aggregates

in Roads (UNBAR 3), 77 73 April 7989 in Nottingham, Eng/and

%,Väg 'De/l Wii./(- Statens väg- och trafikinstitut ( VTI) 581 01 Linköping

ISSN 0347-6049

? VTIsärtryck

130 7.98.9

Use 0f unbound pavement materials in

Sweden and other Scandinavian countries

Peet Höbeda, Swedish Road and Traffic Research Institute ( VTI),

Linköping

Håkan Thorén, National Road A dministration, Borlänge

Reprint from: International Symposium on Unbound Aggregates

in Roads (UNBAR 3), 77 73 April 7989 in Nottingham, Eng/and

?, Väg-UCI) Hf/7!- Statens väg- och trafikinstitut (VT/) - 587 07 Linköping

USE OF UNBOUND PAVEMENT MATERIALS IN SWEDEN AND OTHER SCANDINAVIAN COUNTRIES

P. Höbeda, Swedish Road and Traffic Research Institute (VTI),

Linköping and H. Thorén, National Road Administration, Borlänge

By tradition, unbound pavement materials have been widely used in

Sweden (S) and other Scandinavian countries. Increased traffic

loadings have made it necessary to improve the material qualities and for this reason new specifications are currently being produced

in S. The existing specifications are discussed and compared with a

recent proposal by the National Road Administration. Comments

are made on the use of blast furnace slag and testing of unbound aggregates. Brief comments are made on the situation in Finland

and Norway, while the Danish situation is different and is therefore not included.

INTRODUCTION

Apart from its southernmost parts, Sweden (S.) differs from Great Britain and continental Europe in several respects. Frost penetrates the subgrade and the soil and moisture conditions often promote uneven frost heaving. The risk of freeze thaw weakening must always be considered. Also, soft clays and deep organic deposits are

frequently encountered. Building of roads in winter is considered necessary from the

labour market point of view. In such cases a flexible pavement, built with unbound layers under the asphaltic ones, has been the preferred choice. Also, 5. is not densely populated and therefore the money available for each km of road is not great. There still exist a certain number of unsurfaced low-volume gravel roads. The surfaced secondary road network has thin asphaltic layers. A special problem is wear by studded tyres in winter and the most heavily used roads are frequently resurfaced because of this special form of rutting. Problems concerning road surfacing aggregates have been treated by Hobeda (1989). The conditions in Finland and

Norway are similar, while from the road conditions viewpoint Denmark is more a

part of the European continent. The road networks and the conditions in Scandinavia are presented in the PIARC magazine, Roads No. 265, 1988.

During the 80s, the traffic loading has increased, especially the proportion of heavy

lorries, which also tend to an increased degree to use single mounted wheels with

higher tyre pressures. Therefore their "aggressiveness" on the unbound layers has increased. Harmonization with EG rules in the near future also for S. means an

increased bogie load (from 16 to 18 tons) and total load (from 51AL to 60 tons). All

bridges will be strengthened and improved road material specifications will be

produced.

From the aggregate resources vieWpoint, the situation is favourable in S., since

unweathered hard rocks, mainly of granitic composition, dominate, even if their

faulted rock. Sedimentary bedrock areas are not extensive and such materials are

seldom used in pavements. Of great importance are the glaciofluvial gravel formations, often found as eskers, that have provided a source of cheap aggregate, mostly of good quality, that reflects the composition of the bedrock formations broken up by the inland ice. In areas with sedimentary rocks, the gravel will be

enriched in these components. However, gravel is an exhaustible resource and production is now increasingly restricted. At the same time more quarries producing crushed rock are starting up production, especially near the major cities.

PAVEMENT TYPES IN USE

In S. The National Road Administration (NRA) is reSponsible for the materials specifications for road construction. There are two main types of pavements in use

at present. The first is a fairly conventional type, in S. called the "gravel bitumen" type, which is built when glaciofluvial material is available. The other one is the

rock-bitumen type, constructed when a sufficient amount of rock is found in the road cuttings. In this case, it is often economical to produce aggregate for the whole pavement, possible with the exception of surfacing aggregate, using mobile crushers. Depending on the specifications, it has also been possible to build this pavement type with thinner asphalt layers mostly because of a lower water susceptibility.

Most major roads have in fact been built with this construction using local materials. From the design point of view, the asphaltic layers are about the same

thickness as in most European countries for the "gravel bitumen pavement, but are considerably thinner for the rock-bitumen pavement.

In Finland and Norway, such special designs for "rock-bitumen" type pavements have not been developed.

Many newly build roads in S. have shown unexpectedly short service lives, probably because of the increased traffic loading, as well as construction deficiencies, and for this reason the specifications are now being changed. More emphasis is now being put on quality aspects instead of maximum capacity in a fully mechanized construction, as in the 60s and 705.

(i) "Gravel bitumen" pavement.

This conventional pavement consists of a subbase, base and asphalt bound layers. The subbase can be made of crushed rock but is mostly constructed from unproces sed glaciofluvial material and is then classified as an A type (continuously graded) or a B type (single sized, sandy material). Often, there is a sand surplus in the esker

formations. Problems have occurred with both types. According to the present

specifications, the max. fines content (<0.075mm) in the A-type material may be up to 16% of max. size 16mm, far too much for a material used in a climate with a risk

of spring thaw weakening, when the permeability should be high. No grading envelope is specified. Also, the content of clay and organics may be up to 5 and 2%

respectively. Such "dirty" materials have not been common, but occur in some areas with sedimentary bedrock and therefore these excessive contents appearently have not caused immediate concern. A few cases of road failures are known, however. A material is classified as B-type if it has a content of less that 16% fines, S% clay and 2% organics, but any materials that have a capillary rise less that Im (test

performed on materials <2.0mm) are classified as B type. Such sandy materials have

demonstrated poor performance and therefore in 1986 the NRA specified that the uniformity coefficient (d60/d10) should be greater than 5, if the material is to be used less than 500mm below the surface.

The rather odd Specifications for A and B type materials seem to originate from early work by Beskow (1935), who developed a soil frost susceptibility classification, although he paid no Special attention to the stability properties.

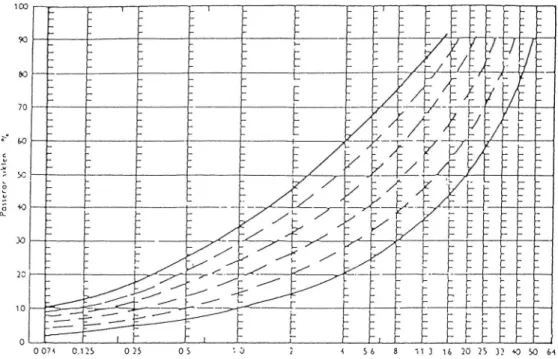

A new grading envelope has recently (Nov. 1988) been proposed by the NRA. There

are in fact two gradings (Figure 1) the inner and more narrow one considers the

material when produced and the outer one the as laid material that has undergone

segregation and degradation. The material must be continuously graded and have a low fines content in comparision with the existing specification. The clay content

must only be determined if the fines (<0.075mm) content exceeds 7% and shall then be <20% of the fines content. Also, the organics content is reduced to 2%. These changes greatly improve the stability and water susceptibility characteristics. The subbase can be manufactured both from uncrushed and crushed material. Probably the use of crushed rock will increase in the future as the grading proposed can hardly be produced from pit-run, glaciofluvial materials. Also, a material with very low fines content should be crushed in order to ensure stability. The voids in the

surface must be filled with a finer sized aggregate before the roadbase can be laid.

The unbound roadbase has been made of crushed gravel or rock. The material has been mostly of the crusher-run type, often crushed only once (Figure 2). The grading envelope is similar to specifications in many countries. The particle size distribution

curve must not cut the subordinate lines inside the grading envelope more that twice

left from the 8mm sieve. The max. fines content has been lO%, quite high for good drainability and the max. clay content has been as high as 3%. This is valid for the compacted material on the road. For high permeability, the fines content should be as low as possible, but such a material will be difficult to handle and compact and

will be less stable than a denser one so that a compromise must be sought. A high

max. particle sixe promotes stability, but increases segregation (Höbeda 1986).

A problem with crushed gravel has been that the content of crushed, angular

material has been too low, which results in reduced stability, and in 1986 the SRA specified that the content of crushed material should be at least 50%. Also, because of the often poor stability of the subbase layer, the base has had the task of

functioning as the platform for construction traffic, with degradation problems as a

result.

A new grading envelope has been proposed by the NRA in Nov. 1988. As for the

subbase, there are two grading envelOpeS (Figure 3). The same values for max. clay

and organic contents are valid as for subbase material. Because of the narrow range for the produced material, simply crusher-run material will probably be difficult to produce and mixing of sizes will be necessary. Laid on an uncrushed subbase material, the base thickness will be 150mm. On a crushed material subbase or

embankment of good quality rock, the thickness is only 70mm and in fact it becomes more of a levelling layer. The min. thickness of subbase and base will be 500mm in

order to provide a sufficient bearing capacity also during the construction stage. A capping layer of sandy material is used when the subgrade conditions are poor.

In Finland and Norway, the Specifications for both the subbase and base materials

have been more stringent than in S., especially considering the fines content. ln

Norway, the Casagrande frost susceptibility classification has been used, which gives quite a low fines content in well~graded materials. No grading envelope is specified for subbase materials. Single-sized graded sand has not been permitted in the upper part of the subbase. Also, in Finland the grading envelOpes for base and subbase materials are similar to the S. proposal, but the fines contents are at a lower level, max. S% for the inner and max. 796 for the outer envelope.

(ii) "Bitumen rock" avementP

If only crushing economy is considered, this means a size reduction as low as

possible. Until 1976, such pavements were constructed of sizes such as 75-200,

25-75 and 0-25mm. The finest material was merely intended to give a smooth

surface for the asphalt paver, but he layers were often laid too thick. The surface was aslo easily degraded by construction traffic and a water susceptible layer thus

formed under the asphalt bound layers that could result in alligator cracking.

The 75 200mm material in particular was difficult to handle, and a change was

made in the NRA specifications of 1976. However, these were rather vague and different types of constructions were built. A typical example is a pavement built with size 25 80mm, often laid with a considerable thickness, and levelled off with a lO-Z5mm material. The surface was then penetrated with approx. 2 kg/m2 of asphalt before construction traffic was allowed onto it. This proportion of binder is much too low for good binding action to take place. Such constructions have often been unstable because of the single sized macadam, especially one with a cubical" particle shape. Sometimes, the rock material has also been of poor quality and has degraded. In the 1984 NRA specifications, three grading envelopes were specified in order to avoid the most single sized materials.

An optimum granular material, crushed from rock, should in fact be of the "drybound" macadam type, were the coarse aggregate particles are in contact with

each other and the voids are filled with angular fines. When properly constructed,

such pavement layers can be superior to ones with well graded materials. However, this type on pavement layer would be very difficult to construct in a fully mechanized way and is not realistic.

The single sized macadam gradings have not been used any more in recent years in S. A continously coarse crushed rock grading has recently (1987) been tentatively specified by the NRA but the material costs would increase considerably. The most economical construction method in rocky terrain seems to be the use of blasted rock

as high up in the pavement as possible and the use of crushed rock only as a rather

thin layer. Such a pavement also will have an especially low deflection according to falling weight measurements. Two major roads have recently been constructed in this way. The coarsely graded (O~70mm) crushed material, which tends to segregate, was surfaced with a thin layer of penetration macadam in order to prepare a smooth surface for the aSphalt paver.

In Finland and Norway, similar specially designed crushed rock pavement using single sized macadam high up in the pavement, have not been specified. In Norway, e.g. blasted or crushed rock, the latter up to l§O~ZOOmm in size, is used as a subbase.

THE SPECIAL CASE OF BLAST FURNACE SLAG

Because of the availability of hard rock in S., air cooled blast-furnace slag was not specified as a base material until 1984. This by-product has been appreciated as a high quality material with low moisture sensitivity and certain frost insulating

properties. However, as the heat outflow also in hindered winter time, the road

surface will be colder that one built with a natural aggregate and the risk of icing

increases in certain cases with high relative air humidity, especially in the early

winter (Gustavsson 1988). Test sections, built in Central S. with a slag base, have shown up as traffic safety hazards since an abrupt change of skid resistance may

take place. Slag roads therefore need extra careful winter maintenance. Important in this respect is that in S. the use of deicing salt for winter maintenance is considerably less than in many other countries.

TESTING OF UNBOUND MATERIALS

For testing the quality of unbound materials, only the grading and crushed material content (for base only) are determinded at present. Rock material is classified in three classes, 1 3, after petrographical composition. According to the new NRA specification proposal, the base material must consist to 90% of class 1 or 2, in fact igneous or metamorphic rock of fairly good quality. There is no strength or abrasion test specified, as is the case for road surfacing aggregate, at present. However, a test is needed, especially as construction traffic is often run over base materials. A wet ball mill test seems to be promising in that respect. In Finland the Los Angeles test is specified and in Norway an impact test similar to that used in S. for road

surfacing aggregate (Hobeda 1989).

The stability and stiffness properties have not been studied yet as it is very difficult to test the coarse gradings necessary for high stability unbound layers. Repeated load triaxial test are considered, but no apparatus, suitable for coarse gradings, yet exists. Because of the need for rapid drainage, especially during the spring period, permeability tests seem relevant, and experiments are in progress with a method,

which is suitable for coarse gradings, described by Bioczysko (1985). The CBR test,

not specified in Scandinavia, has shown promise with sandy, B type materials. There is a certain relationship with the uniformity coefficient and specifying this particular grading prOperty, as is the case at present, seems to be appropriate.

CONCLUSIONS

Increased traffic loadings make it necessary to improve the quality of the unbound materials. Beacuse of the uniformity coefficient restriction, the use in certain parts

of S. of sandy material in the subbase has already changed to the use of crushed

rock, e.g. O lOOmm, a quite substantial bearing capacity improvement, if the material is properly handled.

The use of unbound bases is likely to continue in a hard rock" country such as S. However, such materials must be manufactured in a more sophisticated way than at present, in order to improve their prOperties. From the pavement design viewpoint, the thickness of the aSphalt layers often has to be increased, especially for the

lower volume roads, many of which are underdesigned or constructed with poor

materials. In Finland, the excellent performance of asphalt penetrated macadam bases, compared with the unbound, more water-sensitive bases, has been noted (Orama 1988, pers. comm.). Also cement bound bases have been used with success in such cases where the subgrade conditions have been favourable. In S., the often poor behaviour of cement-stabilized bases is mainly due to use on too poor subgrades.

Continuously graded bases seen to be out of favour in Norway because of their water susceptibility and penetrated macadam, asphalt bound or cement bound bases will be used more often (Refsdal 1988, pers. comm.). However, the quality of gravel aggregate is often less favourable in Norway than in the two other Scandinavian

REFERENCES

Beskow, G. (1935). Soil freezing and frost heaving with special application to roads and railroads. (In Swedish). The Swedish Geological Survey, Yearbook 26, No. 3.

Bioczysko, S, J. (1985). Permeability of subbase materials. Unbound Aggregates in Roads (UNBAR 2), Nottingham University.

Gustavsson, K. (1988). Icing risks on roads built with slag. (In Swedish with an English summary), VTI Meddelande 570.

Finnish Road Administration. (1985). Road Specifications. Pavements (In Finnish).

Höbeda, P. (1985, 1987). Literature studies concerning the properties of road base

and macadam type materials. (In Swedish with English summaries), VTI

Meddelande 4112 and 469.

Höbeda, P. (1989). Influence of aggregates on the durability of road surfacing and

testing of aggregates Swedish experience. Conference on the Durability and Performance of Bituminous Highway Materials. Hatfield Polytechnic.

Norwegian Road Administration. (1980). Specifications (Vegnormaler. In Norwegian).

National Road Administration, Sweden. (1981+). Construction Specifications and

Advice, (BYA 8# and later additions. In Swedish).

_

1 ' ' 100 _ ..> r _b l ._ : ... ... .- E » p _ _ _ _ _ .__ _ _ _ _ _ _ _ _ _ _ _ 90 __ _. _ _ _ _ _ - _ > r.- > - > g .._ __ __ __ __ __ __ __ __ __ _... E __ __ H I ,. .. l .. _l .- ,. .. _| .. _. __| .. .. _ - - - » _- . _ _ _ _ _ _ _ .... O.. __ __ __ .__ . _ _ _ .... _ _ _ _ p _ _ _- . - _ _ _ _ __ _ _ _ _ _ _ _ _ _ _ _ L.. _ _ _ _ _ _ A __ _. _ _ _ _ P l _ '_ F _ | _ __ - __ __ - _ - _ _ 7 _ __ __ __ ._ __ __ .- ,. ,- .. [I ... __ _ _ .. .. _- : :_ - :-_-_ .._ :'- ;:. ' r:- _- LT. * __ .. _ _ ... ... _ _ _ _. _, .. _ : "d .... _ _ _ _ _ _ _ _ _ _. _ . u __ _. __ __ _ _ _ _ _ >- - >-- _ g». 70 ' __ ___ l .. - -_ - _. .. ... -. __! _ _ ... C __ __ . .... .. _ _. _ > _ r ? » >-- » . __ ... _ _ _ _ _ _ _ _ _ _ _ _g __ __ ._ ._| __ .. _ _ _ _ _l _. _ _ _ 0 - _ _ | - _ _ > 7- _ |_ _ _ _ _ >_ _ = _ _ _ _ _ ... _ ... _ v - r o _ _ 7 - _ _ _ _ _ .. .. _ _. _ _ » - - r- " _ > _ C I ... _ | _ _. ' _ .. _ - :C .. -__ __ _ _ _ _ > - 7 _ _ p _-__ u_... -_ _" V -_ _"" _'_' >'_' >- - Il_ --_ _ _*

1.

_~

_ 1--

-l

> - _ _ _4

_ _'1:-:

I

_.-

,. .. U __ __ __ __ __ __ _ _ _ _ : _ _ _ _ _ _ h l _ _. > > p _ __ _ _ _ _ _- > f 1 > _ r bc _- _ P'- |- > ha |_ _- _- _ P1 1 _.. .._ 1 ___._. ___|- _.__.. _-__ _.._ J:ä. -_ __.. _-..- | _..- >_.. -__ __ .. .. __ _. _ _ _ _ _ _ __ __ _ _ _ _ _ _ _- > : > ' 40 ' __ _ _ _. .... _ __ _| > | P ] ____ _____ I .._. ..l.. .... .... ..7_ .."'I _..:. __ .._| ..... _. __ _. _ _ _ _ _ |_ _ >-- > - r l * __ __ __ ._ __ __ ' .... .- .. ... _ _ _' _ __ _ _ _ _ / _ _ _ _ _. _ | >- -__ P__ I "__ .__P- >r ___ _ _.. x __ __ __ __ /__ _ _ _ _ _ _/ _ v h ' " _ "" _ 80 __ __ _ _. _ _. _ _l » - - r / » ' i _= ::- | =- ="| -: -' ::- -2? -]= =_ ___.. __- _ _:= E/ ___ __ __ _ _ ._ / _ _. ... _ _ _ _ _ -_ _ __ 7 , _ _ > > > -'p - _ __ __ _ _o _ _ v O >- - F | _' _ _. _ _ I E 1 - K _ _ _ _ _ ' ... .... __ __ . _ __ ,... _ _ Z : v -20 __= ___ __ *..f-_ - __ -... _- _- : - 1=_J _ />- > r -__ ... _ ,..'.- _ _ _ >_- v-v _- _ _ > * _ __ _ _ _ _ _ >_ 7 " > r > - * _ __ __ H __ _ __ _. _ l _ _ 1 -)- _ _,7 4 _ _ _ _ _ å. _ _ _ __ __ _. _. _ _ _ r - _ " F '_' "" 10 __ ... ... _ ... _ > > > -- _-'f _ __ __ __ __ ... _. _ _. _ > -1 __. ..._ _._, E _ -> - , -> C -_ -> _ _ _ >_ / - -,/I _ = : = : : > E 5 t: : E : -_ _ | _ _ _ _ > - _ t >_- " 0 l __ , . _ _ _ .... _- * >- >- » > - ) '_' 0,074 0,125 0,2 0,5 1 2 4 5,6 811,216 25 32 50 Kornstorlek, nmFigure 1: Proposed road subbase grading evelope according to the S. National Road

1w T I I > y # b ,_ r- L" F- r > L __ ». > > - L » r~ r P » > - » ,,_ __ ... _ ! >- ) > >- »- > r > r- > I 90 * > "" ' + 1» > >- _ r :]L » ?> ». L.. - >- > E > >- » E > Jp r > r -- >- >- >- > r- * >

~

_ ,-

/ ./. A 1- C

w , T'7' > > - > >. _ 7- > - P » r > > r E * r- > p > > > F- | > r r > 70 __ _ . L » > > J L ,__&,

_

_

_

_

_

_;

_ _

1: _

° so , w . C P »- - > > E & L F + r U > .-. . - > r > 1 -;3 x; v > > ~ g ] / *"- P" > : -- »- > >- /> Y ' '.! u L- » r >-8 f ) L > - V > ' -: : : ** r Ef _ t * * " a +o ~- T . z/ , » > > ) r - * P > 7- » > 30 _ _ _ > » >. r & > > > » 1-" " F _ ;P / f L E _ _ _ F _ _ _ 1- ?- >- >- * - > >- » > > > - > ) . ) p » r- » . .. _ > 23 v ' L > b- L b L- .'- F t F. >- p > k '". L- P r' " r > >- r v 1»- > L- > > 1o+ ___, _ P ,. > >- > _r- r > r ' ""'- l » > > L * -- - >"

F

f

£

"' * ' _ _ *" 13

" C

"" ?

1 1

4

r

n ~ ~ ~ r

~ ~

0074 0.135 025 05 30 ? 4 56 8 .13 16 20 25 37 40 50 64Figure 2: Grading envelope for roadbase according to the S. National Road

Administration Specification from 1984.

100 4) 5 g 90 H B* 94 ; 80 &; 2 70 25 45 so S H U 2 50 0 H 40 30 20 10 0 0,074 0,125 0 25I 0 5I 1 2 4 5,6 8 11,2 16 25 32 50 64 Kornstor Ich, nm

Figure 3: Proposed grading enve10pe for roadbase according to the S. National Road