Implementation of

eco-design in

product

development

Knowledge management for effective eco-design

implementation

MASTER THESIS WITHIN: General Management NUMBER OF CREDITS: 15 Credits

PROGRAMME OF STUDY: Engineering Management AUTHOR: Oskar Franzén & Liyi Guo

i

Acknowledgments

We are very grateful to all the people who helped us in the process of our thesis. First of all, we sincerely thank our supervisor Carla Gonçalves Machado, who provided us with valuable feedback with her patient guidance and has helped us throughout the study. Secondly, we would like to thank the two participating companies. The open attitude of all participants provided important contributions to this research. Thirdly, we would also like to thank the opponents of the seminars, it is their unique viewpoints and positive attitude that gave us the motivation to further explore the topic. Finally, a heartfelt gratitude to our family and friends who have always supported us. It is you who gave us the strength to continue our efforts.

Thank you all from the bottom of our hearts. Without everyone’s support, we wouldn’t be where we are now.

Jönköping, 2021-05-24

_____________________ _____________________ Oskar Franzén Liyi Guo

ii

Master Thesis in General Management

Title: Implementing eco-design in product development Authors: Oskar Franzén & Liyi Guo

Tutor: Carla Gonçalves Machado Date: 2021-05-24

Key terms: Eco-design implementation, Sustainability, Product development, Management, Knowledge management.

Abstract

Background: The accumulating concern for environmental change has increased the need for companies to take a closer consideration to the negative impact of their operations. One effective approach to mitigate the impact is to, from the very first stages when a product is developed, analyse the environmental impact of the product’s entire lifecycle from the raw materials extruded from the ground to the disposal of the product. This type of practice is often referred to as eco-design. Unfortunately, the rate of companies implementing these practices are progressing slowly and a truly sustainable society is yet not in reach.

Purpose: This study aims to investigate some of the most commonly cited obstacles in previous research. These problems can be concluded as the lack of specialized competencies, regarding the environmental impact of products in design teams. The reason this is problematic is that the practice of eco-design often requires a lot of information to be interpreted by a person with knowledge in the field. Companies have attempts to solve this issue by hiring eco-design specialists, however this often leads to difficulties in communication and disagreements with product developers. Therefore, this relationship between different stakeholders has been the second focus of the thesis. To find solutions to these problems the topic will be investigated from a knowledge management perspective.

Method: To begin with, background data was reviewed to give a firm understanding of the topic and to create the basis of the theoretical framework. Later a multiple case study of two companies were performed and empirical data was gathered mainly from interviews. The empirical findings were analysed and compared to the theoretical framework in order to answer the research question.

Conclusion: The results show that implementing eco-design in a company's product development can be hard in the implementation phase but when the practices are established the flow of information receives less problems. Furthermore, the hiring of professional eco-designers can be a good choice although they need to be implemented directly into the design teams.

iii

Table of contents

1. Introduction ... 1

1.1. Background ... 1

1.2. Problem statement ... 4

1.3. Purpose and research question ... 6

2. Theoretical background ... 7

2.1. Sustainability... 7

2.2. Product development ... 8

2.2.1. Product development process ... 8

2.2.2. Eco-design in product development ... 9

2.3. Eco-design... 9

2.3.1. Environmental Assessment ... 11

2.3.2. Environmental improvement ... 11

2.4. knowledge management... 12

2.4.1. Defining knowledge management ... 12

2.4.2. Knowledge management and eco-design ... 13

3. Methodology ... 15

3.1. Research structure ... 15

3.2. Multiple case study ... 17

3.3. Data Collection ... 17

3.4. Data Analysis ... 19

3.5. Research quality ... 19

3.5.1. Trustworthiness ... 19

3.5.2. Ethics... 20

4. Empirical findings and analysis ... 22

4.1. Introducing the cases ... 22

4.1.1. Company A ... 22 4.1.2. Company B ... 24 4.2. Distribution of knowledge ... 27 4.3. Stakeholders' Attitudes ... 29 4.4. Analysis... 31 5. Conclusion ... 33 6. Discussion ... 35 6.1. Discussion of findings... 35 6.2. Implication ... 36 6.3. Limitation ... 36 6.4. Further research ... 37 References: ... 38 Appendices ... 49

Appendix 1. Interview questions ... 49

Appendix 2. Invitation email and statement ... 51

iv

List of Abbreviations

CCM – Continuous Comparative Method COVID-19 – Corona Virus Disease 19 DfE – Design for EnvironmentE-KM – Explicit Knowledge Management GDPR – General Data Protection Regulation GHG – Greenhouse Gases

I-KM – Implicit Knowledge Management

IPCC – Intergovernmental Panel on Climate Change ISO – International Organization for Standardization KMS – Knowledge Management System

LCA – Life Cycle Assessment PDP – Product Development Process PPP – Pollution Prevention Pays RRR – Reduce, Reuse, Recycle

SDG – Sustainable Development Goals SME – Small and Medium sized Enterprises TBL – Triple Bottom Line

1

1. Introduction

This chapter aims to introduce the subject of the thesis, and a general background will be provided alongside the presentation of the problem. This research regards the obstacles and challenges

encountered by companies when implementing eco-design in their product development process. First and foremost, the importance of eco-design to the environment and the company as well as its

significance in future product development are highlighted, and the barriers that eco-design faces in the product development stage are described. Secondly, the specific topic of integrating eco-design-related knowledge and concepts into product development are proposed. Although there have been many relevant studies in this field, specific measures still need to be investigated. Finally, this chapter discusses the main gaps in the implementation of eco-design hinted at by previous literature, the investigation’s purpose is clarified, and research questions are put forward.

1.1. Background

The environmental and social impact of corporations’ operations and products are a subject of

increasing concern. Paulson and Sundin (2015) point out that according to the Intergovernmental Panel on Climate Change (IPCC), the increase in man-made greenhouse gases (GHG) is responsible for the highest concentrations of carbon dioxide, methane, and nitric oxide in 800,000 years, which leads to climate change and deterioration of the environment. Consequently, environmental activists require companies and consumers to take effective measures to reduce greenhouse gas emissions (Paulson & Sundin, 2015).

In the late 1980s Brundtland and Khalid (1987) aimed to mobilise the world and create momentum for environmental change. However, the momentum is still growing and new worldwide agreements and joint efforts like the Paris agreement, the United Nations Sustainable Development Goals (SDG), are pushing the world into a new sustainable era (United Nations, 2015; United Nations Department of Economic and Social Affairs, 2015). Schäfer and Löwer (2021) add that demands from customers, environmental activist groups, as well as demanding environmental laws, with an increased risk for legal consequences, adds to the push for sustainable behaviours by companies.

One increasingly important step taken by companies to reduce their environmental impact is to introduce environmentally friendly design practices in their product development (Paulson & Sundin, 2015). Such practices can be referred to with many different definitions but any clear and widespread definitions are missing (Schäfer & Löwer, 2021). Some commonly used terms related to the topic are

2

Sustainable Innovation, Environmental Design, and Eco Innovation, another term is Design for Environment (DfE) which includes many different tools and concepts, but lacks agreement from the scientific community on how to effectively put them into operation (Schäfer & Löwer, 2021). Schäfer and Löwer (2021) gathers all these concepts under the eco-design term and provide three

characterising aspects: “(1) It refers to the design and development of products; (2) it is aimed at reducing the environmental impact of these products; and (3) it takes the complete product life cycle into account” - (Schäfer & Löwer, 2021, p.7).

Another commonly cited definition for eco-design is provided by ISO 14006:2011 (Dekoninck et al., 2016; Manzano et al., 2015). According to this definition, similarly to the aspects provided by Schäfer and Löwer (2021), eco-design’s primary purpose is to reduce environmental pollution, aiming to reduce the adverse impact on the environment during the entire life cycle of the developed product (International Organization for Standardization [ISO], 2011). Similar definitions that emphasise that eco-design aims to reduce environmental pollution during the whole life-cycle of a product are repeated by other sources, for example, by Sakao (2007).

Schäfer and Löwer (2021) elaborates that the word “eco” in eco-design usually refers to “ecological”, but can in some cases also include “economical”. Social factors are, on the other hand, rarely

considered in the concept of eco-design (Schäfer & Löwer, 2021). Eco-design can in this way, although its close relation to the concept, be separated from sustainable development. Sustainable development aims to increase financial profit while reducing the environmental impact and maintaining social fairness (Purvis et al., 2019). The statement represents the three pillars of

sustainable development: finance, environment, and society (Purvis et al., 2019). Similar to the case of environmental sustainability there is mounting pressure on companies to align their operations with all the three pillars (Labuschagne & Brent, 2005). Zetterlund et al. (2016) argues that the social aspect needs to be included together with the environmental aspect in product development work. However, since this is usually excluded from the concept of eco-design it will be excluded from the investigation to follow the scope of the majority of the research in the field.

There is a broad consensus amongst researchers praising the positive impacts that the implementation of eco-design could have on the environment. Schäfer and Löwer (2021) emphasises that

implementing eco-design in the product development phase can lead to a path to achieving several of the 17 SDG. Zetterlund et al. (2016) are on the same track, agreeing that sustainability in product

3

development can play a key role in the transformation towards a sustainable future. This is further strengthened by Romli et al. (2015) that discusses eco-design’s roles in reducing a product’s

environmental impact during its entire life-cycle. Additionally, several authors highlight eco-design or implementation of sustainability in product development as a way for companies to improve their sustainability (Siva et al., 2018; Paulson & Sundin, 2015; Waage, 2007).

In order to reduce GHG emissions, thereby achieving its purpose of mitigating climate change, eco-design combines multiple disciplines and considers the environmental factor of a product’s

development (Schäfer & Löwer, 2021). Furthermore, eco-design introduces several tools and methods developed to aid companies that are applying the concept (Paulson & Sundin, 2015; Schäfer & Löwer, 2021), additional, methods such as Life Cycle assessment (LCA) aims to objectively evaluate the environmental impact of a product, process, or material (Boks & Stevels, 2007). Eco-design’s influence on product development includes product drawings, dimensions, aesthetic factors, cost, quality, safety, and other aspects that may be involved in the development process (Romli, et al., 2015). Cicconi (2020) states that the material selection and the related processes made in the early stage of product development influence the environmental impact of a product. Furthermore, several authors support that eco-design applied in the early stages of products development promotes

improved product design specifications (Gehin et al., 2008; Cerdan et al., 2009; Vinodh & Rathod, 2010)

Tukker et al. (2001) state that in the industry, a growing number of researchers have focused on the extent to which eco-design is implemented in product development. Although studies have shown that many companies are committed to implementing eco-design (Bey et al., 2013; Lee-Mortimer & Short, 2009) the general uptake of eco-design tools and degree of implementation are low (Schäfer & Löwer, 2021; Zetterlund et al., 2016). These findings are echoed by Dekoninck et al. (2016) that expresses concern over the limited spread of the eco-design practices and tools. The author emphasises that the practice has not moved forward with sufficient speed to realise a sustainable society, and the process of implementing eco-design in product development continues to be slower than desired. This is

unexpected since the academic knowledge of the topic has increased, and tools and processes are fairly mature and manageable (Dekoninck et al., 2016).

To summarise, as more companies put the implementation of eco-design on the agenda, improving product sustainability has become a key point that needs to be implemented in the product

4

development process. However, the process of implementing eco-design is far from going as expected, and there are still many obstacles in the process of integrating eco-design into product development.

1.2. Problem statement

Presently, the world is working towards improving the environment and minimising the negative impact of polluting industries (Buzuku, & Kraslawski, 2017). Reducing environmental pollution into product development is a vital step to improve product sustainability. An effective way to integrate these environmental factors into products is to implement eco-design in early product development practices (Siva, et al.,2018). The initiative to implement sustainable eco-design has gained an increased strategic value. Consequently, companies seeking to improve eco-design and environmental practices are becoming more common (Buzuku, & Kraslawski, 2017). Del Val Segarra-Oña et al. (2011) agrees with this, stating that the implementation of eco-design has become a big trend that can establish a positive image for the company and thus become more competitive in the market. One example is given by Buzuku and Kraslawski (2017) who acknowledges that Chinese companies have begun to encourage companies to integrate eco-design into product development and use recyclable materials and parts to improve product sustainability.

Regardless of the trend, transforming a company's product development into utilising eco-design is not entirely pain free. The implementation of eco-design undoubtedly adds a layer of uncertainty and complexity to the product development process (Keoleian & Menerey, 1994). To start off, product development personnel must acquire knowledge and experience in the field of eco-design. The surplus of research aimed to assist in this process, can instead become an obstacle for future eco-design

practitioners trying to learn. Research has led to large quantities of information and an excessive amount of existing eco-design tools. Pigosso et al. (2014) found 107 tools and techniques, this is further strengthened by Schäfer and Löwer (2021), who confirms that there are hundreds available. To further add to the complexity, various terms are used to describe similar concepts as eco-design, some that, in other situations, are used for significantly different concepts (Schäfer & Löwer, 2021).

Bey et al. (2013) confirm that one of the major obstacles encountered when implementing eco-design practices is the lack of professional knowledge. Furthermore, due to the complex nature and

disorienting terminology related to eco-design, implementing the practice often encounters problems with the distribution of knowledge and suffers from poor communication (Paulson, & Sundin, 2015). Schäfer and Löwer (2021) propose that, to prevent this from happening, companies should hire a

5

professional eco-designer as a mid-level manager, (commonly referred to as a gatekeeper or

environmental champion) to coordinate the development team, set goals for the product development work and allocate resources to ensure the smooth progress of the product development process. The use of gatekeepers is also favoured by many other researchers (Dekoninck et al., 2016), although the effectiveness of such a person is disputed by Boks (2006) who found that there was no need if the eco-design practices are systemised. Furthermore, hiring an eco-eco-design specialist might not be plausible for all types of companies, for example start-ups and Small and medium-sized companies (SMEs), that commonly end up in a situation where they have pressure from larger actors, but suffer from lack of knowledge and resources (Schäfer & Löwer, 2021).

Due to the uneven spread of knowledge, hiring professional eco-designers can cause some issues, Boks (2006) argues that feeding environmental data from the top-down can often be viewed as criticism. On the other hand, Buzuku and Kraslawski (2017) found that lack of encouragement from managers was directly linked to low employee engagement in the practice. Boks (2006) and Wolf (2013) adds that since eco-design essentially integrates activities of multiple disciplines and fields, stakeholders involved at each stage need to actively participate in the sustainability aspects of the products life cycle. Although, with such an approach the challenges of communication and cooperation follows.

Johansson (2002) provides an extensive review of the factors that are connected to successful

integration of eco-design in the product development process. The author lists six areas of concern in which success factors are identified, the areas of concern include management and supplier

relationship amongst others while some of the success factors include commitment and support from management as well as a close supplier relationship. (Goepp et al., 2013; Boks, 2006)

However, on the basis of existing research, there are still gaps in the research regarding the knowledge management of integrated eco-design in the product development stage. According to Boks (2006) there exists plenty of knowledge regarding eco-design, the challenge lies in making it available to the right people and ensuring that they know how to use it. Additionally, Goepp et al. (2013) state that there is a gap in studies on how the knowledge management system supports eco-design

implementation. The need for sufficient research about knowledge management connected with eco-design is echoed by Schäfer and Löwer (2021) who states that a better understanding of knowledge flows would be beneficial.

6

1.3. Purpose and research question

Building on the problem outlined in the previous section there is a need to investigate the barriers and challenges encountered when companies implement eco-design in the product development process, specifically looking at the problem from a knowledge management perspective.

To summarise, during the implementation of eco design, product developers are not knowledgeable enough about the subject which hinders effective cooperation as well as communication with other stakeholders (I.e., managers, gatekeepers, production & manufacturing personnel). Furthermore, while there is literature that identifies the problem, articles investigating solutions are lacking. In order to address this gap in the literature, the aim of this article will be to investigate how companies resolve these issues. The following research question are stated to research the flows of information and knowledge for effective implementation of eco-design practices:

RQ 1.

How can knowledge be distributed to efficiently integrate eco-design into a company'sproduct development practices?

Additionally, to investigate the collaboration between the involved stakeholders closer (referring to the product development staff, gatekeepers, upper and lower level management and other affected

personnel) and identify the how to get the necessary engagement between these actors the following research question was stated:

RQ 2.

How can companies get all involved stakeholders committed to implementing ecodesign in product development?

By answering these questions, the aim is to contribute to the existing literature about eco-design implementation and get a better understanding of the knowledge flows of the process.

7

2. Theoretical background

This chapter provides the theoretical background for this research and the knowledge framework of the thesis is introduced. Relevant topics that will aid the reader in understanding the subject are explained and discussed with the aid of literature. An introduction to sustainability, the concept of eco-design, as well as product development is provided. Finally, the theoretical basis for the management of

knowledge is provided and put into the context of eco-design.

2.1. Sustainability

The areas covered by this research include eco-design and product development, all of which plays an important part of sustainable development on a macroscopic scale. After reviewing and analysing previous research relating to the topic, sustainability can be defined in the following way.

Schäfer and Löwer (2021) explains that due to the second law of thermodynamics (The entropy within the universe always increases over time) it is impossible to fully realise sustainable development. This is agreed upon by (Ljungberg, (2007) who states that it is almost out of the question to truly achieve a sustainable state within the current maximum range of human capabilities. Therefore, Schäfer and Löwer (2021) state that sustainability should be a concept of time, and be understood as

time-dependent. For example, a product can be sustainable within one month, but if the period is extended to one year or even ten years, it may be unsustainable (Schäfer & Löwer, 2021). Taking this in consideration, sustainable development was defined in the Brundtland report as the ability to satisfy requirements even after time spans of multiple generations -"the needs of the present generation without compromising the ability of future generations to meet their own needs'' (Brundtland & Khalid, 1987 p.29).

The company, its products, or its production processes should not be viewed as sustainable on their own but should be evaluated as a system (Schäfer & Löwer, 2021). It is these systems that should be the basis for sustainable evaluation. The nature of the systems may lean towards one or a mix of technical, social, biological/environmental aspects. As systemic participants, the personnel who implement eco-design often pay more attention to technological aspects, while ignoring other aspects such as social aspects (Schäfer & Löwer, 2021).

8

It is for this reason that a clear definition of sustainable development is needed. The most common definition of the concept covers the economy, environment and society (Purvis et al., 2019). These aspects are often referred to as the three pillars of sustainability or the triple bottom line (TBL), and express the interdependency between the three (Siva, et al., 2018). Furthermore, these aspects of sustainability cannot and should not always be viewed in isolation in the process of product-development (Schäfer & Löwer, 2021; Zetterlund et al., 2016). To the contrary, the aspects are interrelated and often heavily correlate or contradict one another.

In the process of practicing eco-design, the interdependent consideration among these three aspects should be regarded as a breakthrough in development (Bettley & Burnley, 2008; Dangelico & Pujari, 2010). Although the close relation between the aspects will inevitably result in the need to prioritise one over another so-called trade-offs. such situations can also be resolved through comprehensive considerations and compromise (Bettley & Burnley, 2008; Linton, et al., 2007).

2.2. Product development

Howarth and Hadfield (2006) uses the term product design to refer to the practice of developing old as well as new products. The authors state that the designer (i.e. product developer) is responsible for developing the technical aspects of a product while at the same time considering several other factors such as cost, aesthetics, ergonomics and more. On the other hand, the responsibility the product developer carries for the product's sustainability are not always as clear (Howarth & Hadfield, 2006).

2.2.1. Product development process

Waage (2007) describes a product development process (PDP) as a succession of four phases: understand, explore, define and refine, and implement. The first stage focuses on understanding the problem and observing and emphasising with the customer, the second phase explores possible solutions to said problem and often include rough prototyping. In the third phase, the best solution is developed into a product, and finally in the last phase the product is produced. The process is not always linear and the product development team might choose to execute some phases simultaneously or jump back and forth between them (Waage, 2007).

The PDP includes the provision of immaterial services, such as market and customer research, in addition to the development of the actual product. These invisible services can better meet the needs of the end customer after being integrated with the design (Tukker & Tischner, 2006). Eco-design aims to

9

reduce the input of materials in the process of product development to decrease environmental

pollution (Tukker, 2015). The author points out that the concept of PDP is very mature and it is a cross of multiple disciplines, involving multiple research topics and fields.

2.2.2. Eco-design in product development

Waage (2007) suggests a pathway for product developers to consider sustainability throughout the entire PDP, by first establishing what sustainability factors should be considered and sequentially evaluating and assessing the sustainable implications of different solutions for the design problem. Howarth and Hadfield (2006) applies a different approach and suggests a tool for evaluation of the risks and benefits of a product.

What sets Howarth and Hadfield (2006) and Waage (2007) apart from the most studies on eco design are that both articles acknowledge the three pillars of sustainability in their different approaches not just the environmental and economical. Although, the environmental and economical have received the most attention in the past there is a growing support for a more holistic approach by including social sustainability Thomé et al. (2016).

Although eco-design is conducted by the product development department, the development process of new sustainable products should involve multiple departments and fields such as manufacturing, business management, and environmental studies, engineering and more (Thomé et al., 2016). According to Zetterlund et al. (2016) the implementation of sustainability in product development is weak in most companies. However, recognising that the PDP is moving in a positive direction may be the first step to promote the implementation of eco-design (Mattioda et al., 2015).

2.3. Eco-design

Eco-design can be defined as a practice performed by the developers of a product, where the aim is to reduce a products negative environmental impact during its entire life-cycle (Schäfer & Löwer, 2021). Additionally, Schäfer and Löwer (2021) mention three defining characteristics of eco-design that most definitions of the practice have in common: 1) It regards products’ design and development, 2) the aim is to reduce the environmental impact of these products 3) and it consider the complete life-cycle of the products. In the viewpoints of Karlsson and Luttropp (2006) eco-design does not only mean "ecology", it also means economy. Although most of the known literature focuses on the benefits of eco-design on the environment, the economical dimension should also be taken seriously (Karlsson & Luttropp, 2006; Watz & Hallstedt, 2018).

10

Keoleian and Menerey (1994) points out that it is necessary to extend the concept of eco-design in process and purpose to encompass a complete ecosystem, arguing that the practice should consider the complete consequences of decisions on nature as well as people. However, social aspects are rarely considered (Thomé et al., 2016; Schäfer & Löwer, 2021). There are on the other hand an increasing number of authors that argue that an interdependent consideration of all three pillars of sustainability would be a positive development (Bettley & Burnley, 2008; Dangelico & Pujari, 2010; Zetterlund et al., 2016; Thomé et al., 2016).

The close relation between the aspects will inevitably result in the need to prioritise one over another in so called trade-offs. Trade-offs occur when the developer of a product must choose between environmentally friendly factors and other factors, e.g. cost-effectiveness or quality. The company must weigh the different alternatives and consider which one will give them an advantage over the competition. Since the value of environmental aspects is hard to compare to other aspects, other alternatives are often given a higher priority and get support from stakeholders. (Ilgin & Gupta, 2010; Schäfer & Löwer, 2021; Dekoninck et al., 2016) These situations should only be resolved through comprehensive considerations (Bettley & Burnley, 2008; Linton, et al., 2007).

Following another definition of eco-design by ISO/TR 14062 (ISO, 2002), Le Pochat et al. (2007) put forward two core objectives of the practice: Environmental assessment and environmental

improvement. Environmental assessment refers to the assessment of the environmental impact by products after the implementation of eco-design, while environmental improvement is aimed at finding solutions to environmental issues and decreasing the impact. Both of these help companies in the process of product development to reduce the harm to the environment. (Le Pochat et al., 2007)

Since there is no consensus regarding a single definition of eco-design this research will mainly focus on the more general definition provided by Schäfer and Löwer (2021), this due to the fact that the core interest of the study lies in the management of knowledge and the relationships involved in

implementing eco-design, rather than pushing the concept of eco-design forward. The definition by Schäfer and Löwer (2021), was viewed as wider spread and less exclusive since it does not necessarily exclude consideration of social sustainability, wish was deemed beneficial for the thesis.

11

2.3.1. Environmental Assessment

First of all, it is necessary to evaluate the environment, which the product will affect in the future, so as to facilitate a preliminary understanding of the product's possible impact on that environment, at the same time, the product design must be evaluated (Vallet, et al., 2013). The product life cycle is considered the starting point of eco-design standards (Thomé et al., 2016).

Masui et al. (2003) state that the first step of the assessment is to point out the environmental issues in the design of a product. Perhaps one of the most objective strategies used to determine the

environmental impact of a product, a process, or a material, is the LCA (Boks & Stevels, 2007). Using the evaluation method in the product design phase will expose the product’s environmental impact throughout its life-cycle (Romli et al., 2015). A product's life-cycle starts from the choice and sourcing of materials, to the processes involved in the production, to the use of the product, and in the end disposal or recycling of the product.

The focus on the complete life cycle stems from the fact that a product affects the environment during its entire life span, and initiatives to resolve one issue might lead to other issues elsewhere in its life span. Replacing plastics with metal can increase recyclability but will likely cause extra pollution during production (Boks & Stevels, 2007). The tool, and thus eco-design, is hence needed to determine a product's true impact on the environment and to avoid misclassifying products as environmentally friendly.

Multiple sources link the method to a reduction in used resources (Zhang, 1999; Senthil et al., 2003; Heijungs et al., 2010; Adhitya et al., 2011). Furthermore, when LCA is considered in product

development, the developers commonly consider the cost benefits, thus developing more sustainable products (Heijungs et al., 2010).

2.3.2. Environmental improvement

The other aspect involved in eco-design is the need for solutions and innovations to reduce

environmental pollution and impact of products (Le Pochat et al., 2007). Some examples of existing measures include the use of simple indicators to improve product recyclability (Cerdan et al., 2009), basic principles and guidelines such as reduce, reuse, recycle (RRR) and pollution prevention pays (PPP) (Boks & Stevels, 2007), or the use of more environmentally friendly materials “eco-materials” (Cicconi, 2020).

12

Eco-materials have the potential to reduce environmental impact in many different ways, they can improve the recyclability, reduce the amount of material used, and reduce energy consumption both during the manufacturing as well as the use of a product (Halada & Yamamoto, 2001; Allione et al., 2012; Cicconi, 2020). Additionally, innovative eco-materials can make use of already recycled materials to increase the lifetime and durability of a product (Cicconi, 2020).

Considering environmental factors when implementing eco-design usually means an increase in product costs, and the product development stage is often already related to high costs. But by adding inspiration and strategy when designing products, it can better solve these problems (Vallet et al., 2013). This mainly relies on creativity and the use of strategies (Brezet & Van Hemel, 1997). Since multiple aspects are generally involved in the process of product development, redesigning the product and integrating creativity into the design can better improve the sustainability of the product.

Therefore, companies are motivated to explore various methods to better make use of creativity to integrate eco-design concepts into product development.

2.4. knowledge management

2.4.1. Defining knowledge management

Knowledge can be either explicit, formalised and annotated knowledge such as data, or tacit,

unformulated personal knowledge that is hard to transfer (Gao et al., 2018). Knowledge management in an organisation refers to the process by which knowledge workers manage and transform knowledge that exists itself in the organisation as well as knowledge that are newly discovered (Gao et al., 2018). Goepp et al. (2013) defined the strategy of knowledge management and stated that it is composed of at least three subsystems: “(1) E-KM (explicit knowledge management and basic knowledge management functions) for codification, (2) T-KM (tacit knowledge management providing a cooperative working environment) and (3) I-KM (knowledge discovery)”- (Goepp et al., 2013, p.5805 were I-KM refers to Implicit knowledge management.

Chalmeta and Grangel (2008) defined the entire process of knowledge management design to reduce its complexity and divide it into five stages: “(1) analysis and identification of the target knowledge, (2) extraction of the target knowledge, (3) classification and representation, (4) processing and storage and (5) utilisation and continuous improvement” - (Chalmeta & Grangel, 2008, p.744)

13

Knowledge management is usually the basis for companies to integrate eco-design into the product development process (Reyes, 2007). Goepp et al. (2013) point out that effective eco-design requires effective knowledge management. Therefore, knowledge management is helpful to companies and projects working with eco-design (Saad et al., 2005).

2.4.2. Knowledge management and eco-design

Today the requirements for competence among enterprises is becoming more and more demanding. Completing the development of new products within budget, while achieving various technical requirements is all goals that companies must achieve within the specified delivery time (Hesselbach, et al., 2003). Due to market and legal requirements, consideration of products’ environmental impact has become increasingly important in the process of product development, further adding to the competencies required by companies (Dammert et al., 2003).

Although many companies have several years of experience in how to integrate technical requirements into product development, they still lack the knowledge of eco-design considerations and evaluations (Gruner & Birkhofer, 1999). In this sense, implementing eco-design is a huge challenge for many companies (Goepp et al., 2013). Cicconi (2020) emphasizing the need for a platform that enables quicker knowledge sharing especially regarding eco-materials and their processes.

Hesselbach et al. (2003) indicate that one way to successfully implement eco-design is to use a specific knowledge management system (KMS). Such a system can support the creation, transfer and use of knowledge in the organisation (Alavi & Leidner, 2001). However, Ma and Hemmje (2002) state that a KMS cannot be developed directly through the theory of knowledge management, because in most cases technical personnel do not understand the structure and function of the KMS.

Birch, et al. (2012) discuss the topic of the environment and summarise their experience in DfE and pointed out that a combination between integration activities and functions in the early stages of product development can promote the consideration of the environment in product development. On the other hand, cooperation in multi-functional teams during product development, will make it easier for internal team members to learn about environmental issues and marketing (Lindahl & Ekermann, 2013).

14

According to Hesselbach, et al. (2003), in order to implement eco-design efficiently, two main challenges must be solved: (1) Provide information in order to enable product design technicians to solve environmental problems from the early stages of product development; (2) Strengthen multi-functional teamwork. Knowledge management and related knowledge management systems can effectively deal with these problems.

Maier (2004) indicates that the creation of new knowledge and the management of existing knowledge can be realised through the following functions: discovery of new knowledge, management of explicit knowledge and professional knowledge. In other words, an efficient knowledge management system can effectively improve the eco-design practices of the product development stage (Goepp et al., 2013).

15

3. Methodology

This chapter aims to provide a description of the methodology used to conduct the thesis. The

methodology is the foundation of which academic work are built on and are therefore a crucial part of the overall research. Firstly, an introduction to the founding philosophy, methodology and research design will be provided. Secondly, the methods applied for data collection and analysis will be explained and finally the ethics and trustworthiness of the study will be clarified.

3.1. Research structure

Often when students attempt to select research methodology, incompatible methods are combined, and consequences of the choices are disregarded (Håkansson, 2013). This thesis methodology were

generally based on the research portal (Figure 1) provided by Håkansson (2013) as a support for selecting an appropriate methodology. Additionally, Harrison et al. (2017) was used for more specified knowledge aligning with the thesis methodology.

Figure 1: The research portal as described by Håkansson (2013).

The initiating process of the research were focused on at identifying gaps in previous research, which were used to identify the research question. To align the methodology with the stated questions, it was

16

apparent that the answers needed to be qualitative nature giving an insight into the problem. Due to the nature of the problem an inductive approach was used to deliver a general answer based on particular facts (Håkansson, 2013).

To gather the necessary data, empirical research was considered, previous research on the subject could however not be disregarded, and the method would therefore need to be combined with applied research methods. The methods were performed in the format of a multiple case study. Since case studies enable a holistic view of a research problem and can allow a deep understanding of a researched case, it was considered a good research strategy for the thesis (Baškarada, 2014).

Philosophy helps the researcher motivate their work and assume a perspective of the world in which the research is conducted. To define the philosophy both an ontology and epistemology needs to be defined although they are to a high degree related to each other Ontology regards how the world works and how the researcher views reality, and epistemology regards “the nature of knowledge” and aims to explain how the researcher makes sense and interprets information.

It is important to realise that to make sense of the qualitative data, reality must be constructed by the understanding and experiences created by the observer which is described as the constructivist view of knowledge by Harrison et al. (2017). This will be the epistemology followed in this thesis and is chosen with regards to the connections to the rest of the methodology. Furthermore, a pragmatic ontology will be applied in accordance with one of the philosophical variations for qualitative case studies described by Harrison et al. (2017). This variation allows the researcher to approach the research in the most suitable for the purpose. Harrison et al. (2017) mentions that it is common for researchers using this philosophical variation to conduct case studies to choose their cases with the research questions in mind focusing on what they can reveal. Therefore, a nonprobability sampling method were applied inspired by maximum variation cases described by Flyvbjerg (2006), the cases were chosen based on their relevance to the research question, their comparability, as well as their large variation in size.

The main source of data was gathered from interviews with the cases in accordance with the philosophical approach (Harrison et al., 2017). Further information was gathered in the theoretical background as well as other secondary sources such as the cases web pages to allow for triangulation.

17

3.2. Multiple case study

Flyvbjerg (2006) indicates that case studies have a long history as a method of exploration strategy. However, various backgrounds of diverse disciplines, undoubtedly adds complexity to the structure of case studies (Farquhar, 2012). In the past, many researchers have provided definitions and descriptions for case studies. Yin (1994) emphasises that the nature of case study research is empirical, while it focuses on the process and scope of the case study, while the stance of Stake (1995) is more flexible and focuses on the content of the case rather than the method. (Harrison et al., 2017)

Case studies are applied to get a holistic understanding of problems in real life setting and suitable to answer how and why research questions (Harrison et al., 2017). It is a common approach although frequently performed poorly (Baškarada, 2014). From an academic standpoint one argument against case studies is the difficulties that can arise with justifying the validity of the findings, as well as the scientific importance. However, performed correctly it offers a good path to investigating a research problem. Other benefits include, amongst other, comparisons between best practises. (Baškarada, 2014)

Baškarada (2014) offer a modified six step approach to case study research which was followed in this study. The steps consist of Plan, Design, prepare, Collect, Analyse, and Share the process allows for iterative updating when new information is discovered. The author emphasises that it is significant that the performers of the case study are well understood with the concepts and theories regarding the research problem already before proceeding, therefore the theoretical background was an important part of this thesis. To analyse multiple cases rather than a single case was decided, since multiple cases can give more robust results (Baškarada 2014).

3.3. Data Collection

The empirical data was collected by interviewing managers responsible for product development from two different companies. In order to get a detailed understanding of the obstacles encountered in the implementation of the eco-design process and achieve the purpose of this research, the participants were interviewed for a duration of approximately 45-60 minutes using semi structured interviews. The impact of the covid-19 pandemic as well as the distance to the companies made face to face interviews an impossibility, instead the video conference software zoom was used to conduct the interviews online. Throughout April 2021, 6 experienced practitioners working in product development

18

departments was interviewed. A list of the interviews is shown in Table 1. Table 1: Interview schedule

Date Duration Participant

Company A 12-04-2021 60minutes Manager

Company A 16-04-2021 56minutes Product development technician Company A 19-04-2021 45minutes Product development technician

Company B 22-04-2021 43minutes Manager

Company B 28-04-2021 35mins Product development technicians

As shown in Table 1, a manager and two technical personnel active in the product development department from Company A was interviewed. Each participant was interviewed separately for 40 to 65 minutes. similarly, a manager and two technicians from Company B were interviewed as well, however the format was slightly different compared to the interviews carried out with Company A. The two technicians from Company B were interviewed at the same time, while the duration of the two interviews was about 35-45 minutes slightly shorter than the interviews with Company A.

When conducting qualitative research, semi-structured interviews are the most common method (Stake, 2005). Before the start of each interview, the interviewer should investigate the background of the interviewed company, their product information, and carefully prepare the interview questions Dilley (2000). An interview guide was created considering the company's knowledge and

circumstances, the questions can be seen in Appendix 1. During the interview, the interviewees were asked to share their opinions, focusing on their own experiences and views on eco-design during the entire product development process in order to get a complete understanding of the situation and understand the relationships and knowledge barriers that exists. With consent from the interviewees the interviews were recorded and later transcribed. At the same time, it was important that the interviewer took notes of the key points mentioned by the interviewee and interpreted the answers paying attention to expressions, body language, context, as well as what’s not being said (Dilley, 2000). To avoid influencing the interviewees answers throughout the interview process the interviewer didn’t interfere with individual thoughts or remarks, on the other hand follow-up questions was used to

19

create a better understanding, a good discussion between the interviewer and the interviewee and thereby creating qualitative data (Dilley, 2000).

To conclude, interviews were used to collect necessary empirical data. Furthermore, the interviews were held with personnel and stakeholders responsible for product development. five semi-structured interviews were performed with two companies and an interview guide was established with several open-ended queries.

3.4. Data Analysis

To make sense of the collected data from the interviews the transcripts, recordings, and notes taken during the interviews was used. To get familiar with the data and initiate a within case analysis write ups were created individually for the two cases. The write ups were used to find patterns within the cases wish in turn simplified the cross-case comparison of the data. (Eisenhardt, 1989)

A continuous comparative method (CCM) as described by Baškarada (2014), was used for iterative interpretation as new information was discovered. The data was scanned for similarities as well as differences in between and within the two cases in order to achieve a more mature understanding (Eisenhardt, 1989). The information was coded based on the discovered similarities and differences to reduce the complexity and simplify analysis. To triangulate the coded findings from the interviews, they were compared to data collected from the company’s webpages as well as the data collected in the theoretical background (Easterby-Smith, et al., 2018). Finally, the most relevant discoveries were selected and applied to draw a conclusion about the research questions. The conclusion was aimed at describing and representing both the cases similarities and differences as well as the relationship between the cases and the gathered theoretical background.

3.5. Research quality 3.5.1. Trustworthiness

In the 1980s, Guba and Lincoln pioneered the use of “trustworthiness” instead of “reliability” and “validity”. Trustworthiness covers four aspects: credibility, transferability, dependability and confirmability. Morse et al. (2002) on the other hand indicate that reliability and validity are still concepts that make qualitative research rigorous. Håkansson (2013) mention confirmability and transferability as additional factors to be addressed for qualitative research as well as dependability as an equivalent to reliability.

20

To avoid tainting the research’s trustworthiness with biases during the investigation and analysis process, and to take responsibility for the dependability and validity of interviews self-reflection and integrated verification measures was used. Tis was to ensure that the requirement of the research’s quality was met analysing the information as well as during the interview and data collection (Morse et al., 2002). Furthermore, to increase the confirmability and the transferability of the research, quotes from the interviews was provided (Håkansson, 2013).

To ensure that the chosen cases were appropriate for the research, it was important to do an investigation before selection. Various kinds of information about the company’s products and operations was collected through online sources (such as their official websites, email, and social platforms) to determine whether the company fitted the requirements.

Additional steps were taken to further increase the dependability and quality of the collected data. Since the purpose of the research was to explore the knowledge distribution problems and the obstacles to stakeholder participation encountered in the implementation of eco-design practices in the product development process, to avoid a one-sided view from the managers perspective additional interviews were help with other personnel involved in the product development process in order to triangulate the data.

3.5.2. Ethics

In order to protect and maintain participants privacy and avoid any type of coercion ethical practices was considered during the entire thesis (Håkansson, 2013). While collecting the empirical data, the interviews were carried out according to the interviewees’ individual preferences. Preceding the interviews information about the thesis was sent out informing all participants about the objectives of the thesis as well as the ethical conduct of the interview. The first contact with the companies were made with an invitational email (Appendix 2) and additional information was provided about the purpose and conduct as seen in Appendix 3. The interviews were recorded with the consent from the interviewees wish were informed that consent could be withdrawn at any point of time in wish scenario the records would be deleted.

21

Throughout the research process, contact was maintained with the interviewees and data as well as personal information were stored according to General Data Protection Regulation (GDPR) guidelines. This ensured that during the processing of the collected information, data, as well as personal and sensitive information was kept confidential and would not be leaked to a third party. The interviewees were informed that the data collected through the interviews would be used for this research only and was to be destroyed after the completion of the thesis.

22

4. Empirical findings and analysis

This chapter describes the data and content obtained from the interviews. It also introduces the analysis process based on these empirical results in detail. To solve the problems raised in this thesis, a more practical understanding of the difficulties encountered in the implementation of eco-design in the product development stage was gained trough the interviews with the two companies.

4.1. Introducing the cases

This section contains a brief introduction of the backgrounds of the two interviewed companies and their efforts and achievement in implementing eco-design in their product development phase are described.

4.1.1. Company A

Company A is a medium size manufacturer which is located in Hubei Province, China. The company specializes in the production of automobile back covers. It is worth mentioning that Dongfeng Motor Group is located in Hubei Province as well. Dongfeng Company is one of China's super large motor manufacturing corporations, while its main business covers commercial vehicles, new energy vehicles and other related businesses. As one of the suppliers of Dongfeng Motor's back cover, Company A enjoys a good reputation locally.

The business scope of Company A is distributed all over China, as far as Inner Mongolia in north western China. Although Company A is a recently established start-up company, although it has accumulated a large number of customers in its first years of development. Their main products are car back covers. However, they also provide follow-up maintenance services.

With the continuous development and maturity of the motor industry, competition has become increasingly fierce. As Company A develops, it has discovered that end customers are cumulatively demanding sustainable products. The company decided early on to integrate eco-design into product development. As the Company A proceeds to mature, it systematically considers quality, cost and environment in the early stages of product design, and at the same time proposes a set of

23

Integrating eco-design into product research and development has become a new development direction for Company A. The company carry out environmental balance and environmental analysis in their production, uses and final recycling process of the product, and aim to reduce the enterprise's internal and external environmental costs as well as impact on society through preventive measures (Romli et al., 2015). So as to get closer to the goal of effectively solving the environmental pollution problem caused by the motor industry.

As an important part of the overall car body, the car back cover is located at the end of the car body, accounting for about 23% of the weight and is an indispensable body covering part. Therefore, in order to reduce the weight of the car so that it emits less GHG during its operation, a lightweight car back cover is an important focus for research.

Among the many products produced by this company, an investigation on the research and

development process of the steel back cover and aluminium alloy back cover of gasoline vehicles was conducted.

Company A aims to incorporate environmental factors into the company's strategic development. At the same time, the company also considers eco-design in the product development process. While considering the long-term goal of sustainable development of the company, it also focuses on the current needs of customers (Fargnoli et al., 2018).

It was apparent that the company not only considers the impact of the product on the environment at a certain stage of its life cycle, but also evaluate the entire life cycle of the car. They comprehensively considered product requirements for resources, performance, and cost, in order to make its products more sustainable. The company continues to explore new ideas to achieve this goal during its product development stage. In the process of its exploration, they have considered optimised design, use of lightweight materials and application of advanced technology to make products more environmentally friendly. In its implementation of eco-design, the company found that using lightweight materials was the most effective measure to reduce pollution.

24

4.1.2. Company B

The second company interviewed in this study, is a global high-tech company originating from Taiwan that specialises in production of mobile phone parts and semiconductor technology. The interview was conducted with Company B's branch base in Henan Province, China and should be seen as the subject of the interviews. As a mature company, Company B implements a corresponding eco-design strategy for its new products and has its own set of eco-design solutions. In the product development stage, they consider selecting materials with low environmental impact and aim to minimise the use of materials, while continuously optimising production technology.

As a national company, Company A reports that it has always fulfilled its social and environmental responsibilities and advocated green operations. Focusing on the corporate goal of "energy saving, emission reduction, greening and recycling", Company A has established environmental protection associations to respond to the call for environmental protection. While meeting the environmental protection requirements of international customers, the company assumes social responsibility and makes its own contribution to environmental protection.

In order to increase employees' environmental awareness, Company B advocates that all employees participate in the sustainable development theme. The company regularly holds lectures to employees and organises environmental protection exchange conferences. At the same time, the interviewees declare that the company invests large amounts of money every year in environmental protection work such as park greening and waste recycling.

Company B insists on independent research and development in production, actively uses the most advanced technology to promote environmental protection. In the product development stage, it integrates the entire life-cycle of the product. In the process of implementing eco-design, the company mainly focuses on the three stages of product demand analysis, requirement analysis and specific implementation process analysis.

In the product development stage, the product will be developed with consideration for its entire life-cycle. Furthermore, the process of implementing eco-design is mainly concentrated in the three stages of market demand analysis, product requirement analysis, and specific implementation process

25

Before implementing eco-design, an analysis of the basic needs of the market are conducted by

investigating the current market environment. Then, the company improves and innovates based on the performance and cost requirements of the product itself. Finally, the products are redesigned by

adopting appropriate eco-design measures.

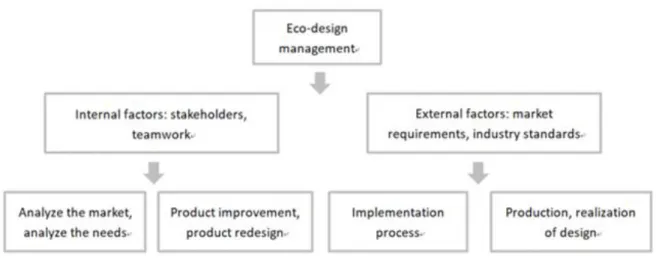

Figure 2: The implementation of eco-design practices as described by Company B

According to the data obtained in the interviews and the materials collected from the company's website, it can be seen that Company B has a complete design framework when implementing eco-design. As shown in Figure 2 above, the management of eco-design is mainly divided into two parts, one is the company's internal factors, which includes relevant stakeholders and teamwork; the other is determined by external factors such as market requirements and industry standards. In the process of implementing eco-design, enterprises should not only meet the standards of the external environment, but also meet the needs of consumers (Crul et al., 2009). Product development personnel and design teams are core participants that play an important role in the industrial market (Spangenberg et al., 2010). They need to integrate various environmental dimensions and combine multiple conditions to increase the success rate of implementing eco-design (Vallet et al., 2013).

Company B considers the demand of the market from an internal perspective. While redesigning products for improvement, consider quality, cost and environmental factors (Kobayashi, 2006). On the other hand, driven by external factors, the implementation process and product design are the main focus of Company B. From the point of view of eco-design practices, product improvement means further adjustments to existing products; while product redesign means replacing original product

26

components. (Vallet et al., 2013). However, whether it is product improvement or product redesign, it is an innovation of function and system (Brezet et al.,2001).

When implementing eco-design in the product development stage, the first consideration by Company B is the choice of materials. In the eco-design process implemented by the company, no matter which materials are considered, the ultimate goal is to choose the most environmentally friendly alternatives for the products, so as to reduce the negative impact on the environment.

Company B declares that they currently promote the use of clean materials in the production process vigorously, and avoids the use of additives or fuels that may produce toxic gases during the

manufacturing process. For example, the use of added metal compounds that will destroy the ozone layer such as chlorine, fluoroethyl, bromide, etc. is minimised in the production process. Additionally, the company are actively exploring new technologies and finding alternatives to traditional treatment technologies to reduce harmful gases emitted during the production process.

In the long run, the use of environmentally friendly materials will inevitably increase the cost of raw materials for enterprises. Therefore, some materials that contain environmentally friendly properties will also lead to increased procurement costs.

As a professional manufacturer of mobile phone parts, Company B has a system for implementation of sustainability in their product development and production processes. A professional eco-design team is responsible for the implementation of eco-design in the product development process. The team incorporates environmental factors into the design whish allows the product development personnel to focus on the direction of the design. The entire life-cycle of the product is considered to ensure that the harm to the environment is minimised and ultimately lead to the creation of a sustainable products and production systems.

The integration of eco-design in the product development stage is also in line with Company B's corporate culture. The company emphasises that, in recent years, with the increasing demand for the production of sustainable products, companies that are responsible in the industry have all set an example, established a positive corporate image, and strive to become the benchmark in the industry.

27

4.2. Distribution of knowledge

It is not that simple to integrate eco-design into the product development process. When implementing eco-design, the designers apply the key activities related to environmental assessment in order to evaluate and improve the environmental performance of the products, however, there are still difficulties (Le Pochat et al., 2007). While trying to use different management tools to promote eco-design, a knowledge-centric management approach is necessary for companies that intend to implement eco-design into their operations.

Baouch et al. (2014) emphasise that the issue of integrating eco-design in the product development stage, seen from the perspective of knowledge, is that product designers and the product development personnel lack relevant knowledge of eco-design. One of the reasons is that the professional

knowledge in eco-design cannot be well established or shared (Gregory et al., 2013).

Company A reports that their product development team is composed of a group of energetic young people. Everyone in this department has a complete understanding of product development and

technology, at the same time as they have certain knowledge in the field of eco-design. The company’s product development leader mention that in the early days of the company’s creation, the product development team did not integrate the concept of eco-design into product development. The reason was that in the beginning of the company's development, as expected from entrepreneurs, it is

inevitable that the first task is to improve the company's performance to ensure and maximise profits in the shortest possible time. Therefore, at the beginning, the knowledge of and concept of sustainable development was not distributed to everyone in the product development team.

With the development of Company A and the growing call for environmental protection, the

company's senior management began to consider the concept of eco-design. More and more customers regard sustainable products as one of their requirements of suppliers, which also forces the company to make environmentally friendly products one of its corporate goals (Karlsson & Luttropp, 2006).

Company A explains that it is constantly exploring and learning in order to efficiently integrate eco-design into product development. When they integrate eco-eco-design concepts into product development, they often face the phenomenon that product development personnel do not know enough about sustainable development or eco-design (Johansson, 2002). Developers often report to leaders, and

28

discuss with team members, about technical issues, but they often overlook the important issue of making product and production more sustainable.

After realising the importance of implementing eco-design, the manager of Company A's product development team played the role of distributing eco-design knowledge. In the process of developing a product, the managers distribute the knowledge to the teams, which is then implemented by the

technical staff. But in the process, it was discovered that because the person in charge is not a

professional in the eco-design field, they don't always have the knowledge to understand the concept of eco-design (Bey et al. 2013). The interviewed manager mentioned that the initial knowledge

distribution process was not ideal. It's not that managers don't want to integrate eco-design into product development efficiently, but that they lack the necessary knowledge to do so.

Based on the feedback received during the implementation process, after continuous learning and improvement along the way, the decision makers tried to hire a professional team in eco-design to provide guidance (Schäfer & Löwer, 2021). However, this method has been proved in subsequent practice and it cannot solve the problem of knowledge distribution very well (Boks, 2006).

Considering the fact that professional eco-designers often specialise in environmentally friendly product development and lack the understanding of the company's specific product technology. The designers can contribute with deep insights into areas such as implementing eco-design or

environmental protection, however, there is a lack of professional knowledge in product development and quality improvement. Therefore, Company A often faces situations where eco-designers and product development teams disagree (Luttropp & Lagerstedt, 2006).

After realising this problem, Company A's senior management began to think about how to solve this problem in a better way. In the end, they decided that at least 60% of the product development team must be compound talents who understand product technology as well as eco-design. Because only those who have a certain amount of involvement in product research and development combined with eco-design can quickly find the entry point to combine these two and achieve the purpose of efficiently integrating environmentally friendly design.

Dekoninck et al. (2016) also indicated in the study that one of the important criteria for companies that can implement eco-design plans for a long time is their employees with rich experience in

29

implementing design. That is, there is at least one employee who has officially implemented eco-design.

Most of the members in Company A’s product development team are experienced practitioners in the field of eco-design, and consider both product development and implementation of eco-design.

Concerning the distribution of knowledge, because more than half of the people in the team have been involved in these two fields, knowledge can be naturally and efficiently transferred.

For Company B, the interviewed supervisor, who is in charge of team research and development said in the interview that the company has a relatively complete implementation process for eco-design and there is basically no problem in the distribution of knowledge. The team in charge of eco-design will collaborate with product development personnel during the product development process, and communicate the final materials and innovative technologies. The entire process is regulated and controlled by the external regulatory department, while the final product design plan must be consistent with the company's sustainable development strategy.

Company B continues to improve the company's sustainable strategy during its development, and has developed relevant departments to implement eco-design. The manager of Company B mentioned that at the beginning of the company's development, they inevitably encountered the problem of knowledge management when implementing eco-design. The problems confronted by Company A were also confirmed at the beginning of Company B's development.

Compared with Company A, Company B has adopted more comprehensive measures in implementing eco-design, and can effectively distribute knowledge where it’s needed. On the other hand, the

company has independent supervision and sustainable development strategy departments to control it at all times, these departments contribute to the more efficiently distributed knowledge.

4.3. Stakeholders' Attitudes

As mentioned above, Company A has improved the material of the car's front cover through their integration of eco-design into their product development. Aluminium alloy materials are used instead of traditional steel materials. The weight and density of aluminium alloy are only one-third that of steel at the same time as the energy absorption capacity of aluminium of the same mass is twice that of