Strategy for digital

transformation that supports

manufacturing business value

Master thesis work

30 Credits, Advanced level

Product and process development

Production and Logistics

Jens Brauer & Alexander Stenfeldt

Commissioned by: MITC

Tutor (Company): Erik Andersen

Tutor (University): Anna Granlund and Mats Ahlskog

Examiner: Antti Salonen

i

ABSTRACT

The emergence of new digital technologies and their potential strategic contribution is currently one of the most prominent concerns for organizations. Despite the opportunity brought on by modern digital technology, an estimated 66-84% of digital transformation projects end up failing. Therefore, a research question was formulated as; How to formulate a strategy for digital transformation that supports

manufacturing business value?

An abductive research approach was utilized to reach two main research objectives; Creating a description of how the current and future digital landscape is understood and creating a description of how digital transformation can be constructed and what strategies and/or strategical elements exist within that construct. Furthermore, one manufacturing case company within the automotive industry and specifically its formal initiative and efforts to conduct a digital transformation were examined. By creating this comprehensive context, it was believed that existing knowledge could be solidified, and new knowledge could be created to answer the research question.

Scattered and diverse findings regarding a multitude of elements are presented in the frame of reference, in order to build a strong basis for analysis. Distinguished levels of conceptual strategies within the construct of digital transformation are recognized as “Digital Business Strategy” and “Digital Transformation Strategy”. An empirical study is presented that examines present elements such as a conceptual roadmap, task teams, and an overall description of a formal initiative towards digital transformation, as well as how these elements are interpreted and understood by leaders within the organization.

The analysis consists of a comparison between the presented literature and the empirical findings. This is viewed through the lens of the research objectives in order to show commonalities and differences between the literature and the case company, and to corroborate findings. Most prominent is the absence of a digital business strategy at the case company in contrast to the expressed necessity for one in the literature.

In a presented discussion, strategy as a linkage between business value and digital transformation is argued to be direct through a digital business strategy. The answer to the stated research question is that digital transformation and strategy formulation can not be understood as a linear, but rather an iterative and evolving process involving building an absorptive capacity, assessing maturity, formulating a digital business strategy, and creating a roadmap and a digital transformation strategy that support the digital business strategy and the maturity level.

Conclusively, the findings of this report are corroborated by each other but lack empirical evidence as to the meaning of being successful and valuable manufacturing business in the setting of the fourth industrial revolution is yet unknown. However, practitioners are encouraged to employ a conscious business model perspective, while researchers are discouraged of thinking about digital transformation as a linear and sequential process.

ii

ACKNOWLEDGEMENTS

First and foremost, we would like to express our upmost gratitude towards the case company representative who initiated this thesis project and trusted us with and supported us through the task. Secondly, we want to thank Mälardalen Industrial Technology Center (MITC). Partly, for sponsoring the work, but more importantly for welcoming us into your facilities and supporting, spawning new ideas and angles, challenging, and questioning the research continuously. In our mind, you facilitate a fascinating playground for ideas and have been an invaluable source of inspiration. We have enjoyed every minute. Thirdly, we are deeply thankful to our academic tutors Anna Granlund and Mats Ahlskog, who have provided brilliant feedback and support throughout the entire process. Your support and encouragement to clarify and crystallize arguments and ideas have been one of the most important assets throughout the writing of this thesis.

Fourthly we would like to thank the respondents of the study for taking the time and really engaging in our conversations and interviews. We are very grateful for your engagement and enthusiasm.

Eskilstuna, 2021-01-06

iii

Table of Content

1. Introduction ...1

1.1 Background ... 1

1.2 Aim and Research question ... 2

1.3 Research scope and limitations ... 3

2. Research Methodology ...4 2.1 Research approach... 4 2.2 Data collection ... 4 2.2.1 Literature review ... 5 2.2.2 Observation ... 6 2.2.4 Interview ... 7 2.3 Data analysis ... 7

2.4 Quality of the research ... 8

3. Frame of reference ... 10

3.1 Industry 4.0 - The current technological era ... 10

3.1.1 Technologies ... 11

3.1.2 Design principles ... 11

3.1.3 Applications ... 12

3.1.4 Challenges ... 13

3.2 Digital transformation ... 14

3.2.1 Evaluation of the Digital Maturity ... 16

3.2.2 Strategies in the context of digital transformation ... 17

3.2.3 Methodological Approaches ... 20

4. Empirical findings ... 22

4.1 Introduction to the case... 22

4.2 Digital Transformation Initiative ... 22

4.3 Roadmap ... 24

4.4 Task Team ... 25

4.5 Maturity Assessment Model ... 26

5. Analysis ... 28

5.1 How is the current and future digital landscape understood? ... 28

5.2 How is the digital transformation constructed? ... 30

5.2.1 Evaluation of maturity ... 31

5.2.2 Strategic Orientation ... 31

5.2.3 Implementation ... 33

6. Discussion ... 35

6.1 How to formulate a strategy for digital transformation that supports manufacturing business value? ... 35

7. Conclusion ... 37

References ... 39

Appendices ... 43

Appendix 1 – Framework by Correani, et al. (2020) ... 43

iv

List of tables

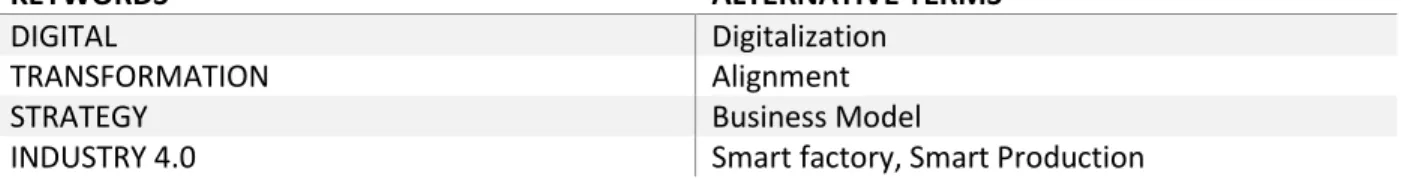

Table 1 Keywords and Alternative terms ... 5

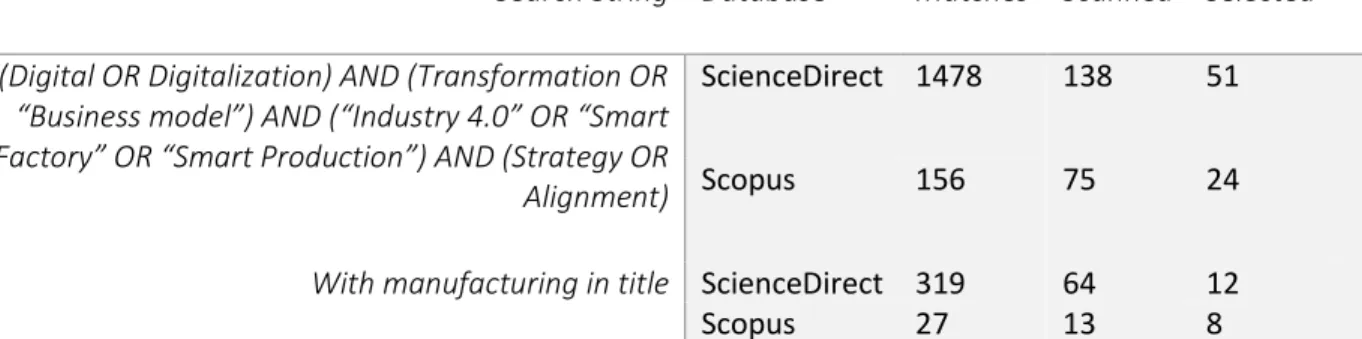

Table 2 Illustration of search strings, data bases and results ... 6

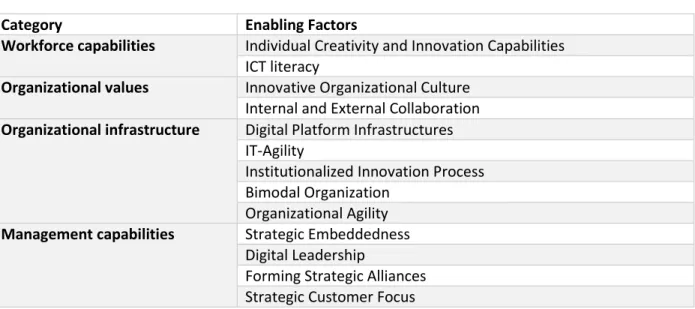

Table 3 Categories of factors enabling Digital Transformation initiation (Muehlburger, et al., 2019) ... 16

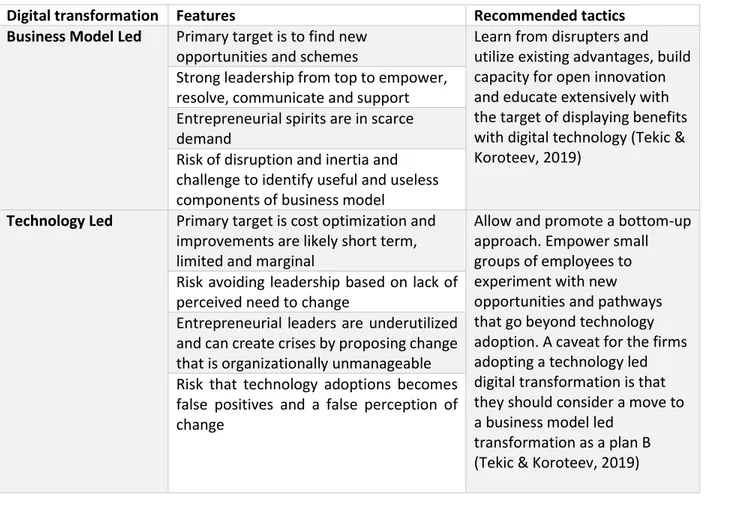

Table 4 Business Model Led and Technology Led Digital Transformation ... 19

1

1. Introduction

In this section a background to the problem is explained leading to the aim and research question for this thesis. The section sums up with a description of the scope and limitations for the research.

1.1 Background

The emergence of new digital technologies and their potential strategic contribution, is currently one of the most prominent concerns for organizations (Korachi & Bounabat, 2019). The 4th industrial revolution signified by the adoption of cyber-physical-systems and new digital capability, is predicted to enable fully autonomous and intelligent production systems, leading to immense impacts on the global economy (Piccarozzi, et al., 2018). Embracing the digital technology brought on by the fourth industrial revolution and driving digital transformation can enable strategic advantage for individual companies, in terms of aligning products and services with customer demands as well as enabling better internal processes for example with faster innovation and shorter time to market (Brown & Brown, 2019; Correani, et al., 2020). As digital transformation in the current technological environment is described as bringing massive business improvement that enable future competitiveness (Brown & Brown, 2019), there is also a perceived urgency to transform as the disruptiveness may limit the time frame of opportunity (Tekic & Koroteev, 2019).

Despite the opportunity brought on by the modern digital technology, an estimated 66-84% of digital transformation projects end up failing. For example, General Electric’s software operations facility

intended to support their digital strategy, ended up firing 100 employees and Nike ended up discontinuing their Nike+ products, even though the transformational initiatives in both cases arguably made strategical sense (Correani, et al., 2020).

Another example that provides some clues to the high failure rate and the problematic nature of technology adoption, is the enabled information sharing across supply chains brought on by the technological advancement of the industrial fourth revolution. It is a claimed advantage from a logistics and supply chain management perspective that information and knowledge travels at a higher speed and enable more accurate planning and decision making. At the same time, one of the most prominent barriers for adoption of the corresponding innovation is the unwillingness from participants within the supply chain to share information with each other. I. e. technology enables pivotal strategic advantage that is not in alignment with the organizations information sharing policy (Preindl, et al., 2020).

The observed effects of management activities to drive digital transformation towards an Industry 4.0 maturity, substantiate the meaning of these observations. For example, “Mission and Vision Statements” are found to be positively associated with industry 4.0 readiness while “Strategic Planning” is found to be negatively associated with industry 4.0 factors, even though they are closely related. This would indicate that strategic plans and roadmaps are poorly developed and generally fail to increase digital maturity. This finding is suggested to reflect a lack of strategic focus and poor definition of goals and understanding of implementation (Črešnar, et al., 2020).

One key finding in literature, is the seemingly paradoxical observation that organizations that are digitally more mature, do not treat digital advancement as a goal but a tool or means to reach strategic objectives (Tillväxtverket, 2017). Along the same lines, digital maturity of a company can be understood as a

2

company and its leaders having a well understood vision for how to benefit from digital technology (Brown & Brown, 2019).

Research on distinct success cases of ABB, CNH Industrial and Vodafone indicate the importance of consistency between strategy formulation and strategy implementation while providing a generic framework that guides digital transformation efforts through a description of the given business model (Correani, et al., 2020). The view, that the coherence between business objectives and transformational efforts is important is widely shared (Brown & Brown, 2019; Zineb & Bouchaib, 2020). According to Kane, et al. (2015) it is not necessarily the technology that drives a digital transformation, it is the strategy. The topic of digital transformation strategies is extensively researched although there is still conflict in the literature regarding what success factors and key elements that are required for successful digital transformation, as well as the barriers and problems that companies are faced with (Korachi & Bounabat, 2019).

Common features that correlate with the above-described examples and issues, can however be distinguished. One obvious example is the common recommendation, that is often suggested to be at the core of transformation management, of an overall vision for a strategically beneficial future state (Albukhitan, 2020; Brunetti, et al., 2020; Korachi & Bounabat, 2019). Similarly, some conclude that in silo and stand-alone initiatives are futile in conducting an organizational digital transformation (Zaoui & Souissi, 2020; Brunetti, et al., 2020) and that lack of strategy and vision is a major barrier to overcome (Vogelsang, et al., 2019). Parallel to the notion of the importance of vision and strategy, is the observation that the development of such a vision and strategy is a struggle for many organizations (Mushore & Kyobe, 2019; Fischer, et al., 2020). It is a challenge in terms of incorporating interrelations between processes, work practices and stakeholders and creating alignment in objectives (Mushore & Kyobe, 2019), as well as being able to design material and strategic objectives from overwhelming opportunity and challenge (Fischer, et al., 2020).

The topic and phenomena of digital transformation is documented and presented as frameworks (Korachi & Bounabat, 2019; Tekic & Koroteev, 2019; Correani, et al., 2020), broken down into fundamental interrelated concepts (Brown & Brown, 2019), interrelated building blocks (Zineb & Bouchaib, 2020), as well as step by step guides (Albukhitan, 2020), varying in methodological approaches, purposes, levels of abstraction, focal topics and depth.

1.2 Aim and Research question

This thesis builds on the idea that digital transformation is not merely a digital technology adoption, but rather an organizational change that aims to adapt to a digital landscape, as proposed by Brown and Brown (2019). Furthermore, it is assumed that digital maturity and business excellence is overlapping and dependent on the value that can be extracted from the technological paradigm of industry 4.0. Implicitly, it is assumed that digital maturity in the Industry 4.0 era will not be achieved within the manufacturing realm, unless it is understood how it supports business goals in manufacturing companies.

As the rich literature on the topic of digital transformation is built by examining empirical findings and synthesizing ideas based on common features and described success stories, this thesis aims to provide a novel perspective by comparing compiled literature to the digital transformation efforts of a manufacturing company within the automotive industry, in order to understand the formulated research question;

3

RQ: How to formulate a strategy for digital transformation that supports manufacturing business value?

1.3 Research scope and limitations

In order to answer the formulated research question, two main research objectives were formulated to guide a literature review. First, to create a context for the phenomenon of digital transformation and highlight its relevance, the study aims to develop a description of how the current and future digital landscape is understood. Second, to create an understanding of the actual phenomenon of digital transformation itself, the study aimed to create a description of how digital transformation can be constructed and what strategies and/or strategical elements exist within that construct. Furthermore, one manufacturing case company within the automotive industry and specifically its initiative and efforts to conduct a digital transformation is examined, in order to create an empirical reference, to add to the current body of academic work. By creating this comprehensive context to support the analysis and elaboration on specific ideas about strategies for digital transformation, it is believed that existing knowledge can be solidified, and new knowledge can be created to answer the research question. The empirical study at the case company is limited to the formal initiative and efforts produced by the company. The case company is a global organization that has factories around the world. The global organization has initiated the digital transformation and prescribed certain activities for local plants. One of those activities is to create a local task team at each plant, responsible for investigating and exploring digital technologies to apply in manufacturing. This study was conducted in cooperation with one of the local plants and with some engagement from the global organization. Specifically, the leader of the local task team is the initiator of the thesis project and the main respondent for the study. Conclusively, there could be informal events and ICT-initiatives within the local plant, as well as throughout the global organization that are outside of the scope of the study.

4

2. Research Methodology

In this chapter, the methodology behind the thesis is described in depth. For each method used or chosen, a description and arguments on how and why the method has been utilized are presented. The chapter starts with an introduction to the research approach and case study method. It is followed by the data collection which describes how data were collected for the Frame of Reference and Empirical evidence. Finally, an analysis of the gathered data is presented, and the quality of the research is deliberated in terms of validity and reliability.

2.1 Research approach

In this thesis a single case study was conducted. The choice is based on being able to describe a phenomenon with in-depth knowledge and the formulation of the research question include a "How" question (Yin, 2014). Data collection methods used in this thesis such as literature review, observation and interviews are commonly used in a case study (Patel & Davidson, 2011) and the choice of a case study were suitable. As the focal topic of the thesis is the phenomenon of digital transformation and elements of strategy, the case study was designed to examine a manufacturing case company that has initiated and is actively engaged in a digital transformation. Hence, the phenomenon can be described based on firsthand observations. By combining the mentioned techniques for data collection (more described in section 2.2) it was possible to complete a triangulation of data. It was an important step to ensure the quality of the data. When employing a triangulation, Säfsten and Gustavsson (2020) mentions weaknesses from one technique can be compensated from a strength from another technique.

When choosing a research approach for the thesis, it was a choice between performing a deductive or an abductive approach. The importance of this thesis for the case company was to gain insights from academic research and its knowledge in the field of digital transformation. To carry out a deductive approach, a hypothesis is set up that is based on the theory and then tests it against reality. In this case, it could be an appropriate choice as what is to be answered must be substantiated against current research. However, the weakness of developing a hypothesis from theory and then testing it is the risk that it does not correspond at all with what is expected to be investigated (Saunders, et al., 2015). Therefore, this thesis is based on an abductive approach to be able to go from data to theory and theory to data to ensure not to end up in the wrong with what is to be answered (Bryman & Bell, 2015). With the possibility to adapt the literature afterwards the empirical data collection was an enabler to have a complete frame of reference and support a clear structure.

2.2 Data collection

Data collection has been used to create a perception of the academic research that is available at present time and the collection of empirical data has been done by using various forms of collection techniques such as interviews and observations. As this thesis leans towards a qualitative research rather than a quantitative, capturing the perceptions and experiences of employees was an important step (Säfsten & Gustavsson, 2020). Both primary data and secondary data have been used in this thesis. The primary data collected has originated from the use of the different data collection techniques which is described later in this section and the secondary data collected has consisted of different control documents and statistical documents that have been important for the work with the empirical part of the study. Using both primary and secondary data is common and the difference between primary and secondary data is that the primary is a phenomenon that is happening at the time while the study is ongoing and secondary

5

data consists of such content that has already happened, for example statistical documents (Bell and Waters, 2016). For this thesis, it has been useful to have both types of data as they have been able to complement each other. Using historical data with data from the current situation facilitates an analysis of why it looks the way it does. The secondary data collected has been made through email correspondence with the contact persons who have been involved from the case study company. Secondary data that was requested from the case company in this thesis was the following:

• Information about the case companies’ global initiative of digital transformation • The model for their maturity assessment

• Organizational structure • Statistics on KPI: s

• Information about conducted and upcoming pilots • Business goals

All data in this thesis was collected between 2020-08-31 and 2020-12-11.

2.2.1 Literature review

A literature review was conducted to create a theoretical framework to support argumentation and conclusions. The use of the literature review provided a good basis for understanding what previous research in the same field has discovered (Saunders, et al., 2015). The literature review began at the start of this thesis work. The phenomenon that was to be studied is not a new phenomenon but it belongs to an area that many are currently investigating and then it was a necessary step to formulate the research problem to know what the latest research has shown in the area (Säfsten & Gustavsson, 2020). When formulating the research question, keywords for the study were also identified and the keywords were used in the search to set parameters and to limit the search result as only articles in the area to be studied were important to find (Table 1). To have a broader search for articles and to enable the literature that could be important for the study to be found, alternative terms were added to the search for each keyword. The choice to add alternative terms was based on getting several hits in the search for literature and that the terms that were added were words that appeared in the first search where only the keywords were used.

Table 1 Keywords and Alternative terms

KEYWORDS ALTERNATIVE TERMS

DIGITAL Digitalization

TRANSFORMATION Alignment

STRATEGY Business Model

INDUSTRY 4.0 Smart factory, Smart Production

The databases used to find literature were ScienceDirect and Scopus. Other databases were also used as a complement as certain articles found via Scopus or ScienceDirect was labeled as "Article in press". What was done then was to search further on the article to identify whether it has been published or not. Many of the articles found as "Article in press" were published. As an additional complement to databases, the snowball effect was applied as a search strategy. When reading articles, some quoted sentences could be interesting which resulted in going to the original source that was referenced and then using it in the literature review. As the snowball effect was used, no restrictions were set for the published year, a language limit was used, and it was English. Table 2 illustrates the search strings, which databases and

6

how many hits the searches returned. The search string was built up by using the keywords and alternative terms and by using "OR" and "AND" the result of the search can be that it finds articles with either a combination of certain keywords but also between the keywords and the alternative terms. Since the case company is a manufacturing company, it was tested to narrow the search to find items closer to the case company. This was done by choosing as an option in the search that manufacturing would be included in the title of the articles. Another attempt to capture more articles with the search was to test wildcards. An example might be whether a search should include either manufacture, manufacturer, or manufacture and then by using a wildcard, it is sufficient to formulate the search string "manufact *". Then all results with the beginning of "manufact" come up. ScienceDirect did not support wildcard searches, but Scopus did.

Table 2 Illustration of search strings, data bases and results

Search String Database Matches Scanned Selected (Digital OR Digitalization) AND (Transformation OR

“Business model”) AND (“Industry 4.0” OR “Smart Factory” OR “Smart Production”) AND (Strategy OR Alignment)

ScienceDirect 1478 138 51

Scopus 156 75 24

With manufacturing in title ScienceDirect 319 64 12

Scopus 27 13 8

Once the search strings were structured and the various tests on how the search was to be formulated, the next step was to start selecting articles from the search. This was divided into different parts and at the beginning to select articles with relevance, the summary of the articles and the introduction were read. The next step was to go through the articles that were first selected by also reading the conclusion given in the article. In order to finally be able to decide which articles to select, the entire article was scanned through. When scanning the articles, an Excel sheet was created to sort the relevance and to categorize the content. A color system was used to maintain a good structure when sorting and categorizing the items (Bryman & Bell, 2015)

2.2.2 Observation

The observations for this thesis would be classified as unstructured, mainly because the nature of the thesis is qualitative data and the observations done has been by attending different meetings. The meetings have been both informative meetings and some of them included practical demonstration on new technology the case company is reviewing for application. Before attending the meetings no specific agenda for the meeting was announced, the main purpose was to listen and learn how the smart team worked. By attending the meetings, discussion afterward was held and gave a better insight into the case company, and empirical data was contained. Why this type of observation would classify as an unstructured is based on that the authors did not control the environment or had a specific phenomenon to observe, the outcome was unknown. The main purpose of the observations has been to capture a realistic view on how they are working instead of asking how they conduct their work, what people say and what they actually do is not always the same thing (Säfsten & Gustavsson, 2020).

7

2.2.4 Interview

In the progress of analyzing data that had been collected, it was realized that the data needed to be clarified or verified. Interviews were conducted as a step to ensure the quality of the documents and to gain new perspective of how others within the company would explain the data received for the thesis. The interviews in this thesis have been both unstructured and semi-structured. When the phenomenon was known and more knowledge about it was needed, semi-structured interviews were suitable to fill the knowledge gap. The interviews were made through a snowball selection were the interviewees were selected by recommendation. The choices of interviewees were made by recommendation, and on what questions needed to be answered. To know that the one who got the questions could answer them, a recommendation was needed. When the interviews were conducted, there was already some knowledge in the subject and each interview had a purpose linked to the research question. The interviewees were selected based on their connection to or involvement in the case company’s digital transformation thus the possibility to acquire the necessary information or data that needed to be clarified or verified. The interviewees had the following positions within the case company:

• Director Manufacturing Engineering (ME) • Global Director Manufacturing Engineering • Project Manager

The interview with the Director of Manufacturing Engineering was held to receive information on how the top management for the local plant think they should work with digital transformation. There was some critical information needed to fully gain an understanding if there were a current strategy and vision in place for their work with digital transformation.

The purpose behind the interview with the Global Director ME was to understand the background of the digital transformation initiative, as he is the owner and co-creator of it. It gave the opportunity to obtain information on the global management perspective on industry 4.0 and its significance to the company. The Project Manager leads the local task team and has a responsibility to both the local and the global management. Before the interview, he had provided different data and through the interview it was possible to obtain more information on how the local task team work with digital transformation and how they currently work to align efforts with the sites vision for industry 4.0.

2.3 Data analysis

In general, the data analysis was done with the research question in mind to support decisions on what is relevant for the thesis (Saunders, et al., 2015). During the search for scientific articles, a coding system was applied to facilitate the work of sorting and categorizing the articles collected (Bryman, and Bell, 2015). In parallel with identifying which articles were relevant to the study, the color code system was additionally used to identify themes in the selected articles. The color code system was used in both Mendeley and in an Excel spreadsheet. After the scanning process when the final selection was made, most of the articles had been read through. When several articles had been read and analyzed it became clear that most of the articles had similarities in their structure and some patterns was identified. These similarities were then used in the literature review to create a good structure. The technique used to analyze the scientific articles is called thematic analysis. A decision on what was an appropriate theme where done by analyzing and visualize how the themes was connected to each articles purpose. Säfsten and Gustavsson (2020) mentions that it is important for the researcher to determining what could

8

characterize as a theme and a theme may be something that occurs frequently. However, they mention furthermore that a theme should be capturing something essential regarding the research question. For each article, to grasp the underlying theme that was related to the purpose of the study, the coding system was supporting a systematic approach to the identification of the patterns.

At the point when empirical data was collected, it was still important to connect what type of information which necessary for the purpose of the thesis. By receiving a great amount of data, described in section 2.2, sorting and categorizing was a necessary step to support the analysis of the raw data. At each observation, notes were written, and those notes can easily become unclear after a while and hard to interpret (Säfsten & Gustavsson, 2020). To ensure not to lose any information, all notes were discussed and rewritten into a more comprehensive text.

As mentioned, when analyzing the literature, a thematic analysis was used, and themes could be identified. Those themes were useful when collecting the empirical data. By using the themes, an identification of what type of data was critical for an analysis and they supported the work of reduce data. However, by working with abduction approach for this thesis, an iterative process between collecting theoretical and empirical data resulted in a massive data collection. There were at multiple occasions a change of direction how the research question should be answered in a suitable way. This happened due to new knowledge attained from continuously analyzing the literature and at the same time the empirical data. If this thesis had focused on the empirical part at first and a hypothesis where drawn, the outcome from the analysis of the empirical data would have impact on how to analyze the literature or the other way around. Although, it could be confusing, the knowledge attained by working with an iterative approach produced a deeper understanding within both literature and empirical data. Finally, a decision was made on how to answer the research question, and an alignment between literature and empirical data was found. By localizing similar themes, based both on literature and empirical findings, it was possible to sort literature and empirical data into categories and produce an analysis that synthesized the components to answer the research question.

2.4 Quality of the research

According to Säfsten and Gustavsson (2020) validity and reliability are two factors when ensuring the quality of the scientific study. When talking about the validity of a study, you examine whether what has been studied really corresponds to what was predestined to study. Validity can also be divided into internal validity and external validity where the internal focuses, for example, on whether the study delivers the answers needed to answer the study's research question and the external validation is about how the study is generalizable to similar studies in the same research area.

At different times where the collected data was analyzed and where there were certain parts needed to be interpreted by the authors, the interpretations was strengthened by having a continuous discussion throughout the study with the case company. Some of the secondary data received consisted of data files in PowerPoint format or in Excel spreadsheets, and those type of data files where not always fully informative and descriptive. In situations where information was deficient or was not entirely descriptive to interpret, complementary questions were formulated and sent to the case company. By updating and reconciling that the interpretations corresponded to reality, the possibility that the interpretations would deviate from what the current situation looked like was reduced (Bryman, 2018). By combining the primary and secondary data and that the collection of primary data has been done by different techniques,

9

triangulation was done. This technique is accordingly to Yin (2018) a step to strengthen the validity of the study.

Bryman (2011) describes reliability to the extent that a study can be repeated or be similar when the same measurement or studied phenomenon gives the same results as a previous study. The reliability can be affected by random event and Säfsten and Gustavsson (2020) mentions it can be caused by either the research subject, the researchers, or the study situation. As this study is mainly of a qualitative nature and is concerned with a phenomenon that is progressing and ongoing, the reliability concerns are somewhat obvious. The interviewees and the studied organization are in a process of change and the participants of the organization and the interviewees of this study is learning and adapting to new knowledge. It seems plausible rather than possible that the interviewees as well as the studied organization will change and therefore the results of this study will, by nature, be hard if not impossible to replicate. Furthermore, the literature review has been conducted with an emphasis on breadth and context rather than with a narrow and deep focus. Therefore, it is possible that other researchers would present the subject differently and emphasize other aspects of the body of research. This concern has been addressed to some extent by trying to show significance of statements and findings through highlighting where there are discrepancies, similar views held by several authors, and in some cases tracking down cited articles and original sources, in order to comprehensively present the current academic knowledge on the topic as honest, exhaustive, and accurate as possible.

10

3. Frame of reference

This section is divided into two main subsections with the purpose of giving a comprehensive view of the subject and context; firstly, describing the current industrial context and paradigm in which manufacturing industry is operating and also the terminology and ideas that are present in the academic discourse. Secondly, describing the ideas and concepts that aim to deal with strategies by which to operate under to successfully transform the manufacturing enterprise into compliance with the current and future era.

3.1 Industry 4.0 - The current technological era

Since 2011, industries globally have been working towards a digital transformation which is a part of and/or referred to as the fourth industrial revolution, Industry 4.0. It was in 2011 in Germany that the concept of industry 4.0 emerged (Gaspar & Juliao, 2020). The concept is a broad term that describes a technological transformation of industry that have a significant impact on the global economy (Piccarozzi, et al., 2018) and change the way in which industrial enterprise operates (Piccarozzi, et al., 2018; Narula, et al., 2020). Industry 4.0 realization may require changes in operations of production systems (Yin, et al., 2018) and changes can be considered driven by IT (Mantravadi & Møller, 2019). This resonates with the definition of digital transformation being an adapting of an organization to a digital landscape (Verhoef, et al., 2019; Saarikko, et al., 2020), and the statement by Sarvari, et al. (2019) makes sense, that Industry 4.0 is driven by digital transformation. Furthermore, Osterrieder, et al. (2020) identify “Digital Transformation” as one of eight distinct research topics within the field of the smart factory concept. In historical context the demand for the fourth industrial revolution is driven by customer demand dimensions namely Variety (multiple models per product), Time (short requested delivery time and uncertain length of life cycle) and Volume (fluctuating and uncertain demands) (Yin, et al., 2018).

Within the realm of Industry 4.0, there is a variety of concepts or paradigms that are used to describe and materialize the vision of what the current technological era will realize, even though they are more or less synonymous (Cohen, et al., 2019). “Smart manufacturing”, “Cyber-physical systems”, “Industry 4.0” (Cohen, et al., 2019), “industrial internet” (Büchi, et al., 2020), as well as “digital manufacturing” or “digital machine-building production” (Kholopov, et al., 2018) are all examples of concepts that share the goal of responding to real time conditions and a market demand for highly customized products, through the use of a digitalized, flexible, reconfigurable, intelligent and fully autonomous production systems (Kholopov, et al., 2018; Piccarozzi, et al., 2018; Cohen, et al., 2019). There is some discrepancy in the extension of the formulated definitions and explanations of the concepts, as the inclusion of services (Cohen, et al., 2019) and the value chain (Piccarozzi, et al., 2018), as well as changes in governance and stakeholder relations (Büchi, et al., 2020) are not always explicitly included. There is also discrepancy that can perhaps be understood as a variation in depth and level of abstraction. For example, Gaspar and Juliao (2020) see Industry 4.0 as being based on the integration of information and communication technology, which is a description that is perhaps a coinciding but not necessarily a comprehensive understanding of the Industry 4.0 construct as described above.

Regardless, it is popularly argued that Industry 4.0 is a fundamental change to the current state. Osterrieder, et al. (2020) for example, refer to the notion of how the production plant is now viewed as a construct of four distinct layers of physical, data, cloud & intelligence, and control layer, rather than a plane of activities.

11

3.1.1 Technologies

The significance placed on separate technologies within the Industry 4.0concept vary to some extent throughout literature. Impacts on the current era and competitive environment for businesses are analyzed based on the inclusion of different clusters of technologies. The digitization and namely IoT and Big Data can be understood as central to the digitalization of organizations and imperative to master in order to thrive through business digitalization (Sestino, et al., 2020). Similarly, Artificial Intelligence, Blockchain, Cloud and Data Analytics are studied based on them being perceived as being interconnected and driving data to support business decisions (Akter, et al., 2020).

Even within the focal topic of manufacturing industry, the technical understanding of Industry 4.0 and basis for discussion vary to some extent. However, a reoccurring and comprehensive view of the Industry 4.0 concept includes nine pillars; Advanced Robotics, Additive Manufacturing, Augmented Reality, Simulation, Vertical and Horizontal System Integration, Industrial Internet of Things, Cloud Computing, Cybersecurity and big data analytics (Alcácer & Cruz-Machado, 2019; Büchi, et al., 2020; Narula, et al., 2020; Ribeiro da Silva, et al., 2020). It can however be noted that this is not an exclusive definition and for example a tenth pillar of “other enabling technologies” is sometimes proposed (Büchi, et al., 2020). The description and distinction of technologies and tools etc. are not always clear and is presented differently. For example, the concept of Digital Twin shows up as an enabling technology (Mantravadi & Møller, 2019), as well as a digital manufacturing tool (Ribeiro da Silva, et al., 2020).

The technologies can be distinguished as front-end- and base-technologies. Front-end technologies consider four dimensions (smart manufacturing, smart products, smart supply chain and smart working) and are considered to have an end-application for the value chain and address needs of the market and environment. Base-technologies consider four elements (internet of things, cloud services, big data and analytics) described as information and communication technologies that are utilized by multiple front-end technologies and support all dimensions. (Frank, et al., 2019a)

Demeter, et al. (2020) however, point out the interrelatedness of the technologies in the sense that for example that functional use of big data analytics, rest upon the use of IoT, sufficient data storage processing capacity and human knowledge. Saarikko, et al. (2020) point out this same feature, that technologies need to work together in a hierarchy from sensor to server and system. Furthermore, Saarikko, et al. (2020) elaborate on this point and highlight the importance of the sociocultural aspect of integration as the large system can be difficult to oversee if it penetrates an organization through individual and sound use cases resulting in a large non-cohesive patchwork.

3.1.2 Design principles

Industry 4.0 and its implications for individual businesses and industries are also proposed to be more clearly understood through design principles as they are the base for development and can act as a guide towards the benefits of technology adoption (Ghobakhloo, 2018; Santos & Martinho, 2019). Similar to the technologies, some discrepancy exist in literature about the significance of principles and which to include. Ghobakhloo (2018) describe 12 design principles; Service orientation, Smart product, Smart factory, Interoperability, Modularity, Decentralization, Virtualization, Real-time capability, Vertical integration, Horizontal integration, Product personalization, Corporate social responsibility. Santos and Martinho (2019) propose; digitalization, connectivity, interoperability, adaptability, scalability, efficiency,

12

predictive capability, reconfigurability. Worth noting is the overlap with other distinctions, where for example, horizontal and vertical integration is included in the nine pillars (Alcácer & Cruz-Machado, 2019; Büchi, et al., 2020; Narula, et al., 2020; Ribeiro da Silva, et al., 2020) and smart product are included as a dimensions by Frank, et al. (2019a) as well.

3.1.3 Application areas

The applicability of Industry 4.0 is researched, elaborated on, and understood in varying depth and comprehension. Büchi, et al. (2020) suggest that Industry 4.0 opportunities adhere to one of six main typologies being; production flexibility through manufacturing of small lots, the speed of serial prototypes, greater output capacity, reduced set-up costs and fewer errors and machine downtimes, higher product quality and less rejected production, and customers’ improved opinion of products.

Frank, et al. (2019b) elaborate on how servitization and Industry 4.0 are not just creating value for customers but can lead to a faster time to market and elevate internal processes such as inventory management, production planning and control.

Through stratification, Narula, et al. (2020) show the end to end manufacturing aspects responsible for Industry 4.0 application to be; Design and development, environmental protection, customer support, logistic management, supply chain management, quality assurance, production planning and control, process control, maintenance of equipment and tooling, traceability, strategy leadership and culture, technology integration and cybersecurity. For each of the aspects, the authors provide sub factors highlighting some interesting application areas.

Ribeiro da Silva, et al. (2020) show application domains for technologies through a map of a manufacturing life cycle areas; Production requirements, production (re)design, engineering of manufacturing systems, manufacturing system integration and ramp up, production, re-use/recycle. For each of the areas, the authors present relevant technology and applications for them.

Fritschy and Spinler (2019) argue that autonomous trucks will change the relations within the

automotive and logistics industry and reconfigure the relations of logistic service providers, OEMs and tier 1 suppliers.

Schumacher, et al. (2020) highlight the interrelation of Industry 4.0 and lean production system and that Industry 4.0 is commonly suggested to support lean production systems and Hoellthaler, et al. (2018) suggest that a sound approach for digitalization is to implement digital technology, where lean has reached its limits and digital technology can overcome them.

Kristoffersen, et al. (2020) elaborate on how digital technology can support circular economy strategies (in extension sustainability) and should be part of the Industry 4.0 agenda. Maffei, et al. (2019) stress this point even further and highlight that digitalization has an overwhelmingly positive impact on the transition towards circular economies. Bag, et al. (2020) add to this field and argues that a strong procurement strategy as well as a procurement 4.0 review process enable the enhancement of circular economy performance. Li, et al. (2020) conclude that digital technology has a positive impact on environmental and economic performance and that supply chain platforms are a mechanism that explains the linkage. Along the lines of sustainability, Shrouf, et al. (2014) present an approach to enhance energy efficiency with the use of IoT enabled energy management.

13

3.1.4 Challenges

During the adoption of digital technology, there will be challenges in the implementation. This arises through the difficulty of understanding the new technology and which leads to the importance of attaining the knowledge before implementing (Parviainen, et al., 2017). Albukhitan (2020) mentions challenges such as Traditional processes, Resistance to Change, Legacy Business Mode, Limited Automation, Budget restrictions, Absence of relevant knowledge, Inflexible company structure, and Security. The challenges mentioned relate partly to organizational culture and to the existent production systems. How ready is the organization for a change and not only the culture, how is the readiness of the production processes to handle new technology embedded into the existent systems and is it possible to connect older machines. It is important to understand the investment cost through a digital transformation and what kind of knowledge is essential for integrating the technology (Albukhitan, 2020). At the same time, Sarvari et al, (2019) bring up similar challenges for an Industry 4.0 transformation. They emphasize the challenge of lack of knowledge that is necessary to understand the technologies and the opportunities. In a similar way, it is the same with the benefits of the Industry 4.0 transformation, it is important to have functional communication through the organization c mentioned the challenge of budget restrictions, Sarvari et al, (2019) shares the opinion and mentions a possible challenge of human and financial resources. To meet the challenges and overcome the integration of the new technology, roadmapping is an appropriate approach for the strategic planning. Roadmapping has been widely used since it first was introduced in the late 1970s and it is considered as a complex long-term planning instrument. It is a useful approach for estimating the potential of new technologies, products and services (Vishnevskiy, et al., 2016).

When the new technology is implemented such as IoT, computer vision, digital twins, additive manufacturing and augmented reality (AR), challenges in both manufacturing and assembly will take place (Cohen, et al., 2019). Technologies such as mentioned comes with different applications and some of those may not be planned for and expertise could be missing as Sarvari, et al. (2019) mentions. Cohen, et al. (2019) highlights some challenges regarding the assembly of products in contexture to the new digital era. In an assembly line there is existing technology and when adopting new additional technology, it is critical to fully utilize the potential of the technology and consider the aspect of synergetic integration between existing and new technology. Some other effects of adopting new technology is the possibility to create new smart assembly line were the assembly line can handle different products due to increase flexibility and a challenge would be how to design the line when multiple products can be mounted on the same line without creating a high level of reconfiguration for each product. Another challenge mentioned is an open issue with new collaborated robots, the solution how the integration between the human operator and the robot would be is stated as a major challenge for the assembly line. The last challenge mentioned by Cohen, et al. (2019) connects with the challenge both Albukhitan (2020) and Sarvari, et al. (2019) mention about knowledge. Cohen, et al. (2019) stresses the importance of having human specialist in maintaining the new smart assembly 4.0 systems. Even tough more assembly operation becomes automated, skilled, and trained personnel are still needed to maintain and operate the assembly systems and will be throughout the Industry 4.0 era.

Cohen, et al. (2019) do highlight challenges for the manufacturing in a similar context to the assembly and describing the challenges as almost the same. New challenges mentioned for manufacturing would be the part of all data handling, due to the digitalization of manufacturing along with the development of computers, information and communication technologies (ICT), and artificial intelligence (AI), larger amount of data will be created. This data would be categorized as industrial big data and with the sorting

14

of the 4Vs (Volume, Velocity, Variety and Value) new manufacturing challenges arise. The challenge comes from how the structure of the data is different from how it was before and it will be necessary for the data collected to be processed efficiently (Cohen, et al., 2019; Singh, 2020). As for the assembly integration issues for manufacturing is consider as a challenge by Cohen, et al. (2019) in the way how they highlight the vertical, horizontal, and end-to-end integration in cyber-physical production system and social cyber-physical production system how these integrations challenge the traditional.

3.2 Digital transformation

Three domains for understanding the diffusion of digital technology are digitization, digitalization, and digital transformation. Digitization is presented as the converting of analog signals to digital signals, digitalization is a leveraging of digitized products or processes while digital transformation refers to the process of adapting organizations or firms to the digital landscape (Verhoef, et al., 2019; Saarikko, et al., 2020).

Verhoef, et al. (2019) mentions three different external drivers of digital transformation that make companies consider transforming; Digital Technology, Digital Competition and Digital Customer Behavior. Savastano, et al. (2019) show that digital manufacturing applicability is industry-dependent even within the manufacturing sector and that there is a growing widespread of tools, strategies and applications tied to the specificity of their needs. This align with the point raised by Zaoui and Souissi (2020) that there are different input variables like size, activities and targets linked to companies approaching digital transformation and therefore there is a need for adapting transformation instructions.

Although, the phenomenon of digital transformation is studied closely by researchers and experts, there is still no consensus on how to successfully accomplish the journey of transformation (Zaoui & Souissi, 2020; Zapata, et al., 2020). Similarly, Zapata, et al. (2020) state that there is still a knowledge gap in the literature of empirical evidence on how manufacturing companies have adopted a successful digital transformation. Correani, et al. (2020) point out that even though the implementation phase of a digital transformation is strategically planned, there is still risk and uncertainty due to the disruptiveness of technology to the business. Frank, et al. (2019a) also highlight uncertainty being associated with digital transformation in regard to both technology requirements and potential benefits. Büchi, et al. (2020) further add to this point as the necessary investments in organizational development through innovation research and acquiring competence and skill can only be assessed in the long term while literature lack confirmatory studies at this point. Santos and Martinho (2019) share the same view and argue that the high complexity of the organizational change likely leads to years of planning and implementation of incremental changes to realize positive impacts on profitability. Along the same lines, investments in digital technologies of the sort associated with industry 4.0 require significant up-front costs before any major benefits can be realized (Demeter, et al., 2020; Saarikko, et al., 2020).

Lipsmeier, et al. (2020) argue that a digital transformation is a dynamic and continuous process and should be coordinated by a digital strategy that is integrated with and central in strategic management. Matt, et al. (2015) argue that the transformational progress and the digital transformation strategies should be evaluated and reassessed continuously. Similarly, referring to the business model being a description of a company, Tekic and Koroteev (2019) point out that the development of a business model is an iterative process and that it is rarely correctly blueprinted but rather evolve over time. To this point it should also be added that seeing a business model as a description of a company’s activities and digital transformation as an organizational adaption to digital technology, makes digital transformation a business model

15

development, per definition. Sarvari, et al. (2019) also point to the inability of many enterprises to launch roadmaps because of a lack of qualified staff and that long term planning should be handled by specialists. However, suggestions for methods and tools for roadmapping and planning activities exist. According to Osterrieder, et al. (2020), initiation of activities involving developing a smart production, is advised to start with selected use cases, which align somewhat with for example Lipsmeier, et al. (2020), who propose that identifying use cases is a part of developing a digital strategy.

Technology development through the last years may be the obvious factor to transform an organization nonetheless to understand the transformation, the aspect of culture and leadership are as important as technology (McKinsey, 2018; Nadkarni & Prügl, 2020). Saarikko, et al. (2020) notes that it is necessary for companies to develop competencies to learn how to use or implement digital technology for business purposes. To further increase the meaning of this, Sarvari, et al. (2019) suggest that many enterprises are even unable to launch roadmaps due to lack of competence.

Furthermore, it is not only a matter of transforming the organization to successfully adopt technology, but also to transform the organization into a changeable organization. Gaspar and Juliao (2020) develop arguments related to operations management in the Industry 4.0 era, suggest that the data streams and information flow will increasingly demand organizational change and that operations management will need to increase flexibility and responsiveness to meet the future needs of the market. Verhoef, et al. (2019) follows this line of reasoning and suggest that digital agility (the ability to sense and seize opportunity provided by digital technology) is vital even for market incumbents survival. Verhoef, et al. (2019) argues that organizations must allow for repeated switching of organizational roles, introduce new technologies to meet customer needs and to respond to intensified competition as market boundaries and barriers are blurred and removed. Along the same lines, Mohelska and Sokolova (2018) argue that Industry 4.0 implementation require continuous innovation and education, they stress that involvement from top management is a necessity for promoting comprehensive change management.

Tekic and Koroteev (2019) suggest that there are different kinds of leaderships in organizations based on their digital transformation strategy. They propose that technology led digital transformation is general coordinated bottom-up and leadership from top management is more passive and “allow” initiatives, while organizations that employ a business model led digital transformation are prone to an active top management leadership communicating and supporting the overall initiative (Tekic & Koroteev, 2019). The business model led digital transformation also generally employ entrepreneurial leaders that drive disruption and new thinking (Tekic & Koroteev, 2019). Tekic and Koroteev (2019) also suggest activities such as innovation labs and hackathons in order for firms leading a business model led digital transformation to scout for entrepreneurial talent as it is often in scarce demand. This might be key initiatives as collaborative, explorative and entrepreneurial mind-sets in employees is a success factor for Industry 4.0 implementation i. e. digital transformation (Muehlburger, et al., 2019).

Haffke, et al. (2016) identify that there may be a need for a Chief Digital Officer (CDO) leading the overall digital initiative in organizations with a digital business strategy. Haffke, et al. (2016) define 4 different CDO roles (Digital Evangelist, Digitization Coordinator, Digital innovator, Digital Advocate) based on a matrix with axises of supply/demand side of IT and Implications of digitization.

Muehlburger, et al. (2019) present a framework of categorized enabling factors for initiation of digital transformation which all relate to organizational features (see Table 3).

16

Table 3 Categories of factors enabling Digital Transformation initiation (Muehlburger, et al., 2019)

Category Enabling Factors

Workforce capabilities Individual Creativity and Innovation Capabilities ICT literacy

Organizational values Innovative Organizational Culture Internal and External Collaboration Organizational infrastructure Digital Platform Infrastructures

IT-Agility

Institutionalized Innovation Process Bimodal Organization

Organizational Agility Management capabilities Strategic Embeddedness

Digital Leadership

Forming Strategic Alliances Strategic Customer Focus

Müller, et al. (2020) point to the absorptive capacity of organizations i. e. their ability to utilize new external information. Müllers, et al. (2020) view is that partners in value creation as well as innovation partners in ecosystems are vital in order to acquire information and not only business transactions. Müller, et al. (2020) means that this involves engaging with research institutes and universities as well as growing a culture of cross-functional thinking and collaboration, as Industry 4.0 potential is not siloed in individual functions. In the context of external partners for firms, Tschandl, et al. (2020) elaborate on the role and meaning of learning and research factories in terms of applied research and development. Zangiacomi, et al. (2020) elaborate on the utility of sharing skills and knowledge with research institutes and universities as important points. Burchardt and Maisch (2019) address the need for changeability and a collaborative culture by suggesting employing concepts like agile principles and open innovation.

Through a literature review, in which reviewed material distinguish information and communications technology-integration from digital transformation and consider technology integration as a subset of digital transformation, three indispensable pillars make up the digital transformation; Evaluation of the digital transformation, definition of the strategic orientation of the digital transformation, and implementation of the digital transformation (Zaoui & Souissi, 2020).

3.2.1 Evaluation of the Digital Maturity

Zapata, et al. (2020) view maturity evaluation as a key component of digital transformation and suggest that dimensions and levels of the maturity models must be specific to the users. Santos and Martinho (2019) propose a model with five dimensions; organizational strategy, structure and culture, smart products and services, workforce, smart factories, and smart processes, and four levels spanning from 0 (No degree of implementation) to 5 (reference in applying concepts and implement Industry 4.0 technologies. The proposed framework is bifunctional as it is suggested to both serve firms in evaluation of their own transformational strategy as well as being a functional tool to compare firms across industry boundaries and benchmarking competition.

Brown and Brown (2019) elaborate on a classification of firms in different digital transformation scenarios and approaches; Beginners who are not in a hurry to advance beyond internet and e-mail, Conservatives who have foresight and capability in place but stall implementation, Fashionistas who rush do adopt

17

technologies without a strategic orientation or vision, and Digiratis who have leadership committed to a clear and well understood vision that will leverage the business. As a guidance for considering digital transformation, Brown and Brown (2019) cite Schumacher, et al. (2016) and suggest considering eight elements being; Strategy, Leadership, Products, Operations, Culture, People, Governance and Technology.

Schumacher, et al. (2019) cite Schumacher, et al. (2016) and described how their maturity model was further developed, resulting eight similar dimensions; Technology, Products, Customers and Partners, Value creation process, Data and information, Strategy and Leadership, Corporate standards and Employees. This framework by Schumacher, et al. (2019) is specifically linked to the assessment of individual firms to derive action fields and roadmaps to develop Industry 4.0 maturity.

Issa, et al. (2018) propose a structure where individual focal areas are assessed and compiled based on three dimensions; technology, organization and process. Tonelli, et al. (2016) assess and compile individual processes and activities without reference to dimensions. Both Issa, et al. (2018) and Tonelli, et al. (2016) use the assessments as a tool to derive and prioritize actions into roadmaps.

3.2.2 Strategies in the context of digital transformation

Kane, et al., (2015) implies that companies with a clear digital strategy combined with a culture and leadership who strives to accomplish added value from digital transformation is what separate digital leaders from the rest. Lipsmeier, et al. (2020) show that there is not a clear consensus on the position of a digital strategy within the organization or if it should be separated or integrated with the business strategy. Lipsmeier, et al. (2020) refer to Bharadwaj, et al. (2013) on this point and propose that it should be placed on the business level of a company and also that it should be separated from the business strategy at first, but integrate over time as digital maturity develops. However, it is important to realize that Lipsmeier, et al. (2020) is referring to a digital strategy while Bharadwaj, et al. (2013) is referring to a digital business strategy. Winkelhake (2019) emphasizes the importance of not preserving the digitization strategy isolated, when formulating a strategy that emphasize all key business processes it should be integrated into a strategic corporate planning process. As shown by Verhoef, et al. (2019) and Saarikko, et al. (2020), digitization can be understood as a subset of digital transformation, and Winkelhake (2019) actually suggest business model review, should precede digitization. This seems to substantiate the point that from the very start, a digital transformation and its business impacts should at least be considered and reviewed at a corporate level.

The definition of the strategic orientation of the digital transformation can be further unpacked, as it relates both to defining the objectives and what is to be achieved through the digital transformation as well as the planning and unpacking of the transformational efforts and activities needed to achieve those objectives (Zaoui & Souissi, 2020). This unpacking resonates with (Brown & Brown, 2019; Tekic & Koroteev, 2019) that separate two distinct levels of strategy; digital business strategy and digital transformation strategy.

Digital Business Strategy can be understood as an organizational strategy that combines business strategy and information system strategy to exploit digital technology for business value (Brown & Brown, 2019; Tekic & Koroteev, 2019). Many authors cite Bharadwaj, et al. (2013) when discussing the topic of Digital Business Strategy and hence understand the concept as being different from regular business strategies through four elements being speed, scope, scale and source (Tillväxtverket, 2017; Tekic, and Koroteev, 2019a; Lipsmeier, et al., 2020). Scope refers to the extension of a company’s direct control and ownership,

18

in terms of activities and portfolio of business and products. A digital business strategy should transcend functional areas and even traditional business boundaries. An example could be Frank, et al. (2019b) and their display of how servitization in Industry 4.0 serves internal processes. This shows how supply chain and logistics adapt their activities through product and service data and how the digital transformation of the product and service portfolio serves departments that do not have direct influence over them. Scale refers to the dynamic capability to scale business up and down. Cloud computing is an example of how pay per use and on demand access to computing capability can be accessed, enabling scaling up and down digital capability seamlessly. It is also perceived that network effects will play a major role in the new digital landscape and that business partnerships and business ecosystems will be increasingly important and understanding how to utilize and access channels of huge data streams for business value. Speed refers to the speed of decision making, product launching, supply chain, networks, and adaption to circumstances. It builds on the network aspect in the sense that faster decision making is possible due to the access of channels of information, from both internal and external resources. It is noted that within supply chain, digital networks are far superior to the traditional value chain, especially in the automotive, chemistry and textile industry. Source refers to the nature of business value creation and capture in digital business models. This involves for example the ability to personalize products and offering based on customer preferences, multisided and multidimensional business models where value is created and offered for free in order to capture some other value, coordinating business models in networks, or value creation from control of industry architecture. (Bharadwaj, et al., 2013; Tillväxtverket, 2017)

Business model as a construct to understand the digital transformation is a popular theme. According to Winkelhake (2019), initiatives within the digital transformation should align with the business model and consider all key business processes. Savastano, et al. (2019) highlight that technology is advanced enough and mature to the point that the keys issue of adoption is the design of business models rather than technological innovation. Savastano, et al. (2019) argue that firms need to first, outline explicit strategic objectives and ensure commitment by all functions. Second, identify innovations that can improve process and add business value. Third, prioritize by business benefits and ease of implementation in accordance with market and long-term objectives.

Correani, et al. (2020) provides an example of a framework presented in appendix 1, that is used to investigate business model components and apply a business model perspective to the digital transformation. It is worth mentioning that the utility of a business model perspective is not exclusively serving the digital business strategy, but is an important perspective to incorporate in order to understand the effects of implementation and how to formulate a digital transformation strategy (Correani, et al., 2020).

Savastano, et al. (2019) notion that it is important to ensure commitment from all functions coincide with Saarikko, et al. (2020) recommendation. Ritter and Pedersen (2020) elaborate on this by pointing to a feature of digitization which is that digitization of one business model component has effects on other components. This arguably underscore the need for a transfunctional digital business strategy, described by Bharadwaj, et al. (2013), and Ritter and Pedersen (2020) suggest that it could be more beneficial to study the effects of digitization by looking at relations between business model components rather than components in isolation. For example, Gaspar and Juliao (2020) also highlight the interrelated nature of digitization from another angle when researching Industry 4.0 impact on operations management, and argue that there are implications for operations management strategizing based on emergence of data from external as well as internal channels.