The role of

pentachlorophenol

treated wood for

emissions of dioxins

into the environment

REPORT 5935 • JANUARY 2009

treated wood for

emissions of dioxins

into the environment

What quantities of dioxins are spread in the environment due to the use of wood products treated with chlorophenols? Can these sources be identifi ed, and what is the best way to provide protection against them? This report describes the results of a literature survey within the area, together with chemical analyses of a number of selected products. It concentrates on attempting to estimate the magnitude of the problem and to show ways in which future emissions can be reduced. Between 1956 and 1978, it is estimated that about 640 and 1000-1500 tonnes of chlorophenol products for pressure impregnation and dip treatment of wood respectively were used on the Swedish market.

Most of the wood products receiving this treatment were used for garden and residential end-uses, i.e. decking, fences and other outdoor structures. Whether or not these treated wood products are still in use depends on what they were intended for, and whether they have been used indoors or outdoors. The estimated quantity of dioxins emitted from chlorophenol-treated products is relatively substantial. However, as the dioxin sources are diffuse and scattered, it is very diffi cult to conduct any remediation campaign to reduce the spread and the number of sources of the material.

The most effective way of reducing the spread of dioxins from chlorophenol-treated products is to attempt at least to control the waste streams of demolition wood so that it is collected and burnt in incineration plants under properly controlled conditions. In addition, it will be interesting to identify and investigate the signifi cance of built-in chipboard panels and that of construction waste and sawmill waste in affecting the spread of dioxins in the environment.

SWEDISH ENVIRONMENTAL PROTECTION AGENCY

Internet: www.naturvardsverket.se/bokhandeln

The Swedish Environmental Protection Agency

Phone: + 46 (0)8-698 10 00, Fax: + 46 (0)8-20 29 25 E-mail: registrator@naturvardsverket.se

Address: Naturvårdsverket, SE-106 48 Stockholm, Sweden Internet: www.naturvardsverket.se

ISBN 978-91-620-5935-4 ISSN 0282-7298 © Naturvårdsverket 2009 Print: CM Gruppen AB, Bromma, 2009

Preface

On behalf of the Swedish Environment Protection Agency, SP Technical Research Institute of Sweden has investigated the role of wood products treated by chlorophenols in the spread of dioxins in the environment. The work was carried out during 2008 by Dr Evalena Wikström‑Blomqvist and Jöran Jermer.

Most of the work has been carried out in the form of literature surveys, complemented by chemical analyses of selected treated wood products.

Content

PrEfAcE 3

SummAry 6

AbSTrAcT 8

1 InTrOducTIOn 9

1.1 Scope and limits 9

1.2 Methods 9

2 ThE chArAcTErISTIcS And PrOPErTIES Of dIOxInS 10

3 PrOducTIOn Of chlOrOPhEnOl-TrEATEd wOOd PrOducTS 12

3.1 Pressure treatment 12 3.2 Dip treatment of freshly sawn timber 15 3.3 Remedial treatment of fungal decay and insect attack 16 3.4 The Do-It-Yourself (DIY) sector 17

4 ThE uSE Of chlOrOPhEnOl-TrEATEd wOOd PrOducTS 18 4.1 Pressure-treated 18 4.2 Dip-treated timber 19 4.3 Products for remedial treatment 20 4.4 DIY products 20 4.5 Imported wood 20 4.6 International outlook 20

5 OccurrEncE Of dIOxInS 22 5.1 Occurrence of dioxins in wood preservatives 22 5.2 The occurrence of dioxins in impregnated wood 24 5.2.1 Measurement of chlorophenols and dioxins in treated wood 25

6 dISPOSAl Of chlOrOPhEnOl-TrEATEd wOOd 28

7 dIScuSSIOn 31

7.1 Estimate of dioxin from chlorophenol-treated wood products in the environment 31 7.2 Proposals for remedies 35

8 cOncluSIOnS 36

9 rEfErEncES 38

Summary

Chlorophenols were used in Sweden until 1978 for treating wood to prevent attack by discolouring fungi during storage and transport, and to provide long‑term protection against fungal decay. The various chlorophenol prepa‑ rations that were used were contaminated by dioxins to various degrees. Due to the high persistence of dioxins, it is likely that they are still present in trea‑ ted wood that is still in use, or that they have spread into the vicinity of such wood. No clear links between adverse human or animal health effects resul‑ ting from close contact with chlorophenol‑treated wood products have been found in the literature.

Between 1956‑1978, about 640 tonnes of pentachlorophenol were used on the Swedish domestic market for pressure impregnation of wood pro‑ ducts, and about 1000‑1500 tonnes for dip treatment. The remedial treat‑ ment and DIY (Do‑It‑Yourself) sectors are estimated as having used about 15 tonnes and 200 tonnes respectively. Most of the treated wood products were used fordecking, fences and other outdoor structures. As the dip‑treated timber was usually planed before use, it is therefore likely that it represents only a small reservoir of chlorophenol and dioxins in the environment. The shavings, on the other hand, can provide a path for the spread of dioxins via landfills and chipboards. Whether the treated wood products are still in service depends on their application, and on whether they have been used indoors or outdoors. In principle, treated wood in indoor applications has a potentially unlimited life, which is likely to be ended only by replacement or demolition. Wood in outdoor situations above ground may still be in use, unless aesthetic aspects have resulted in its demolition or replacement. Treated products in contact with the ground have very probably been decom‑ missioned.

The amount of dioxin in the various wood products is reduced with time, but only very slowly. Degradation has not been observed: instead, the diox‑ ins can diffuse out of the product and be bio‑accumulated in the vicinity. Migration from the product’s core to the surface has also been found. The total estimated quantity of dioxin (I‑TEQ) in the environment today, in the form of remaining treated wood products, has been estimated in the work described in this report as between 0.4 and 3.7 kg, mostly in the form of dif‑ fuse sources in the environment. This estimate is based on the following assumptions: that the main sources are pressure‑impregnated wood and DIY‑treated products. Of the pressure‑impregnated material, about 50 % of the above‑ground material is still in use (equivalent to about 225 tonnes of pentachlorophenol, 0.4‑2.0 kg I‑TEQ), while about 40 % of the DIY pro‑ ducts are still in use, equivalent to about 55 tonnes of pentachlorophenol and 0.0‑0.6 kg I‑TEQ. It should be pointed out that there are considerable uncer‑ tainties in these estimates, and that the quantity of wood products still in use has been estimated on the relatively high side.

As most of the dip‑treatment plants were in southern Sweden, it is very likely that most of the dip‑treated wood was used in this region, probably for the construction of detached houses built over the period 1960‑1975. Remedial treatment products have been used throughout the country, but it is probably safe to say that substances such as Gantix HB and Husbocks‑Cuprinol, and similar, have found most use in areas where the house longhorn beetle (Hylotrupes bajulus) is common, i.e. southern Skåne, Blekinge, eastern Småland and Östergötland, Södermanland, Öland, Gotland and Roslagen.

When removing and destroying treated products, controlled incineration is the only method available today which can safely break down the dioxins in the materials, thus helping to reduce their spread in the environment.

As the dioxin sources are diffuse and scattered, it is very difficult to con‑ duct any form of coherent destruction campaign in order to reduce the spread and number of sources. The most effective means of reducing the spread of dioxins from chlorophenol‑treated products is to attempt to control the flows of waste materials (e.g. demolition wood) so that it can be dealt with and burnt in incineration plants under controlled conditions. In addition, it can be interesting to identify and investigate the importance of chipboard panels still‑in‑use and landfills with demolition wood and shavings from chlorophe‑ nol‑treated wood in spreading dioxins in the environment.

Keyword: Preservative‑treated wood, PCP, pentachlorophenol, dioxins,

Abstract

The role of pentachlorophenol-treated wood for emissions of dioxins into the environment

This study has investigated the importance of pentachlorophenol‑treated wood in emissions of dioxins into the environment. A thorough inventory of the use of different products treated by different methods has been carried out, in addition to chemical analyses of four different treated wood products.

Between 1956 and 1978 between 1 900 and 2 400 tonnes of pentachlorop‑ henol were used in Sweden for different pentachlorophenol‑treated wood pro‑ ducts. The estimated amount of dioxins (I‑TEQ) in the environment today due to the use of these chlorophenol‑treated wood products is estimated to be between 0,4 and 3,7 kg. The considerable uncertainty is due to the wide variation in analytical data. In addition, a quite high figure has been used to approximate the amount of wooden products still in use, in order to avoid underestimation.

Dioxin sources resulting from the use of chlorophenol‑treated wood pro‑ ducts are diffuse and scattered, and thus difficult to clean up efficiently. The most efficient method of reducing dioxin emissions is to ensure that all demo‑ lition wood is destroyed in a modern incinerator with efficient air pollution control systems.

1 Introduction

Pentachlorophenol, together with a number of less chlorinated phenols, was used until 1978 for the treatment of freshly sawn wood and timber, primarily to prevent attack by blue stain fungi during storage and transport (dip treat‑ ment), and also to provide long‑term protection of the wood against fungal decay and insects (pressure impregnation). As the drying of freshly sawn timber in kilns became increasingly common during the 1970s, so also did the need for protection treatment against blue stain fungi decline.

The various chlorophenol preparations that were used were contaminated, to varying degrees, by polychlorinated dioxins (PCDD) and dibenzofurans (PCDF). The name dioxin is used hereinafter in this report when the inten‑ tion is to refer to both groups PCDD and PCDF. Dioxins have hydrophobic and persistent properties which, coupled with their low vapour pressure, can mean that dioxins remain in treated timber if it is still in use.

There are no accurate figures for the amount of dioxins that have found their way into the environment from treated wood products. The purpose of this work has therefore been to attempt to estimate the size of the problem caused by the presence of chlorophenol‑treated wood in buildings etc. on the basis of the presence and spread of dioxins in the environment. The report also provides suggestions intended to control or reduce the problem.

1.1 Scope and limits

The spread of dioxin from chlorophenol‑contaminated ground, sediment, old landfills with treated wood wastes etc, is not considered in this report.

Dioxin data in this report origin from several time periods. Unfortunately, dioxin concentrations have been reported in different ways at different times, which sets restrictions on the comparison of concentrations from one period with those of another.

1.2 Methods

The information in this report is based on personal contacts with those invol‑ ved with the sector, printed sources, articles and internet searches. Most of the scientific articles have been taken from relevant data bases. Oral informa‑ tion from those involved in the sector has provided another important channel for identifying suitable sources and objects from which to take samples.

Pentachlorophenol and dioxin concentrations have also been measured in four wood samples: from indoor panelling, from an outdoor test stake (both above and below ground), and from a utility pole. The samples were analysed for dioxins by ALcontrol i Linköping in accordance with accredited methods of analysis.

2 The characteristics and

properties of dioxins

Dioxins have never been intentionally manufactured. The main source of dioxin in the environment is that of unintentional emissions, generally from industrial activities. Natural production of dioxins in biological systems has also been documented [1, 2].

PCDD and PCDF are two groups of polycyclic organic substances that are very similar to each other. There are eight positions on the two rings where chlorine can be substituted, which means that dioxins can occur with chlori‑ nation chemistry from mono to octa. In total, there can be 75 different PCDD molecules and 135 different PCDF molecules (congeners). The number and positions of the chlorine atoms determine the size and shape of the molecules, which are two properties that determine how toxic and persistent the dioxins are. Dioxins with chlorine atoms in positions 2, 3, 7 and 8 are the most toxic of all. 17 of the dioxin congeners are classified as toxic because they carry chlorine in all the above‑specified positions. The toxicity varies between these 17 isomers, and is evaluated/weighted using an estimated Toxic Equivalency Factor (TEF) value. The most toxic isomers, 2, 3, 7, 8‑TCDD, have a TEF of 1. The TEFs of the other 16 congeners vary between 1.0 and down to 0.01, depending on their estimated toxicity. The total toxicity is then calculated by multiplying all the TEF values by the measured concentrations of the parti‑ cular isomer. The sum of the toxicity of all 17 congeners is then added and presented as the total Toxic Equivalent (TEQ) value of the sample. A problem that arises when attempting to compare results from different time periods is that different methods of calculation have been used to obtain the TEQs of the samples. The point of difference between the models is that the estimated TEF values of some congeners vary. Examples of evaluation methods that we have encountered include Eadon‑TEQ, Nordic‑TEQ, International‑TEQ and, most recently, WHO‑TEQ. As the models differ in their consideration of indi‑ vidual congeners, it is necessary to access congener‑specific data from earlier investigations in order to be able to recalculate the stated TEQ values. The latest calculation model (WHO‑TEQ) is described by Van de Berg et al [3]. However, even this model is at present being modified, with a new version due to come into use in the near future.

The occurrence and behaviour of a substance is controlled by its chemical structure and properties, as well as by the environmental conditions in which it exists. Dioxins are hydrophobic, which means that they bind relatively strongly to organic material such as wood and earth, and are not easily moved by the water phase. In addition, it has been found that dioxins bound into the ground are usually difficult to access for physical, chemical or biological conversion mechanisms [4]. Dioxins are therefore assumed to remain in the ground for a long period of time, strongly bound to particles of earth [5].

The spread of dioxins in the ground from five selected sawmill areas has recently been investigated in a PhD thesis by Y. Persson [6]. The results indi‑ cate a change in the dioxin composition in the contaminated ground in com‑ parison with the chlorophenol preparation that was used, indicating that some breakdown or transport of selected dioxin congeners is occurring. A possible explanation of this phenomenon could be that the dioxins have been transpor‑ ted through the ground by partly binding themselves to the mobile parts of the soil and of the colloids carried by the water flows in the ground [6‑10].

Dioxins are very stable molecules, which means that they are broken down only very slowly, i.e. they are persistent and bio‑accumulate in nature. All dioxin congeners are classified as hydrophobic and persistent molecules, but these two properties are accentuated within the group as the degree of chlorination increases.

In more or less all of the analyses of various ground and soil samples, it is PCDD that dominates, rather than PCDF, and octa‑chlorinated congeners are dominant in the profiles [1]. It is difficult to decide whether this enrichment of OCDD in particular is caused by the transportation of other lower‑chlori‑ nated congeners from the material and/or by transformation, or if there is also natural creation of new OCDD material. Both processes probably contribute to the dominance of octa‑chlorinated chlorophenol in nature [1, 2].

A number of investigations have looked at how humans and animals are affected by living in environments with elevated concentrations of chlorop‑ henols and dioxins. Elevated dioxin contents have been found in blood, milk and eggs in cattle and chickens living in environments contaminated by dioxins resulting from the use of chlorophenols [11‑13]. Elevated dioxin concentrations have also been found in cattle with access to premises contain‑ ing chlorophenol‑treated wood. Cattle chew the wood, while chickens peck around in contaminated soil, both of which are assumed to be exposure paths [11‑13].

Three recently published exposure investigations of sawmill workers and others living in the vicinity of sawmills that treated timber with chlorophenols all report finding elevated concentrations of hepta‑CDD and OCDD in the blood of the persons investigated [14‑16]. The congener profiles agree with those found in soil contaminated by chlorophenol. Possible exposure paths are assumed to be through the inhalation of contaminated dust particles, and also by the eating of fish [14, 15]. However, no clear links to high frequencies of cancer or other illness‑related effects in the area could be found [16].

No clear links to adverse health effects have been noted in any of the above reports, despite the fact that both humans and animals had been exposed to higher levels of chlorophenol‑treated products and environments than normal.

3 Production of

chlorophenol-treated wood products

3.1 Pressure treatment

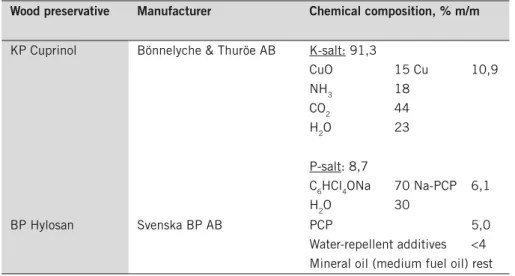

Pressure treatment using chlorophenol products was carried out in Sweden between 1956 and 1978. Only two different brands were used; namely, KP Cuprinol and BP Hylosan. KP Cuprinol was used in an ammoniacal aqueous solution, while BP Hylosan was an oil‑borne wood preservative, i.e. the pentachlorophenol was dissolved in a mineral oil similar to medium fuel oil. Table 1 shows the compositions of both substances.

Table 1. composition of KP cuprinol and bP hylosan.

wood preservative manufacturer chemical composition, % m/m

KP Cuprinol Bönnelyche & Thuröe AB K-salt: 91,3

CuO 15 Cu 10,9 NH3 18 CO2 44 H2O 23 P-salt: 8,7 C6HCl4ONa 70 Na-PCP 6,1 H2O 30 BP Hylosan Svenska BP AB PCP 5,0 Water-repellent additives <4 Mineral oil (medium fuel oil) rest

Thanks to the excellent statistics concerning quantities of preservative‑treated timber that have been produced since 1950 by the Swedish Wood Preservation Committee and later by the Swedish Wood Preservation Institute, reliable information is available on the quantities that were treated with the particular wood preservatives over the period while they were used. Table 2 shows pro‑ duction data based on this information.

Over the period concerned, about 18 % of the total production of preser‑ vative‑treated sawn timber was treated by KP Cuprinol, whereas BP Hylosan‑ treated wood constituted only about 3 % of the production. CCA wood preservatives, based on copper, chromium and arsenic, were by far the most widely used, accounting for about 70 % of the total production of preserva‑ tive‑treated sawn timber.

According to calculations made on the basis of production quantities of treated timber [18], a total of about 640 tonnes of chlorophenols, expressed as pentachlorophenol, was used for preservative treatments for the Swedish market over the period 1956‑1978.

BP Hylosan was also used to a limited extent for industrial dip treatment of sawn timber for protection against decay.

Table 2. Production of KP cuprinol- and bP hylosan-treated timber (m3) 1956-1978 [17].

wood preservative year Sleepers Poles Sawn timber Total

KP Cuprinol 1956 6 476 600 7 500 14 576 1957 1 231 1 510 7 600 10 314 1958 1 130 1 418 4 926 7 474 1959 - - 7 104 7 104 1960 - 300 9 200 9 500 1961 - 514 12 410 12 924 1962 - 1 807 4 050 5 857 1963 282 277 11 050 11 609 1964 435 157 13 906 14 498 1965 272 79 17 110 17 461 1966 58 282 26 117 26 457 1967 178 161 28 815 29 154 1968 60 - 32 896 32 956 1969 23 55 38 827 38 905 1970 100 236 36 873 37 209 1971 105 125 45 435 45 665 1972 45 193 60 728 60 966 1973 44 190 60 106 60 340 1974 100 200 65 800 66 100 1975 90 185 55 625 55 900 1976 - - 50 000 50 000 1977 - 1 700 41 200 42 900 1978 700 - 42 700 43 400 BP Hylosan 1963 - - 85 85 1964 - - - -1965 - - 3 300 3 300 1966 - - 5 017 5 017 1967 - - 7 900 7 900 1968 - - 10 414 10 414 1969 - - 10 600 10 600 1970 - - 9 650 9 650 1971 - - 9 250 9 250 1972 - - 9 500 9 500 1973 - - 8 500 8 500 1974 - - 6 900 6 900 1975 - - 10 250 10 250 1976 - - 8 625 8 625 1977 - - 9 200 9 200 1978 - - 5 100 5 100

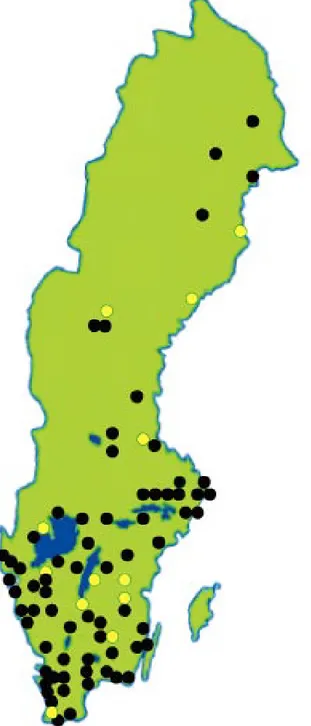

Figure 1 is a map of Sweden, showing production sites for timber treated with KP Cuprinol and BP Hylosan. The map makes no claim to be complete, as it has not been possible to obtain all information concerning production sites, but nevertheless its provides a good picture of where most of the treatment plants using these two wood preservatives was carried out. All the plants had a relatively modest annual production, in the range 500‑2000 m³.

Figure 1 Geographical location of production facilities for timber treated with KP Cuprinol (black dot) and BP Hylosan (yellow dot).

3.2 Dip treatment of freshly sawn timber

Dipping of freshly sawn timber in a chlorophenol product for protection against discolouring fungi, i.e. mould and blue stain fungi, during storage and transport was a recognised successful method. Several products were registe‑ red with the Products Control Board mainly containing potassium or sodium salts of 2, 4, 6 trichlorophenol (e.g. BT Blåskydd, Gullviks Blåskydd), as well as sodium salts of pentachlorophenol (e.g. Dowicide G, Santobrite). These products were normally used as 1‑2.5 % aqueous solutions in relatively simple facilities, often with poor protection against environmental contamination, as shown in Figure 2. There was considerable spillage on to the ground, together with drips from the products, and a number of accidents occurred during the 1960s and 1970s in the form of overflows of dip tanks.

Figure 2. A timber dipping facility for freshly sawn timber, Photo: Swedish Wood Preservation Institute

As far as the number of sawmills dip‑treating their timber is concerned, vari‑ ous estimates indicate that about 10‑15 % of sawmills (i.e. 400‑500) [19, 20] performed dip treatment. Preliminary results from an ongoing new survey and investigation, being carried out by the county councils, indicate that the number of dipping facilities was probably more than 500. Dip‑treatment was required primarily by sawmills that did not use kilns, and supported by data from the 1973 and 1970 sawmill surveys we can also draw the conclusion that it was mainly the smaller sawmills that dip‑treated their products [21, 22]. On the basis of county councils’ surveys of contaminated areas using the MIFO model, we can get an idea of where the sawmills concerned were in the country. Not surprisingly, southern Sweden had by far the most saw‑ mills, in counties such as Kronoberg, Kalmar and Västra Götaland (previously Älvsborg and Skaraborg) [23], although dip treatment was performed at saw‑

In contrast with pressure‑treated timber, there is no information on the quantity of sawn timber treated against blue stain fungi with chlorophenol products between the 1950s and when its use was banned in 1978. There are also no reliable figures on the quantities of these products that were sold. Over the period 1956‑1978, annual use of sawn timber on the Swedish domes‑ tic market amounted to about 4.2 million m³ [24]. Bearing in mind that only 10‑15 % of sawmills, most of which were also smaller sawmills, were thought to have treated wood by dipping, it is unlikely that more than about 600 000 m³ of dip‑treated wood were used per year during this period and remained in the country. Moreover, most of the dip‑treated timber was expor‑ ted.

With an average absorption of about 0.1 kg/m³ [25], the consumption of chlorophenols for dip treatment of timber for the domestic market over the period 1956‑1978 would have been about 1000‑1500 tonnes.

3.3 Remedial treatment of fungal decay and

insect attack

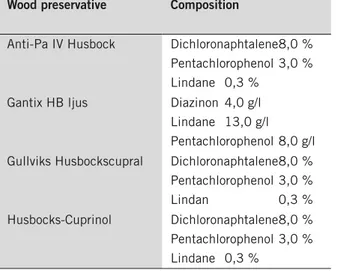

A few products, mainly for professional use, for remedial treatment of fungal decay and insect damage, contained chlorinated phenols. Table 3 [26] lists some examples of such products.

Table 3. Examples of products containing chlorinated phenols for remedial treatment. wood preservative composition

Anti-Pa IV Husbock Dichloronaphtalene 8,0 % Pentachlorophenol 3,0 % Lindane 0,3 %

Gantix HB ljus Diazinon 4,0 g/l Lindane 13,0 g/l Pentachlorophenol 8,0 g/l Gullviks Husbockscupral Dichloronaphtalene 8,0 % Pentachlorophenol 3,0 % Lindan 0,3 % Husbocks-Cuprinol Dichloronaphtalene 8,0 % Pentachlorophenol 3,0 % Lindane 0,3 %

Husbocks‑Cuprinol was perhaps the best known and most widely used of these products, and was also available for use by ordinary consumers, and not restricted solely to professional users. Tests carried out at SP indicated that about 0.7 Litres of Husbocks‑Cuprinol were used per m³ of timber for con‑ trolling an existing attack [27].

No reliable information on the quantities that were used is available, alt‑ hough the quantity of active substances – i.e. the total of dichloronaphtha‑ lene, pentachlorophenol and lindane – were estimated as less than 2 tonnes/ year [19]. Over the entire period 1956‑1978, this would mean that about 15 tonnes of pentachlorophenol were used.

3.4 The Do-It-Yourself (DIY) sector

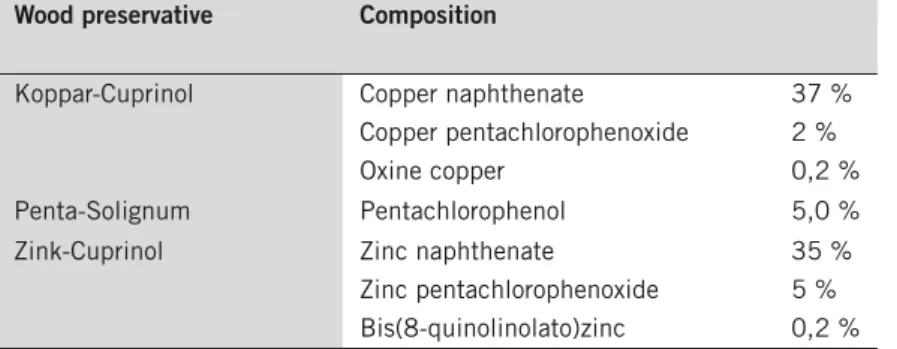

A number of products containing chlorinated phenols were produced for the DIY sector: Table 4 shows a number of typical examples [26].

Table 4. Examples of wood preservatives containing chlorinated phenols for application by brush or dipping, and intended primarily for the dIy sector

wood preservative composition

Koppar-Cuprinol Copper naphthenate 37 % Copper pentachlorophenoxide 2 %

Oxine copper 0,2 %

Penta-Solignum Pentachlorophenol 5,0 % Zink-Cuprinol Zinc naphthenate 35 %

Zinc pentachlorophenoxide 5 % Bis(8-quinolinolato)zinc 0,2 %

There are no statistics for the sales quantities of these products throughout the period. The press release from the Products Control Board concerning the ban on wood preservatives containing chlorophenols issued on 27th May 1977

states that the use of wood preservative stains and textile treatment products accounted for about 10 % of total use, which would therefore indicate a total quantity of about 200 tonnes [28]. Information from the UK [25] indicates that this seems to be a reasonable proportion.

4 The use of chlorophenol-treated

wood products

4.1 Pressure-treated

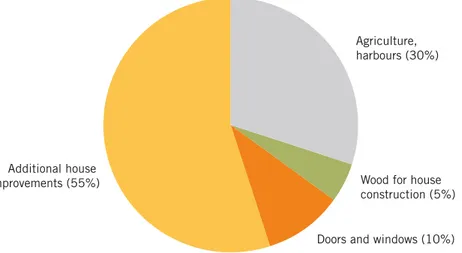

As shown in Table 2, both KP Cuprinol and BP Hylosan were used mainly for impregnation of sawn and planed timber. Against the background of esti‑ mates described in IVA Report No. 22 [29], we can assume that most of this timber was used outdoors for residential end uses, such as decking, fences and pergolas, as shown in Figure 3.

Figure 3. Estimated proportion (%) of use of impregnated timber for various application on the Swedish domestic market (IVA, 1982).

KP Cuprinol was also used for treating wood for windows and panels by the Royal process, which involved treating the wood as a first stage, and then drying and staining it in a second stage, as well as for timber used in wall plates in detached houses built during the 1970s.

It was relatively common for the wall plate to be cast into the foundation slab, or to be laid on slabs without a moisture barrier. This sometimes resul‑ ted in mould attack, and the associated problem of odour. Timber treated with KP Cuprinol is regarded as having been over‑represented as far as odour problems in detached houses are concerned [31]. A possible explanation for the occurrence of odour was that the fungi reacted with the chlorophenols, to produce a characteristic smell of mould.

In comparison with other uses, the use of KP Cuprinol‑treated wood for windows and wall plates was relatively small.

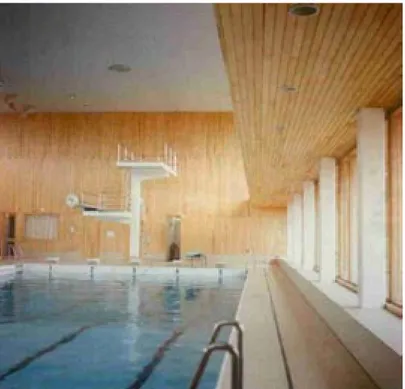

In addition to typical garden end uses, BP Hylosan was also used for treating claddings or, indoors, for panelling in several swimming pools (see Figure 4).

Agriculture, harbours (30%)

Wood for house construction (5%) Doors and windows (10%) Additional house

According to our estimates, timber impregnated with KP Cuprinol or BP Hylosan was mainly used close to where it was produced, which means that we can say that, in general, such treated timber was used mainly in south‑ ern Sweden. In the case of KP Cuprinol, this was predominantly used in south‑western Sweden, as can be seen in Figure 2.

4.2 Dip-treated timber

It can be assumed that, in by far the majority of cases, dip‑treated timber was planed before being used for joinery or as structural timber. As the active sub‑ stances do not penetrate significantly into the wood with this method of treat‑ ment, but only to a depth of about 1‑2 mm, it can also be assumed that most of the chlorophenols have ended up in the shavings, with the wood used in the end‑product being more or less free from chlorophenols [30].

Some of the shavings may have been used as raw material for the manu‑ facture of chipboard. According to a questionnaire mentioned by Edlund [19], shavings from dip‑treated wood were sometimes mixed with shavings from untreated wood and delivered to the chipboard manufacturers. It is not possible to estimate the quantities that might have been concerned.

As most of the sawmills with dip treatment facilities were located in south‑ ern Sweden, it is most likely that most of the users of such wood are to be found in this part of the country, with the main application being for detached houses constructed between 1960 and 1975.

Figure 4. Interior of the swimming pool in Finspång (built 1967) of which the interior panels were made from wood impregnated with BP Hylosan. The pool is now closed. (Photo: Svenska BP AB).

4.3 Products for remedial treatment

Products for remedial treatment of fungal decay and insect attack have been used throughout the country, although it can be assumed that products such as Gantix HB, Husbocks‑Cuprinol and similar products have found their main use in areas in which the house long‑horn beetle (Hylotrupes bajulus) is found, i.e. southern Skåne, Blekinge, Östra Småland and Östergötland, Södermanland, Öland, Gotland and Roslagen [32].

4.4 DIY products

Wood preservatives for brushing or dipping in the DIY sector have been widely used for residential timbers and other applications above‑ground. Considerable quantities have also been used for marinas and for fence posts and miscellaneous ground works, e.g. where, for various reasons, pressure‑treated wood was not used.

Geographically, use of such wood cannot be pinned down more precisely, although house and cottage‑owners, as well as farmers, are likely to have been the main users of products of this type, rather than professional users such as painters or other businesses.

4.5 Imported wood

Smaller quantities of chlorophenol‑treated timber have been imported over the years. No figures are available, but import quantities have been negligible in comparison with domestic use.

In connection with, and following on from, the ban on the use of chlorop‑ henol‑treated wood, attention was paid to the import of sawn timber from Finland. Finnish sawmills were continuing to use chlorophenol products even after the Swedish ban. There was no ban on the import of such wood, although it was considered [33]. The quantities of wood that were imported from Finland seemed to have amounted to a maximum of some tens of thou‑ sands of m³ per year, of which only some was treated.

A few small batches of railway sleepers were imported from France by SJ during the beginning of the 1980s. They had been treated with chlorophe‑ nol‑containing fungicide, which was found by the harbour workers’ health and safety representatives when the sleepers were being unloaded.

Some consignments of tropical woods, together with various items made from wood, such as furniture or decorations, that were imported may have been treated with chlorophenol products.

4.6 International outlook

On the international arena, chlorophenols are among the most widely used wood preservatives. For many years, sodium or potassium salts of tetra‑ and trichlorophenols have been the most commonly products for protecting newly

sawn timber against attack by blue stain and other fungi during storage and transport.

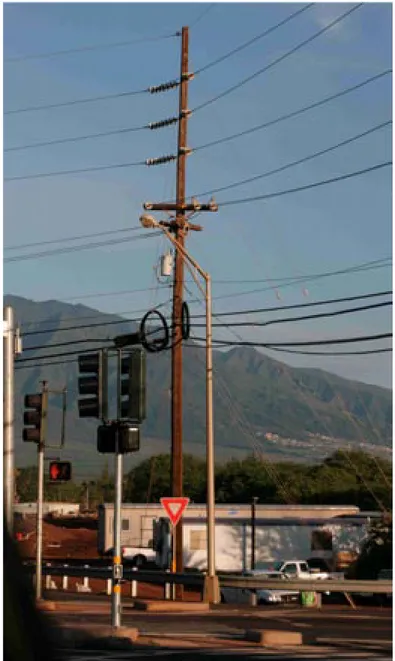

Pentachlorophenol in oil finds its largest markets in the USA and Canada, where it is used for impregnation of utility poles. Annual production of such poles in the USA is 1‑1.5 million per year [34], with pentachlorophenol being the most widely used preservative for poles, more so than creosote or CCA (Figure 5).

Figure 5. A utility pole in the USA (Pi’ilani Hwy, Maui) treated with pentachlorophenol (Foto: Tomas Jermer).

We have found that chlorophenol products are no longer used in Brazil (banned in 2007), Chile (banned in 1998), Malaysia, (banned in 1999), South Africa, Australia or France [35].

5 Occurrence of dioxins

5.1 Occurrence of dioxins in wood

preservatives

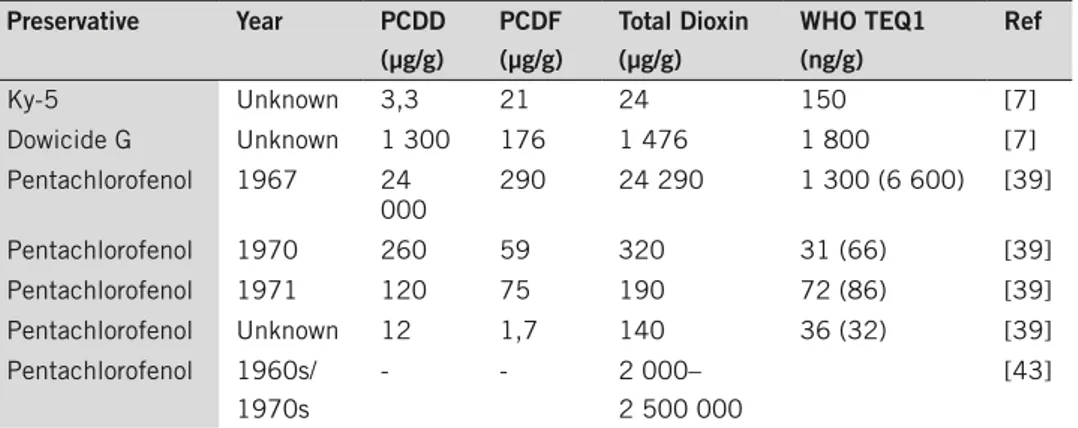

Dioxins and other chlorinated organic substances are formed during the manufacture of chlorophenols as a result of a smaller proportion of the chlorophenols reacting with each other to form chlorinated cross‑linked struc‑ tures. Table 5 shows the varying levels and presence of dioxin contaminants in a number of chlorinated organic substances made at various times. The manufacturing process has improved with time as a result of such means as optimised process temperatures and the use of different catalysts, reducing the concentration of contaminants in the various products.

Table 5. Pcdd och Pcdf concentration in Ky-5, dowicide G and pentachlorophenol as well as from five different production years. concentrations are expressed in μg/g (mg/kg) of end-product. dioxin concentration is given in the same unit as source references.

Preservative year Pcdd (μg/g) Pcdf (μg/g) Total dioxin (μg/g) whO TEQ1 (ng/g) ref Ky-5 Unknown 3,3 21 24 150 [7] Dowicide G Unknown 1 300 176 1 476 1 800 [7] Pentachlorofenol 1967 24 000 290 24 290 1 300 (6 600) [39] Pentachlorofenol 1970 260 59 320 31 (66) [39] Pentachlorofenol 1971 120 75 190 72 (86) [39] Pentachlorofenol Unknown 12 1,7 140 36 (32) [39] Pentachlorofenol 1960s/ 1970s - - 2 000– 2 500 000 [43] 1) Concentrations expressed in brackets are I-TEQ ng/g

Figures 6 and 7 show the proportions of tetra‑ and octa‑chlorinated diox‑ ins, together with the toxic congeners, in three products: namely Ky‑5 from Finland, Dowicide G from Sweden, and pentachlorophenol from Japan. The figure shows the differences in contamination levels between the products, with Ky‑5 in particular differing from the other two products, which are clearly dominated by OCDD.

As far as the dioxin contents of KP Cuprinol and BP Hylosan are con‑ cerned, the manufacturers stressed that they did not contain dioxin at all, or that they contained only the less toxic variants. Kymmene AB, who supplied Bönnelyche & Thuröe AB, the manufacturer of KP Cuprinol, wrote to the latter on 1971‑10‑13 [40] that “our polychlorophenol is direct‑chlorinated,

and thus does not contain dioxins”. The company also claimed that “our polychlorophenol is the only one of similar products that does not contain dioxins”.

On behalf of Svenska BP AB, IVL analysed BP Hylosan from the factory in Jönköping, finding the following dioxin concentrations in two samples [41]: hepta chloro dibensodioxin 1.8 and 1.1 μg/g, and octa chloro dibenso‑ dioxin 26.8 and 14.9 μg/g.

In its response to the Swedish Ministry of Agriculture, Svenska BP AB wrote on 1977‑06‑30, concerning the dioxin content in pentachlorophenol, [42]:

“PCP contains only octachlorodibenzo‑p‑dioxin (OCDD), which is less toxic than PCP. OCDD does not seem to have carcinogenic or teratogenic proper‑ ties. There is nothing to indicate that OCDD can be broken down into more toxic dioxins”.

Figure 6. Relative proportions of tetra-chlorinated and octa-chlorinated dioxins in six different analyses of chlorophenol-based dipping preservatives: three different products, Ky-5, Dowicide G and pentachlorophenol from four different years of manufacture. The red fields indicate the proportions of various PCDF congeners, while the blue fields represent the quantities of PCDD [7, 39].

Figure 7. Relative distributions of the 17 toxic congeners, as found in six different analyses of chlorophenol-based wood dipping preservatives: Ky-5, Dowicide G, and pentachlorophenol from four different years of manufacture. The red field indicate the proportions of various PCDF congeners, while the blue field represent the quantities of PCDD [7, 39].

0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

Ky-5 DowG 2 PCP 1967 PCP 1970 PCP 1971 PCP Unknown

OCDF SHpCDF SHxCDF SPeCDF STCDF OCDD SHpCDD SHxCDD SPeCDD STCDD 0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

Ky-5 DowG 2 PCP 1967 PCP 1970 PCP 1971 PCP Unknown

OCDF 1234789-HpCDF 1234678-HpCDF 123789-HxCDF 234678-HxCDF 123678-HxCDF 123478-HxCDF 23478 PeCDF 12378 PeCDF 2378 TCDF OCDD 1234678-HpCDD 123789-HxCDD 123678-HxCDD 123478-HxCDD 12378 PeCDD 2378 TCDD

5.2 The occurrence of dioxins in

impregnated wood

Relatively little information has been published concerning the occurrence of dioxins in treated wood products. However, the data that is available indicates relatively low toxic concentrations in various wood products. The reason for the low toxic concentrations is that it is mostly the highly chlori‑ nated dioxins, which have a relatively low toxicity, that are found in the pro‑ ducts. Table 6 shows levels of dioxins in a number of different products and sawmill waste [11, 44‑46]. Two samples taken from waste wood landfill at two different sawmills show a wide spread of TEQ, from 0.067 to 2.1 ng/g of waste [45]; a result which illustrates not only the importance of the sampling method, but also that the concentrations in materials can vary widely.

A dioxin exposure investigation of cattle analysed the chlorophenol and dioxin concentrations in various different wooden materials used in buildings for the animals [11], finding a clear positive linear relationship between the concentrations of chlorophenol and dioxins in the wood samples (Figure 8). Unfortunately, the article did not give any data that can link the chlorophenol and dioxin quantities to the number of years for which the wood had been in use.

Figure 8. Relationship between chlorophenol concentration and WHO-TEQ in wood used in buil-dings etc. for cattle [11].

Lorber et al [46] have carried out a relatively large investigation into dioxin concentrations in utility poles. Two samples were taken from recently trea‑ ted poles, before they were erected, as well as from poles that had been in use for between 1 and 34 years. In addition, samples were taken from different depths in the poles. The investigation found an enrichment of dioxin in the

surface layers, most probably as a result of migration from the centre of the pole towards the surface [46]. Table 6 shows that the concentration of dioxin in the poles exhibits a falling trend with time, indicating that the dioxins mig‑ rate from the pole to the surrounding ground, or are broken down, but with significant differences in the rate of migration or degradation between items. However, it should be noted that the material used in the investigation was limited, and that there can be individual variations between samples.

Table 6. dioxin concentrations expressed as TEQ in various wood products and sawmill waste products. concentrations are expressed in ng/g (μ/mg). dioxin concentrations are expressed in the same units as in the source reference, i.e. either I-TEQ or whO-TEQ.

Product TEQ (ng/g) reference

Ky-5 treated wood* 38 [44]

Wood used in agricultural application 0,016-315 [11] Sawmill waste landfill 0,067 och 2.1 [45] Utility pole, freshly treated, 1996 3,1 [46] Utility pole, freshly treated, 1999 6,8 [46] Utility pole after 1 years’s use 15 [46] Utility pole after 4 years’s use 14 och 15 [46] Utility pole after 11 years’s use 6,3 och 14 [46] Utility pole after 24 years’s use 7,7 [46] Utility pole after 34 years’s use 0,71 [46] *Wood that had been left in the bottom of a dipping tank

Ref [44] and [45] are TEQ expressed as I-TEQ Ref [46] is TEQ expressed as WHO-TEQ

An earlier work, by Morgan and Purslow [47], also found a decline in chlorophenol concentrations with time. Clear reductions were noted over a period of two years. However, it should be added that chlorophenols are transported and transformed considerably more easily than the heavier orga‑ nic dioxin molecules in nature, due to such effects as their polarity.

5.2.1 measurement of chlorophenols and dioxins in treated wood

Samples from four different applications (indoor panel, a field trial stake and utility pole) have been analysed in order to obtain an idea of the quantity of dioxins bound in products of these types. Samples from the field trial stake were divided into two groups: one from the part of the pole above ground, and one from the part in the ground, in order to identify any differences in dioxin or pentachlorophenol contents. Data is shown in Table 7.

The indoor panel was from a swimming pool in Finspång (Figure 4), built in 1967. According to Svenska BP AB, the panel was treated with BP Hylosan. The treatment was expected give a retention of 5 kg of pen‑ tachlorophenol per cubic metre of wood.

The field trial stake was treated with KP Cuprinol, and formed part of a field trial of wood preservatives started by the Nordic Wood Preservation Council (NTR‑NWPC) in 1968 [34]. The stake was exposed at a site belong‑ ing to the Danish Technological Institute in Tåstrup, and was the final sur‑

viving one from those treated with KP Cuprinol. The original retention of wood preservative in the stake was about 2.2 kg/m³ (about 0.5 % m/m) of Na‑PCP, and about 3.9 kg/m³ (about 0.8 % m/m) of copper, as shown in Table 1. This particular stake had been treated with about twice the normal concentration of the preservative. Copper concentrations in the sample were also measured, in order to obtain data on the uptake of copper both above and below ground.

The sample from a utility pole was taken from the above‑ground part of a pole of Douglas fir that had been in use for about 25 years in western Oregon in the USA. The original retention of pentachlorophenol can be assumed to have been about 9‑10 kg/ m³, i.e. approximately twice as high as was nor‑ mally used in Sweden when treating with BP Hylosan.

The analysis results of the test stake from Denmark show clear differen‑ ces in concentrations from above and below ground. In the below‑ground part of the stake, the dioxin concentration is about four times higher, while the pentachlorophenol concentration is about 30 times lower. This indicates more rapid transport and degradation of dioxins above ground than in the ground, most probably due to the effects of weathering. In addition, both the absolute and the relative concentrations of high‑chlorinated congeners (octa and hepta) are considerably higher in the below‑ground portion of the stake. Enrichment of the high‑chlorinated congeners is not unexpected, and has been encountered in many other matrices in nature. This increase can be caused not only by new formation of the high‑chlorine congeners, but also by more rapid degradation of the lower congeners [1, 2]. As the mobility of dioxins in earth and the ground is relatively low, there is a risk that the dioxins will tend to accumulate in the soil around the stake [4, 5]. The average values of dioxin concentrations (both above and below ground) in the 40‑year‑old test stake (5.6 μg/kg) is about ten times higher than similar previously reported con‑ centrations found in utility poles (Table 6). One of the explanations for this somewhat high concentration can be that the stake was treated with twice as high a concentration of chlorophenol than usual.

The lower concentrations of pentachlorophenol and copper in the below‑ground parts of the test stake indicate more rapid degradation and transport in the soil matrix than in air. This result is in good agreement with other experience [58]. In comparison with the stated original absorption, it can be noted that about 30 % of the copper is left in the above‑ground part, and over 20 % in the part exposed to the soil matrix.

Analysis of the Oregon pole shows that the residual retention of pen‑ tachlorophenol is about 50 % of the original quantity used. Dioxin concen‑ trations are relatively high, despite the fact that the pole has been in use for about 25 years. The reason for these high concentrations may be high initial concentrations, or slower transport and degradation than for the other pro‑ ducts listed in Table 6.

The chlorophenol‑treated panels from the swimming pool in Finspång exhi‑ bit very low residual pentachlorophenol content. The reason for this is not known, although it may indicate that the initial uptake in the particular panel was low. However, there are still clear remaining concentrations of PCDD and PCDF today, which is to be expected, as the wood has not been exposed to any particularly severe conditions in terms of air, water or UV exposure. The samples exhibit a clear dominance of octa‑chlorophenol, both in terms of OCDD and OCDF. However, it is the OCDD concentration in the panel that is clearly dominant in the sample, corresponding to over 70 % of the total concentration.

Table 7. Quantities of pentachlorophenol (mg/kg), Pcdd and Pcdf (ng/kg) in interior panels from 1967, a field trial test stake from 1968, and an approximately 25-year old utility pole from Oregon, uSA. copper concentrations were also measured in the field trial pole.

Indoor panel Test stake, above ground Test stake, in the ground utility pole 2378-TCDD 70 24 12 86 12378-PeCDD 170 1 000 860 1 100 123478-HxCDD 150 60 59 2600 123678-HxCDD 4 700 12 000 40 000 110 000 123789-HxCDD 580 2 500 9 600 7300 1234678-HpCDD 130 000 8 800 30 000 1 700 000 OCDD 1 100 000 4 300 13 000 11 000 000 2378-TCDF 270 5,5 <2 470 12378-PeCDF 90 11 18 3 200 23478-PeCDF 130 19 48 3 300 123478-HxCDF 810 85 1 100 11 000 123678-HxCDF 360 85 470 5 500 123789-HxCDF 620 19 250 11 000 234678-HxCDF 790 110 1 000 13 000 1234678-HpCDF 40 000 13 000 260 000 130 000 1234789-HpCDF 4 300 48 800 8100 OCDF 240 000 9 900 230 000 70 000 I-TEQ (ng/kg) 4 100 2 300 8 900 49 000 Eadon-TEQ (ng/kg) 630 1 500 2 600 8 400 Pentachlorophenol (mg/kg) 660 260 9,8 8 400 Cu (weight-%) - 0,25 0,18

-6 Disposal of chlorophenol-treated

wood

As far as waste treatment is concerned, we distinguish between processing waste, offcuts, sawdust and shavings (which are produced in connection with machining the processed wood), and demolition wood, i.e. material that has been discarded due to the item in which it was included having reached the end of its service life for various reasons.

Today, almost all waste in Sweden is treated with controlled methods. Most wood and wood‑based materials are combusted under controlled con‑ ditions in special incineration plants. Wood‑based waste was previously also combusted, partly in the wood industry’s own boilers and partly in open, completely uncontrolled fires. However, large quantities of wood waste were also sent to landfill: sawdust that was not combusted, or which was used for some other purpose, such as chipboard or animal bedding, was often simply dumped in sawdust landfills. These landfills are often still in existence, and would probably be of interest to locate and investigate in more detail. Individual consumers may also have combusted wood in their boilers and open fires, but this is likely to have constituted only a very small proportion of all waste disposal.

For understandable reasons, there is no information on how waste from chlorophenol‑treated wood has been dealt with. However, the more recently that it has been disposed of, the more likely it is that it was combusted under controlled conditions.

Today, disposal by means of controlled combustion is the method that provides greatest protection against the spread of further dioxins in the form of diffuse emissions. The controlled combustion conditions quickly destroy dioxins and other chlorinated aromatic substances in the treated timber. Dioxins are then re‑formed in the convection zone of the boiler but are che‑ mically caught by the flue gas cleaning equipment and finally disposed of in landfill under controlled conditions. There are no indications to say that any larger quantities of dioxins are being spread from properly operated plants due to larger or smaller quantities of chlorophenol‑treated wood. Emissions data from 10 % joint combustion of chlorophenol‑treated wood with coal do not show any changes in emissions [48]. However, an analysis of dioxin concentrations in ash taken from a plant operating with poor combustion conditions showed elevated contents of dioxins in fly ash [49]. These results emphasise the importance of destroying the wood under good combustion conditions.

Meier D. et al [53] investigated pyrolysis of treated wood products on a pilot scale (5 kg/hour), investigating wood products contaminated with both inorganic and organic preservatives. In comparison with the reference case, the work noted a substantial increase in dioxin formation when pyrolysing chlorophenol‑treated wood products [53]. Destruction of various materials

in an open fire, i.e. uncontrolled combustion, generally produces high dioxin emissions. A relatively recent study investigated the emission levels from open uncontrolled combustion of ‘clean’ garden waste in a bonfire on the ground and those from garden waste with an admixture of unsorted waste fractions (RDF). Dioxin concentrations were very high in both experiments, at more than 30 ng WHO‑TEQ per kg of fuel [50]. This work also investigated the emissions from the same mix of fuels, but under somewhat better combus‑ tion conditions, i.e. in a barrel burner, rather than directly on the ground. Emissions from the bonfire on the ground were somewhat higher than those from uncontrolled combustion in the barrel burner. Another study, of uncon‑ trolled combustion on laboratory scale using four different wood fuels – two natural and two contaminated (fibreboard and chipboard) – found higher dioxin emissions from the contaminated wood fuels, of 15.4‑20.4 ng/kg as compared with 0‑2.5 ng/kg of WHO‑TEQ1 [51].

The main reason for the formation of high dioxin concentrations in uncontrolled combustion is that the oxygen input to the process is very uneven. While some parts of the bonfire might be burning too intensely, combustion in other parts might be proceeding by pyrolysis. This creates con‑ ditions which favour the formation of dioxins, while existing dioxins in the material might not be completely broken down. For obvious reasons, there is no data on uncontrolled combustion of chlorophenol‑treated wood. The fact that uncontrolled combustion has and does occur both in industry and by pri‑ vate persons is quite certain, but it has progressively reduced since the begin‑ ning of the 1970s, when the Environment Protection Agency published its first rules concerning impregnation of wood [54], recommending disposal by con‑ trolled landfill or combustion under controlled conditions.

At the end of the 1980s, an estimated 4500 kg of pentachlorophenol was burnt in a six and half hour‑long fire at a sawmill in the USA. The fire was very fierce, producing a large cloud of smoke which spread over the vicinity. Subsequent health investigations in the area found elevated dioxin contents, mainly of OCDD, although the measured levels were not toxic for residents in the area. The highest detected dioxin level in earth samples was 70 ppt of tetra‑CDD and 15 ppb of OCDD [52].

Landfill disposal of chlorophenol‑treated wood products is a very unsatis‑ factory way of disposal, as it represents a risk of diffuse emissions over a very long period of time, together with loss of potential energy recovery. No data is available today concerning the quantities of scrapped chlorophenol‑treated wood products sent to landfill.

Composting experiments carried out on wood that had been treated with Ky‑5 found somewhat elevated dioxin concentrations after 25 weeks’ com‑ posting [44]. However, it must be pointed out that these concentrations were only insignificantly higher than the reference case. Another investigation

1 The authors have assumed that the reported concentration is expressed in WHO-TEQ, but

found that microbial decomposition of dioxins in treated wood products was more or less non‑existent after eight weeks’ of laboratory trials [55]. The results indicate that dioxin quantities in scrapped wood products are probably not broken down by biological activity in landfill. In addition, elevated dioxin concentrations were also found in the surface layers of the ground where the Ky‑5‑treated wood had been stored. These results can be explained both by direct contamination by Ky‑5, and also by degradation of the treated wood products that had lain on the ground for a long time.As dioxins bind strongly to the organic phase, it is very likely that they remain in the ground after the product has decayed [44]. Leakage of dioxins from treated telephone poles into the surrounding ground has also been described in two other studies [56, 57].

Breakdown of chlorophenols and dioxins in soils contaminated with Ky‑5 has also been investigated by Laine et al [58], who reported the effects of trials in four composters over nine weeks. The results indicated an unchanged dioxin concentration in the compost but a clear breakdown of chlorophenol. No formation of toxic metabolites as a result of the chlorophenol breakdown or polymerisation was found. In addition, field investigations have found that 90 % of chlorophenols in the ground disappear after the first six months [58].

The above results are in good agreement with earlier theories that diox‑ ins that are chemically bound to organic materials are resistant to biological breakdown mechanisms [4]. These results indicate that if dioxin has found its way into a landfill site via contaminated wood products, it is very likely that most of it is still in the landfill, bound to the wood residues and soil.

7 Discussion

7.1 Estimate of dioxin from

chlorophenol-treated wood products in the environment

An earlier report from the Swedish Environment Protection Agency [59] estimated the total quantities of dioxins expressed as the sum of PCDD and PCDF in the environment resulting from the use of chlorophenol‑treated wood products as 30 kg. This figure was calculated on the basis of data for total production of chlorophenols, coupled with the assumption that 90 % of this quantity was bound up in products. It was then assumed that parts of these products had been disposed of, and that 15 % of the dioxins had evapo‑ rated. Corresponding calculations were made in Denmark in 1999 and 2003, with the result that it was estimated that the total concentrations in products in society amounted to 100‑5000 g I‑TEQ [60].

In order to make reliable estimates of the quantities of dioxin still in exis‑ tence in chlorophenol‑treated wood, it is necessary to have as accurate know‑ ledge as possible of the following factors:

a. The quantity of dioxins in treated wood.

b. The quantity of chlorophenol‑treated wood that is still in use.

In this report, the quantity of dioxin remaining in existing material has been calculated on the basis of available analysis data, as shown in Table 8.

Table 8. dioxin quantities (I-TEQ μg/kg) used for calculating residual dioxin quantities in wood treated in various ways.

Treatment dioxin concentration (I-TEQ μg/kg) Pressure-treated: * KP Cuprinol * BP Hylosan Max = 8,9; Min = 2,3 Max = 49; Min = 4,1 Dip-treated Max = 3,8; Min = 0,1

DIY Max = 4,9; Min = 0,1

Remedial treatment products Max = 4,9; Min = 0,1

The quantity of dioxins in products treated with KP Cuprinol has been based on the analysis values of the above‑ground and below‑ground parts of the test stake in the Danish field trials (Table 7). This particular pole was treated with twice the normal concentration as compared with the normal value, which means that the remaining dioxin concentration can be regarded as a maxi‑ mum value. However, as dioxin concentrations in products that have been used indoors are probably higher than those exposed outdoors to weather and wind, the elevated concentration in this test pole can be regarded as a repre‑ sentative value for wood in both indoor and outdoor applications.

The value from the utility pole in Oregon, together with the indoor panel from Finspång (Table 7) have been used for estimating the quantities of diox‑ ins in BP Hylosan. The particular pole concerned had been treated at a rate twice as high as that normally used for Hylosan‑treated wood, so again the value can be regarded as a kind of maximum value. The detected concentra‑ tion in the indoor panel was almost ten times lower than this, and is regarded hereinafter as a minimum value.

The maximum value for the dip‑treated products has been based on ana‑ lysis of a piece of wood that was left lying on the bottom of a dipping tank (Table 6). As we do not know for how long it was exposed to the treatment solution, we have assumed that the analysed concentration is at least ten times higher than the normal concentration, while setting a minimum value close to zero, as the majority of these products were planed. The assumption of a maximum value ten times higher than the normal concentration is based on the fact that the concentration in dip‑treated wood cannot reasonably be higher than that in pressure‑treated wood. However, it should be noted that even this reduction to ten times lower gives most probably an unreasonably high concentration for dip‑treated wood.

The same approach – i.e. estimating maximum and minimum values – has been used for DIY and remedial treatment products. As there is no data from remaining products in this group, a ten times lower concentration from pressure‑treated products using BP Hylosan has been taken as the maximum value, with a value close to zero as the minimum.

Estimates of the remaining quantity of chlorophenol‑treated wood pro‑ ducts have been made on the basis of available knowledge concerning the quantities originally used, and on the approximate expected life of the wood. As far as the life of the wood is concerned, we can make the following assumptions:

‑ Built‑in wood, such as panels, sheets and sole plates, with essentially unlimited life. If the building is still in existence, the wood is nor‑ mally also still in use.

‑ However, note that wood used as sole plates, and treated with KP Cuprinol, has in several cases been replaced by other wood due to problems of mould and associated odour.

‑ Wood in outdoor above‑ground applications is probably still in use in many cases, provided that aesthetic aspects have not led to it being pulled down or replaced.

‑ Wood in contact with the ground, regardless of whether it was pressure‑treated or merely surface‑treated or dip‑treated, has almost certainly reached the end of its life and been replaced. The typical life of superficially treated or dip‑treated wood in contact with the ground is of the order of 5‑20 years, depending on how the treat‑ ment was applied [36], while tests show that wood that was pres‑ sure‑treated with KP Cuprinol or BP Hylosan should have a life of about 15‑30 years [37, 38].

With these assumptions, and using available information and estimates con‑ cerning past production, we can arrive at the following possible scenario for the remaining quantities of chlorophenol‑treated wood:

Pressure-treated wood:

‑ About 30 % has been used in contact with the ground: all has been replaced, with nothing left in service. However, dioxins leached out of the structure may still be in the ground where the structure origi‑ nally stood.

‑ 70 % has been used above ground, including indoor applications, and of this about 50 % is still in use. This means that about 240 000 m³ (about 115 000 tonnes) of wood treated with KP Cuprinol is still in use, and that about 40 000 m³ (about 20 000 tonnes) of wood treated with BP Hylosan is still in use, equivalent to respective total quantities of about 125 and 100 tonnes of pentachlorophenol.

Dip-treated wood:

‑ About 75 % of the dip‑treated wood is still in use, built into buil‑ dings, and including chipboard panels produced from shavings from chlorophenol‑treated wood.

‑ Although it is assumed that most of the dip‑treated wood was pla‑ ned, we should still assume (for safety) that 5 % of the remaining wood, equivalent to about 500 000 m³ or about 250 000 tonnes, contains chlorophenols, and thus also dioxins.

DIY:

‑ About 30 % of this has been used in contact with the ground, and all has now been replaced. However, dioxins leached out of the wood can still be in the ground beneath.

‑ About 70 % of the wood in this group (including that used indoors) has been used above ground, with about 40 % of it left. This repre‑ sents a quantity of about 55 tonnes of pentachlorophenol. With an uptake of about 0.2 kg/m³, this is equivalent to about 250 000 m³ of wood, or about 130 000 tonnes.

Remedial treatment products:

‑ About 75 % of the treated wood is still in existence, equivalent to about ten tonnes of chlorophenols. With the same reasoning as for the DIY group, this is equivalent to about 25 000 tonnes of wood.

On the basis of these scenarios for residual quantities of chlorophenol‑treated wood, and of the dioxin concentrations as given in Table 8, we can quantify the residual amounts of dioxin today, expressed as kg I‑TEQ, as shown in Table 9. The table also shows a comparison with the total quantities of delivered dioxins, based on the analysis data for the different chlorophenol products as shown in Table 5. As the dioxin concentrations in the various analysed products vary both in terms of product name and year of manufac‑

ture, we have used the highest and lowest values from Table 5 in our calcula‑ tions. Further, as the data in the source material has used various calculations for determining the toxic content of the products, the results in Table 9 are presented in I‑TEQ, as it is that quantification that is used most often.

Table 9. Summary of estimated quantities (kg) of dioxins (I-TEQ) released into the environment in connection with the manufacture of treated wood products, expressed as total accumulated quantities over time. In addition, the table shows estimated quantities still remaining in wood products in use. Appendix 1 gives details of the calculation methods.

remaining quantity today Accumulated input quantity Pressure-treated: * KP-Cuprinol * BP-Hylosan 1,0 – 0,3 1,0 – 0,1 100 – 20 Dip-treated 1,0 – 0,0 220 – 45 DIY 0,6 – 0,0 30 – 6 Remedial treatment products 0,1 – 0,0 2 – 0 Total 3,7 – 0,4 kg 360 – 70 kg

It can be seen from the table that it is estimated that there are between 0.4 and 3.7 kg of dioxin (I‑TEQ) in the environment today, in the form of diox‑ ins bound to treated wood products2. The wide spread of the estimate is due

to the wide variations of the analysis data. The assumptions concerning the quantities of products still in existence are deliberate overestimates, although probably fairly small, in order to avoid underestimating the quantities.

With the above assumptions, the accumulated quantity of dioxins released into the environment is estimated as somewhere in the range 70 ‑ 360 kg of dioxin (I‑TEQ). The higher limit was calculated on the basis of an estimated maximum concentration equivalent to 150 ng I‑TEQ/g of pentachlorophenol product. This value has been taken from values given in the literature (Table 5). However, the highest reported concentrations in Table 5 are most likely not representative of the majority of chlorophenol products used throughout the particular period of time concerned. The minimum value shown in Table 9 above is probably closer to reality, as the degree of dioxin contamination in the products declined with time as a result of efforts by the manufacturers.

2 In the case of dip-treated products, the estimated concentrations also partly include

7.2 Proposals for remedies

During the work of preparing this report, much time was expended and many contacts utilised in order to identify representative and good quality sample materials and objects for determining dioxin concentrations in products today. The fact that it has been difficult to find such items gives an indication of the difficulty of finding ways of carrying out some form of large‑scale remediation of chlorophenol‑treated materials in the environment.

There can be no question that chlorophenol‑treated wood products have spread dioxins in the environment. However, the results of this investigation indicate that the quantity of wood and wood‑based products that were trea‑ ted with chlorophenol products, and which are still in use, is relatively small, and probably spread mainly over southern and south‑western Sweden. To determine with certainty whether some particular product has been treated with a chlorophenol product requires a relatively expensive chemical analy‑ sis. Attempting to conduct an extensive remediation campaign to deal with chlorophenol‑treated wood would therefore be very complicated and equally expensive. No clear links to adverse health effects in humans or animals have been noted in any of the earlier works referred to here, despite the fact that they refer to relatively high exposures to chlorophenol‑treated products and/ contaminated environments [11‑16]. It is therefore likely that there is no particular health risk in living in a house where chlorophenol has been used, as the doses are probably very low. Any remediation measures should be weighed against their potential value in limiting the spread of dioxins to the environment, where they can be bio‑accumulated and contribute to continued exposure of persons and the environment.

On the basis of this reasoning, we are of the opinion that the most effec‑ tive and most feasible way of reducing the spread of dioxin from chloroph‑ enol‑treated products is to aim for that all demolition wood is collected and combusted in incineration plants under controlled conditions. Demolition

timber must not be combusted in open fires or in plants intended only for pure biofuels.

Bearing in mind that there can still be waste landfills of sawdust and wood chips here and there, mainly associated with sawmills in the south of Sweden, and containing contaminated materials, it could be interesting to attempt to locate and list them, together with information on how large a source of dioxin they represent. It could also be of interest to investigate whether chip‑ board panels that were manufactured during the 1960s and 70s, and which were used primarily for walls, floors and furniture, represent any significant source of dioxin emissions against the background of the available informa‑ tion concerning the use of chlorophenol‑contaminated shavings in their manu‑ facture.

8 Conclusions

The following conclusions can be drawn from this investigation: ‑ No reliable exact figures for the total quantity of wood for the

Swedish market that was treated with chlorophenols, or for cor‑ responding quantities of chlorophenols that were used, have been obtained. However, the highest concentrations are those that are to be found in pressure‑treated wood, of which a total of about 800 000 m³ were impregnated between 1956 and 1978, which represents a consumption of about 640 tonnes of chlorophenols, expressed as pentachlorophenol.

‑ Most of the treated wood products consisted of sawn and planed wood for residential end uses and for structural purposes.

‑ Wood treated by dipping has generally been planed before use, which means that it presents only a minor source of spread of chlorophenols and dioxins in the environment. The shavings, on the other hand, do represent a potential source, partly through having been utilised for the manufacture of chipboard, and partly as a result of having been discarded in waste heaps. A current investigation indicates that the number of dipping plants in Sweden probably exceeds 500, and that they were spread over the entire country, although with a majority in southern Sweden.

‑ Both production and use of chlorophenol‑treated wood products were greatest in southern and south‑western Sweden.

‑ Pressure‑treated wood products probably represent the largest source of dioxin emissions from treated wood products.

‑ Dioxin concentrations in wood products decline with time, but only very slowly. Migration from the product cores to the surface has also been identified, which indicates that the dioxins are released through evaporation/diffusion.

‑ Controlled thermal destruction is the only method of safely breaking down the dioxins in these products, and reduces diffuse spread into the environment. Composting does not show any clear signs of biological breakdown.

‑ The total quantity of dioxins (I‑TEQ) in the environment has been estimated as a maximum of 3.7 kg. However, it must be emphasised that there are considerable uncertainties in this estimate, and that the quantity of residual products has probably been overestimated in connection with these calculations.

‑ The remaining quantities of dioxins exist mainly as diffuse sources in the environment, which complicates any work of remediation. Countermeasures should instead be concentrated on ensuring that all demolition timber is disposed of by controlled combustion in suita‑ ble incineration plants, and that there is no uncontrolled combustion

in open fires or in plants intended only for clean biofuels. In addi‑ tion, it would be interesting to identify and investigate the effects of chipboard panels still in use and of structural timber waste and sawdust or wood shavings waste landfills in contributing to the spread of dioxins in the environment.

![Table 2. Production of KP cuprinol- and bP hylosan-treated timber (m 3 ) 1956-1978 [17].](https://thumb-eu.123doks.com/thumbv2/5dokorg/3008689.4446/14.892.178.698.162.1137/table-production-kp-cuprinol-bp-hylosan-treated-timber.webp)