Transition towards circular economy

through a multi-readiness level

model

An explorative study in the construction equipment

industry

Federica Balestrucci

Master’s Thesis in Innovation and Design 30 credits

Course: ITE500

Thesis Supervisor: Koteshwar Chirumalla Industrial Supervisor: Anna Sannö

Abstract

Circular economy is considered one of the most viable approaches to sustainability and it has gained a lot of traction in recent years. It challenges the linear approach to production and consumption that generates waste and is unsustainable for the planet and future generations.

It is crucial to counteract the negative impacts of production on the environment by implementing new and effective business strategies that are compatible with circular economy.

Nowadays, manufacturing industries are struggling to make the transition towards circularity because of the intrinsic complexity of adapting new business models, product development, production processes and supply chain management to a non-linear approach. The literature on the transition towards circular economy extensively covers the aspects connected to either one of the above-mentioned domain-specific areas, developing different tools such as roadmaps and frameworks to support companies in the transition for a specific area. Yet, there is a lack of a systematic tool that can give support in each stage of the process based on the different business areas that need to be adapted to circularity. The purpose of this study is to explore the existing state-of-the-art knowledge with a systematic and holistic approach to factors that are connected to circular economy, so to create a practical tool for facilitating the process of transitioning towards circularity in a step-by-step manner, in connection to activities and strategies that can be implemented in different business domains.

An explorative case study in a manufacturing company in the construction equipment industry was carried out, with a twofold purpose: firstly, to gather, analyse and frame the existing state-of-the-art knowledge on the implementation of circular economy. Secondly, to explore the suggested multi readiness level model with the case study company in order to validate it. In order to do so, a set of ten semi-structured interviews with senior managers and experts in the field was carried out to gather valuable insights and practical knowledge. The outcome of this study is a multi-readiness level model for transitioning towards circular economy that explores the most important strategies and activities that should be implemented by a manufacturing company in four different areas of intervention, namely Ecosystem of External Partners, Customer and Business model, Company’s Culture and Internal Capabilities and Design and Product Development. Each area of intervention will be presented in connection to identified strategies and activities that must be implemented to reach circularity.

Keywords: Circular economy, readiness level model, circular transition, manufacturing

Acknowledgments

This thesis would not have been possible without the support and help of several people, to whom I would like to express my sincere gratitude. First and foremost, I owe much to my advisor Koteshwar Chirumalla, whose expertise and careful attention to detail helped me immensely to refine the technical aspects of my work.

I am likewise extremely grateful to Anna Sannö, who provided me with substantial assistance and feedback, not to mention kindness, and who supported me with invaluable insights and interesting discussions.

Additionally, I would like to extend my profound thanks to the people who generously set aside their time to conduct interviews with me despite the difficult situation.

Lastly, Nicolò, for always being by my side, and my family, for being immensely supportive throughout this whole process. I am incredibly thankful to them for everything, especially for the care packages containing guanciale and pecorino, which were vital during the long winter nights.

Federica Balestrucci Stockholm, June 2020

Table of Figures

Figure 1. Thesis Work Context

Figure 2. Visualization of research process Figure 3. Flowchart of articles selection process Figure 4. Visualization for the Triple Bottom Line Figure 5. Circular Economy material cycles. Figure 6. Technology Readiness Level Model

Figure 7. Tool for visual assessment of readiness level

List of Tables

Table 1. Inclusion Criteria for Research Database Table 2. Exclusion Criteria for Research Database Table 3. Overview of Retrieved Articles

Table 4. Details of interview recipients

Table 5. Categorization of articles according to type of outcome

Table 6. Categorization of articles in connection to the presented areas of intervention Table 7. Clustering of sub-groups for the Ecosystem Area

Table 8. Clustering of sub-groups for the Business Model and Customer Area Table 9. Clustering of sub-groups for the Firm Area

Table 10. Clustering of sub-groups for the Design and Development Area

Table 11. Multi Readiness level model for transitioning towards Circular Economy

Table 12. Final version on the Multi-Readiness Level model for transitioning towards Circular

Table of Contents

1. Introduction ... 1

1.1 Background ... 1

1.2 Problem Statement and Research Gap ... 2

1.3 Purpose of the study and Research questions ... 3

1.4 Delimitations ... 3 1.5 Thesis Outline ... 4 2. Research Methodology ... 6 2.1 Research Strategy ... 6 2.1.1 Research Context ... 6 2.2 Case Study ... 7 2.2.1 Company Background ... 8 2.3 Research Process ... 9

2.4 Systematic Literature Review ... 9

2.4.1 Inclusion and Exclusion Criteria ... 10

2.4.2 Identification of Papers and Application of Practical Screening ... 11

2.4.3 Overview of the Retrieved Articles ... 11

2.5 Empirical Data Collection ... 13

2.5.1 Observation and Immersion ... 13

2.5.2 Interviews ... 14

2.6 Data Analysis ... 15

2.7 Ethical Considerations ... 15

2.8 Quality Criteria ... 15

3. Theoretical Background and Development of a Conceptual Model ... 18

3.1 Sustainability and Sustainable Development ... 18

3.2 Defining Circular Economy ... 19

3.3 Defining Circular Business Model ... 21

3.4 Maturity Models ... 21

3.5 Readiness Level Models ... 22

3.6 Process for the Development of the Conceptual Readiness Level Model from the Systematic Literature Review ... 23

3.6.1 Categorizations of Articles ... 23

3.6.2 Extraction of Key Elements ... 25

3.6.3 Categorization of Findings ... 26

3.7 Synthesizing a Multi-Readiness Level Model for Facilitating the Transition towards Circular Economy ... 28

4. Empirical Results ... 35

4.1. Perceptions about the circular economy transition ... 35

4.2 Strategies and activities for the transition to circular economy ... 36

4.3.1. Areas of intervention ... 37

4.3.2 Ecosystem of External Partners ... 38

4.3.3 Customer and Business Model ... 39

4.3.4 Company’s Culture and Internal Capabilities ... 40

4.3.5 Design and Product Development ... 40

4.4 Presentation of the final version of the Multi-Readiness Level model for transitioning towards Circular Economy ... 41

5. Discussion ... 44

5.1 Answering Research Questions and their respective Theoretical Contributions ... 45

5.2 Practical Implications ... 47

6. Conclusions ... 51

6.1 Limitations of the Study ... 51

6.2 Future Research ... 52

7. References ... 54

8. Appendix ... 60

Appendix A. Systematic Literature Review: Main keywords, aims and description of outcomes and key results ... 60

Appendix B. Systematic Literature Review: extensive analysis ... 65

Appendix C. Overview of nature of interactions brought forward at Volvo CE ... 68

Appendix D. Extraction of key elements ... 70

Appendix E. Extraction of key elements and chromatic clustering ... 74

Appendix F. Fixed visualization of retrieved key elements divided by macro-areas ... 78

1. Introduction

This chapter presents an introduction that provides a background for better describing the area of interest of this study. The problem statement is highlighted, as well as research gap, purpose of the study and research questions.

At the end of the chapter, a general outline of the next sections of the thesis is provided to the reader.

1.1 Background

From the late 18th century, Planet Earth has entered the Anthropocene era, defined as the geological era dominated by human activity, which is characterized by remarkable emissions of carbon dioxide in the atmosphere (Crutzen, 2002). Since the second half of the last century there has been an intensive growth of the global population, going from 3 billion in 1960 to 7.7 billion in 2019, and expected to reach 8.5 billion in 2030 (United Nations, 2019). Population growth is directly linked with increased demand for natural resources such as the exploitation of lands, disappearing of forests and use of fossil fuels (Crutzen, 2002). Moreover, agriculture, farming, transportation and manufacturing activities grow at an exponential pace, releasing greenhouse gases that affect the climate and pollution levels. The pressure of human activities on ecosystems could lead to irreversible and even catastrophic environmental changes (Nykvist et al., 2009).

Particularly, manufacturing industries have an important impact on the environment due to a substantial share of pollutant emissions as well as generation of waste (Lawton et al., 2014). Therefore, since the second half of the last century, environmental concerns have been a priority for manufacturing industries, and academics and practitioners have started to contribute to such matters (Alblas et al., 2014). There are several measures and regulations on national and international levels have been implemented in the past few decades. Among these, the most recent ones are the European Agenda 2020 (European Commission, 2012) and the 17 Goals for Sustainable Development by the United Nations and European Agenda 2030 (United Nations, 2015).

The manufacturing industry has explored different approaches to sustainability such as material efficiency, eco-efficiency and resource efficiency (Rashid et al., 2008). One approachthat has been gaining momentum is the Circular Economy. Over just a decade, there has been a steep increase in scientific publications connected to Circular Economy, especially from Chinese and European scholars (Geissdoerfer et al., 2017). Circular Economy challenges the linear take-make-dispose practices of traditional manufacturing (Blomsma and Brennan, 2017) while focusing on avoiding waste and closing loops for reducing the dependency on finite resources. The European Commission is not only encouraging all manufacturing industries to make the shift towards circular economy, but also foreseeing a

great opportunity for increased competitiveness, protection of businesses against scarcity of resources and volatile prices and creation of innovative business opportunities (European Commission, 2015). Recently this year, a Circular Economy Action Plan called“The European Green Deal” was published to revise legislation around batteries, packaging, end-of-life vehicles, and hazardous substances in electronic equipment in order to focus on preventing waste, increasing reuse of parts and recycled content, promoting safer and cleaner waste streams, and ensuring high-quality recycling (European Commission, 2020).

Making the transition from linear to circular is a demanding operation that requires to completely change the way industries shape all aspects of their developmental, managerial and operational efforts, as well as supply chain, business model and customer relationship (Frishammar and Parida, 2019) . Moreover, there is a very diverse understanding of the Circular Economy concept by different stakeholders (Corona et al., 2019), thus leading to an unclear strategy for implementation and operationalization. Taking this into account, it is necessary to create a solid strategy for handling such complexity in the most effective way. A systematic approach is needed, as well as the creation of a tool for assessing the current status of a company and for defining a transition path towards circularity in a step-by-step manner.

Literature that belongs to the field of circular economy is often divided into domain-specific areas, such as business model innovation (Bocken et al., 2019; Reim et al., 2015; Tukker, 2015), operations management (Lopes de Sousa Jabbour et al., 2019) or product design (Pigosso et al., 2010; Vanegas et al., 2018). Literature shows that the most recurrent circular initiatives that are already implemented by manufacturing companies usually pertain to chemicals and material selection (Shahbazi et al., 2017), greener design guidelines (Glenn, 2002) as well as energy consumption and lower CO2 emissions. This are very promising aspects, but further research is needed to develop a more solid and extensive plan for making progress in the transition towards circularity, especially for large manufacturing industries that rely on complex supply chains, complex products and traditional customer-driven requirement approaches. Therefore, this study goes beyond the single domain-specific approach and undertakes a more comprehensive and holistic perspective to understand the transition towards circularity in large manufacturing companies.

1.2 Problem Statement and Research Gap

Circularity is nowadays addressed as one of the most viable approaches to successfully create sustainable development (Mas-Tur et al., 2019; Centobelli et al., 2020) and yet, there is no agreed framework on how manufacturing companies can practically make the transition towards circular economy. Moreover, such transition is proven to be rather risky and uncertain for companies due to financial issues that can occur (Frishammar and Parida, 2019). In particular, the implementation strategies and monitoring the adoption of circular economy is lacking guidance and accuracy (Pauliuk, 2018). In fact, due to the considerable

complexity of handling a transition towards circularity, previous research has generally attempted at researching on specific topics around it, such as risk management strategies or facilitating aspects to the adoption of circular business models, resulting in scattered knowledge that belong to different focus areas.

Yet, research can support companies in many ways in the transition to circularity by providing different sets of tools such as maturity models (Mohamed Sultan et al., 2017), frameworks (Dawson and Spedding, 2010; Mendoza et al., 2017) guidelines (Lopes de Sousa Jabbour et al., 2019) and checklists (Bocken et al., 2019). Every tool presents diverse characteristics and features that can be suitable for facilitating strategic change that is necessary for the transition towards circular economy. Nevertheless, these frameworks seldom present a holistic and practical overview on activities and strategies that are needed for a more comprehensive set of areas of intervention. Therefore, the research gap for this study is the need for a tool that can help to assess the current status of a manufacturing company in the transition towards circularity, in connection to the different activities that can be implemented. An assessment from multiple perspectives is needed from different departments of the company so to have a “helicopter view” of the situation, in order to think about the long-term direction that must be taken.

1.3 Purpose of the study and Research questions

The purpose of this study is to gather and analyse and frame the existing state-of-the-art knowledge on the implementation of circular economy, as well as to explore and validate the suggested multi readiness level model with the case study company. The suggested model is a practical tool that can facilitate the process of transitioning towards circularity in a step-by-step manner, in connection to activities and strategies that can be implemented in different business domains.

The research questions are designed as follows:

1. Which are the most prominent areas of intervention that a manufacturing company needs to take into account when making the transition towards circular economy? 2. Which are the necessary activities and strategies that can be implemented for each area

of intervention?

3. How can a manufacturing company visualize the progress of its transition towards circular economy?

1.4 Delimitations

This study mainly contributes to the innovation management field connected to the transition towards circular economy. The research is conducted through a single case study

in a well-established, large manufacturing company in the construction equipment industry. The main source for empirical data is semi-structured interviews. The perspective of other companies in the same industry, nor of small and medium enterprises or start-ups is included in the study.

1.5 Thesis Outline

Having established the introduction in Chapter 1, Chapter 2 presents the research methodology. A systematic literature review is conducted to gain extensive knowledge of the state-of-the-art. The nature of the collaboration with the case study company Volvo Construction Equipment is described.

Chapter 3 includes an explanation of the key concepts and topicsof relevance that are the theoretical basis of this study, as well as the process for developing the conceptual model for transitioning towards circular economy.

Chapter 4 presents the empirical findings of the study, in connection with the ten semi-structured interviews that have been conducted.

Chapter 5 provides a discussion on empirical and theoretical results.

Chapter 6 highlights the suggestions for future research directions, as well as an action plan for a possible collaboration with the case study company to bring things forward in the practical transition towards circular economy.

2. Research Methodology

This chapter presents the research context and selected research approach, describing the interaction with the case company. Subsequently, a systematic literature review is presented to the reader. The following section includes the selected methods for data collection. Ultimately, ethical considerations and quality criteria are highlighted.

2.1 Research Strategy

This research is based on pragmatism, which is a philosophical paradigm with a prominent focus on actions, situations and their consequences (Creswell, 2014). As emphasized in the research questions of this study, particular attention will be used to retrieve the areas of intervention, as well as activities and strategies in connection to the transition towards circular economy for a large manufacturing company.

An interactive approach to research is undertaken in this study, since it is based on a joint learning process between the researcher and participants from the industrial context (Svensson et al., 2007). Such approach is generally defined as in contrast with traditional research especially due to the role of the researcher. In fact, traditional research perceives the researcher as an objective observer that should not in any way have an impact on the observed context, whereas interactive research aims to “understand the system under study and to let this understanding evolve in the interaction between the researcher and the actors in the system” (Ellström, 2007). Therefore, this study aims to gain a deep understanding of the areas of intervention and connected strategies activities that a large manufacturing company should take into account when making the transition towards circular economy. This will be allowed by a joint exploration of theoretical findings as well as practical knowledge from the field.

The intrinsic nature of this research study seeks to understand how a large manufacturing company can practically approach and manage the implementation of circularity within its practice. The aim to answer “how?” questions generally pertain the case study research (Yin, 2009). The case study allows the researcher to focus on contemporary phenomena in its real-life context (Yin, 2009), which in this case is the complexity of framing, understanding and planning a suitable strategy for transitioning towards circular economy in a well-established company in the construction equipment industry. The phenomenon of adopting circular economy in existing manufacturing companies is a recurrent concept in the spotlight of scientists, researchers, governmental and non-governmental organizations and policy makers.

2.1.1 Research Context

The research context of this thesis project is a co-production between two main actors, namely Mälardalen University and Volvo Construction Equipment. There are several stakeholders from Mälardalen University, including the main researcher of this thesis project, the thesis supervisor and the Innovation and Product Realization Department. Volvo

Construction Equipment includes its employees and the company supervisor of the thesis, responsible for the practical side of the previously highlighted purposes through informal interaction and observations. Figure 1 shows a visualization of the research context and is inspired by the publication “Increasing the Impact of Industry-Academia Collaboration through Co-Production” (Sannö et al., 2019).

Existing research acknowledges the need for organizations to have a systematic approach for implementing the transition, and yet struggle to provide an extensive overview of the complexity of such topic while only focusing on specific single-domain areas (business model innovation, design guidelines, supply chain management). Therefore, this study will provide a holistic and systematic approach to facilitate the transition towards circular economy in large manufacturing companies. The expected outcome for this study is the development of a practical tool that can comprehensively support the company in tracking its progress and efforts towards circularity with a cross-functional approach to innovation and future technologies.

Figure 1. Thesis Work Context. (Adopted from the source: “Increasing the Impact of Industry–Academia

Collaboration through Co-Production”)

2.2 Case Study

A case study is a detailed and intensive analysis of a single case (Bryman, 2012). The most important characteristics of case studies are the “search for meaning and understanding, the

strategy, and the end product being richly descriptive” (Merriam and Tisdell, 2016,p. 37). A large manufacturing company in the construction equipment industry is a case study company of this study. It has been selected as a good fit for this study according to the following criteria:

- Through several initiatives, the company has shown a commitment to environmental sustainability and to make the transition towards circular economy.

- The company has a strong drive towards sustainability and deeply embraces the triple bottom line by Elkington: environmentally sustainable, socially beneficial and economically viable (Elkington, 1999).

- The company needs a practical tool to understand what has been done so far and what still needs to be done to implement the transition towards circular economy. - The firm is actively supporting and engaging in the co-creation process with the

Academia, thus showing a commitment in knowledge sharing and new knowledge development with and in-depth collaboration.

2.2.1 Company Background

Volvo CE is a large manufacturing companyin the construction equipment industry. It is part of the Volvo Group, which operates within the manufacturing of trucks, buses, industrial and marine engines. The group has over 105,000 employees, production facilities in 18 countries and is present in more than 190 markets (Volvo Group, 2018). Its headquarters are located in Gothenburg, Sweden. Volvo CE is one of the leaders in products and services for the construction, extraction, waste processing, forestry and materials handling sectors (Volvo Group, 2018). Its major production facilities are located in North and South America, Europe and Asia. Volvo CE has over 13,000 employees and a network of 6,000 suppliers.

Volvo CE is committed to Volvo Group’s strategic priority of continuous improvement in order to deliver the best quality of products, improve customer satisfaction and reduce waste (Volvo Group, 2018). Therefore, the company has an interest in understanding how to implement circularity within their processes and aims at visualizing the required steps towards it. The company’s interest and commitment towards the transition to circular economy can be seen in several initiatives connected to environmental sustainability. Among others, the Construction Climate Challenge is an initiative hosted by Volvo Construction Equipment to promote sustainability throughout the entire construction industry and provide funding for environmental research (Volvo CE Website, 2020). It aims at actively creating a solution to address the industry’s impact on climate with a life-cycle perspective from extraction and production of building materials, to road and general construction, to demolition and recycling (Volvo CE Website, 2020). Moreover, Volvo CE is committed to cutting CO2 emissions in the atmosphere and has successfully implemented the Electric Site project, aimed to electrify each transport stage in a quarry – from excavation to primary crushing, and transport to secondary crushing – reporting a 98% reduction in CO2 emissions (Volvo Group, 2019). The company has also taken part in a very important study in the field of circular business model transformation as it is a company that has sustainability

as a vital aspect of its strategy (Frishammar and Parida, 2019). Lastly, the company has shown a commitment in implementing electrification and automation within its products so to be at the technological forefront of sustainable innovation practices.

2.3 Research Process

The research process (Figure 2) that has been followed in this study can be divided into 5 steps:

- exploration of company needs and problematization. In this exploratory phase, the researcher has been in close contact with the organization in order to thoroughly understand the company’s approach to the theme of sustainability and circularity, as well as to frame the different needs and perspectives regarding the problem. Informal discussions, observation and immersion in the industrial context are of pivotal importance in this phase.

- systematic literature review. A key part of the research process is represented by the systematic literature review that was conducted to extensively retrieve and analyse state-of-the-art knowledge related to this study’s focus and purpose in the field of circular economy - development of a multi-readiness level model for facilitating the transition to circular economy. The conceptual model is developed by the retrieved and analysed articles. The model presents four areas of intervention and a set of activities and strategies that can be implemented on a scale from 1 to 5. Moreover, it includes an underlying vision for the changes to be embraced for each area of intervention.

- empirical data collection and validation of model. During this phase, semi-structured interviews are carried out to gain deeper insights and understanding of the transition towards circular economy from a practical perspective, as well as to test and validate the conceptual model with the help of key people who have strategic roles in the company. - final conclusions. In the final stages of the study, a discussion is drawn upon the whole research process with regards to the most important findings and conclusions.

More extensive details on each phase of the research process are provided in later sections of this chapter and next chapters.

Figure 2. Visualization of research process

2.4 Systematic Literature Review

The systematic literature review establishes the theoretical framework for the study and provides a solid foundation for contributing to the knowledge base (Merriam and Tisdell,

Exploration of company needs and problematization Systematic literature review Development of multi readiness level model Empirical data collection and validation of model Final conclusions

scientific publications in the field of circular economy with regards to different aspects and approaches that are to be considered when initiating and engaging in a transition. Such factors will be later synthesized in a thematic analysis and subsequently presented in the form of a conceptual model.

2.4.1 Inclusion and Exclusion Criteria

The literature search is based on material retrieved from the scientific database Scopus. The database was searched for published articles from any year given the novelty of the topic. Only English-written articles were included in the search.

Inclusion and exclusion criteria are elements of pivotal importance when conducting a systematic literature review, since the application of a clear selection protocol allows the researcher to retrieve literature that is relevant to the research. Table 1 and Table 2 give an overview of the different criteria and connected reasons for inclusion and exclusion.

Table 1. Inclusion Criteria for Research Database

CRITERIA REASONS FOR INCLUSION

SPECIFIC INDUSTRIES AND SECTORS To get an overview of the most relevant aspects connected to

manufacturing industries

ALL COUNTRIES To gain a broad knowledge over research conducted worldwide

regardless of geographical location

ENGLISH LANGUAGE To avoid mistakes and misunderstandings that could occur by

using translation software

ANY GIVEN YEAR Given the novelty of the topic, to gain a wide overview of the

knowledge created so far

RESEARCH AREA Scientific articles that belong to the areas of manufacturing

industry, engineering business, strategy and management

Table 2. Exclusion Criteria for Research Database

CRITERIA REASONS FOR EXCLUSION

DOCUMENT TYPE: Master and

Bachelor thesis, Conference papers, Online blogs

To ensure new knowledge can be built on peer-reviewed research material

RESEARCH AREA To exclude many articles that belong to areas that are too far

from research focus (such as arts and humanities, agricultural and biological sciences, chemistry, physics, health sciences)

The following search strings has been applied to the database:

TITLE-ABS-KEY (“Circular economy” OR “business models” OR “circularity” OR “circular*”) AND TITLE-ABS-KEY (“roadmap” OR “readiness levels” OR “maturity models” OR “readiness” OR “implementation stages”) AND (LIMIT-TO (DOCTYPE) “ar”)) AND (LIMIT-TO (SUBJAREA, “ENGI”) OR LIMIT-TO (SUBJAREA, “BUSI”)) AND (LIMIT-TO (LANGUAGE, “ENGLISH”)).

2.4.2 Identification of Papers and Application of Practical Screening

The initial number of the selected articles is 119. The first selection is based on the title analysis. The ones that were not relevant to the chosen theme were excluded. By doing so, the number of articles was initially reduced from 119 to 34. Subsequently, the abstracts were analysed according to the same criteria, and the number decreased to 18. Lastly, the full texts of papers were analysed, and the number decreased to 10 articles; 10 additional papers were identified by looking at references and citations, gathering a total of 20 selected articles.

Figure 3 shows a flowchart for the process of selection of the retrieved articles.

Figure 3. Flowchart of articles selection process

2.4.3 Overview of the Retrieved Articles

As mentioned before, the retrieved articles have been analysed by reading the full text. Table 3 was compiled to have a comprehensive overview of each article’s title, author and journal. A number from 1 to 20 was assigned to each article to easily relate to it in the subsequent analysis.

Table 3. Overview of Retrieved Articles

ARTICLE NUMBER

AUTHORS TITLE JOURNAL NAME

(1) Dawson and

Spedding (2010)

Simulation modelling and strategic change: creating the sustainable enterprise

Australasian Journal of Information Systems

(2) Valkokari et al. (2014)

Road-mapping the business potential of

sustainability within the European manufacturing industry

Foresight

(3) Marques and

Cunha (2014)

Integrating Product-Service Systems with New Business Models Definition for

International Journal of Service Science, Management,

119 •Initial number of retrieved articles

34 •Number of remaining articles after

title analysis

18 •Number of remaining articles after abstract analysis

10 •Number of remaining articles after full text analysis

Engineering, and Technology

(4) Lewandowski

(2016)

Designing the Business Models for Circular Economy—Towards the Conceptual Framework

Sustainability

(5) Mohamed Sultan et al. (2017)

What should be recycled: An integrated model for product recycling desirability

Journal of Cleaner Production

(6) Mendoza et al. (2017)

Integrating Backcasting and Eco-Design for the Circular Economy

Journal of Industrial Ecology

(7) Planing (2018) Towards a circular economy - how business model innovation will help to

make the shift

International Journal of Business and Globalization

(8) Oghazi and

Mostaghel (2018)

Circular Business Model Challenges and Lessons Learned—An Industrial Perspective

Sustainability

(9) Rosa et al. (2019) Towards Circular Business Models: A systematic literature review on

classification frameworks and archetypes

Journal of cleaner production

(10) Teixeira and

Canciglieri Junior (2019)

How to make strategic planning for corporate sustainability?

Journal of Cleaner Production

(11) Frishammar and

Parida (2019)

Circular Business Model Transformation: A Roadmap for Incumbent firms

California Management Review

(12) Bocken et al.

(2019)

A Review and Evaluation of Circular Business Model Innovation Tools

Sustainability

(13) Franco (2019) A system dynamics approach to product design

and business model strategies for the circular economy

Journal of Cleaner Production

(14) Parida et al.

(2019)

Orchestrating industrial ecosystem in circular economy: A two-stage transformation model for large manufacturing companies

Journal of Business Research

(15) Lopes de Sousa

Jabbour et al. (2019)

Circular economy business models and operations management

Journal of Cleaner Production

(16) Blomsma et al.

(2019)

Developing a circular strategies framework for manufacturing companies to support circular economy-oriented innovation

Journal of Cleaner Production

(17) Hernandez (2019) Sustainable Product-Service Systems and Circular

Economies

Sustainability

(18) Whalen (2019) Three circular business models that extend

product value and their contribution to resource efficiency

Journal of Cleaner Production

(19) Dev et al. (2020) Industry 4.0 and circular economy: Operational

excellence for sustainable reverse supply chain performance Resources, conservation, recycling (20) Werning and Spinler (2020)

Transition to circular economy on firm level: Barrier identification and prioritization along the value chain

Journal of Cleaner Production

Subsequently, a further Table (Appendix A) was compiled to briefly analyse the different keywords, aims and descriptions of outcomes for each chosen article. Such Table can be found in the Appendix at the end of this study, as well as the comprehensive Table (Appendix B) for a more thorough analysis of purpose and focus of the paper, type of industry, research method, definition of Circularity, type of outcome and description of key results, challenges mentioned in the paper, capabilities and pre-requisites and directions for future work.

2.5 Empirical Data Collection

The research approach to empirical data collection is based on observation and intensive formal and informal interaction between the researcher and the research strategy manager of the company, as well as with other several key people with strategic roles within the company, for an approximate number of 30 face-to-face meetings in the course of 4 months. Moreover, tensemi-structured interviewsare conducted with different people from inside and outsideof the company. Eight recipients either have worked or currently work for the company, whereas two senior researcher and project managers from the Swedish public research institute, RISE, have been selected for two expert interviews. The decision to include two experts that do not work in the case company was made so to give further validity and credibility to the presented model. Empirical data have a pivotal role in two distinct phases of the research: observation and informal interaction is conducted especially at the beginning of the study during the exploration of company needs and problematization, whereas the interviews are conducted after the development of conceptual multi readiness level model.

2.5.1 Observation and Immersion

Immersion in the site as a participant observer is the primary method of data collection within case studies (Merriam and Tisdell, 2016). Observation and attendance at the company took place for a total of 20 days. For this reason, field notes are performed on a daily basis and kept in a field diary. The field diary includes notes on facts and happenings, as well as personal insights and ideas around different topics and events. Notes taken while participating in remote meetings in the form of calls and videoconferences are also included in the diary.

Appendix C shows an overview of important moments of interactions and communication with different peoplein the company during the exploratory phase for company needs and problematization earlier illustrated in the research process.

As it can be seen in Appendix C, several discussions were brought forward based on different topics and issues connected to the transition towards circular economy. For instance, the potentials of application of circularity are examined, and discussions on the definition of circular economy are performed with different people.

2.5.2 Interviews

Ten individual semi-structured interviews with different people from inside and outside of the company are conducted. Purposeful sampling (Patton, 2001) is used to select the most suitable people within the organization to iterate the findings from the research and engage in a discussion that can generate new valuable data. Established criteria for purposeful sampling of interview recipients are the following: extensive past working experience in the company, having a high managerial position, showing an interest and or a background in the field of sustainability and circularity. Table 4 shows an overview of the recipients’ job role, education background, number of years’ experience and interview duration.

Table 4. Details of interview recipients

Recipient Job Role Education Background Years of working experience Interview duration

Recipient 1 Research Engineer for Emergent

Technologies

Engineering 13 1 hour 35

minutes

Recipient 2 Vice-President of Sustainability and

Public Affairs

Engineering and Management

22 42 minutes

Recipient 3 Responsible for Brand Communications

and Co-founder of the Construction Climate Challenge

Communication and media

11 1 hour 3

minutes

Recipient 4 Manager at Manufacturing Technology

Development and Governance

Materials Technology

16 1 hour 15

minutes

Recipient 5 Former employee - Technology Planning

Manager

Engineering 11 59 minutes

Recipient 6 Director Sustainability and Public Affairs Environmental

Science

15 1 hour 16

minutes

Recipient 7 Researcher at RISE institute Chemistry and

Environmental Science

20 1 hour 38

minutes

Recipient 8 Chief Project Manager for Advanced

Engineering

Computer Engineering

8 1 hour 27

minutes

Recipient 9 Researcher at RISE institute Chemistry and

Environmental Science 3 1 hour 11 minutes Recipient 10

Global Business Development Manager Economic sciences 12 1 hour 40 minutes

A semi-structured approach allows the researcher to make use of a set of questions where neither the exact wording nor the order of questions is predetermined (Merriam and Tisdell, 2016). The interviews are conducted via Skype and tape-recorded, while notes and reflections are taken on the field diary. The written protocol with the structure and general questions that have been followed for the interviews can be found in the Appendix at the end

of this study (Appendix D). The interview is divided into two main phases. In phase 1, the recipient is required to share general information regarding his/her past working experience and perceptions regarding the concept of circular economy, as well as personal insights. Moving forward, in phase 2 of the interview, a knowledge-sharing discussion on the conceptual model for transitioning towards circular economy is carried out.

2.6 Data Analysis

The semi-structured interviews are recorded, and notes are collected and summarized. The data analysis process involves consolidating, reducing, and interpreting what people have said, and it often starts during the data collection phase (Merriam and Tisdell, 2016). The researcher has to make sense of what has been said and discussed together with recipients, as well as the outcome of the joint learning process that takes places during the interview. This body of newly retrieved data and knowledge is reported in the empirical findings of the study by incorporating the most relevant and recurrent themes related to circular economy and transition towards it. Notes on concepts and topics that have emerged during the interviews are initially collected and coded. Moreover, during each interview, the conceptual multi readiness level model is discussed and modified according to each participants’ suggestions, understanding and experience in the field. Therefore, such modifications are compared in a further analysis that takes into account the most recurring suggestions. The outcomes of such process for data analysis can be seen in the empirical findings section (Chapter 4) of this paper.

2.7 Ethical Considerations

The term ethics comes from the Greek ethos, meaning either a community’s shared customs or an individual’s character, and usually defined as good or bad (Booth et al., 2008). Four ethical issues applied to research are identified by Diener and Crandall (Diener and Crandall, 1978) and highlighted by Bryman (Bryman, 2012), namely: harm to participants, lack of informed consent, invasion of privacy, deception of participants. The data gathering and data analysis of this study are performed with an ethical approach that complies to the above-mentioned criteria. In fact, participants are protected by a non-disclosure agreement that has been signed at the beginning of the thesis work, and informed consent has been asked and obtained by the researcher to record interviews and take field notes.

2.8 Quality Criteria

Conducting valid qualitative research can be seen as a rather complex task, and it is often criticized as subject to biases from the researcher side as he/she is immersed in the field as one of the main instruments for data collection and analysis (Merriam and Tisdell, 2016). Such biases can be reduced by following quality criteria that promote credibility and

encourage good research practices. In this regard, Tracy develops eight criteria for conducting excellent qualitative research (Tracy, 2013), namely:

- Worthy topic - Rich rigor - Sincerity - Credibility - Resonance - Significant contribution - Meaningful coherence

These criteria have been of pivotal importance while conducting this research as they have guided me throughout the different stages of the research process. In fact, I consider the main topic of this research, circular economy, as worthy to be researched upon as it is nowadays very relevant and present in the research agenda of many different stakeholders, and it is growing momentum internationally. This can be seen in the actions of young activists such as Greta Thunberg, who is trying to increase the awareness and support among policy makers, governments, industries, young and old people. The rigor of this study is secured by the extensive body of literature that was retrieved and analysed, providing a solid theoretical background. Moreover, the iteration of findings within a practical context has also contributed to the rigor and validation of this study. The value of sincerity is seen in the transparency regarding the chosen methods for data collection and analysis, and credibility is given by the richly descriptive approach for presenting the different stages of the research process. Resonance (as meaning quality of richness and variety) is achieved through literary clarity and organization, so to allow a positive engagement in the readers of this study. Similarly, the study aims to be a significant contribution both on a theoretical and practical perspective, and to show meaningful coherence throughout each phase of the research process.

3. Theoretical Background and Development of a Conceptual

Model

In this chapter, the theoretical basis of the thesis work is presented to the reader. Firstly, concepts of sustainability and sustainable development are presented, then definitions and key aspects of circular economy and circular business models, as well as readiness levels and maturity models. Subsequently, the process for the conceptualization of the multi-readiness level model for transitioning towards circular economy is presented. The first step consists of categorizing the articles by type of outcome and subsequently extracting key elements from the texts. Then, a further categorization is conducted to create clusters of inter-connected elements. Finally, a multi readiness level model is designed and proposed.

3.1 Sustainability and Sustainable Development

In the last decades, there have been growing concerns about environmental degradation, resource overconsumption and social inequity, resulting in the need to transform our economy and society in a more sustainable way (Adams et al., 2016). In Our Plundered Planet, one of the first environmental books to gain media coverage, the author describes how human actions and settlements negatively affect the environment, clearly stating that humanity is destroying the planet as if it was on war with it (Osborn, 1948). In later years, other publications have investigated the limits of the current approach of humanity towards the environment, while predicting an irremediable ecological disaster for the planet and a dreadful future for human kind (Cole, H. et al., 1973). These fears and points of view have consequently made their way into the agenda of institutions such as the United Nations, showing the path towards sustainable development with the World Conservation Strategy (United Nations, 1980). A few years later, with the Brundtland Report, the concept of sustainable development gains even more traction by introducing the well-known definition of “development that meets the needs of the present without compromising the ability of future generations to meet their own needs” (Brundtland, 1987, p.41). Ultimately, the most famous definition of sustainable development is given by the triple bottom line, people, planet, profit (Elkington, 1999), which includes environmental, social and economic aspects simultaneously (Figure 4). The concept of sustainable development has not escaped criticism, and some researchers have defined it as a rather vague catchphrase (Lélé, 1991) or even a theoretical dream (Naudé, 2011).

Nevertheless, manufacturing industries and companies in general have been asked to act in accordance to the founding principles of sustainable development since the second half of the last century (Adams et al., 2016), and several approaches to sustainability have been experimented (Rashid et al., 2008). A structured and comprehensive way of categorizing sustainability efforts has been recently developed by the United Nations in the 17 Goals for Sustainable Development by the United Nations (United Nations, 2015). The Agenda is a “historic decision on a comprehensive, far-reaching and people-centered set of universal and

transformative Goals and targets” (United Nations, 2015). It includes all three dimensions – economic, social and environmental, and aims at stimulating action in all countries and stakeholders involved.

Practical incorporation of sustainability into a firm’s strategic approach is considered a difficult achievement for companies (Jeremy, 2009), even though an abundance of tools and indicators of sustainable targets is nowadays available (Moldan et al., 2012).

Figure 4. Visualization for the Triple Bottom Line by J. Elkington

3.2 Defining Circular Economy

Circular Economy has recently gained a lot of traction among policy makers and institutions (Brennan et al., 2015) and many authors consider it a viable approach for reaching sustainable development (Mas-Tur et al., 2019; Centobelli et al., 2020). Early-stage development of circular economy can be traced back to the work of Stahel and Reday, who conceptualized the vision of an economy in loops and its impact on job creation, economic competitiveness, resource savings, and waste prevention (Stahel and Reday-Mulvey, 1981). Recently, Geissdoerfer (2017) has conducted a bibliometric analysis on the state of the art in the growing field of circular economy, showing that it has gained a remarkablyincreasing interest over only a short timeframe and that there is a steady and exponential growth in publications (Geissdoerfer et al., 2017). Non-academic parties are proven to lead the way in driving the progress of the work on circular economy (Schut et al., 2015). Various stakeholders have started to familiarize themselves with the concept of Circular Economy, thus leading to a wide set of definitions and understandings of it (Lieder and Rashid, 2016), often unclear and diverse (Corona et al., 2019). In a recent academic study that has become very popular in the field, a systematic approach to the investigation of circular economy has found and selected 114 available definitions among peer-reviewed journals, policy papers and reports (Kirchherr et al., 2017). The outcome of Kirchherr’s study is a comprehensive definition for Circular Economy that is designed as follows: “Circular Economy is an economic system that replaces the ‘end-of-life’ concept with reducing, alternatively reusing, recycling and recovering materials in production/distribution and consumption processes. It operates at the

Planet environmental performance Profit economic performance People social performance

(city, region, nation and beyond), with the aim to accomplish sustainable development, thus simultaneously creating environmental quality, economic prosperity and social equity, to the benefit of current and future generations. It is enabled by novel business models and responsible consumers" (Kirchherr et al., 2017, pp. 224-225). One of the most important features of this definition of Circular Economy lays within the concept of micro, meso and macro level expressed by Kirchherr et al. (2017). The distinction of such levels is imperative for understanding Circular Economy. In fact, initiating a transition towards circularity requires a systemic shift rather than an incremental twisting of current practices (Kirchherr et al., 2017), and employing the concept of micro, meso and macro level can help understand the possible levels of depth of different interventions. This way of approaching the concept of circularity will be of paramount importance throughout the development of this study.

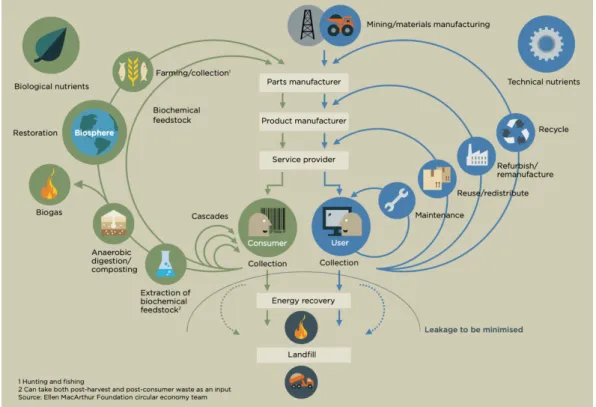

According to Geissdoerfer (Geissdoerfer et al., 2017), one of the most prominent definitions of circular economy is given by the non-governmental organization Ellen MacArthur Foundation: “Circular Economy is an industrial system that is restorative or regenerative by intention and design. It replaces the ‘end-of-life’ concept with restoration, shifts towards the use of renewable energy, eliminates the use of toxic chemicals, which impair reuse, and aims for the elimination of waste through the superior design of materials, products, systems, and, within this, business models.” (Ellen MacArthur Foundation, 2013, p.7). A rather well-known way of visualizing the concept of Circular Economy with a focus on material cycles as expressed by the Ellen MacArthur Foundation can be seen in Figure 5.

Figure 5. Circular Economy material cycles.

(source: “Towards the Circular Economy” by Ellen MacArthur Foundation)

Figure 5 shows the different cycles of technological products and biological nutrients and through the economic system in connection with the principles of a restorative economy:

energy recovery, restoration, recycling and refurbishing, reuse and maintenance, and generally minimization of waste.

In the following section, an important aspect of circular economy is presented with a definition of circular business models.

3.3 Defining Circular Business Model

“A business model is a conceptual tool that contains a set of elements and their relationships and allows expressing a company's logic of earning money. It is a description of the value a company offers to one or several segments of customers and the architecture of the firm and its network of partners for creating, marketing and delivering this value and relationship capital, in order to generate profitable and sustainable revenue streams” (Osterwalder, 2004, p.15). A linear business model follows a take-make-dispose pattern (Ellen MacArthur Foundation, 2013), whereas a circular model is restorative by intention; aims to rely on renewable energy; minimizes, tracks, and eliminates the use of toxic chemicals; and eradicates waste through careful design (Ellen MacArthur Foundation, 2013, p.22).

The traditional and linear approach to production and consumption currently implemented by most manufacturers is based on virgin raw materials that are processed in products with a planned life span, and later discarded by consumers at the end of life. Such approach speeds up the production rates, leaving little or no space for different practices such as recycling, repairing, servitization and dematerialization. Therefore, in the linear model, the productivity of our natural ecosystems is paying the highest price for the production of goods, and the pressure put on these ecosystems is negatively affecting water, air and soil. The shift from linear to circular model is deemed mandatory to sustain growth despite the limited amount of resources on our earth (Planing, 2018).

Making the shift from linear to circular model is a rather complex and costly operation that can present different causes for uncertainty. Among these, the need for specialized technological expertise and foreseeable operational risks (Linder and Williander, 2017). Therefore, the creation of a solid strategy for supporting the transition is needed, and the aid of specific tools is absolutely essential. Several tools can support companies in the implementation and of new strategies within the field of change management. Among these, maturity models and readiness level models are widely used, especially in large manufacturing companies, to facilitate the level of progress of different stages of a project. For this reason, the following sections of this chapter will lay the basis for better understanding the main features of such tools.

3.4 Maturity Models

Maturity models are tools used for the evaluation, comparison, identification, and prioritization of the improvements to be done in order to reach a certain performance (Teixeira and Canciglieri Junior, 2019). Maturity models can be employed for improving

weaknesses (Khoshgoftar and Osman, 2009), or to control the progress of the implementation of new strategies. Such tool can be defined as a sequence of maturity levels for a class of objects (Becker et al., 2009). Over the years, several maturity models have been developed: organizational project management maturity models (Fincher and Levin, 1996), (Kwak and Ibbs, 2002); quality management maturity grids (Maier et al., 2012); maturity models for IT management (Becker et al., 2009). When organizations develop and apply maturity models they gain the ability to measure and assess domain capabilities at a given point in time as well as an opportunity for improved success in that domain (de Bruin et al., 2005).

An important feature of maturity models that will be employed in the final outcome of this study is the concept of improvement. Maturity models in fact are generally used to show how a progression of different actions and decisions can lead to an overall improved situation which happens to be better than the one prior to a certain intervention.

3.5 Readiness Level Models

A commonly used tool for assessing maturity in engineering projects is the technology readiness level, TRL, created by NASA in the 1970s. It was made to assess the readiness of specific technologies that were to be used in aeronautics and space explorations. The TRL features a scale from 1 to 9, and each level has a specific degree of complexity and maturity, from basic research and knowledge to full readiness for implementation in space missions (Figure 6).

Despite TRL were firstly developed in a very closed and non-commercial environment, over the years it has been widely adopted to more general industries and sectors (Ramsden, 2018). The use of TRLs enables a consistent discussion of technical maturity across different types of technology (Neill and Hashemi, 2018). The creation of such tool has initiated a school of thought according to which research and development can be perceived as something that is stratified in categories (Young and Hirst, 2012).

Over the years, several authors have proposed modifications to the TRL model by applying its underlying concept in rather diversified applications, such as Commercial Readiness Levels model (Hodgkinson et al., 2009), the Manufacturing Readiness Levels model, the Business Case Readiness Level model and the Ecosystem Readiness Level model (Wang, 2018). Each and every model just presented makes use of the TRL layout, but differentiates in the number of levels (7, 9 or 10) and of course in the nature of the content. A remarkable feature of readiness level models is the extensive versatility of application and the rigor that can be followed to explain the sequence of steps required to reach a certain goal or state.

3.6 Process for the Development of the Conceptual Readiness Level Model

from the Systematic Literature Review

The Multi-Readiness level model for Transitioning towards Circular Economy was conceptualized and developed after conducting the systematic literature. The three-step process for the development of the conceptual model are presented to the reader in the following sub-sections of this chapter with regards to followed actions and processes:

- categorization of articles - extraction of key elements - categorization of findings

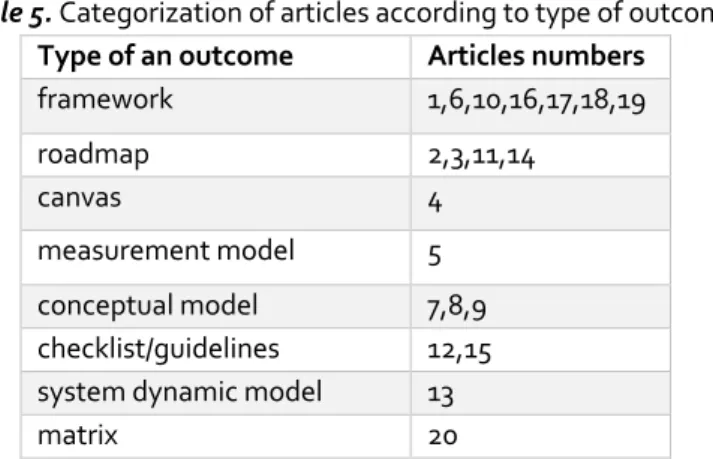

3.6.1 Categorizations of Articles

The first step after the systematic literature review is the categorization of retrieved and analyzed articles according to the different types of outcome, as can be seen in Table 5. “Type of an outcome” was one of the criteria analyzed in the extensive Table that can be seen in Appendix B. Such extraction has allowed me to look at each article with a critical lens, as I was able to go back to its content according to different frames. In fact, when thinking about the kind of outcome produced in each paper, general features and considerations would become evident and easier to retrieve. Depending on the outcome classifications, I was able to conceptually frame the general structure and type of information that was shared by the authors. This framing process for the nature of different articles according to the outcome categorization has had a positive impact on the next steps of the study. In fact, clarity, mental framing and logical organization are much needed features in the approach to a rather consistent number of papers.

Table 5. Categorization of articles according to type of outcome

Type of an outcome Articles numbers

framework 1,6,10,16,17,18,19 roadmap 2,3,11,14 canvas 4 measurement model 5 conceptual model 7,8,9 checklist/guidelines 12,15 system dynamic model 13

matrix 20

As it can be seen in the Table above, most retrieved articles belong to the category of frameworks. In fact, the most common way for authors to describe the transition towards circular economy is by employing abstract visualizations of different aspects and themes to consider when making a strategy for change. Frameworks can employ different set of phases or stages with a description of key roles involved in each stage, or simply show how different concepts are connected to each other regardless of the temporal frame during which they will be implemented.

Frameworks such as the one in article 1 explain the complexity of change processes when integrating sustainability within organizations (Dawson and Spedding, 2010). This framework also includes the time factor (present, past and future) and explores the valuable input of simulation modeling tools in support to strategic planning. The framework presented in article 6 displays how backcasting and eco-design activities can support the transition towards circular economy (Mendoza et al., 2017), yet with little information on practical activities that can be implemented. Article 10 has a focus on strategic planning for sustainable product development (Teixeira and Canciglieri Junior, 2019), whereas article 16 presents a more comprehensive and extensive framework on circular strategies that can be implemented (reinvent, rethink and reconfigure, restore reduce and avoid, recirculate) within business model innovation, energy consumption and product development (Blomsma et al., 2019). The framework provided in article 17 has a strong focus on business model innovation and especially product service systems, presenting different actions that can be undertaken in circular economies (Hernandez, 2019), while article 18 shows how to extend product value in circular business models through three archetypes: facilitators, redistributors and doers (Whalen, 2019). Finally, article 19 presents a framework for reverse logistics with the aid of principles of industry 4.0 and the ReSOLVE framework by Ellen MacArthur Foundation (Dev et al., 2020).

Roadmaps, on the other hand, present different sets of specific phases that have a consequential order, and activities and goals are presented for each phase. This is the case for article number 2, where an indication of three phases is given for creating the actual strategy for circular economy inside an organization. Moreover, three sub-roadmaps are provided in regards to different timeframes: 1-3 years, 4-9 years and over 10 years-time

(Valkokari et al., 2014). Article 4 presents four different phases for implementing circular strategies (analysis, design, implementation and evaluation), and identifies several activities, main inputs, outputs and actors involved in each phase (Marques and Cunha, 2014). Article 14 only presents two stages for the ecosystem transformation and connects the expected outcomes to the triple bottom line by Elkington (Parida et al., 2019). Article 11 presents a four-phases roadmap for circular business model transformation: initiate circular business model transformation; audit the circular business model; design and develop a circular business model; scale-up the circular business model. Each phase has an objective, principles and key activities and expected outcomes (Frishammar and Parida, 2019).

The canvas model suggested in article 4 has a focus on business model innovation and presents eleven building blocks, encompassing not only the 9 traditional components of business model canvas, but also material loops (take-back system) and adoption factors (Lewandowski, 2016).

Article 5 presents a measurement model for the integrated measurement of the desirability of recycling end-of-life products that takes into account product complexity, recycling Technology Readiness Level, the monetary value of materials and criticality of the materials (Mohamed Sultan et al., 2017).

Conceptual models presented in articles 7, 8 and 9 have a strong focus on circular business models and give respectively an overview on different business model categories (Planing, 2018), circular business model archetypes and challenges (Oghazi and Mostaghel, 2018) and circular business models classification methods (Rosa et al., 2019).

Checklist and guidelines present a focus on specific requirements, such as in article 12 for the development of a tool that facilitates circular business model innovation (Bocken et al., 2019). The guidelines in article 15 guidelines connect operations management decision-making with each circular business model presented in the ReSOLVE framework by Ellen MacArthur Foundation (Lopes de Sousa Jabbour et al., 2019).

The system dynamic model presented in article 13 is a visualization of how different factors that are pivotal when transitioning towards circular economy are inter-connected and related, such as functional risk and green image factor, product replacement, product reuse, product service system, maintenance and repair, disassembly and recycling, product lifecycle and demand redistribution (Franco, 2019).

3.6.2 Extraction of Key Elements

After conducting the categorization of articles according to type of outcome, a further in-depth reading of each text has been carried out. Simultaneously to the reading process, the extraction of key elements was brought forward, and short notes and keywords have been