Nr 17-1997 Titel: Författare: Verksamhetsgren: Projektnummer: Uppdragsgivare: Distribution: Utgivningsår: 1997

Intryck från "Harmful clay fines" workshop, arrangerat av CEN TC 154

Aggregates vid UNPG, 5 februari 1997, Paris

Peet Höbeda Konstruktion &Byggande 60117 Vägverket Fri div Väg- och transport-forskningsinstitutet ä

Harmful clay fines workshop, arrangerat av CEN TC 154

Aggregates vid UNPG, 5 februari 1997, Paris. AV Peet Höbeda, VTI

Innehållsförteckning

Sida Allmänt

Testmetoder för bedömning av Ierhalt

Effekt av lera på bruk och betong

Effekt av lera på bituminösa massabeläggningar

Effekt av lera på obundna och hydrauliskt bundna material.

Ekonomiska aspekter och allmän diskussion 1

ODC J ' l -ÄC J O R J H L o o o o o xl o vc n VTI notat 17-1997

Harmful clay fines workshop, arrangerat av CEN TC 154

Aggregates vid UNPG, 5 februari 1997, Paris.

Av Peet Höbeda, VTI

1 Allmänt

Mötet, som arrangerats av CEN TC 154, hölls på den franska grus- och makadamföreningens, UNPG, kontor. Programmet, som inte sänts ut i förväg, framgår av bilaga 1 och deltagarlista av bilaga 2. Norden var dåligt representerat, förutom undertecknad fanns en dansk (Jensen), som dock arbetade vid SINTEF i Norge med betongfrågor. Vissa av bidragen erhölls som sammanfattningar eller också som fullständiga papers och dessa medtas som bilagor 3-14.

Enligt CEN TC 154 terminologi kan fine aggregate eller sand omfatta både natursand och stenmjöl. Definitionen varierar dessutom i olika produktstandarder, övre gräns för obundna material är således 4 mm och för bituminösa stenmaterial 2 mm maskvidd. I det nedanstående används därför termen sand för fine aggregate , både av krossat berg och natursand, och inte som en term enligt geoteknisk eller geologisk nomenklatur. Den innefattar också stenmjöl.

Ordföranden Piketty (?) från UNPG hälsade välkommen. Han nämnde att man i Frankrike i möjligaste mån använde sig av fine aggregate , med befintligt ñn-material <0,063 mm ( fines ), medan man i vissa länder tvättade bort finmaterialet (och då fick tillsätta filler vid framställning av produkter).

Ordföranden för SC6, D.Storrar, förklarade sedan att ñnmaterialkvaliteten ännu utgjorde ett olöst problem inom TC 154 och därför hade en ad hoc task group harmful clay fines bildats för att reda upp situationen. Ordföranden för denna task group, Souwerbren från Holland, påpekade sedan olikheterna i de olika förslagen till produktstandarderna, från SCl till SC4. Man hade gjort försök till kategorisering enligt tester som sandekvivalent (SE) och metylenblåabsorption (MB eller blåvärde ), men misslyckats med att ställa upp kravvärden. Många länder saknade helt erfarenhet. Han hade förhoppningen att workshopen skulle bidra till en ökad information, ge underlag för kravvärden, men också peka på konsekvenser av dessa, särskilt för länder där metoderna inte används. Man har också utarbetat ett förslag till forskningsprogram (bilaga 14).

L.Primel, LCPC, gav några kortfattade geologiska aspekter (ytvittrat berg i Frankrike och heterogena förhållanden). Tvättning innebär alltid negativ miljöpåverkan. Otvättad sand var dessutom ofta bättre från teknisk synpunkt (jfr nedan). I sammanhanget bör nämnas att i Sverige inlandsisen rensat berggrunden från Vittringsprodukter och naturgruset i regel är rentvättat (speciellt under högsta kustlinjen).

lerhalt i den mening som den används i VÄG 94. En fransyska, S.Decreuse, från UNPG, gick i detalj genom SE- och MB-metoderna. SE utgjorde ett flockuleringsförsök, medan MB det gav mått på katjonbyteskapaciteten hos lermineralen i finmaterialet (<0,063 mm). Förmodligen överdrev det senare försöket skadligheten hos svällande lermineral (det framkom dock inte riktigt i vilket sammanhang).

W. Steyert nämnde att båda metoderna användes i Belgien, dock inte helt i överensstämmelse med europaförslaget (skriftligt bidrag i Bilaga 3). SE bestämdes vid 10% finmaterial (proportionering behövs) och MB för finmaterial <0,08 mm. Han menade att en hel del forskning behövdes, speciellt med avseende på relationen till funktionsegenskapema för de färdiga produkterna.

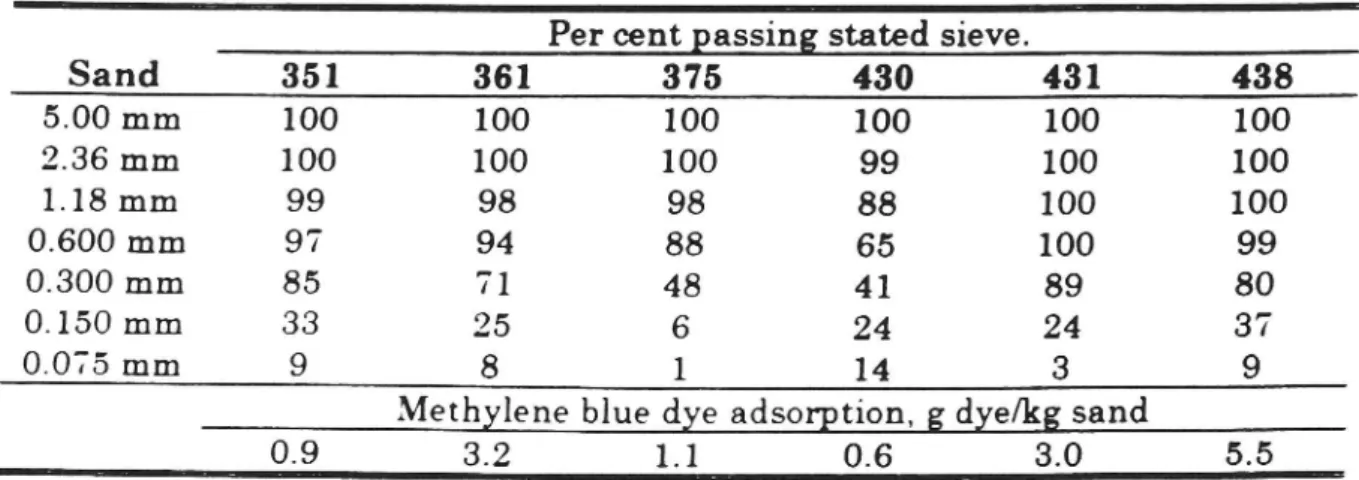

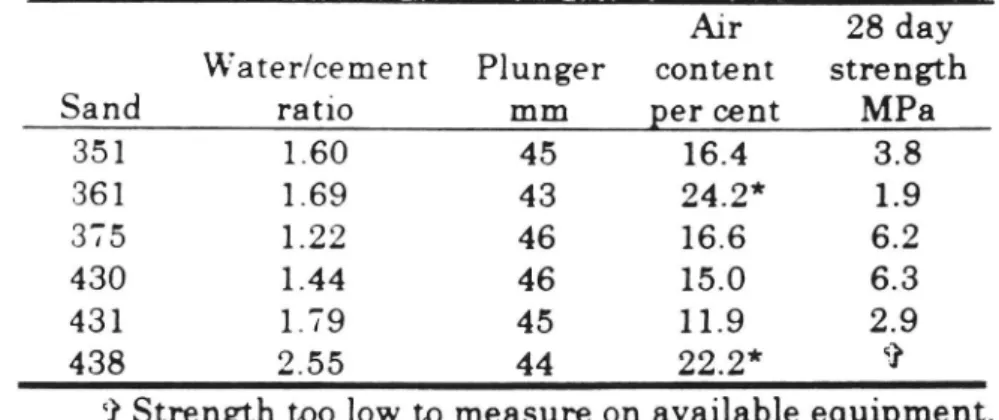

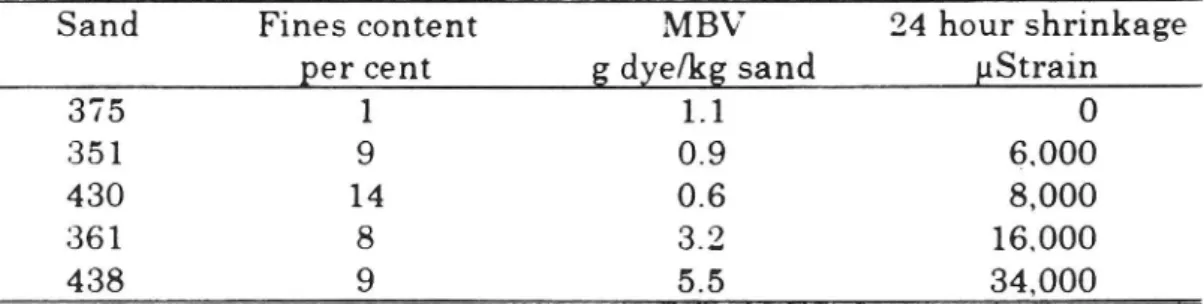

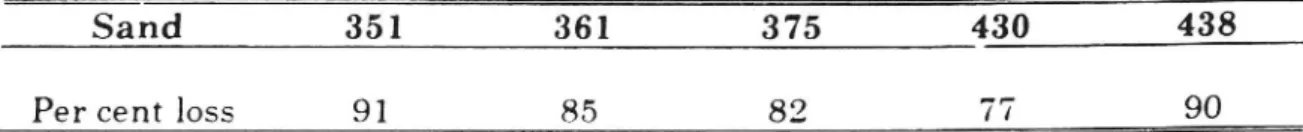

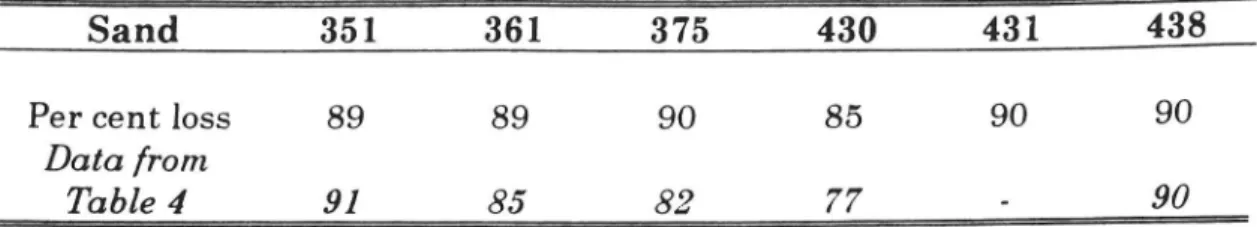

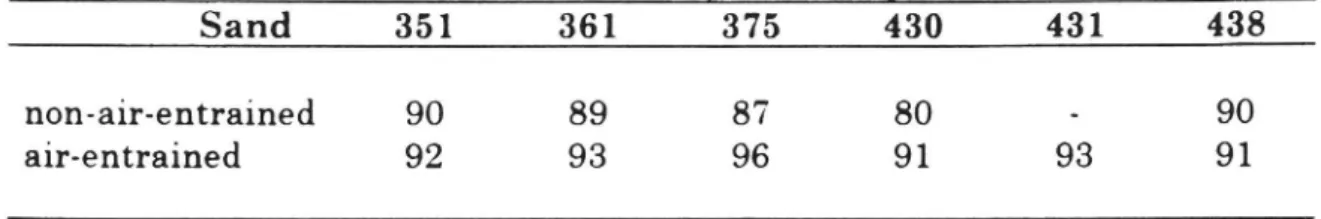

A. Yool, vid Green Land Reclamation LTD, England, har på uppdrag av BRE (engelska byggforskningsinstitutet, Bilaga 4a) gjort studier av 154 engelska sandsorter (från grus- och bergtäkter), använda för bruk och betong, både tvättade och otvättade material (sammanfattning i Bilaga 4b). SE-värdet korrelerar inte med MB-värdet (inte oväntat) och endast den senare metoden har studerats mer i detalj. Man har gjort försök att med valda sandsorter dämpa utslaget vid MB-bestämningen genom tillsatser som blockerar inträngningen av färgämnen i de svällande lermineralen eller också genom att använda sig av färgämnen med större molekyler än metylenblått, dvs. molekyler som inte kommer in i de svällande lermineralen så lätt. Man kan notera att Green Land Reclamation Ltd hade flera bidrag vid workshopen (jfr nedan). Detta beror sannolikt på att firmans VD, dr. D.C. Pike, doktorerat just på MB-provningen.

Ritter, från tysk intresseförening för kalkstensproducenter, redogjorde för ett forskningsprojekt varvid både tvättade och otvättade material, från 31 täkter undersökts med avseende på SE- och MB-värde. SE-metoden används lokalt i vissa tyska delstater, dock endast för obundna material. Inom forskningsprojektet har man relaterat finmaterialhalt, SE och MB med varandra (Bilaga 5). Dåliga samband erhölls och man menar att sådana samband är bergartsberoende. Ritter menade att man f.n. i Tyskland inte har underlag för några slutsatser beträffande metodernas användbarhet eller till kravvärden. Han nämnde att material <2 mm, avsett till asfaltbeläggningar, i Tyskland testas enligt andra metoder. Vattenkänslighetstest utförs således först på bruksprov (dvs. sand, filler och bitumen), sedan på hela asfaltmassan.

Vid efterföljande diskussion av den första sessionen nämnde F. Norman att man i Irland hade vissa erfarenheter att MB-värdet, utslaget för krossand från en basalttäkt sjönk således markant efter tvättning. Han ansåg som Ritter att metoden gav utslag som gick att relatera till finmaterialegenskaper endast vid samma typer av bergarter (och det ligger något i detta).

SE-provet ansågs bättre än tvättsiktning eftersom det var utvecklat som en snabb fälttest (dock inte enligt europastandardförslaget?). Jag nämnde gamla, egna

förlängdes från 20 minuter till förslagsvis två timmar. Då var flockvolymen fortfarande hög för lerförorenade prov, medan flockningen i stort försvunnit för bra prov, t.ex. prov innehållande kalkstensfiller. Någon påpekade att man då inte har ett enkelt fälttest (meningen med europastandard?).

Jensen påpekade att man i Norge inte kände till problemen med lerförorenad sand, men hade bekymmer med glimmer som ökade vattenbehovet och nedsatte hållfastheten hos betongen. Han föreslog röntgendiffraktion som analysmetod, något som dock ansågs orealistiskt i sammanhanget.

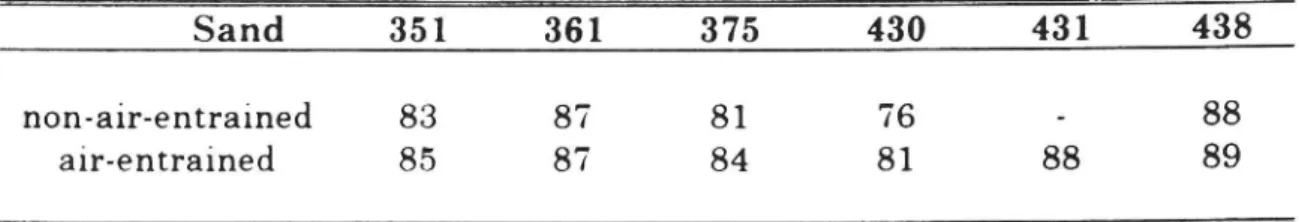

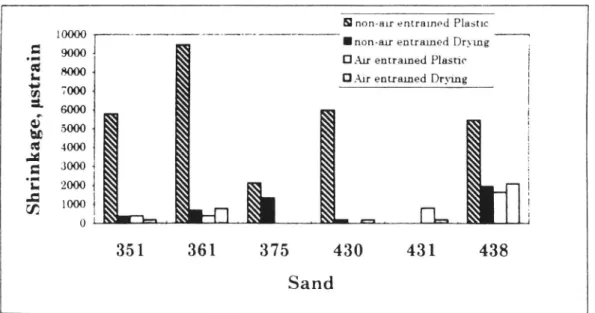

3 Effekt av lera på bruk och betong

Nästa session handlade om inverkan av ler- och siltföroreningar på bruk och betong. H. Borsje från Holland berättade om ett forskningsprojekt (sammanfattning i bilaga 6). Man har blandat in olika typer av lera i olika halt i bruk och betong och därefter bestämt funktionsegenskapema. Man hade dock inte använt sig av SE- och MB-provningar. För bruk påverkades krympningen vid torkning med lerinnehållet, däremot inte hållfasthetsvärdena nämnvärt. För betong erhölls större effekt på torkkrympning och vid högre lerhalt även på tryckhållfasthet. Den mineralogiska sammansättningen hos leran verkade vara utan betydelse. Man har stränga krav på renhet hos sand till bruk och betong i Holland (jfr nedan) och dessa anses vara välmotiverade.

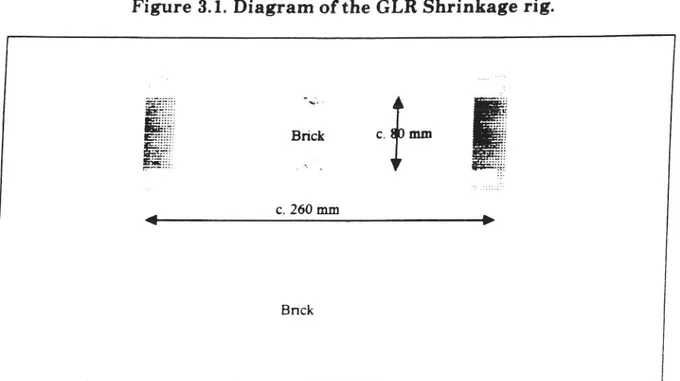

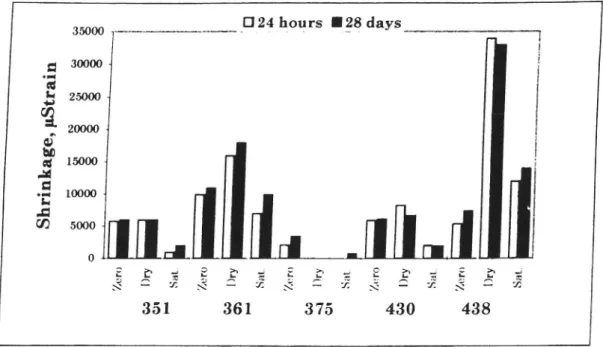

T.P. Lees, England från samma företag som A. Yool, berättade om undersökningar av engelska sandsorter och konsekvenser för England vid införandet av nya testmetoder som SE och MB (Bilaga 7a). En ny test för plastisk krympning hos bruk presenterades. Bruket applicerades direkt på tegel på ett realistiskt sätt (Bilaga 7b). Ett annat bidrag erhölls också (dock var baksidorna inte kopierade). Man har undersökt 154 sandsorter och inte funnit relation mellan finmaterialhalt och MB annat än i två fall. Det verkade dock som om MB-värdet gav indikation för sandsorter som resulterat i bruk med dålig frostbeständighet. Man efterlyste mer erfarenheter, även på europeisk basis, för att kunna dra säkrare slutsatser.

F. Hawthorne, från UNPG, redovisade för tidigare franska erfarenheter av betongballast (Bilaga 8). Man har funnit att lermineral utövade en negativ effekt medan malet kalkstens- eller kvartsmjöl kunde ge bättre betong (lägre vattenbehov och högre hållfasthet). En puzzolaneffekt var ibland tänkbar. Man menar att SE och MB är relevanta tester som är enkla och snabba att utföra. I Frankrike föredrar man benämningen cleaniness of sand snarare än harmful fines content . Sikt- och slamningsförsök är onödiga som rutinanalyser, om jag förstått detta rätt.

Vid efterföljande diskussion berättade en engelsman från Ready-Mixed Concrete att problemen med cleaniness of sand inte var stora i England. Vid undersökning av 150 förekomster visade sig 4-5 täkter vara skumma . Han menade att man ofta tvättade i onödan. MB verkade vara en bra test, betong med dåliga värde fick nedsatt hållfasthet och större krympning, medan SE inte gett

4 Effekt av lera på bituminösa massabeläggningar

Sessionen som behandlade bituminösa material var mycket mager och kort (lunchtiden var nära!). Delorme behandlade ett pågående forskningsprojekt vid LCPC varvid man blandade in olika lermineral i varierande halt (egentligen efter varierande MB-värde) i bärlager- och slitlagermassa samt provade sedan asfaltmassorna enligt franska funktionsrelaterade testmetoder (Sammanfattning i Bilaga 9). Packningsegenskapema påverkades föga vid lertillsats, styv-hetsmodulen ökade och motståndskraften mot plastisk deformation förbättrades (Tydligen förstyvar lermineralen bitumenet). Vattenlagring gjordes 7 och 28 dygn och förvånansvärt nog hade lermineralen ringa negativ inverkan (möjligen med undantag för illitlera efter den längre vattenlagringen). Delorme reserverade sig dock för att resultaten erhållits vid rena laboratorieförhållanden. (Förmodligen skulle asfaltmassor med lermineral som filler vålla svårigheter, bl.a. vid hantering i praktiken). Bitumenhalter, hålrumshalter mm. redovisades inte.

Detta resultat förvånar eftersom man i tidigare Frankrike visat en negativ effekt av lermineral, speciellt svällande sådana, på vidhäftningen hos asfaltmassa. Någon i församlingen frågade varför man behövde krav på SE och MB för stenmaterial till asfaltbeläggning, dock utan att få något svar. Jag har letat rätt på resultat från en fransk undersökning från 1981 av C. Tourenq (som var närvarande men inte gärna pratar engelska) där han visat att lermineral i fillern har stor inverkan på vidhäftningen hos asfaltmassa (Bilaga 10a). Vid lunchen hörde jag att det finns krav på SE och MB i franska anvisningar, men erfarenheterna är begränsade.

Det verkar som de europeiska experterna är ganska ovetande om vad som sker utanför deras länder. SE-metoden utvecklades således i USA, men man har på senare tid även intresserat sig för MB-metoden. En inventering av beläggningar i Colorado, USA, har således visat att snabbt sönderfallande beläggningar har dåliga MB-värden (Bilaga lOb, ej visad vid workshopen). SE-metoden ger däremot inte sådan relation. Några internationella erfarenheter av SE-metoden har tidigare behandlats i VTI Notat 73-1988. Metoden ingår även som materialtest i Superpave proportionerings- och dimensioneringssystem som utvecklats inom SHRst asfaltprogram.

5

Effekt av lera på obundna och hydrauliskt bundna

material.

Efter lunchen handlade det om hydrauliskt bundna och obundna material. Två portugisiska bidrag behandlade obundna material. Det ena erhölls i sin helhet, men på portugisiska (OH-bilderna var dock på franska) och det andra i sammanfattning. F.C. Branco, TH i Quimbra, redovisade praktikfall från en kalkstenstäkt där man påträffade både ren och förorenad bergart (Försök till sammanfattning i bilaga 11a). Båda hade nära samma Los Angeles- och Micro-Devalvärde (något som är ovanligt, i varje fall för den senare testen.) Man har studerat hur stenmaterialen förändras från produktion till utläggning. Man fann

också beroende på nedbrytningen vid utläggning. MB-värdet, som var ganska lågt för båda materialen, visade ingen sådan förändring. Portugisisk klassificering av materialen enligt SE- och MB-v'a'rden, både i täkt och efter utläggning, ges i figur B, bilaga 11a. Det rena materialet klarar krav för bärlager även efter utläggning, medan det förorenade har något för dåligt SE-värde efter utläggning. Den kan dock användas i förstärkningslager.

Samma material hade studerats av prof. A. Gomes-Gorreia; TH i Lissabon, i treaxialutrustning av franskt ursprung. Han har tidigare gästforskat i Frankrike. Utrustningen presenterades och sades ingå i förslag till europastandard (CEN TC 227/TG2). De två materialen, ren och oren kalksten, hade provats vid olika vattenkvot, dock hela tiden under optimal vattenkvot varför några dramatiska skillnader inte erhölls. Det visade sig (sammanfattning i Bilaga llb) att den orena kalkstenen hade sämre styvhet och större permanent deformation. Budskapet var att man inte kan klassificera lokala material enligt indextester som Los Angeles-och Micro-Devalförsök utan funktionsrelaterad provning måste tillgripas. Förutom treaxialförsök, som är komplicerade, kunde enligt Gomes-Correia kanske CBR-test kompletteras med MB-provning.

Samma resultat från treaxialförsök verkar varamed i Branco's artikel, figur C i Bilaga lla, där man fört in resultaten i den franska klassiñceringen enligt styvhet och permanent deformation enligt Paute (som nyligen kritiseras av F. Lekarp i hans lic. avh. vid KTH). Man kan för övrigt notera att kalkstenar får betydligt bättre klassificering än hårda eruptivbergarter, speciellt mjuka, unga (tertiära) kalkstenar. Metoden verkar därmed missgynna svenska hårda bergarter.

N.L. Tran från LCPC gav franska erfarenheter av obundna material (sammanfattning i Bilaga 12). Man har bl.a. utfört accelererad provning på fullskaleanläggningen i Nantes. Två kalkstenar undersöktes som bärlager under asfaltbeläggning, dessutom en granit som dock var tillsatt bentonit som artificiell förorening. Provsträcka med det förorenade bärlagret tålde inte många överfarter. Tyvärr har inte granit av bra kvalitet testats. Man ansåg att material men MB<l kan bedömas som varande bra.

N.L. Tran berättade vidare att för cementbundna material har man konstaterat att draghållfasthet och fransk bärighetsklass försämras med ökande MB-värde, men både lerans beskaffenhet och cementtyp spelar roll i sammanhanget. SE-metoden har inte gett så bra överensstämmelse. Man har, enligt erfarenheter gjorda under 20 år, funnit att följande kravvärden är relevanta vid franska förhållanden:

SE MB

hydrauliskt bundna material <60 <l obundna material <50 <2,5

berg- och grustäkter. Ibland utfördes torrsiktning på 1 mm sikt varvid 0-1 mm kasserades. En producent kan antingen leverera natursand resp stenmjöl med befintligt finmaterial eller också en tvättad produkt varvid tillverkaren tillsätter ett filler. Det förstnämnda arbetssättet är vanligt i Frankrike, den senare regel t.ex. i Holland. Tvättning medför alltid extrakostnader, deponering av överskottsmaterial och miljömässiga olägenheter. Enkla tester behövs för testning av sandens kvalitet. Ibland kan t.o.m. det egna finmaterialet ge bättre funktionsegenskaper åt slutprodukten.

Det framhölls vid efterföljande diskussion att flodgruset i Holland var förorenat av lera som ibland dessutom förekom som klumpar. Intensiv tvättning var därför nödvändig. Vad jag hört tvättar man även importerade, ej lerförorenade produkter

(7)

Vid efterföljande paneldebatt framkom att kunskaperna var otillräckliga och testmetoderna var helt nya för flera länder. Man kan inte plötsligt komma med helt nya krav. Erfarenheter av finmaterialegenskaper bör därför inventeraspå europanivå. Ordförandena för de olika TGzna och SC 6 inom CEN TC 154 bör således mötas och fundera på hur man kan fylla i de tomma boxarna i produktstandardförslagen. För bruk och betong verkade det som de extremt dåliga materialen kan urskiljas genom MB-metoden, men det finns ett diffust mellanregister. Kunskaperna verkar särskilt dåliga för obundna och bituminöst bundna material.

Mer forskning behövs tydligen. Det hänvisades till pågående engelska försök att mildra utslaget vid MB-provning (tveksam aktivitet enligt min mening) och till franska försök vid LCPC att kombinera SE- och MB-provningarna (se Bilaga 13 som delades ut, men inte togs upp vid workshopen). Risker föreligger att testen blir alltför komplicerad. Ad hoc gruppen har tidigare utarbetat ett forskningsförslag, som dock verkar främst knyta an på redan gjorda undersökningar i England med sand till bruk och betong (Bilaga 14).

Det hävdades också att det är svårt att få fram skadefall från praktiken för bedömning av relevansen hos testmetoderna eftersom både beställare och entreprenör var intresserade av att göra upp i tysthet och undvika negativ publicitet (samma sak som kan konstateras i Sverige). Kanske situationen är annorlunda i USA, där man gärna gör inventeringar av olika problem, jfr Lex. Bilaga lOb?

Workshopen visade således att det fanns en del erfarenheter från provning av bruk och betong, medan underlaget är mycket magert för bituminösa och obundna stenmaterial. SE-metoden fick en hel del kritik, men är enligt egen mening främst till för att bedöma materialet i samma täkt, främst för att påvisa ev. förekomst av lerföroreningar, också i form av vittrat berg. Metoden har använts sedan länge i Danmark, synd att ingen dansk var närvarande.

träffas även nästa dag. Vad man kommer fram till ska presenteras vid nästa CEN TC 154 Chairman's Panel.

Mötet hölls på alltför kort tid och man hann inte riktigt smälta det sagda. Jag hade med mig en del egna OH-bilder som det inte fanns någon möjlighet att Visa.

Workshop « Harmful clay fines in aggregates »m

5 February 1997 - Paris

Programme

9,00 hrs - Welcome by the chairman of TC154 Mr Kirkbiide - Presentation by the chairman of « Harmful clay fines » Ad-hoc Group Mr Souwerbren 9,20 - Geological aspects ofthe presence ofclay in aggregates Mr L. Pn'mel 9,30 Testsfor assessing clay content

- Present tests for assessing clay in aggregates Ms S. Decreuse - Tests with Methylene Blue: Applications and Expenments in Belgium Mr Steyaert - Developments of dye tests for clays Mr A. Yool - Testing and evaluation of harrnful fmes in Germany Mr Ritter 10, 45 Discussion

11,00 Pause

11,15 Effects ofclay on the behaviour ofcement mortars and concrete

- Impurities in aggregates for concrete Mr H. Borsje - Effects of clays in cement pastes and mortars Mr Hawthorne

- Effects of clays in mortars Mr T.P. Lees

Discussion

12,15 Ejfects ofclay on the behaviour ofbitumen-based materials

- Effects of clay on bituminous mixtures Characteristics Mr Delorme Discussion

12, 30 Lunch

14,00 Effects ofclay on unbound and hydraulically bound material behaviour

- Mechanical behaviour of an untreated limestone aggregate Mr F.Castelo Branco - Effect of fmes on the mechanical behaviour of unbound materials Mr A. Gomes Correi; - Effects of clay on cement treated and untreated all-in materials Mr Tran NL

14, 40 Discussion

14,50 Economic aspects ofclay contamination in aggregates

- Actual costs in the aggregate end-uses due to clays Mr Pctitjean 15, 1 0 General conclusion

CEN/TC154 « Aggregates »

Workshop «Harmful clay fines in aggregates»

5 February 1997

Paris - France

To all participants in the workshop:

Members of CEN/TC154 Mr Mr

?

ååêåg

ååååååi

åQ

Q

T. Kjrkbride C. Souwerbren PJ. Nixon U. Hahn M. Charrcau D. Storrar B.V. Brown C. Curtis A. Mishellany F. Norman Tran NL L. Primel Delormc HY. Ritter W. Steyaert Ray Ryle Geurts Ton Chajnnan of CEN/TC154 Chairman of TC154/SC] and of« Harml'ul clay l'ines ad hoc » Group Chairman ofTC154/SC2 Chairman of TC154/SC3 Chairman of TC154/SC4 Chairman of TC154/SC6 Chairman of TC154/WG?! Chairman of TC154/WG3 (UEPG) Chalnnan ofTC154/WGÖ Chairman of TC ISMWGQ Secretanal TC 154/SC4 TC154/ Editing Panel TC 154/SC3 TC154 TC 154/SC4 TG Convenor SC3 UK Netherlands UK Germany France U K UK U K France Ireland France France France Germany Belgium UK Netherlands

Vm'ä Mr Hawthorn Dr C. Tourenq Mr Georges Cuvelliez Mr H. Borsje Mr V. Jensen

Prof A. Gomes Correia

Dr M. Castelo Branco Mr P. Hobeda Mr A. Leemann Dr Pike Dr T. Lees Dr T. Yates Mr A. Yool UNPG BNSR-LCPC UEPG TNO-Bouw IST DECivil Greenland BRE Greenland France France Belgique Netherlands Norway Portugal Portugal S weden S wi tzerland U K U K U K UK

Tests with Methylene Blue

v Applications and Experiments in Belgium

(texte original en français)

CEN T0154 Workshop

Paris, 5th February 1997

W. Steyaert

Holderbank European Services Obourg Granulats S.A.

7530 Gaurain-Ramecroix Belgium

REFERENCE DOCUIWENTS MENTIONED

1. Research Report LPC No. 110, Influence des argiles sur les propriétés des mortiers de cirnents (Influence of clays on properties of cement mortars), Z. R. Unikowski.

2. LPC Liaison Bulletin No. 160 (1989), L'essai au bleu de méthyléne (Testing with methylene blue), A. Mishellany.

3. LPC Liaison Bulletin No. 159 (1989), Mise en evidence des argiles par l'essai au bleu de méthylene (Determination of clays by testing with methylene blue), C. Tourencq and Tran Ngoc Lan.

4. Annals of the Institut Technique Bátiment and T.P. No. 490 (1991), Le röle

des argiles dans les Matériaux de Génie Civil (The role of clay in Civil

Engineering Materials), C. Tourencq and Tran Ngoc Lan.

5. BENOR Marking Committee

-Part 2: Technical Speciñcations CRIC PTV No. 401 Part 3: Technical Memorandurn N.T.N. No. 401.

6. Materials and Structures No. 20 (1987), Sables Calcaires a ñnes calcaires

et argileuses

(Calcareous sand with calcareous and argillaceous fines),

Ramirez, Barcena, Urreta.

CEN TClS4 Workshop

Tests with Methylene Blue S.E. S.E.10 B.T. BV.f. MB.s.

ABBREVIA TIONS USED

Sand equivalent

Sand equivalent with ñnes content reduced to 10%.

Blue test (BV.f. or MB.s.)

Blue value determined on ñnes fraction of sand, expressed in gr/ 100 gr.

Result of blue test determined on a sand sample, including ñnes, expressed in gr/ 1000 gr.

CEN TC154 Workshop

SUIWIVIARY

The BENOR certiñcation regulations impose a check on the (possible)

harmfulness of ñnes in sand, by two test methods considered (in principle) as . equivalent:

- the SE. 10, on 0/2 sand with a ñnes content reduced to 10%. - BV.f., blue test on lines (currently O/0.08 mm).

The S.E.10 test, has been known and practised for a very long time, whilst the BV.f. test was not ofñcially introduced until 1989, although practised by several crushed-rock quarries from the publication of the first French standard (1980). The market is still dominated by round river sand and in this respect, it is mainly the SE. 10 which is practised. The BV.f. test is practised by several producers of crushing sand with high ñnes contents, for a better knowledge of their product. The SE. test (and with greater reason the S.E.10 test) does in fact have some substantial gaps. Experiments have shown that the BV.f. test is more suitable than the SE.. 10 test for establishing the harmlessness of the ñnes.

Whilst the BV.f. test and the interpretation of its results can be considered nowadays as well-known (to be supplemented in certain limited cases by . turbidimetry), a research programme is necessary with regard to the MB.s. test.

The level of requirements with the BV.f. test merits a review in respect of some USCS.

CEN TC154 Workshop

Tests with Methylene Blue

PLAN

1. Checkinq harmful fines in sand in Belqium.

Summary of what is planned in order to obtain BENOR certiñcation. 2. Criticism and iustiácation of this procedure.

In fact, it is mainly the SE. which is practised and when the results do not conform, the BT is then carried out on the lines. The requirements have been copied from various French documents.

3. Future application in Belqium of the CEN standard.

This will not pose any problem, as the CEN standard on the BT now provides also for the test on ñller (below 125 microns) and harmless ñnes will satisfy the granulometric definition of "ñllers .

4. Practical applications of the BT in Belgium. Applications in quarry production tests.

Applications within the CSTC, CRR, BENOR organisations, U.C.L, inter alia.

5. Economic aspects of the BT. 6. Ideas on the subject of research.

The French publications showing some gaps in the application of the BT indicate what remains to be done.

ANNEXES

1 . Te sts at Obourg Granulats (calcareous crushing sand).

The introduction of the BT in Belgium has enabled crushing sand to be

introduced in some applications where it was originally excluded.

2. Results of cross-checking tests at the "Carriere du Milieu".

CEN T0154 Workshop

1.

Checking harmful fines in sand in Belggim, as it is currently practised.

Reference document: see reference 5.

Checking the harmfulness of ñnes in sand (in Belgium, ñnes are still defined by passing through 80 p) is provided for within the scope of aggregate certiñcation (BENOR) on the basis of standards documents , which are replacing the old standards (1970), no longer suitable since the introduction of the new sieves. The standards documents also make good the lack of certain norms in Belgium, pending the introduction of the CEN standards.

The cleanliness concept no longer rests on a more or less severe limitation of

the ñnes content, but on the following two types of test:

' 0 the presence of organic matter (oxygenised water test) with a maximum

requirement of 05%.

i"

0 the degree of harmfulness of the fmes, checked by the sand equivalent test with 10% ñnes , as defined by the French method NF18-597 (1990). If the result does not conform to the requirement, the harmfulness is verified by the blue test , practised on the fraction of ñnes (below 80 p) in the sand, according to the standard NBNBl 1-210 (publication deferred because of work by the CEN). The check can also be made directly by the blue test.

The document provides for three classes on the basis of the lines harmfulness tests:

on sand with 10% Blue test on ñnes Recommended fmes - N.F. 18-597 NBN Bl 1-210 uses

Class a SE > 60 or BV < lgr/ 100 gr cement concrete and asphalt mixes

' Class b SE > 50 or 1.5 lean concrete

mortar

Class 0 SE > 40 or 2 foundation and

sand-cement

CEN TC154 Workshop

Tests with Methylene Blue

No requirement is provided with regard to ñnes content, but the latter must be

notiñed by the producer. Impositions are provided concerning the variability of

the ñnes content. The choice of the maximum content of fines belongs to the

' users (inter alia, the Type Speciñcations of various authorities).

The requirement of S.E.(1) and B.T.(f) may be discussed again after a period of

two years within the BENOR framework. This was decided because of the lack of experience with the B.T.(f) test. No revision of the requirements has been imposed so far.

CEN TC 154 Workshop

2. Criticism and justification of the planned procedure in Belgium

2.1 SE. test followed up if necessary by the V.B.(f) test.

The introduction into the BENOR regulations of the SE( 10) test to replace the SE test provided in France, leads to the consideration of an equivalence between the SE(1) and the BWO tests.

French literature advocates the SE test, followed by the BV(f) or the BV(s) test.

In fact, these practices do not differ:

- the production of round river sand is controlled by test SE(10) but as the ñnes content is always below 10, it is in fact the SE test which is practised.

- the production of crushed rock sand, rich in ñnes, will also be checked by the SE(lO) test, but often supplemented by the BV(f) test, either because the SE(10) result does not conform to the requirement, or for more information about the product.

2.2 Blue test on fines and not on sand.

The BT was standardised in Belgium at the time when the French standard was itself planning for a test on ñnes. We believe that this methodology offers many advantages over that conducted on sand (with the sole

drawback: that of having to sieve the lines before testing):

° better reproducibility and repeatability (which can be seen from the diagrams in Annex 2).

- the influence of the 0.06 - 2 mm fraction of the sand is thus avoided.

0 in all cases the addition of kaolinite is eliminated (sand poor in fines is checked by the SE test).

- CEN TClS4 Workshop

Tests with Methylene Blue

0 the test on the sand incorporates in its result harmfulness and content and

therefore presents the same short-comings as the sand equivalent, in the case

of sand rich in fines.

2.3 Choice of requirements (methylene blue test).

The requirements on ñnes shown in the standard document 401, correspond to those provided for the same applications in France, where they were based on numerous studies and experiments (see in particular ref. 1).

Depending on the final usage, the requirements on fines are from 1 to 2 gr/ 100 gr.

It has been agreed within the framework of BENOR certification that these requirements are subject to revision every two years.

Reason: the lack of experience available when commencing with the test. ' Our own experience in the area of cement concrete and asphaltmixes (see point 2

of Annex 1) reassures us onthe level of requirements which are shown in the BENOR Technical Specifications 401. Some observations made within the certiñcation framework do however justify a more liberal requirement than that now planned for the asphaltmixes. (cf 4.4).

A certain logic may lead to providing a different type of requirement (see also references 2 and 3):

V.B. on ñnes x Fines content .

It is hoped in this way to obtain a result comparable to a result obtained by the

blue test on sand, whilst avoiding the disruptive effect of the sand fraction above 80u. This consideration is based on the idea: what counts is the total content per cubic metre and the nature of the clays in the mixture .

CEN TC154 Workshop

This kind of requirement has not been provided for in Belgium and our objections

are as follows:

- to respond correctly to the problem posed, it would also be necessary to take into consideration the sand content in the mixture and one would thus arrive at being stricter on mortars than on concretes (experience dictates otherwise). 0 in the present state of our knowledge, basing ourselves on the blue stain-test (as also provided for in the CEN standard), nothing enables it to be afñrmed that a clay A1 with BV1 and a content t1 presents the same harmfulness in a mixture as a clay A2 with BV2 = BV1/2 but with a content tg - 2 x t1 (turbidimetry would indeed allow this approach, see ref. 4).

Our own experience (Obourg Granulats: see point 1 of Annex 1) causes us to doubt the suitability of an requirement of this type.

CEN TC 154 Workshop

Tests with Methylene Blue

3. Future application in Belgium of CEN standards for judggig the harmfulness of fines.

The two tests concerning the harmfulness of ñnes applied to-day: O Sand equivalent with 10% ñnes,

- Blue test on ñnes (below 80u) are to be replaced by:

- Sand equivalent (on 0/2 as it is) - Blue test on 0/2 sand.

The new sand equivalent test should not raise any problem of application and

few changes with regard to requirements, since it applies above all to sand low in

ñnes (below 10%). "

The SE. test on the contrary offers the advantage of ñguring truly as a screening test for sand rich in ñnes, with the obligation to pass on to the next test (blue

test) to determine whether the poor sand equivalent is due to the degree of

harmfulness of the clay present or to an excessive ñnes content.

The new blue test on sand, with the facility of replacing the sand equivalent, will

pose the following problems:

° complication and tendency to reject the test, by the proposed addition of kaolin.

- the impossibility of proposing adequate requirements due to a lack of

experience with this methodology.

The recent introduction of Annex A into the CEN standard which describes the

blue test, will however enable Belgium to apply a test on fines and to keep its

present requirements. Annex A provides in fact for the blue test on filler with a fraction of 0/ 125 (1.

The fact that the test on ñnes in Belgium is conducted on the fraction below 80 microns is of no great importance. The problem may be the subject of some minor research in Belgium.

- CEN TC154 Workshop

4.1

4.2

Practical applications of the blue test (on fines] in Belgium.

Application in production control at the Carriere du Milieu (Obourg Group) A systematic, regular check on the harmfulness of the ñnes with the

S.E.(10) and V.B.(f) tests, is provided for by the BENOR certiñcation

organisation. An example is given in Annex 2, with a recent, remarkable

evolution of the test results on the occasion of the exploitation of a new rock face.

The S.E. test alone would lead to sanctions, the V.B.(f) test gives reassurance of the unchanged nature of the lines.

(Explanation: evolution of the granulometry of the lines).

The B.T. has also enabled the appropriate cut to be selected on the general

run of 0/250 mm after primary crushing, in order to obtain the fraction

intended for production of washed aggregates. Inadequate cut of this

fraction leads to the production of dry aggregates, whose ñnes.no longer

meet the most stringent requirements (for concretes and asphaltmixes).

Applications at the Belgian Centre Scientiñque et Technique de la Construction (CSTC - Scientific and Technical Building Centre)

The blue test (on ñnes) is frequently employed there and considered as a

necessary tool in the work carried out by the Centre. The only reproach

expressed concerns repeatability which does not appear to be satisfactory

when two laboratory assistants are involved in the test (it is thought that

the problem is on the level of the preparation of the specimen).

The Centre is particularly active in the field of recyclable materials and will

be devoting time in the future particularly to the study of the lines

fraction in this type of material.

CEN TC154 Workshop

Tests with Methylene Blue

4.3

Given the complexity of the problem, research will be based on the

following tests on different samples:

- sand equivalentt - blue test on ñnes

chemical composition and X diffraction for a thorough knowledge of the nature of the fmes.

Comparative tests on concrete will enable the requirements in force to be verified. This research programme is currently under preparation.

The CSTC will also soon be engaged on a complete investigation (including

the blue test, as this test could give some significant results) of small sand

quarries (dry exploitation of natural sand) which have been opened to meet the market demand. Tests on these sands were too often limited to granulometry alone. A check on the purity of the fines is necessary.

Applications at the Belgian Centre de Recherche Routieres (CRR - Road Research Centre)

The blue test on fines has frequently been used in a study of recyclable materials (and sand).

The CRR has also applied the French standard, i.e. on sand in monitoring a TGV-site and has made no comment or comparison with the Belgian standard on ñnes.

The study on certain recyclable aggregates (based on concrete and

brickwork) enables the following comments to be made:

the SE. test on sand as such is highly selective, but (as is well known) greatly influenced by the high content of ñnes.

CEN TC154 Workshop

4.4

The SE 10% test is not selective enough, since it allows the requirements to

be met without causing any concern about the nature of the lines.

the BT on fines on the same sample enables it to be determined when the fines are in fact of poorer quality (even if they meet the requirement which prevails in this case for their use).

COPRO, inspection organisation for BENOR certiñcation of aggregates. Only nine producers have been approved by BENOR for sand. The producers of round river sand use the SE with 10% fines (the precentage of

ñnes in this case is always well below 10%), meet the requirements and

therefore do not employ the BT.

Producers of crushing sand often conduct both the SE and particularly the BT on ñnes.

COPRO'S inspection enables the following comments to be made:

some inspection laboratories have problems in correctly carrying out the stain BT test; an informatory meeting is to be held in Belgium with a demonstration.

certain calcareous crushing sands present mean results which are slightly above the requirement for 1 gr/ 100 gr ñnes for asphaltmixes; such sands have however always been widely used for road-building coated products without the least problem. A revision of the requirement (already suggested in some studies in France) must therefore be envisaged.

CEN TC154 Workshop

Tests with Methylene Blue

° 4.5 Engineering laboratorv - Catholic University of Louvain la Neuve. This laboratory makes constant use of the blue test, particularly on sand ñnes (also on soils). Some special applications, however, often necessitate X diffractions analyses (after the blue test).

Numerous tests have enabled some good correlations to be established

between the blue value and the nature of the clay revealed by X diffraction.

In case of ordinary applications for concretes and asphaltmixes, the

blue test could be considered as perfectly reliable.

It is however appropriate to be more prudent for highly specialised applications and in such a case to carry out an X diffraction analysis. Certain harmful elements are sometimes missed by the blue test.

CEN TC 154 Workshop

5.1

5.2

Economic aspects of the B.T.

The promotion of crushing sand, most often rich in ñnes, in regions accustomed to using natural (river) sand poor in ñnes (and where any ñnes are frequently harmful), is not easy. However, the production of crushing sand represents up to 25% of the total production of a massive rock quarry and the quantity of sand will only increase when river gravel is inevitably replaced by crushed aggregates/

The development of the B.T. has provided a tool perfectly suited to checking the quality of ñnes both on the construction site and at the place of

production. This enables the user to be reassured of the quality of the

product (see also Annex 1, Point 2).

When the raw product, after primary crushing, is separated into two fractions, one of which (containing all the fine particles and most frequently originating from altered rock) is sent to a washing plant, the real appropriateness of this operation may be doubted and possible uses of the materials may be examined on the basis of the results obtained with the B.T. (see ref. 4 and 6).

CEN TC154 Workshop

Tests with Methylene Blue

6. Suggestions concerninLa research programme in the field of harmfulness of fines, inspection and requirements.

A great number of studies conducted over numerous years and in all countries

no longer justiñes a fresh research programme in the field of ordinary applications in the construction industry. This is not, however, the case for other morespeciñc applications and also for special construction work (concretes used in nuclear constructions, for example) with special, inherent durability requirements.

However, there is always matter for research in the field of testing methods and the related requirements.

The study in reference 4 provides a good summary of the existing methods. Only the SE test and the blue test are to be considered as practical, rapid methods, suitable both for continuous production controls and for acceptance testing on the construction site. One single exception to date: the exceptional case of the ñnes of certain basalts which do not respond to the spot blue test and necessitate a more thorough laboratory investigation by turbidimetry.

Contrary to the SE test, the blue test methods (on sand and fmes) may give rise to several subjects for research. Some research subjects are mentioned in the

studies in references 1 and 2 whilst certain points of the study in reference 4 are

worthy of further investigation.

The major research ideas which we suggest have thus been inspired by French publications. These are:

the LCPC research report no. 110 studies mortars. The same kind of research should be done on concrete with, inter alia, particular attention being paid to

deformation modules (see page 74).

the same report suggests more fundamental research into the kinetics of

hydration of cements in the presence of various clays (some clays increase

strength when young). (See also page 74).

CEN TC 154 Workshop

0 study of the influence of the sand fraction (above 63u) on the result of the MB. on sand and to deduce from this what is most suitable :

* MB. on sand with 10% ñnes

* VB. on fines (Belgian test and former French standard) * MB. on sand (CEN test)

with what kind of requirement and at what level (depending on the type of application). This is what Mr. Mishellany suggests in the LCPC's Liaison Bulletin No. 160 (1989).

CEN TC 154 Workshop

Tests with Methylene Blue

ANNEX 1

1. Results of the Obourg Granulats company's Milieu Quarry laboratory rests on calcareous crushing sand

The results of the inspections carried out within the framework of BENOR certification are reported in Annex 2 for dry crushing sand with a high fines content. They reveal the quarry's advantage in carrying out the blue test. The same tests on sand produced by other production chains have led to a search for some correlation between the blue tests on fines, on the one hand, and on sand with ñnes on the other. The results (see diagrams) indicate that this correlation is nil. The absence of any true correlation is evident since the test on sand incorporates both the content and the harmfulness of the fines.

This research does however allow for the following considerations: The sand S (with 16% fines) presents an MB on sand of 1.2 gr/ 1000 gr (average)

The sand L (with 2% fines) presents an MB on sand of 0.5 gr/1000 gr (average)

i.e. a ratio of MB sand S = 2.4 MB sand L

whilst the fines contents present a ratio of 8.

These fines are of the same kind with a BV value = 04 gr/ 100 gr.

We therefore consider that in the case of the stain-test (as provided for in the CEN standard) it would be dangerous to accept a requirement of this

EPS

fines content multiplied by BV on ñnes

CEN TC154 Workshop

0

A test on the 0.08/2 rnm fraction of the sand gives a value of MB = 0.5

gr/ 1000 gr. (value confirmed approximately by the tests on sand 8 and on sand L ).

The approximate ratio of 10 between the blue values on the 0.08/ 2 mm

fraction and on the fines is not explained either by the insignificant

presence of low-active clays in the fines (kaolinite and illite), checked by X diffraction or by the specific surface areas of these two sand components. The role of the 0.08/ 2 mm fraction of the sand is therefore too vague to accept without sorne reticence a blue test on sand rather than on ñnes. Further investigations (research) are necessary.

The content of fairly harmless clays alone revealed by X diffraction is insufñcient to explain the blue value determined by the blue test on fines. As shown, inter alia in ref.6, the effect of these low-activity clays on concrete is amply compensated by the positive action of the calcareous

ñnes.

CEN TC154 Workshop

Tcsts with Mcthylenc BIL/c ..

-Essais au bleu sur ñnes el sur sables avec nos sables 0/2.5 S et OI2.5 L

I ' 0/2.ss

Sable de concassage calcaire

dm O VB

3

0/2.5 :cc :15 14 d. fm: :33:32: 003-; 12':) 07/11/95 0.33 1.25 01/10/95 0.4 1.75 24/09/95 0.4 1.75 15/09/95 0.33 1.25 20/05/95 0.33 1.25 5 01/05/95 0.33 0.5 Fmasoznmsozsaaas-va] :33:33: 0%.: 1.2? 2 ' 14/05/95 0.4 1.25 Å Å Ä 24/05/9504/05/95 0.330.4 1.251.5 5 * A * * :i 22/05/95 0.33 1.25 Af __ 2 Å Ä Å Å * ' 04/04/95 0.50 1.75 22/03/95 0.33 1.00 * * * * .L JL 14/02/95 0.43 1.50 L ,k ^ 05/02/95 0.45 1.50 15/01/95 0.45 1.50

*

05/09/9519/09/95

0.400.33

0.75

0.75 7 .. 25/05/95 0.40 0.95_ 0.4 0.33 0.4 0.33 0.4 0.4 0.4 0.50 0.43 0.45 0.4.0 053 0.40 0.47 21/03/95 033 0-55 0.33 0.4 0.33 0.33 0.33 0.33 0.33 033 0.45 0.33 0.40 0.53 0.57 13/07/95 0.53 1.25 V3 W' m 25/05/9503/07/95 0.400.57 0.901.50 13/05/95 0.47 1.50 0/2.5L 5511:5 va '1.43 27/11/95 0.4 0.75Sable de concassage calcaire

12/11/95

0.55

0.75

0051"/ s 2 'Å do 11m: 22/10/96 0.33 0.75 05/10/95 0.33 0.75 25/09/95 0.4 0.35 19/09/95 0.33 0.5 23/05/95 0.4 0.51 12/05/95 0.33 0.35 ; 23/07/95 0.33 0.5 * 09/07/95 0.5 0.5 L. 1.15=0.524557-0.31377-v5] 14/05/95 0.4 0.5 1 L 05/05/95 0.33 0.5 30/05/95 0.3 0.5 4* 15/04/95 0.33 0.5 *1 Å * * * * Å * Å * * 5 * Å Ä 21/03/95 0.33 0.50 -- 05/03/95 0.33 0.50 * Å 19/02/95 0.35 0.35 23/01/95 0.33 0.50 20/09/95 0.33 ' 0.50 04/09/95 0.40 0.50 22/05/95 0.33 0.55 A ;L ,L A A 03/05/95 0.42 0.50 ' 25107195 0.40 0.45 , 04/07/95 0.33 0.35 27105195 0.50 0.35 M 043033035 M 0.53 M 0330; 0.5 M 0.33 OJ 053033053oxoxonoaoonoxzo'wosa 00.500 20105195 0-50 055 V8 m fm: 07/05/95 0.33 0.45

CEN TClS4 WorkshOp

\\

.

Pans. 5th February. 1997

ws/CD/9607

2. Results of tests with a view to the application of crushing sand with 17%

fines.

Main Characteristics: confidence interval (at 90%) of the ñnes content: 15 to

19%

BV on fmes 0.4 gr/ 100 gr With the same confidence interval of 0.3 to 0.5 gr/ 100gr.

Laboratory tests followed by practical applications have given the following results.

' Tests on lean concrete

Given the fines content, this sand must be reserved for lean concrete; it is mixed with other ñnes-free sand for concrete with normal cement-content.

The laboratory xtests have provided very conclusive results. The practical applications are most frequently limited to lean concretes for various foundations.

Tests on prepared dry mortars

The laboratory tests finished up with an increase beyond the 20% fines content in order to optimise the results.

Tests on coated products

The Marshall study and the experimental site at Vaulx-lez-Tournai have led to a regular use of this sand in coated products, where this is permitted, i.e. with the following restrictions:

' some authorities remain attached to a limit of the ñnes content (often to 8%).

0 for road surfaces when a minimum PSV value is demanded for the sandis parent rock.

CEN TC 154 Workshop

Tests with Methylene Blue

Tests on cement-stabilised sand

This material, with a low proportion of cement, is mainly used for ñlling trenches. . The application of crushing sand which meets the definition notiñed enables

either the performance of the mixture to be improved or the cement content to be

reduced. Conclusions

a sand Which meets the definition enables mixtures to be produced which satisfy the user.

- only the systematic application of the blue test has enabled the user to be

reassured on the application of this type of sand.

The application of the blue test is sometimes implicit in the prescription for certiñcation of the aggregates, and sometimes explicity laid down in the speciñcations.

CEN TC154 Workshop

-v -v v v v W I vu V U U U I U U I a l I U I a l b N 0 ca li br c Ca ra ctér is . .I S /ZE 10 Li eux : 0-6 döáåi ér Ap pe la ti on : 0/2. 5 S A 16 II 0 4 0 1 -B EN O R 4 0 1 80 .0 1 70 .0 60 .0 50 .0 40 .0 30 .0 5 i i *r-Lnr-I" -Ot-r-O .w'booo --f-v-Oh 'NQOLD -NNOM --OLDON --Nt-r-N ., ?mg-g-n-OUOOI Da te / \ / / \ / Lég en de Rés ul ta ts M o ye n n e de s im po si ti on s Im po si ti on s M o ye n n e mo bile Fus ea u stat is ti que Eq uiva le nt de s a b l e \ a 1 0 % d e f i n e s ( NF 18 -59 7 ) S a b l e d e c o n c a s s ag e c al c a i r e á 1 6 % d e fi nes en mo yenn e. ANNEXE 2

U O S S I O I Ap pe lati on '; 0/ 2.5 s A 16na 40 1-BE NO R-101 Ca raci ér ié. JB/B f Li eux : 0-6 1. 8 1. 6 1. 4 1. 2 1. 0 0. 84 0. 6 0. 4... . 0. 0 -w-Nom -- 'När-O -OQOF ^PGON "060% -OG'OLD "1-0705 w-LOF'F --r-INF'O -w-coom D a te Lég en de 1 Résul ta ts 1 N M oye n n e de sim po si ti on s -- -Im po si tion s / \ / Moye nn emo bi le / \ / Fus ea u st atis ti que Es sai au bl eu mesur é sur fine s ( NB N -Bl l -21 0) Sa ble de c onc a s s a ge ca lc aire á16 % de fi ne s en mo ye nne.

Ca ra ctér is .AB / 82 I ' Ãp pe lati on ': 0/ 25 5 A 16 na 40 1-BE NO R-10 1 Li eux ;0-6 3. 0« 2. 5 2. 0 1. 5 1. 0 0. 5 0. 0 D a t e n-mq-u-- 'Chin-mq-u--tn-mq-u-- 'Chi-t-" *Ndom ----C\|OOO) -- FmOh -w-voco -- -NQOLO - OQOQ' "4-6001 <4-wor-/ \ / / \ / Lég en de Rås ul ta ts M o ye n n ede s im po si ti ons Im po si ti ons M o ye n n e mobi le Fus ea u st at is ti que E s s a i a u b l e u m e s ur é s ur s ab l e ( pr EN 93 3 -12 ) Sa bl e de c o n c a ssa g e ca lc aire á 16 % de fi nes en mo yenn e.

'wJan-97 06:34P'He1en Cha1strey 01923 664786 Bilaga 4a

CEN/TC '54 Aggregates

HARMFUL' CLAY NES - WORKSHOP

5 FEBRUARY 1997 . PARIS

RESEARCH ON THE EFFECT OF CLAY ON THE BEHAVIOUR OF CEMENT MORTARS

A. D. Russell, T.J.S. Yates and P ._I Nixon Building Research Estahlishment, Carsten,

Watford, W'DZ 7JR UK ABSTRACT

The Building Research Establishment has been involved in research on the effect of clay on the behaviour ul' cement mortars for the last five years. The research has been funded by the UK Department of the Environment and has been carried out in eonjtmetion with (ii-een Land Reelamation Ltd- The main stimulus for the research pregramme was the development of European Standards for sand-3 as aggregates by CEN/TC 154 and the requirements and test methods that were to be included.

The research programme has addressed three key questions:

0 Can the el'leets ut" *hm-mful clay fines* on cement morturs be identified and quantifieil 'z'

0 Can maximum limits be set I"t 1'\han'nful clay fines' '?

0 De the pmposed tests reliany identity and quantify the harmful clay

fines' contents '? The work has included:

- A sun-'ey nl* building sands in the UK

o Assessment of the effect of sands with different clay contents on plastie shrinkugc ;md clrying Shrinknge, frost resistance and weather tightness of masmu'y

0 Studies ut' reliahility and t'eprodueibility to the methylene blue test and sand equivalent test in detennining clay contents in sands.

A brief description nl' holtle of this work will be given; mere detailed results will be presented by Green Lund Reelamation Ltd.

Bilaga 4b

Summary: of presentation to Paris meeting re harmful fines.

A.Yool. Green Land Reclamation Ltd. Maidenhead, UK.

154 sources of washed, dry-screened and blended building sands have been collected and tested for grading, methylene blue dye adsorption and sand

equivalent. Two sources were selected on the basis of the nature and quantity of

their fines and variability trials were conducted using the methylene blue (MB)

and grading test.

The building sand survey revealed MB values up to 5.2 g (dye)/kg sand. For a given ñnes content, there was an upper limit on the MB value of the sands. There was only a limited correlation between the results of the MB test and the sand equivalent test and then only at high values of sand equivalent (clean

sands). The sand equivalent test failed to distinguish between sands with high

dye adsorption values.

Testing of one source for the variability trial revealed a Characteristic range for MB dye adsorption of 3.6 to 4.4 g dye/kg sand whereas the spot sample tested for the building sand survey had a much lower MB value of 2.6 g dye/kg sand. On the basis of ñnes content and MB value, six sands were chosen for use in work on mortar durability and shrinkage. The ñnes of the six sands were tested using a Malvern sizer and the results were used to approximate the surface

area of the ñnes which could then be compared to the properties of the mortars

made with those sands. X-ray diffraction was used to identify the clay minerals

comprising the ñnes.

A programme of work was undertaken to investigate improvements to the MB dye test, the results of which, in its current form, do not rank different clay minerals according to their harmfulness. Various combinations of dye type and pretreatment. were used in dye tests on kaolinite and montmorillonite clay powder. One such combination has reduced the ratio of dye adsorption between kaolinite and montmorillonite from 1 : 34 to 1 : 4. The mechanism is not fully understood, the test has to be developed for use on sand and the programme

1/9 3- 2-97 10200 ;BV KALKINDUSTRIE KOELN B11aga5 +49 221 93467410;# 1/

Bundesvewpand den Deutscher-1 Kalkindusme e.\/.

<(

[- Bundesverband der Deutschen Kalkindustrie e.V.

Poettsch 51 05 50, 50 941 Köln - Telefon: (02 21) 93 46 74 -0

Fax: Int +33 1 42.54.0128 ' , Taiwan: (02 2 96 40 74- 'om Telegramme: Kalldndu Köln

Mr Stadleparkaaae Köln (BLZ 370 501 '38)

I . 81 d d G 1 G Konto-Nr. 7112618

Umon Natten es es Producteurs e anu ats (UNP )

mmm Köln (BU: 370 wo 50)

3, rue Alñ'ed ROH Konto-Nr. 36617-502

F-75849 PARIS FRANCE

Annastrafåe 6741

InneNachncm vom Ihr Zeichen Unser Zeichen Durcnwam 50 968 KOLN

_ a; 40

7.:-. RJ-es

48

3 February 1997

Subject: CEN TC 154 "Aggregates"

Workshop "Harmful clay fines in aggregatcs"

on 5 February 1997 in Paris

Dear Mr. Denis,

I take pleasure in enclosing the paper to be presented by Mr. Ritter. He will also bring a

re-producible printout ofthis paper to the workshop to have copies made for the participants. Please

inform the clmirman ofthe Workshop that Mr. Ritter will present this paper so that it may be

included in the workshop programme. Yours sineerely,

Petra Esser Secretariat

CEN TC 154 "Aggregntes"

Workshop "Harmful chy lines in aggregates" 5 February 1997

Paris - France

Testing and evaluation of hannful f'mes in aggregates in Germany

Situation

In Germany, the evaluation of lines in sands - be it natural or crushed stone sands - is done

one the basis of the applicable regulations for mortar and concrete that specii'y limit values

for the particlc fi'action < 0.063 mm. The German stande DIN 4226 Aggregates for concrete" limits this fraction to maximum 4 percent in weight for sands. For masonry mortars, German standard DIN 1053 "Masomy" speciñes a maximum limit value of 8 %

of lines. All sands meeting these requirements may be used for the applications mentioned

without further examination of the lines contents. To fullil the standard requirements,

producera have to take considerable efforts regarding processing.

For both applications mentioned above, it is also possible to use sands that do not meet the

requirements- In that case, however, it shall be demonstrated in a suitability test of the

concrete or masonry menar containing such sands that the Concrete or masonry mortar

meets the requirements. It this is proven, such sands may be used for this specific case.

Thus, all sands meeting the requirements of the above-mentioned standards can in theory

contain harmful ñnes up to the mMum allowable content without these lines having any

adverse effect on the products manufactured with such sands.

In Germany, there is no further examination of the lines by test methods not directly related

to the sand. .

The maximum contents of harmful ñnes <1 0.063 mm in sands being specified in standards

DIN 4226 and DIN 1053, there has so far been no occurrence in Germany of any damage in

concrete and masonry mortars that can be attributed to the harmñil constituents within the

scopc ofthe allowablc limit values.

There are different methods for the evaluation of the fines contents of sands used in road

construction. For aggregates for unbound mixtures, the pertinent regulation limits the

contents offmes <2 0.063 mm to 7 % or 5 % on site, as appropriate. The ñnes content is not

further examined, except in several Federal Laender which I will explain later On.

-For aggregates for bituminous bound mixtures, the technical speciiications for the deliv

of aggregates (TL Min-StB 94) require a the internal ñller properties of the to be teSted if

the proportion of filler < 0.09 m exceeds 10 percent by weight in the case of double

cmshed sand and 5 percent by weight in the case of natural sand. Ifthe content exeeeds the

required maximum values of 10 percent by weight or 5 percent by weight, as appropriate,

the interna] ñller contained in the Sands shall meet the same requirements as an added ñller.

In the ñller tests, the ñller's effect on the water susceptibility of the bituminous bound

mixtures made up with the filler is examined in addition to its granulometric properties. The

x P89 de i *49 221 93467419

3- 2-97 10:00

;BV KALKINDUSTRIE KOELN

le 03/02/97 09:54 94 NOR" Bg: 3/9

+49 221 93467410;# 3/

three-stage test procedure serves to examine the eEect of harmf'ul fmes, particularly of

swelling clays. The first step is a so-called shaking test, similar to the method described in Dutch standard NEN 3982, which serves to examine the stripping of bitumen nom the ñller in the presence of water. If cloudins of water due to liller particles or fall-out of ñller

particles not covered by bitumen occurs, the second-stage test procedure is carried out.

In this second-stage test, the ñller is mixed with a reference aggregate and a reference

bitumen (B 200) into an asphalt. The specimen (Marshall specimen) produced are stored in

waun water at a temperature of40 °C for 48 hours after which their increase in volume and

decrease in stability are measured. If the requirement is met (increase in volume S 1.3

percent by volume), this ñller can be used in bituminous bound mixtures. If the test result exceeds the limit value, the 3rd stage of the test method may be carried out. In this test, an

asphalt is mixed from the basic materials intended for field use (Le. aggregate, bitumen and

ñller) and subjected to the same test as at the an stage of the test.

The test procedure described in the "Engineering test methods for aggregates (TP Min-Stb) , especially the stage II test method, is a practice oriented method for testing and

evaluation of the effect ofharmñll ñnes on the asphalt.

The use ofthe sand mivalent (SE) and mala/Lene blue value (Q) test methods in

Germany

The determination of the sand equivalent is a test method that has been carried out in

Germany for several years and is included in the "Engineering test methods for aggregates

(TP Min) . In Baden-Wuerttemberg and Thuringia, it is used for the evaluation of the lines

contents of unbound mineral aggregates. The use of this method in factory production

control in Baden-Wuerttemberg made it possible to substitute the natural sand 'haction in

unbound mineral mixtures by crushed limestone sand.

The experience in this Federal Land has shown that the suitability ofthe sand equivalent test

method depends on the aggregate type, and therefore there must be reservations as to the reproducibility of results of sand equivalent tests for various aggregates.

As we know ñ'om European Standardisation, the methylene blue test is used in several

European countries for the determination of -swelling clay minerals, i.e. harmful ñnes, in

aggregates. In Germany, this method has first become known for the evaluation of

limestone to be used in portland linnestone cement. German standard DIN 1164, Part 1

"Cement", which incorporates major parts of the European pre-standard for cement,

' speciñes a limit value for the clay content of the limestone as main component. This clay

content is determined with the methylene blue method by methylene blue adsorption. So far,

the cement standard is the 'only technical speciñcation which to my knowledge prescribes

the methylene blue method for the evaluation of lines, especially clay ñnes.

Testa carried out

To get a ñrst idea of the sand equivalent (SE) and methylene blue value (MB) test methods

discussed within the scope of European standardisation, we had 31 double crushed sands of the particle size 0/2 mm tested in the German lime association's test laboratory in

accordance with the draft European methods for aggregates mentional earlier.

The fraction < 0.063 mm of double crushed sands was determined by means of air jet

sieving. To preclude any influence of the quantity of fmes in each crushed sand on the

determination of the methylene blue value, a second test sen'es was carried out to obtain a uniform fmes contents of 10 percent by weight for all double Crushed sands as far as possible.

The results of the test are sununarised in the table "Sand equivalent (SE) and methylene

blue value (MB) of double crushed sands. Both numbers 10/11 and 16/17 stand for a

unwashed and washed double crushed sand ñom the same quarry.

A comparison of the lines contents and the related sand equivalents shows that these

parameters are interrelated. It is obvious that not only the content of tines has an effect on

the order of magnitude of the sand equivalent, but also the type of ñnes, as is shown by a

comparison ofsands with alm08t identical ñnes contents.

There is no clear link between the lines contents of sands and the MB value (figure 2). That

the type of ñnes can have a strong influence becomes evident when comparing sands no. 2

and 8 which have about the same ñnes contents.

A comparison of the MB values determined for the product size and the aggregate with

10 % < 0.063 mm shows that there is interrelationship of the values for the individual

extraction sites or aggregates, as appropriate, that corresponds to the ratio 10 % < 0.063

mm in comparison to the proportion ofthis particle size in the initial aggregate.

A comparison of SE and MB values for the individual sands does not show any close interrelation (figure 3).

The results of this test show that there is a close interrelation of the lines content and the

sand equivalent. There is no clear link between the tines content and the MB value and the

sand equivalent and the MB value. However, the author believes that the methylene blue

method is better suited for the determination of the types of ñnes (i.e. swelling lines) than

the sand equivalent test method.

Conclusion

In Germany, harmful lines in aggregates - especially in crushed sands '- are specified by a

limitation of their ñ'action <0.063 mm or < 0.09 m for ñllcr, as appropriate. The sand

equivalent and methylene blue methods which have been elaborated within the scope of

European standardisation are already used to some extent (SE) in several Federal Laender.

but mainly for unbound mineral mixtures. A more in-depth examination and evaluation of

ñnes by means of the SE and MB test methods, if limit values are not met, is currently not provided for in the pcrtinent national standards and regulations. For this reason, there are

hardly any results for these test methods in Germany. This is also why we are currently not

in a position to give a statement on the impact ofthe harmñtl lines contents, as established

with these methods, on mortars, concrete and bituminous bound mixtures. As show the results of first tests carried out mainly on sands for road construction, it appears necessary

to take into account the aggregate's specific background when evaluating the results. At this

point in time it is not possible to specity generally valid limit values. Funhermore, the

ñndings as to the water susceptibility of ñnes in sands obtained so far in Germany should be

evaluated in concert with the results of the SE and MB value test methods and with field

experience.

To be able to assess the effect of harle lines exceeding the allowable limit values in

Germany, the appropriate field studies and observations should be carried out.

Dipl. -Ing. Hans-JosefRitter

Bundesverband der Deutechen Kalkindustn'e eV., Cologne, Germany

Rt/'a - 3] Jan 1997

m regn de : +49 221 93467410

le 03/02/97 09:54 64 nonn P9: 5/9

3- 2-97 10:00

;BV KALKINDUSTRIE KOELN

+49 221 93467410;# 5,

Testing and evaluation of 112me fines in aggregates in Germany_w

Sand Eduivalent (SE) and Métñylene-Blue-Yalue (MB)

double crushed sand

I

,

I

11:10.

mineral _

< 0,063 mm

SE

MB

product size 0/2

. , 10 % < 0,063

.

I

% by mass

g/kg

' g/kg

A "

B

c

' D

E

15

l Basalt

unwashed

21,2

57,9

1,1

0,7

2 Basalt

unwashed

19,2

50,2

3,3

1,5

3 Basalt

unwashed

20,3

'. 60,5

1,9

1,0

4 Basaltu

unwashed

15,6

57,7

2,7_

1,1

5 Basalt

unwashed

19,2

50,6

2,3

1,2

6 Diabase

_ unwashed

10,8

60,2

0,7

0,6

7 Gabbro _

unwashed

13,6

57,0

1,3

1,0

8 Gabbro

unwashed'

19,0

44,2

0,7

0,6

9

.

13 Porphy'r

unwashed

14 Porphyr

washcd

15 Pomh

.Washed .

.. ..

1:40.31 1 ,-:4._ssågfåi.2.1.52b52.!+klcgw53+ .. . ... . ._ '0.5':.I :4 him.. . . :Ev :i.. _ _ _ . I;39

° '73- "- ' l1 v33 . a i '2.' aug. ' '. .u ,.;.;.;.;=. . .bstn-'h ' öñ'i'21"'i':a*?;?2"61-3532250w.- '§-$.*-$.f:$!z§.;.;°$