:MaLaxel Re+• n,

Will America in the year 2000 have the energy resources to keep its complex society functioning, Much of the country's

intellectual and financial resources are focused on Ansuring

~-·'

~'it'-'=>Y

answe~. "H • 7¥& Iii ..More and more time and money are being spent on the devel -opment of alternative energy sources--nuclear reactors, solar energy, thermal energy. In the meantime, there is increasing' emphasis on more efficient uses of energy, conservation of existing reserves~ we might survive until technology catches up.

Nowhere is this more true than in agriculture. American agri-culture is a highly complex, mechanized industry. It is inex-tricably bound to energy production. Petroleum, natural gas and electricity are needed in every phase of food production, from growing it to distributing it. Dwindlimg energy supplies and a growing world population make it imperative that ways be found to reduce agriculture's demand for energy without reducing food production.

The problem can be seen ... clearly by looking at the sugar

._,,

'.:"'beet industry. The world demand for sugar is steadily increasing. In 1962, the world wanted only 55 million tons of sugar. Ten years later, it wanted 78 million tons. The American sugar beet industry grew to help meet the increase. From 1962-72, this country's beet sugar production rose from 2.7 million tons to almost 4 million. The industry is still growing, and will cer

-tainly continue. But as it grows, it will face constant short-ages of nonrenewable

j.

energy resources. / d; (t,(. t'

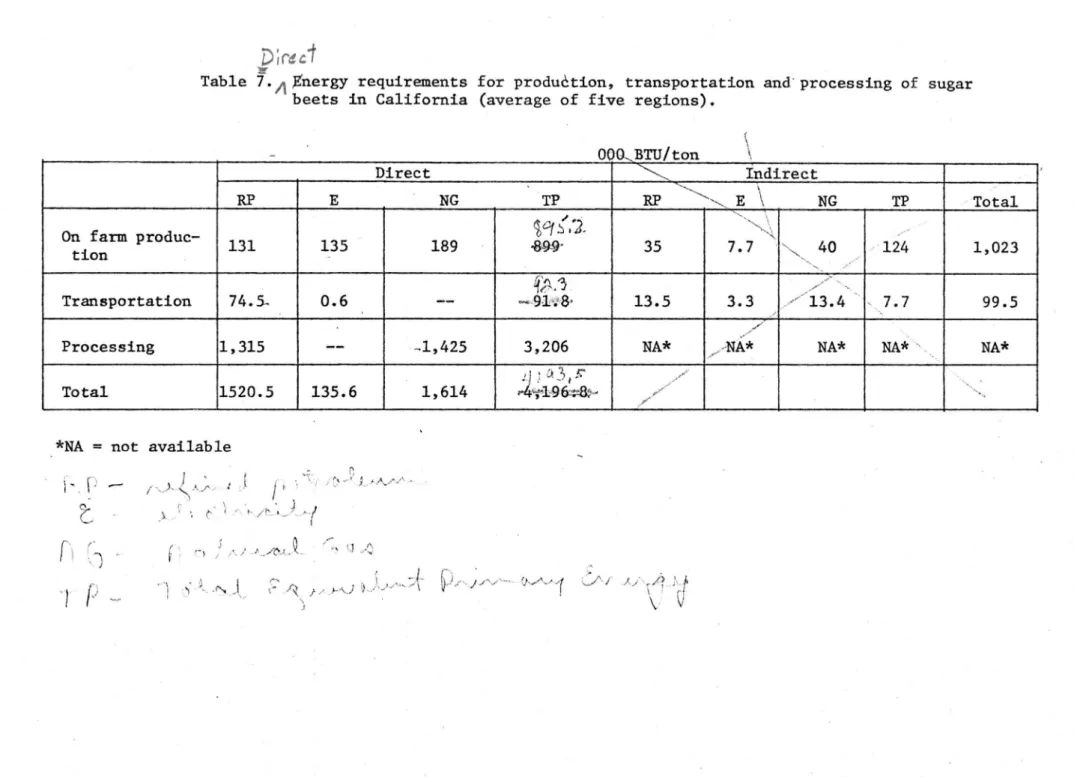

Table • shows the

I\.

amount o needed to produce, trans

-port and process sugar beets., )

,.-t does no,.-t include indirect energy requirements, energy consumed in maintenance, for example, only energy used in the operation of equipment. The "total equivalent primary energy" (TP) accounts for the energy

required by the delivery system--the ener~ needed to produce electricity, for example. The TP is calculated by multiplying each direct energy figure by its corresponding constan, 1.208 for petroleum, 3.78 for electricity

or 1.135 for natural gas. The products are added to arrive at the TP.

L

~ch

ton of beets requires more than 4 million BTU of energy from refined petroleum, natural gas and electricity. But the resources are scarce. At present rates of production, all known petroleum and gas reserves in the United States will be exhausted--gone--by 1987. The situation in the rest of the world is nearly as bad. We have 26 yearsbefore we run out of petroleum, 48 years before natural gas becomes a memory.

How will the industry meet this challenge? Final answers must wait for the development of general energy technology, to

which so much of the sugar

This is especially true

beet production is tied.

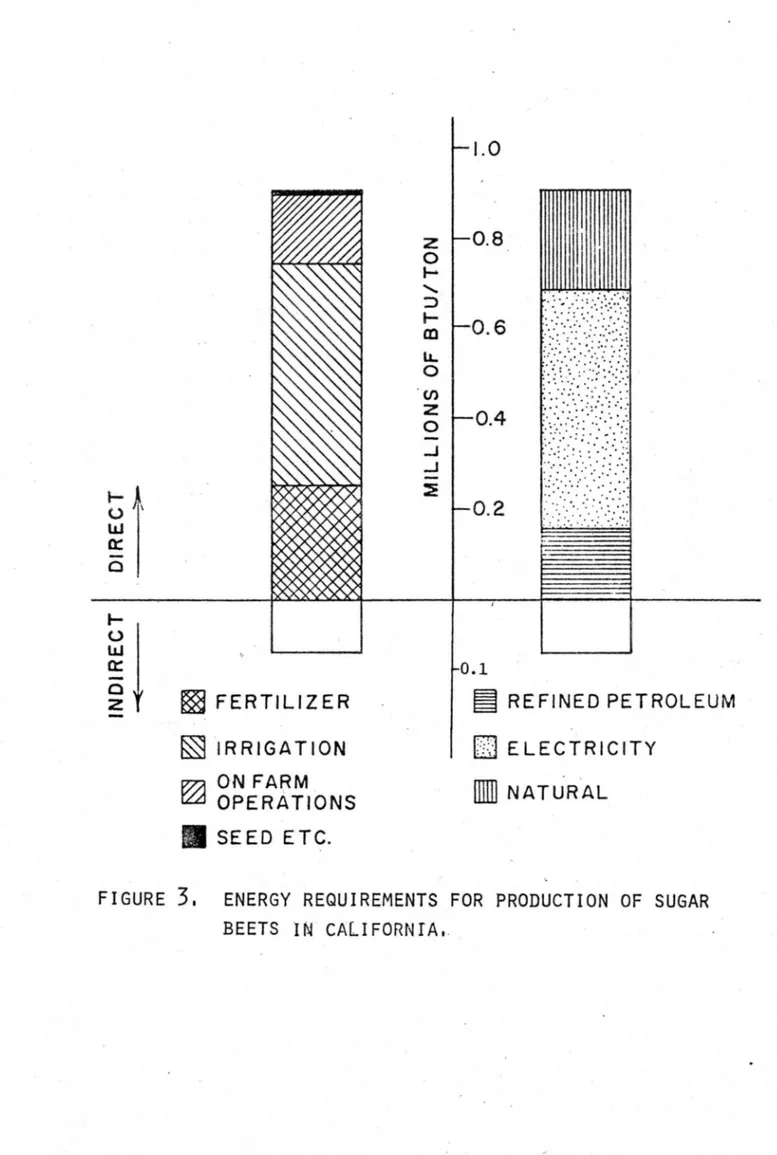

of the sugar'lJeet~ as

"'

: ~

,

'

depicted1

in Figure ~ · For each ton of beets he produces, t h e ~ invests 899,000 BTU of energy, including natural gas used to

~ 6 r al Reswzoe.s

6<t--for various other operations on the farm. Most of the total is in electricity for irrigation. This cannot be replaced by petro-leum, since it would increase both energy consumption and costs.

Nor c a ~ u s e of fertilizers. Nitrogen fertilizer is essential for high yields. So the sugar beet farmer relies heavily on technology that he does not control. There is little he can do about his role in the demand for energy.

The fertilizer industry itself is in a similar situation- -all feasible alternatives to present production methods increase costs and energy consumption.

Taking the sugar:,beets from the field to the processor in-volves a similar situation. While the energy consumed in

trans-d a'r-, cJ t.n u- y

portation is very small--only 2.2 per cent of the tota -the expenditure is vital. The average time lag between harvesting and processing is 24 to 36 hours. To keep this time to a minimum,

the transportation system must be given a high priority in any allotment of energy.

Processing requires by far the most energy, more than 3 mil-lion BTU per ton. This is 76.4 per cent of the total energy requ~ent. About 52 per cent of the energy for processing comes from natural gas. The rest comes from residual and fuel oil.

Sugar beet processors are already somewhat more energy

efficient than many industries. Most of the natural gas is used in boilers that produce both electricity and steam. Many industries

I.A.

use natural gas only for generating steam. This may help s,xgar£_, beet producers in an energy crunch, since they should be given priority over less efficient operations.

And unlike the farmers, the processors have a chance of in-creasing their energy efficiency even more. Dried pulp, a by -product of processing, represents 23 per cent of all the energy

~

they use. Drying the pulp uses about

•,ooo

BTU. This process might be done with solar energy. If this approach is feasible, the processors could save a substantial amount of energy, and reduce their dependence on nonrenewable energy sources.D

i

r

4,

t

~

Table 7./\tnergy requirements for production, transportation and·processing of sugar

beets in California (average of five regions).

-Direct RP E NG farm produc-On 131 135 189 tion -Transportation 74 • .5.. 0.6

--Processing 1,315--

-1,425 Total 1520.5 135.6 1,614*NA= not available

r

-

.

P

t

I ~ 1 •T 9 t r . l , /~ .,.- J ... ···."...,.~·..._,,..,,"i

·-.

)

--·

\

·

'

·..,

·

-

..

I

,

.

" . \ . - ' J ,>.~I ', 1'::' I ,•. ~' / t'-.~-.'~ ,.,( ,. ~-q .. -~ TPiq{

.·2

.

-89~ -fj'I\ ,,qt".

"'

·

- 91'·~·8-· 3,206:2

,l0.

.

\-~

""/tt"96~ ...O()Q... BTU

I

ton\

\~ Indirect \ RP ,...__ E

\

NG TP · Total '-- ~ , , 35 7.7 . '"-... 40 ·124 1,023 "'-, .. ,_,.,,,,,.

,

____ 13.5 3.3,,

/',.,-13.4 ·-, 7.7 99.5 •. / ' _,,,,.,,.NA* ,..,,-NA* NA* NA* ·,_ NA*

,? / ----/ ----/ ' I I-' V, I