Mälardalen University Press Dissertations No. 224

NEAR-INFRARED SPECTROSCOPY AND

EXTRACTIVE PROBE SAMPLING FOR BIOMASS

AND COMBUSTION CHARACTERIZATION

Jan Skvaril 2017

Copyright © Jan Skvaril, 2017 ISBN 978-91-7485-317-9 ISSN 1651-4238

Mälardalen University Press Dissertations No. 224

NEAR-INFRARED SPECTROSCOPY AND EXTRACTIVE PROBE SAMPLING FOR BIOMASS AND COMBUSTION CHARACTERIZATION

Jan Skvaril

Akademisk avhandling

som för avläggande av teknologie doktorsexamen i energi- och miljöteknik vid Akademin för ekonomi, samhälle och teknik kommer att offentligen försvaras onsdagen den 26 april 2017, 09.15 i Pi, Mälardalens högskola, Västerås.

Fakultetsopponent: Professor Anestis Kalfas, Aristotle University of Thessaloniki

Abstract

Biomass is characterized by highly variable properties. It can be converted to more valuable energy forms and products through a variety of conversion processes. This thesis focuses on addressing several important issues related to combustion and pulping.

Experimental investigations were carried out on a biomass-fired industrial fluidized-bed boiler. The observed combustion asymmetry was explained by an imbalance in the fuel feed. Increased levels of carbon monoxide were detected close to boiler walls which contribute significantly to the risk of wall corrosion.

Moreover, extensive literature analysis showed that near-infrared spectroscopy (NIRS) has a great potential to provide property information for heterogeneous feedstocks or products, and to directly monitor processes producing/processing biofuels in real-time. The developed NIRS-based models were able to predict characteristics such as heating value, ash content and glass content. A study focusing on the influence of different spectra acquisition parameters on lignin quantification was carried out. Spectral data acquired on moving woodchips were found to increase the representativeness of the spectral measurements leading to improvements in model performance.

The present thesis demonstrates the potential of developing NIRS-based soft-sensors for characterization of biomass properties. The on-line installation of such sensors in an industrial setting can enable feed-forward process control, diagnostics and optimization.

ISBN 978-91-7485-317-9 ISSN 1651-4238

This thesis is dedicated to my family, my parents Jan and Oldřiška, my sister Hana and my wife Ilaria. Thank you for all the care, inspiration, support and love you have given to me.

Scientia sine conscientia est ruina animæ.

Acknowledgements

This doctoral work was carried out at the Future Energy Center; School of Business, Society and Engineering; Mälardalen University in Västerås, Sweden. It is based on applied research projects which were done in extensive cooperation with several industrial partners.

First and foremost, I would like to sincerely thank my main supervisor Prof. Konstantinos G. Kyprianidis for his invaluable guidance on my research, strict but encouraging leadership and professional advice. It has been a great honor to be one of his PhD students.

I would like to thank to my co-supervisor Prof. Erik Dahlquist for his trust, scientific guidance, inspiring discussions, encouragement and motivation, never ending optimism and for being an inexhaustible source of research ideas.

I would like to express my gratitude and profound appreciation to my co-supervisor Dr. Anders Avelin, for his great kindness, scientific and personal contributions and the wonderful opportunities I received during my PhD studies.

I would like to thank my co-supervisor Dr. Jan Sandberg for all the technical discussions on combustion, heat transfer and steam boilers, and for his friendly and encouraging approach.

I would like to express my gratitude to Mr. Benny Ekman for his kindness and enabling the start of my work in Sweden.

I also thank the reviewers of my work, Prof. Lars Nilsson from Karlstad University and Dr. Ioanna Aslanidou from Mälardalen University, for their constructive suggestions on improving the quality and clarity of my work.

I am very thankful to Mr. Tommy Jönsson, Mr. Thomas Esposito and Mr. Hozan Hajyousef from Sala-Heby Energi for giving me the opportunity to perform experimental work at their combined heat and power plant and for discussions regarding boiler design and operation strategies.

I thank Dr. Nadja Eremina, Mr. Conny Holm and Dr. Anders Nilsson from Bruker Optics Scandinavia for their help and discussions regarding NIR data acquisition and instrumental design and parameters.

I am very thankful to Mr. Lars Månsson and Mr. Örjan Tornberg from Metlab Miljö, Mr. Ivan Andersson from Energi & Miljö Controller, and Mr. Joachim Karlsson and Mr. Oskar Bouvin from AMP Miljöprovning for sharing their knowledge and expertise on boiler emission measurements.

I would like to sincerely thank Prof. Lars Wester for his very valuable suggestions contributing to improvement of my work.

I am indebted to and I thank Mr. Joakim Jansson and Mr. Saywan Jamal for their great material, technical and laboratory support of my experimental works.

I would also like to thank my colleagues from Mälardalen University with whom I had the great opportunity to work: Dr. Monica Odlare, Dr. Hailong Li, Dr. Eva Thorin, Dr. Patrik Klintenberg, Prof. Emma Nehrenheim, Dr. Johan Lindmark, Dr. Sebastian Schwede, Dr. Jesús Zambrano, Dr. Raza Naqvi, Mr. Anders Borg, Mr. Anders Nordstrand and Mrs. Britt-Marie Israelsson.

It is my great pleasure to thank Guilnaz, Alex, Betuel, Federico, Lokman, Nima, Nathan, Anbu, Worrada, Pietro, Ivo, Awais, Eva and Leonard for their friendship, motivation, encouragement and fun moments during my PhD studies.

April, 2017 Västerås, Sweden

Summary

Biomass is an abundant, renewable and carbon-neutral feedstock material. It plays an important role in the modern industrialized world that is characterized by ever-growing energy and material demand, and population growth.

As a feedstock material biomass has highly variable properties which make its use challenging. It can be converted to more valuable energy forms and important end-products through a variety of conversion processes. Biomass conversion is represented mostly by thermo-chemical processes (e.g., combustion and gasification), chemical and biochemical processes (e.g., pulping), and physiochemical processes. This thesis focuses on addressing important issues related to three biomass conversion technologies: combustion, gasification and pulping.

Experimental investigations were carried out on a full-scale biomass-fired bubbling fluidized bed boiler. The results showed that the combustion process is very complicated with high levels of process variability during the course of the experimental campaign. The asymmetric course of combustion reactions was evident and could be explained by the unbalanced fuel feed. Increased levels of unburned carbon monoxide were detected in the vicinity of the boiler walls which increases the risk of carbon-induced wall corrosion.

The near-infrared spectroscopy (NIRS) technique is an optical and non-destructive method able to characterize solid and liquid materials. A literature study was performed covering research trends on applications of NIRS for biomass energy conversion. From the literature examined, it can be seen that NIRS demonstrates an enormous potential to provide fast and reliable property information for heterogeneous feedstocks and end-products. Moreover, NIRS proves its ability to directly monitor processes producing or processing biofuels.

Experimental work, signal processing, and mathematical modeling were performed focused on the utilization of the NIRS technique for measuring different properties of biomass feedstock material. The developed models were able to predict heating value, ash content and moisture content, i.e. characteristics that are fundamental in thermochemical conversion. The investigated biofuel mixtures were consisting of: stem wood chips, forest

residue chips, bark, peat, and sawdust. The NIRS technique was further able to determine the amount of glass in artificial wood/glass mixtures, which is of interest in waste incineration. An experimental NIRS study focusing on the influence of different parameters on lignin quantification was also performed. Spectral data were acquired on moving woodchips as opposed to earlier works that focused on static samples. Models were developed for the prediction of acid soluble and acid insoluble lignin. Data acquisition on moving woodchips was found to increase the representativeness of the spectral measurements leading to improvements in model performance.

Overall, the present work demonstrates the possibility to develop NIRS-based soft-sensors for characterization of biomass properties. The implementation of such sensors on a process line enables feed-forward process control, diagnostics and optimization.

Sammanfattning

Biomassa är en rikligt förekommande, förnybar och koldioxidneutral materialkälla. Detta biologiska material spelar en viktig roll i dagens industria-liserade värld som präglas av både ökande energi- och material efterfrågan och befolkningstillväxt.

Biomassa kännetecknas av mycket varierande egenskaper, och med många utmaningar. Biomassa kan omvandlas både till andra, mer värdefulla energi-former, liksom andra produkter via en mängd olika processer. Omvandling av biomassa representeras främst av termokemiska processer (t.ex. förbränning och förgasning), kemiska and biokemiska processer (t.ex. pappersmassa-tillverkning) och fysiokemiska processer. Denna avhandling fokuserar främst på frågeställningar relaterad till tre omvandlingsprocesser inom biomassa-området: förbränning, förgasning och pappersmassatillverkning.

Experimentella undersökningarna, av förbränningsförlopp, har utförts i en fullskalig biobränsleeldad fluidbäddspanna. Resultaten visade att förbrän-ningsprocessen är mycket komplicerad med stor variation i de studerade parametrarna. Ett asymmetriskt förbränningsförlopp kunde konstateras och kan förklaras främst av en obalanserad bränsletillförsel. Höga nivåer av oförbränt kolmonoxid detekterades i närheten av pannväggarna, vilka bland annat ökar risken för korrosion.

Nära-infraröd spektroskopi (NIRS) tekniken är en optisk och icke-destruktiv metod för att kunna identifiera och karaktärisera fasta och flytande material. En litteraturstudie har genomförts inom forskning och tillämpningar av NIRS tekniken med applikationer inom energiomvandling av biomassa. Från litteraturundersökningen, kan man konstatera att NIRS har en mycket stor potential för att snabbt och tillförlitligt ge information om egenskaper för heterogena råvaror och slutprodukter. Dessutom visar NIRS en förmåga att direkt övervaka processer som producerar eller bearbetar biobränslen.

Ett experimentellt arbete har genomförts som även innefattar, signal- behandling, och matematisk modellering. Syftet med denna studie har varit att med NIRS teknik mäta olika egenskaper hos råmaterial från biomassa. De utvecklade modellerna kan förutsäga värmevärde, askhalt och fuktinnehåll,

dvs. egenskaper som är grundläggande i termokemisk omvandling. De under-sökta biobränsleblandningarna bestod av: stamvedsflis, skogsavfall, bark, torv och sågspån. Med NIRS tekniken kan man också bestämma mängden glas i trä/glas blandningar, som är av intresse vid avfallsförbränning. En experi-mentell NIRS studie med fokus på inverkan av olika parametrar vid lignin kvantifiering har också genomfört. Spektraldata uppmättes på flisblandningar i förflyttning. Detta till skillnad från tidigare arbeten som har fokuserat på statiska prover. Modeller har utvecklats för att kunna förutse syralösliga och icke syralösliga ligninämnen. Datainsamling på träflis i rörelse visade hög representativitet i spektrala mätningar, vilket också ger förutsättningar för modell förbättringar.

Sammantaget visar detta arbete på möjligheter att utveckla en NIRS-baserade ”soft sensor” för karakterisering av biomassans egenskaper. Imple-mentering av denna typ av sensor på en processlinje möjliggör process-förbättringar såsom framkopplad processtyrning, processdiagnostik och process-optimering.

List of papers

Publications included in the Thesis

The doctoral thesis is based on the following articles:

I. Skvaril, J., Kyprianidis, K., Avelin, A., Sandberg, J., & Dahlquist, E. Experimental investigation of part load operation of a full-scale biomass-fired fluidized bed boiler. (submitted to Energy & Fuels). II. Skvaril, J., Avelin, A., Sandberg, J., & Dahlquist, E. (2014). The

experimental study of full-scale biomass-fired bubbling fluidized bed boiler. Energy Procedia, 61, 643-647. doi: 10.1016/j.egypro.2014.11. 1188.

III. Mirmoshtaghi, G., Skvaril, J., Campana, P. E., Li, H., Thorin, E., & Dahlquist, E. (2016). The influence of different parameters on biomass gasification in circulating fluidized bed gasifiers. Energy Conversion

and Management, 126, 110-123. doi: 10.1016/j.enconman.2016.07.

031.

IV. Skvaril, J., Kyprianidis, K., & Dahlquist, E. (2017) Applications of near-infrared spectroscopy in biomass energy conversion processes: A review. Applied Spectroscopy Reviews (epub ahead of print). doi: 10.1080/05704928.2017.1289471.

V. Skvaril, J., Kyprianidis, K., Avelin, A., Odlare, M., & Dahlquist, E. Effect of wood chip moving velocity on NIR spectra acquisition and model calibration for lignin quantification. (submitted to Journal of

Near Infrared Spectroscopy).

VI. Skvaril, J., Kyprianidis, K., Avelin, A., Odlare, M., & Dahlquist, E. (2015). Utilization of Near Infrared (NIR) Spectrometry for Detection of Glass in the Waste-based Fuel. Energy Procedia, 75, 734-741. doi: 10.1016/j.egypro.2015.07.502.

VII. Skvaril, J., Kyprianidis, K., Avelin, A., Odlare, M., & Dahlquist, E. (2016). Fast Determination of Fuel Properties in Solid Biofuel Mixtures by Near Infrared Spectroscopy. Energy Procedia, 2017. doi: 10.1016/j.egypro.2017.03.476.

Authorship contribution in included publications

The author of the thesis designed, planned and executed the experiments, and performed further data processing, analysis, evaluation and writing of Papers

I and II. The author played a significant role in methodology implementation,

performed modeling and model evaluation, and contributed to the writing of

Paper III. The author conducted the extensive literature review and wrote

most of Paper IV, and designed and conducted all the spectroscopy experiments, performed data analysis, signal processing, multivariate modeling, evaluation and writing of Papers V, VI and VII.

Paper III was also included in the PhD thesis of Guilnaz Mirmoshtaghi

(2016): Biomass gasification in fluidized bed gasifiers: Modeling and Simulation. Doctoral thesis, Mälardalen University, School of Business, Society and Engineering, Västerås, Sweden. ISBN 978-91-7485-296-7.

Publications not included in the Thesis

The author also contributed to following related publications which are not included in the present thesis:

I. Kyprianidis, K., & Skvaril, J. (2016). Developments in Combustion

Technology. IN TECH. ISBN 978-953-51-2669-0.

II. Kyprianidis, K., & Skvaril, J. (2017). Developments in Near-Infrared

Spectroscopy. IN TECH. ISBN 978-953-51-3018-5.

III. Moskalík, J., Škvařil, J., Štelcl, O., Baláš, M., & Lisý, M. (2012). Energy recovery from contaminated biomass. Acta Polytechnica, 52. IV. Skvaril, J., Kyprianidis, K., Avelin, A., Odlare, M., & Dahlquist, E.

(2015). Multivariate analysis models for wood properties combined with Open Modelica model for process performance monitoring. IFAC-PapersOnLine, 48, 898-899.

V. Avelin, A., Skvaril, J., Aulin, R., Odlare, M., & Dahlquist, E. (2014). Forest biomass for bioenergy production–comparison of different forest species. Energy Procedia, 61, 1820-1823.

VI. Mirmoshtaghi, G., Skvaril, J., Li, H., Thorin, E., & Dahlquist, E. (2015). Investigation of Most Effective Parameters on Biomass Gasification in Circulating Fluidized bed Gasifiers. Forest and Plant Bioproducts Division 2015-Core Programming Area at the 2015 AIChE Annual Meeting, 189-200.

VII. Skvaril, J., Kyprianidis, K., Avelin, A., Odlare, M., & Dahlquist, E. (2015). Rapid Determination of Selected Compounds in Waste-based Fuel by Near Infrared Spectroscopy. 17th International Conference on Near Infrared Spectroscopy, NIR 2015, Foz do Iguassu-Brazil-18th to 23rd October 2015.

VIII. Skvaril, J., Kyprianidis, K., Avelin, A., Odlare, M., & Dahlquist, E. (2015). Application of Near Infrared Spectroscopy for Rapid Characterization of Feedstock Material in Pulp and Paper Industry. 17th International Conference on Near Infrared Spectroscopy, NIR 2015, Foz do Iguassu-Brazil-18th to 23rd October 2015.

IX. Skvaril, J., Kyprianidis, K., Avelin, A., Odlare, M., & Dahlquist, E. (2015). Fast Determination of Lignin Content in Feedstock Material for Pulping Process Monitoring and Optimization. 8th International Conference on Advanced Vibrational Spectroscopy, 12 July 2015 to 17 July 2015, Vienna University of Technology, Vienna, Austria, 556-557. X. Škvařil, J. (2010). Spalování plynu ze zplyňování biomasy. Energie z biomasy X, 93-97. Vysoké učení technické v Brně. ISBN: 97880-214-4027- 2. (Combustion of low calorific value gas from biomass gasification. Energy from biomass X).

XI. Škvařil, J., Moskalík, J., & Fortelný, Z. (2010). Low Calorific Value Gas Combustion. ERIN 2010, 1-9. ISBN: 978-80-7043-866-4.

XII. Škvařil, J., Moskalík, J., & Štelcl, O. (2010). Spalování kontaminované biomasy a legislativa České republiky. Energie z biomasy XI, 109-114. Vysoké učení technické v Brně. ISBN: 978-80-214-4243-6. (Combustion of contaminated biomass and Czech legislation. Energy from biomass XI).

XIII. Moskalík, J., Škvařil, J., Štelcl, O., Baláš, M., & Lisý, M. (2011). Kontaminovaná biomasa jako palivo. Technika ochrany prostredia 2011 - zbornik prednášok, 313-319. STU Bratislava. ISBN: 978-80-227-3519-3. (Contaminated biomass as a fuel. Technique of Environmental Protection, 2011 - Conference Proceedings).

XIV. Moskalík, J., Škvařil, J., Baláš, M., & Bogdálek, J. (2010). Problémy při měření vlastností tuhých biopaliv. ERIN 2010, 1-7. ISBN: 978-80-7043-866-4. (Difficulties in measuring solid biofuel properties. In ERIN 2010).

XV. Moskalík, J., Škvařil, J., Štelcl, O., Lisý, M., & Baláš, M. (2010). Zplyňování kontaminované biomasy. Energie z biomasy XI, 93-100. Vysoké učení technické v Brně. ISBN: 978-80-214-4243- 6. (Gasification of contaminated biomass. Energy from biomass XI). XVI. Moskalík, J., Škvařil, J., Štelcl, O.; Lisý, M., & Baláš, M. (2011).

Energy usage of contaminated biomass. Acta Metalurgica Slovaca Conference, 2, 145-152. ISSN: 1338-1660.

XVII. Škvařil, J., (2009). Energie z biomasy X: Sborník příspěvků ze semináře. Vysoké učení technické v Brně. (Energy from biomass X: Proceedings of the seminar. Brno University of Technology).

XVIII. Škvařil, J., & Lisý, M. (2010). Energie z biomasy XI: Sborník příspěvků ze semináře. Vysoké učení technické v Brně. (Energy from biomass XI: Proceedings of the seminar. Brno University of Technology).

XIX. Škorpík, J., & Škvařil, J., (2010). Tepelné motory pro energetiku 2010: sborník příspěvků z odborného semináře. Vysoké učení technické v Brně. (Heat engines for power engineering 2010: Proceedings of the expert seminar. Brno University of Technology).

Table of contents

1. Introduction ... 1

Framing the research problem ... 1

Scope and objectives of the thesis ... 5

Research questions ... 5

Contribution to knowledge ... 6

Thesis structure ... 6

Limitations of the work ... 9

2. Literature review ... 10

Biomass conversion processes ... 10

Biomass combustion in steam boilers ... 12

Biomass gasification ... 16

Near-infrared spectroscopy for biomass conversion processes ... 16

2.4.1 Applications of NIRS for biomass characterization ... 17

2.4.2 Spectra acquisition ... 19

3. Methodology ... 21

Suction pyrometry measurements ... 21

3.1.1 Biomass fired bubbling fluidized bed boiler ... 21

3.1.2 Suction pyrometry... 23

3.1.3 Experimental conditions and fuel properties ... 26

Influence of different parameters on biomass gasification ... 28

NIRS for material characterization ... 30

3.3.1 Materials and methods for determination of lignin content in moving wood chips ... 30

3.3.2 Materials and methods for determination of fuel properties in biofuel mixtures ... 33

3.3.3 Materials and methods for determination of glass content in biomass/glass mixtures ... 35

4. Results and discussion ... 37

4.1.1 Temperature distribution and gas concentration profiles –

furnace ... 37

4.1.2 Temperature distribution and gas concentration profiles – flue gas trains ... 45

4.1.3 Effect of bed temperature and bed zone air supply on emissions ... 45

Parameters affecting biomass gasification ... 47

Applied NIRS for material characterization... 51

4.3.1 Determination of lignin content in moving wood chips ... 51

4.3.2 Determination of fuel properties in biofuel mixtures... 60

4.3.3 Determination of glass content in biomass/glass mixtures .... 66

Combining results of the presented works ... 67

5. Summary of the papers ... 68

Paper I. Experimental investigation of part load operation of a full-scale biomass-fired fluidized bed boiler ... 68

Paper II. The experimental study of full-scale biomass-fired bubbling fluidized bed boiler ... 69

Paper III. The influence of different parameters on biomass gasification in circulating fluidized bed gasifiers ... 69

Paper IV. Applications of near-infrared spectroscopy in biomass energy conversion processes: A review ... 70

Paper V. Effect of wood chip moving velocity on NIR spectra acquisition and model calibration for lignin quantification ... 73

Paper VI. Utilization of Near Infrared (NIR) Spectrometry for Detection of Glass in the Waste-based Fuel ... 74

Paper VII. Fast Determination of Fuel Properties in Solid Biofuel Mixtures by Near Infrared Spectroscopy ... 74

6. Conclusions ... 76

Insight into the biomass combustion and gasification processes acquired by using suction pyrometry measurement and multivariate data analysis ... 76

Demonstration of a good ability of near-infrared spectroscopy (NIRS) to characterize materials in biomass conversion processes ... 77

7. Future works ... 79

References ... 80

List of figures

Figure 1. Possible integration of real-time sensor for fuel property

characterization in combustion plants ... 3 Figure 2. Possible integration of real-time sensor for feedstock material

characterization in pulping process ... 4 Figure 3. Thesis outline illustrating relationships between the scope of the

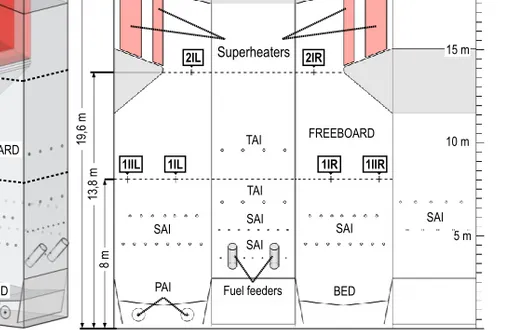

work and papers included in the thesis ... 8 Figure 4. Biomass-fired combined heat and power plant ... 11 Figure 5. Continuous kraft pulping process - pulp and paper plant ... 11 Figure 6. Schematic view of 30.8 MWt bubbling bed boiler: a)

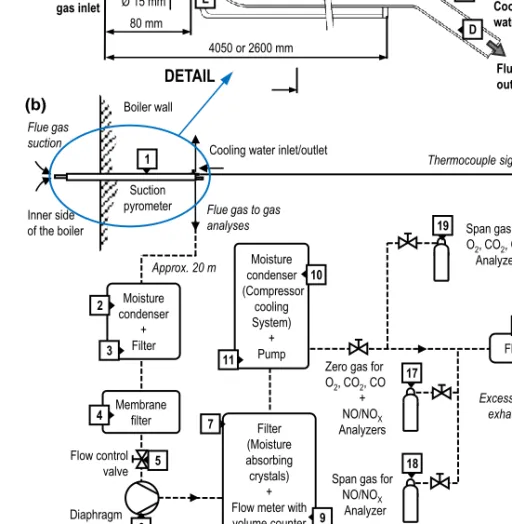

three-dimensional view; b) unfolded view of boiler first pass. ... 22 Figure 7. Experimental system scheme with water-cooled shielded suction

pyrometer ... 25 Figure 8. Spectral acquisition setup ... 31 Figure 9. Resulting temperature and concentration profiles at different

ports in the furnace ... 39 Figure 10. Correlations of temperature and flue gas concentration

measurements ... 43 Figure 11. Correlations of flue gas concentration measurements ... 44 Figure 12. Resulting temperature and concentration profiles in flue gas

trains ... 45 Figure 13. Effect of bed temperature and bed air supply on emissions ... 46 Figure 14. Loadings plots showing correlations between different

parameters: a) PC1 vs PC2; b) PC1 vs PC3; c) PC1 vs PC4. ... 48 Figure 15. Resulting parity plots – independent validation of PLS-R model

predicting gas composition, carbon conversion, heating value and tar and gas yield ... 50 Figure 16. Interferograms acquired at different velocities ... 51 Figure 17. Spectrum with disturbances 7500-4500 cm-1 (1333-2222 nm) ... 53

Figure 18. PLS-R score plots for models developed based on 4 replicated scans (each based on 32 averaged single beam scans) ... 56

Figure 19. Resulting parity plots for best performing models ... 57 Figure 20. Regression coefficients and loading weights for model predicting

content of AIL ... 58 Figure 21. Regression coefficients and loading weights for model predicting

content of ASL ... 59 Figure 22. Parity plots; (a) model predicting moisture content; (b) model

predicting ash content; (c) model predicting higher heating value ... 62 Figure 23. Moisture content predictors; (a) regression coefficients plot; (b)

X loading weights plot ... 63 Figure 24. Ash content predictors; (a) regression coefficients plot; (b) X

loading weights plot ... 64 Figure 25. Higher heating value predictors; (a) regression coefficients plot;

(b) X loading weights plot ... 65 Figure 26. Parity plot - model based on date pretreated by 1st

derivative data ... 66

List of tables

Table 1. Pollutants from biomass combustion [6] ... 13

Table 2. Nominal operating parameters of the 30.8 MWt BFB boiler ... 21

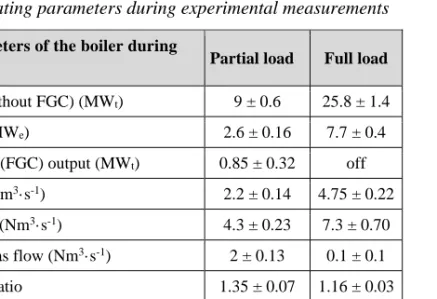

Table 3. Averaged operating parameters during experimental measurements ... 26

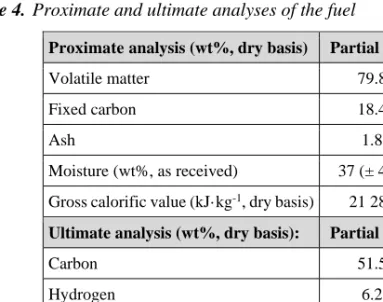

Table 4. Proximate and ultimate analyses of the fuel ... 27

Table 5. Figures of merit – PLS-R model predicting gas composition ... 50

Table 6. RMS mean values for 10 repetitions of single beam spectra ... 54

Table 7. Descriptive statistics of reference data set – lignin content ... 55

Table 8. Descriptive statistics of reference data set – fuel properties ... 61

Table 9. Prediction performance of PLS-R models ... 61

Nomenclature

Abbreviations

1° air Primary air

2° air Secondary air

AIL Acid insoluble lignin

ANN Artificial neural networks

AP Air preheater

ASL Acid soluble lignin

bend. Bending vibration

BFB Bubbling fluidized bed

CFB Circulating fluidized bed

CHP Combined heat and power

def. Deformation vibration

EAR Excess air ratio

ECO Economizer

ER Equivalence ratio

FBC Fluidized bed combustors

FGC Flue gas condenser

FGR Flue gas recirculation

FT-NIR Fourier transform near-infrared

HHV Higher heating value

IR Infrared

MSC Multiplicative scatter (or signal) correction

NIR Near-infrared

NIRS Near-infrared spectroscopy

ot. Overtone

PAHs Polycyclic aromatic hydrocarbons

PCA Principal component analysis PCDDs Polychlorinated dibenzodioxins PCDFs Polychlorinated dibenzofurans

PCR Principle component regression

PLS(-R) Partial least squares regression/ Projection to latent structures RMS Root mean square (statistic expressing spectral repeatability)

RMSE Root mean square error

RMSEC Root mean square error of calibration RMSEP Root mean square error of prediction

RPD Ratio of performance for deviation

SAI Secondary air inlets

str. Stretching vibration

SCR Selective catalytic reduction

S-G Savitzky-Golay

SEmethod Standard error of method

SEC Standard error of calibration SECV Standard error of cross validation

SEL Standard error of laboratory

SNCR Selective non-catalytic reduction

SNV Standard normal variate spectral transformation

SVM Support vector machines

TAI Tertiary air inlets

Symbols

𝐴

𝑟 Relative absorbance𝑏

Regression coefficient𝐼𝑟 Radiation energy (intensity) from the reference 𝐼𝑠 Radiation energy (intensity) from the sample

𝑚 Number of different samples in SEL

𝑛 Number of samples in RMSE

𝑛𝑐𝑣 Number of samples (segments) in cross-validation

𝑛𝑤𝑛 Number of data points (wavenumbers) in RMS

𝑅2 Coefficient of determination

𝑦̂𝑖 Predicted Y value

𝑦̅ Mean of reference Y values

𝑦𝑖1 Analytical value 1 in SEL

𝑦𝑖2 Analytical value 2 in SEL

𝑌𝑖𝑗 Absorbance of the spectrum 𝑗 at the wavenumber 𝑖 in RMS

1. Introduction

This chapter introduces the background of the doctoral thesis and frames the research problem, scope and objectives. The research questions are defined and the contribution of the thesis and papers to the knowledge is highlighted. This chapter also outlines the thesis structure.

Framing the research problem

The member states of the European Union are striving to increase the share of renewable and alternative energy sources in the energy mix. The aim of this effort is to reduce dependence on dwindling fossil fuels and to reduce emissions of CO2 and other greenhouse gases in view of the concern about

global warming. The European Union has therefore created a renewable energy policy with the target of a 20% share of energy from renewable energy sources in gross final energy consumption by 2020 [1].

Among the available renewable energy sources, biomass is considered as the most promising and is in fact the only carbon-based sustainable option to replace fossil fuels. Biomass is CO2 neutral because a growing plant consumes

the same amount of CO2 from the air as is released during its energy

utilization, and consequently there is no contribution of the biomass to the overall CO2 emissions. Furthermore, biomass energy utilization may also

prevent CH4 release to the environment from otherwise landfilled biomass.

Therefore, biomass will play an important role in a world characterized by ever-growing population, energy and material demands.

Biomass is defined as the biodegradable fraction of products, waste and residues of biological origin from agriculture, forestry and related industries, including fisheries and aquaculture, as well as the biodegradable fraction of industrial and municipal waste and agricultural products grown for energy purposes. Many different biomass classification approaches have been proposed in the literature (e.g. [2] and [3]). The classification proposed by Institute for Energy - Joint Research Centre divided biomass into six main groups according to the diversity and similarity of source and origin [4]: (a)

Wood and woody biomass; (b) Herbaceous and agricultural biomass; (c) Aquatic biomass; (d) Animal and human biomass wastes; (e) Contaminated biomass and industrial biomass wastes (semi-biomass); (f) Biomass mixtures.

The diversity of biomass sources and origins implies that biomass has significant physical and chemical diversity. Plant biomass contains cellulose, hemicellulose, lignin and a small amount of other compounds (e.g. lipids, proteins, simple sugar, starches, water and ash). The concentrations of compounds varies depending on species, type of plant, stage of growth and growing conditions [5]. Cellulose is a polymer (C6H10O5)n consisting of a

linear chain of thousands glucose units. It is generally the largest fraction, representing about 40–50 wt% of biomass. Hemicellulose is a group of polymers which contains other sugar derivatives along with glucose (e.g. xylose, mannose, galactose, rhamnose, and arabinose) and represents 20–40 wt% of the overall material. Lignin is a class of complex organic phenolic polymers which occurs in various forms. Wood typically has high lignin content while herbaceous biomass typically has lower lignin content. The most important fuel properties are proximate and ultimate analyses, heating value and ash characteristics. A proximate analysis provides information about fixed carbon, volatiles, moisture content and ash content in the fuel. Ultimate analysis provides elemental percentages of carbon, hydrogen, oxygen, nitrogen, sulfur and chlorine [6].

Biomass can be converted to more valuable energy forms and other important products via a variety of conversion pathways. Biomass conversion processes can be categorized into thermochemical processes (e.g. combustion and gasification), physical processes, biochemical and chemical processes (e.g. pulping), and physiochemical processes [7]. Due to the high variability in biomass properties, the conversion processes face many challenges such as increased emissions, large process instabilities, low or varying final product quality, low conversion efficiency, etc.

Composition and properties of the biomass fuel intended for combustion or gasification has a substantial influence on process performance, formation of environmentally harmful emissions and product gas composition. Biomass-fired power plants have reported issues related to combustion quality. Incomplete combustion can lead to the formation of carbon monoxide (CO), hydrogen cyanides, acid compounds and aromatic hydrocarbons, etc. If the biomass contains high levels of chlorine, highly chlorinated polycyclic compounds such as dioxins and furans may be formed. Moreover, highly corrosive deposits of alkali chlorides and other compounds may be formed on the heat exchangers; this lowers the heat transfer and boiler efficiency and decreases the lifetime of the equipment [8]. Nowadays, control of combustion

quality is based on measurements from flue gas emissions in the stack at the exit of the power plant, which has been shown to be insufficient to address the aforementioned issues.

Furthermore, knowledge of the actual fuel composition of the material fed into the energy conversion unit is limited to direct or indirect continuous moisture content measurements and periodic fuel sampling, which provide the elementary composition. Since the operating conditions of a process unit require continuous regulation, this information is not sufficient for process control and performance optimization, especially when considering the strong heterogeneity of the biomass.

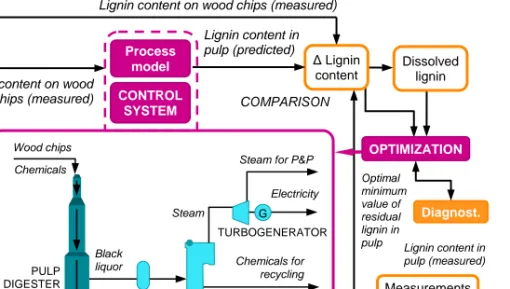

Real-time information about the fuel properties together with data from standard permanently installed process sensors can be used as an input signal to the control system. For this reason, a rapid and non-destructive measurement method for fuel property characterization is needed. Integration of real-time sensors used for feed-forward control in the combustion process is illustrated in Figure 1. This integration will enable the system to react with appropriate operational measures to maintain optimal operation conditions, i.e. high efficiency and low emissions. Similar applications can be suggested for the biomass gasification unit where the product gas composition is of critical importance.

Figure 1. Possible integration of real-time sensor for fuel property

characterization in combustion plants

Moreover, biomass is widely used in chemical conversion applied in the pulping process for production of paper, where its quality as feedstock material plays an important role.

Steam boiler 760 780 800 820 840 0 20 40 60 80 100 120 140 160 Dymola ME 7 Fuel material characterization based on NIRS 0,55 0,6 0,65 0 0,05 0,1 0,15 0 20 40 60 80 100 120 140 160 CO2 H2O SO2 O2 N2(2-axis)

Flue Gas Composition

Flue Gas Temperature Profile

HEAT & POWER

CONTROL SYSTEM Process model

Heat and power

CONTROL SYSTEM Process model OPTIMIZATION Real-time measurement of fuel properties Feedstock material Permanently installed process sensors

Fuel properties (measured)

Fuel properties (measured)

Wood in the form of chips is used as the feedstock material and is transferred to the pulp digester (i.e. the process reactor where the wood is digested) together with chemicals. The digester produces wood pulp, which is further processed resulting in paper as the final product. Most pulp digesters currently in operation are continuous process reactors with significant residence time. The quality of the resulting pulp is affected mostly by cooking conditions, type of wood, physical properties, chemical properties and age of trees, etc. The lignin content and composition are of crucial importance because the pulping process is primarily based on chemical reactions on lignin that is being dissolved. One of the biggest challenges is maintaining a stable operation with limited possibilities to measure and control physical and chemical parameters inside the digester. Hence, there is an urgent demand for a method that continuously determines the characteristics of biomass feedstock that affect the conversion into energy or paper products.

Implementation of real-time measurement used for feed-forward control in the pulping process is illustrated in Figure 2. Information about the feedstock material properties (e.g. lignin content) can be used together with other standard process measurements as an input signal to the control system. The measured amount of lignin in woodchips can be then compared with the measured residual lignin in pulp (e.g. as Kappa number). The process can then be adjusted with appropriate operational measures in order to achieve an optimal minimum value of residual lignin in pulp.

Figure 2. Possible integration of real-time sensor for feedstock material

characterization in pulping process

Feedstock material CONTROL SYSTEM Process model Fiber line Measurements of Kappa number Chemicals Chemicals Pulp Wood chips Black

liquor Chemicals for recycling Electricity RECOVERY BOILER EVAPORATORS Steam PULP DIGESTER

Steam for P&P

TURBOGENERATOR G Lignin content in pulp (predicted) Chemicals Diagnost. Dissolved lignin Optimal minimum value of residual lignin in

pulp Lignin content in pulp (measured) Real-time measurement of lignin content COMPARISON Lignin content on wood chips (measured)

Δ Lignin content

OPTIMIZATION Lignin content on wood

Scope and objectives of the thesis

The overall scope of the thesis is to provide a scientific basis for advanced process control of selected biomass conversion processes which face challenges due to the inherent properties of the feedstock material.

The specific objectives of the thesis are defined based on the motivations described in the previous chapter:

O1: Investigate the temperature distribution and emission formation in the combustion process and influence of different parameters on product gas quality in the gasification process.

Temperature distribution and formation of emissions can be investigated experimentally by extractive probe sampling techniques such as suction pyrometry. Parameters affecting biomass gasification can be investigated by employing multivariate data analysis methods.

O2: Find a fast and non-destructive method suitable for characterization of material flows in biomass conversion processes.

Accurate non-destructive measurements could be achieved by introducing the near-infrared spectroscopy (NIRS) technique, an optical method that enables rapid qualitative and quantitative characterization of solid and liquid materials in material flows and reactors in various processes.

Research questions

In accordance with the scope and objectives, the thesis sets out to address the following research questions:

RQ1: What insight into the biomass combustion and gasification processes can be acquired using suction pyrometry measurements and multivariate data analysis?

RQ2: Does near-infrared spectroscopy demonstrate a good ability for characterization of various materials in biomass conversion processes?

Contribution to knowledge

The main contributions to knowledge provided by doctoral thesis and the appended papers are:

a) Understanding of combustion chemistry and formation of emissions during part load operation of a large-scale biomass-fired fluidized bed boiler, and contribution to operation improvements

b) Enhanced scientific knowledge for operation and control of biomass gasification fluidized bed reactors.

c) Comprehensive classification of past research on near-infrared spectroscopy (NIRS) for biomass energy conversion, including mapping of emerging opportunities.

d) Detailed investigation of the impact of real-life operating conditions on quality of near-infrared spectra acquisition.

e) Best practice development for NIRS multivariate calibrations for lignin content, heating value, ash content and glass content.

The insight gained into biomass conversion processes can be used to optimize the performance of the biomass-fired boiler, using NIRS based soft sensors to control the boiler and profile measurements to correlate permanently installed on-line measurements to real conditions.

Thesis structure

The thesis is divided into seven chapters as follows: Chapter 1 Introduction

The chapter presents formulation of the research problem, scope and objectives of the thesis, research questions and the contribution to knowledge. The chapter also includes the thesis outline to illustrate the relationship between the scope of the work and the included papers.

Chapter 2 Literature review

The chapter presents a brief literature review focusing on biomass conversion processes in general followed by a focus on biomass combustion, gasification and utilization of NIRS for material characterization.

Chapter 3 Methodology

The chapter introduces the materials and methods used for the experimental investigation of the combustion process by suction pyrometry and the gasification process by multivariate data analysis. Furthermore, the chapter also describes materials, experimental methods and mathematical apparatus employed in NIRS material characterization.

Chapter 4 Results and discussion

The chapter discusses the results from the suction pyrometry combustion experiments, multivariate analysis of gasification data and NIRS measurements for feedstock material characterization. The chapter is complemented by a discussion on combining the results of presented works.

Chapter 5 Summary of the papers

The chapter briefly summarizes the included papers. The summarization emphasizes the information in each paper relevant to the research scope and objectives of the thesis. Chapter 6 Conclusions

The chapter summarizes the main conclusions of the thesis in relation to the research questions.

Chapter 7 Future works

The chapter suggests potential future research directions of the work.

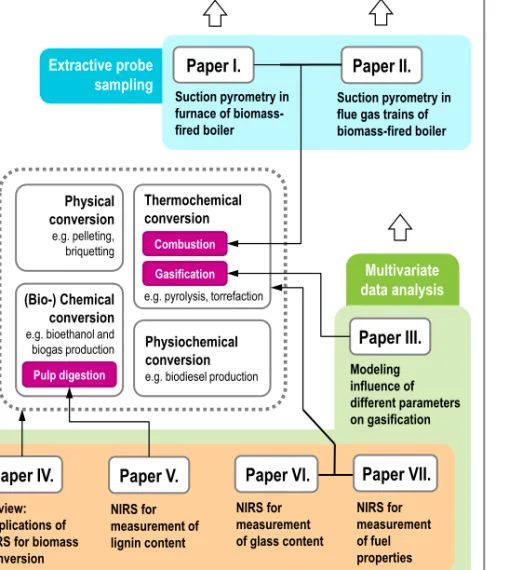

This thesis includes seven scientific papers (Papers I-VII). Figure 3 illustrates the relationships between scope of the work and the papers included in the thesis. The focus of the thesis is on biomass conversion processes, divided into physical, thermochemical, (bio-) chemical and physiochemical conversion.

Paper I and Paper II deal with one the most common biomass conversion

processes, i.e. combustion. Suction pyrometry (i.e. extractive probe sampling technique) is used for experimental investigation in order to address RQ1.

Paper III presents implementation of the multivariate mathematical modeling

approach for system identification of the fluidized bed gasifier while studying the influence of different parameters on gasification. Paper IV presents a review of applications of NIRS for material characterization in all conversion processes and maps future opportunities. Papers V, VI and VII present

development of multivariate mathematical models to enable NIRS for contactless measurements of various parameters of interest, mainly for utilization in thermochemical conversion as well as in (bio-) chemical conversion. Papers IV-VII mostly contribute towards addressing RQ2.

Figure 3. Thesis outline illustrating relationships between the scope of the work

and papers included in the thesis

Multivariate data analysis

Paper IV. Review: Applications of NIRS for biomass conversion NIRS for measurement of lignin content Paper I. Suction pyrometry in furnace of biomass-fired boiler Paper II. Suction pyrometry in flue gas trains of biomass-fired boiler Paper III. Modeling influence of different parameters on gasification Physical conversion e.g. pelleting, briquetting (Bio-) Chemical conversion

e.g. bioethanol and biogas production

Pulp digestion

Thermochemical conversion

e.g. pyrolysis, torrefaction

Gasification Combustion

Physiochemical conversion

e.g. biodiesel production

Paper V.

Biomass

conversion

processes

Extractive probe sampling Near infrared spectroscopy NIRS for measurement of glass content Paper VI.What insight into the biomass combustion and gasification processes can be acquired using suction pyrometry measurements and multivariate data analysis?

RQ1

Does near-infrared spectroscopy demonstrate a good ability for characterization of various materials in biomass conversion processes?

RQ2 Paper VII. NIRS for measurement of fuel properties

Limitations of the work

The presented thesis has the following limitations:

Experimental investigation of biomass combustion in large-scale fluidized bed boiler is limited to measurements of temperature and concentrations of CO, CO2, O2 and NOX gas components.

This work is not primarily focused on ash related issues in biomass combustion such as slagging, sintering, and fouling.

Study of the most influential parameters on gasification is limited to only empirical modelling approach.

Investigation of real-life operating conditions affecting NIR spectra acquisition is limited to addressing the impact of velocity of moving solids in diffuse reflectance mode and changes in ambient humidity.

The developed NIRS models were only validated by using cross-validation. The independent test set validation will have to be done once sensors have been installed in-line/on-line.

2. Literature review

This chapter presents a brief literature review focusing on biomass conversion processes in general followed by a focus on biomass combustion, gasification and utilization of NIRS for material characterization as defined in the research questions.

Biomass conversion processes

As mentioned in the introduction and shown in Figure 3, biomass conversion processes can be categorized into physical processes, thermo-chemical processes, biochemical and chemical processes, and physiochemical processes [7]. Physical biomass conversion processes mostly involve processes where the biomass is compressed to a given form such as pelletization and briquetting [9]. This is done in order to improve the fuel quality parameters of the material, reduce heterogeneity and enable better handling and use in automated combustors. Thermochemical conversion processes [10] include combustion (i.e. complete thermal oxidation of fuel accompanied by large heat release), gasification (i.e. a process that converts fuel to combustible gases such as CO, H2, CO2 and CH4), pyrolysis (i.e. a

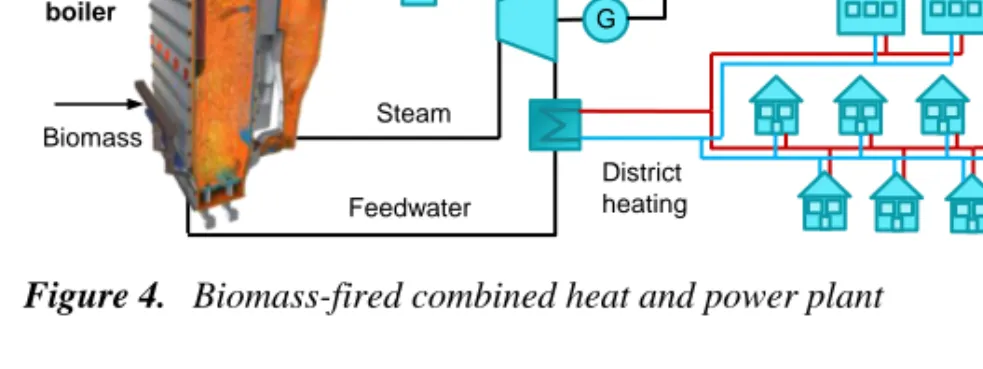

process that thermally decomposes the fuel in the absence of oxygen resulting in charcoal, liquids or gases as products) and torrefaction (i.e. thermal pre-treatment/fuel upgrading of biomass at 200-300°C) [11]. The most widespread thermochemical conversion process is the process of direct biomass combustion in industrial steam boilers employed in combined heat and power plants as illustrated in Figure 4.

11

Figure 4. Biomass-fired combined heat and power plant

Biochemical conversion of biomass employs bacteria, microorganisms and enzymes to decompose biomass into gaseous or liquid fuels (e.g. biogas and bioethanol). The most common types of biochemical processes are anaerobic digestion and fermentation [12].

Chemical conversion of biomass is represented by processes of conversion of a fiber source (e.g. wood, straw, etc.) into pulp, e.g. as in the pulping process (illustrated in Figure 5). Fibrous biomass is cooked in a solution of sodium hydroxide (NaOH) and sodium sulphide (Na2S) (i.e. white liquor) in a pulp

digester. The white liquor disrupts the lignin molecules that bond the fibers together. The liquor and dissolved lignin (i.e. black liquor) are then combusted in the recovery boiler, and the alkaline chemicals are recovered and can be reused. Generated pulp is then treated in several mechanical and chemical steps, resulting in a paper as a final product [13].

Figure 5. Continuous kraft pulping process - pulp and paper plant

Physiochemical biomass conversion processes are mostly represented by biodiesel production. Biodiesel is a renewable and widely used fuel in internal

4 Recovery boiler G Electricity generator Steam to customers Steam Lime Lime kiln

Recycle fiber plant Pulp storage Pulp storage Pulp storage Pulp storage Paper machine White liquor tank Weak liquor tank

Evaporation Black liquor tank

Green liquor tank WL Clarifier Recausticizing plant Washing Bleaching Pulp digester Wood chips + chemicals G Turbogenerator Steam Feedwater Stack Flue gas Electricity District heating Steam boiler Biomass Recovery boiler G Electricity generator Steam to customers Steam Lime Lime kiln

Recycle fiber plant Pulp storage Pulp storage Pulp storage Pulp storage Paper machine White liquor tank Weak liquor tank

Evaporation Black liquor tank

Green liquor tank WL Clarifier Recausticizing plant Washing Bleaching Pulp digester Wood chips + chemicals G Turbogenerator Steam Feedwater Stack Flue gas Electricity District heating Steam boiler Biomass

combustion engines. It is usually produced by chemically reacting fatty acids in vegetable oils, fats, waste oils, etc. with alcohols like methanol or ethanol, producing fatty acid esters [14].

Biomass combustion in steam boilers

The process of biomass combustion involves a number of complex physical/chemical aspects. The combustion process depends on both the fuel properties [5] and the combustion application. The process consists of heterogeneous and homogeneous reactions, and can be divided into: drying, devolatilization, gasification, char combustion, and gas-phase oxidation [15]. The main combustion parameter is the excess air ratio (EAR), which describes the ratio between the locally available combustion air and the stoichiometric amount of combustion air.

Biomass combustion technologies can be classified as: a) fixed bed combustion; b) fluidized bed combustion; c) pulverized bed combustion [16]. The most widely currently used biomass combustion technology is fluidized bed combustion. The fluidized bed consists of a vessel with a perforated bottom plate filled with a bed of inert material (e.g. silica sand). The bed material represents 90–98 % of a mixture with fuel. Inside fluidized bed furnaces, biomass fuel is burned in a mixing suspension of gas and bed material into which primary combustion air is bought from the bottom of the fluidized bed. Depending on the fluidization velocity, the process may be classified as bubbling fluidized bed (BFB) or circulating fluidized bed (CFB) combustion [17].

In BFB furnaces, the bed material (i.e. silica sand) is located in the bottom part of the furnace. The primary air is supplied through a nozzle (i.e. bubble cap) distributor plate from the bottom and fluidizes the bed. The bed material is usually inert sand of about 0.5 to 1.0 mm in diameter. The fluidization velocity of the air varies from 1.0 to 2.0 m·s-1. The secondary air is introduced through several inlets at the beginning of the upper part of the furnace. Overall air ratio can vary between 1.2 and 1.3. The BFB boiler can be operated under stoichiometric bed operation with air ratio about 0.35. Therefore, the bed temperature is low in the range of 650 to 850 °C, and fuels with low melting temperature can be combusted. Boilers can be operated at partial load in the range of 50 to 100 % of the nominal load [18]. Partial load operation is very common for boilers installed as units in combined heat and power plants where the boiler is operated according to demand from the district heating

network and power spot prices. Partial load operation for half of the operational time is not exceptional.

Pollutants from biomass combustion can be classified into two groups [6], as presented in Table 1. The first group comprises of pollutants that result from the combustion process, while the second group contains pollutants from the inorganic species in the biomass fuel.

Table 1. Pollutants from biomass combustion [6]

Origin Pollutant emissions Typical biomass fuels

Pollutants from combustion process

Incomplete combustion

CO, CXHY, tar, PAHs, tar,

unburned char, H2, HCN, NH3 and

N2O

All biomass fuels

Complete combustion

NOX (NO and NO2), CO2, H2O,

N2O

All biomass fuels

Pollutants from inorganic species in biomass fuel

Ash Particulate matter All biomass fuels

Cl a S HCl, SOX, salts (KCl, etc.) Waste wood, straw, grasses, fruit

residues High Cl

fraction PCDDs/PCDFs

Municipal solid waste, waste wood, straw, cereals etc. Heavy metals Pb, Zn, Cd, Cu, Cr, Hg, etc. Urban waste wood, sludge

Carbon monoxide emissions are the result of incomplete combustion. CO formation is usually due to low excess air, low temperature and short residence time. Units that are designed for coal are inappropriate for biomass combustion because of the shorter freeboard. Another cause of CO formation is related to fuel composition. Large fuel particle size and high ash content have been reported to contribute to high CO levels. During combustion, a layer of ash can accumulate around fuel particles and make oxygen diffusion difficult. Heat exchangers in the freeboard can also decrease the temperature too rapidly and inhibit conversion of CO to CO2. CO is considered a good

indicator of the combustion quality [19].

Carbon dioxide is a major product from complete biomass combustion; it originates from the carbon in the fuel. Nevertheless, biomass is considered as CO2 neutral, and this is the main environmental benefit of biomass combustion

[20].

Nitrogen compounds include nitrogen oxide (NO) and nitrogen dioxide (NO2), which are known collectively as NOX. There are three main formation

formation of prompt NOX. Thermal NOX is significant for firing of solid fuels

at high temperatures above 1500 °C. Since the temperatures in fluidized bed boilers are low (usually under 1100 °C) formation of thermal NOX is very rare.

Fluidized bed boilers are usually operated at 800–950 °C and at such temperatures, the formation from fuel nitrogen dominates. Formation of NOX

from fuel bound nitrogen takes place by oxidation of the nitrogenous species released with the volatiles and the oxidation of the nitrogen retained in the char. NO is strongly dominant in comparison to NO2. Nevertheless, NO is

oxidized to NO2 in the flue gas train at low temperature. When combusting

solid biomass, the fuel NOX are formed via two different pathways [21], i.e.

through gas phase oxidation of nitrogenous groups in the volatiles, and through heterogeneously catalyzed oxidation of char bound nitrogen species. Most of the nitrogen is probably in the volatile phase. Nitrogenous volatile species are NH3 and HCN, and their concentrations depend on the

devolatilization and combustion temperature. Formation of NO takes place mostly in the bottom region of the fluidized bed boiler with bottom air injection.

A primary measure to decrease NOx emissions is flue gas recirculation [22], in which primary and secondary air should be injected in geometrically separated furnace sections. Furthermore, air fans should ensure a primary air ratio of 0.6–0.8 in the furnace. The excess of secondary air should be restricted to the minimum amount that allows complete combustion. If NOX reduction

by primary measures is not efficient enough, secondary measures are possible. These are selective catalytic reduction (SCR) implemented by injecting ammonia or urea over a catalyst at about 250–450 °C, and more commonly, selective non-catalytic reduction (SNCR) [23] implemented by injecting ammonia into the furnace at 850–950 °C.

Other issues in biomass combustion such as fouling, slagging, and sintering are related to the ash content and composition [8]. Fouling and slagging are processes that occur when melted ash solidifies on cooler heat exchanging surfaces and forms deposit layers that decrease heat transfer. Sintering occurs in fluidized beds where bed sand particles and ash components form agglomerates, which leads to defluidization and increased formation of emissions, and may result in boiler shutdown. Addressing these issues is however outside the primary scope of this work.

The most critical parameter for consideration in experimental work is temperature and its distribution in the furnace. Temperature is directly or indirectly related to important parameters and processes such as heat transfer, combustion chemistry, production of emissions, material deterioration, etc. For example, low temperatures in the combustion chamber correlate with

incomplete combustion and hence in increased pollutant emissions of CO and unburned hydrocarbons. On the other hand, excessively high temperatures in the combustion chamber can lead to damage of the refractory lining and other equipment inside the boiler, and generation of pollutants such as NOX.

Consequently, knowledge of the temperature distribution is very valuable. Moreover, it is useful to determine the concentration distribution of com-bustion gas species such as O2, CO2, CO, and NOX in order to gain insight into

the combustion chemistry and deeper understanding of pollutant formation mechanisms [6,24].

Industrial steam boilers are commonly equipped with on-line fixed process sensors for measurement of selected parameters. Acquired measurement data are then used for process diagnostics and control purposes. These measure-ments cannot be considered entirely representative since the sensors are installed close to the wall of the furnace or further downstream in the stack, and therefore spatial understanding of the process is limited. Obtaining representative measurements for the internal space of the boiler presents an important challenge.

There is limited available experimental data from full-scale biomass-fired boilers. Vainio et al. [25] present an extensive study on the fate of fuel nitrogen in the bubbling fluidized bed industrial boiler while performing measurements with extractive probes at several levels in the furnace. The measurements are however restricted to only two measured points from a single boiler side in each plane and therefore do not cover the whole profile. Some other thorough experimental works have studied combustion characteristics in full-scale but relatively small (4 and 12 MW) biomass-fired grate boilers [26,27] while measuring complete temperature and concentration profiles at several positions in the boiler. Although there are a few studies available in the public domain that focus on different issues in fluidized bed combustors (FBC), such as pollutant emissions [28], the effect on combustion performance of fuel type [29–31], operating condition optimization [32], the effect of bed material [33], formation [34] and detection of agglomeration [31] and fouling behavior [35], the majority are mostly focused on pilot scale rather than full scale. Furthermore, interesting experimental work on FBC is presented by Chyang et al. [36], who studied the effect of the combustion modes and operating conditions on temperature distribution and CO and NO emissions including effects of bed zone parameters, i.e. bed temperature and local air supply.

Measurement of combustion parameters in a full-scale boiler presents a difficult problem. Studies are often performed with inconsistent combustion measurement techniques. Baukal [24] and Lipták [37] provide an overview of the available techniques and instrumentation for combustion testing. Ballester

and Garcia-Armingol [38] summarize different techniques for monitoring and control, focusing mainly on flame spectroscopy, flame imaging and probing techniques for flue gas analysis and in-furnace measurements.

For custom boiler measurements it is appropriate to use the extractive probe sampling technique (i.e. suction pyrometry) as this technique is well characterized, inexpensive and has reasonable accuracy [39]. The technique is based on rapid extraction of flue gases at high suction rate from specific locations in the boiler by water-cooled probes. On extraction, the gas passes through a temperature sensing element, is rapidly cooled in the probe channels and its composition is subsequently analyzed.

Biomass gasification

Gasification is a thermochemical process which has similar characteristics to combustion and consists of homogenous and heterogeneous reactions. In contrast to combustion however, gasification is only a partial oxidation which takes place at elevated temperatures 700–1000°C [40]. The operating temperature depends on the technology used. The gasification process starts with devolatilization of the fuel. This is followed by combustion of volatiles and other homogeneous reactions between volatile components in the gas phase. These thermochemical reactions are exothermic while the subsequent char gasification is endothermic [41]. The end product of thermochemical biomass gasification is synthesis gas, a gas mixture mostly comprised of CO, H2, CO2 and CH4.

Gasification technologies can be classified as: a) fixed/moving bed gasifiers

(updraft and downdraft); b) fluidized bed gasifiers (BFB and CFB); c) entrained flow gasifiers [16,42]. The CFB is suitable for large-scale biomass

gasification and for production of gas with high heating value.

One of the most important parameters in biomass gasification is the quality of the product gas, which is affected by different parameters such as biomass properties, operating parameters and gasifier design.

Near-infrared spectroscopy for biomass conversion

processes

Non-destructive measurements of biomass feedstock material in biomass conversion processes can be achieved by implementation of the near-infrared spectroscopy (NIRS) technique.

NIRS is an optical method which measures interaction of electromagnetic radiation (i.e. light) in the wavelength range 700 to 2500 nm (i.e. 12,500–4000 cm−1) with matter. Electromagnetic radiation in the NIR region interacts with matter primarily through overtone and combination vibrations which originate in fundamental molecular vibrations in the infrared region. A molecule can absorb energy if the frequency of the electromagnetic radiation is in resonance with specific molecular vibrations [43]. In biomass, electromagnetic radiation interacts with structural molecular groups such as C-H, O-H, N-H, S-H, C=O, C=H and C=C [44].

Chemometrics uses mathematical and statistical methods to provide maximum chemical information from NIR spectra. This is done by applying spectral pre-processing techniques that enhance the interesting information included in the spectrum (i.e. chemical information related to vibration of bonds) followed by development of classification or regression models.

Pre-processing techniques can be divided into two groups: a) scatter

correction methods including multiplicative signal correction (MSC) and its

modifications [45], orthogonal signal correction (OSC) [46], [47], de-trending and standard normal variate (SNV), among others [48]; and b) spectral

derivatives including mostly Savitzky-Golay (S-G) polynomial derivative

filters [49]. Spectral pre-processing is followed by employment of methods for qualitative or quantitative analysis.

Qualitative analysis methods are mostly represented by unsupervised classification methods such as principal component analyses (PCA) and hierarchical clustering analysis (HCA) and supervised classification methods, correlation and distance-based methods (i.e. Euclidean and Mahalanobis distance), linear discriminant analysis (LDA), regularized discriminant analysis (RDA), k-nearest neighbors (KNN), soft independent modelling of class analogy (SIMCA), partial least squares discriminant analysis (PLS-DA), as well as non-linear methods such as artificial neural networks (ANN) and support vector machines (SVM) [50]. Quantitative analysis methods include linear univariate and multivariate methods, i.e. multiple linear regression (MLR), principal component regression (PCR), and most commonly, partial least squares regression (PLS-R) [51,52], as well as non-linear regression methods such as ANN [53] and SVM [54].

2.4.1 Applications of NIRS for biomass characterization

Chadwick et al. [55] presented an extensive review dedicated to infrared techniques for biomass and energy conversion processes. The work focuses on different applications of NIR and IR spectroscopy methods for feedstock

![Table 1. Pollutants from biomass combustion [6]](https://thumb-eu.123doks.com/thumbv2/5dokorg/4880785.133490/37.892.123.613.366.670/table-pollutants-biomass-combustion.webp)