Integration of Digital Twin and Deep

Learning for facilitating Smart

Planning and Construction: An

Exploratory Analysis

Mergen Kor

MASTER THESIS 2021

Master in Product Development with a specialization

SUSTAINABLE BUILDING INFORMATION MANAGEMENT

Product development - Sustainable Building Information Management. The work is a part of the Master of Science with a major Product development, specialization in Sustainable Building Information

Management.

The author takes full responsibility for opinions, conclusions and findings presented.

Examiner: Christoph Merschbrock

Supervisor: Ibrahim Yitmen

Scope: 30 credits (second cycle)

Date: 11/06/21

ADDRESS: School of Engineering, P.O Box 1026, SE-551 11 Jönköping, Sweden

VISIT: Gjuterigatan 5, Campus, Building E

PHONE: +46 (0)36 10 10 00 WEB: www.ju.se

Integration of Digital Twin and Deep Learning for facilitating Smart Planning

and Construction: An Exploratory Analysis

Mergen Kor

Jönköping University, Jönköping 551 11, Sweden kome19vx@ju.se

Abstract. The Architecture, Engineering, and Construction (AEC) industry is known to be overwhelmed with resource planning, risk management, and logistic challenges, resulting in design defects, project delivery delays, cost overruns, and contractual disputes. These challenges have instigated research in the application of advanced machine learning algorithms such as Deep learning (DL) to help with diagnostic and prescriptive analysis of causes and preventive measures. Construction 4.0 develops through continuous innovations towards digitalization and intelligence, in order to realize a considerable boost in automation, productivity, and reliability. The Digital Twins, as the next level of planning and process control and automation towards Construction 4.0, will incorporate cognitive features that enable sensing complex and unpredicted behavior and reason about dynamic strategies for process optimization to support decision-making. However, there is still a lack of awareness regarding the real impact of DT integration, DL, and IoT, all connected to self-learning hybrid models with proactive cognitive capabilities for smart planning and construction. This study investigates the potential integration of DT and DL to facilitate smart planning and construction through an explorative analysis to identify and close this gap. Data were collected from global industry experts in a mixed approach with interviews, focus groups, and a survey focusing on the applicability and interoperability of DL integrated DT with decision-support capabilities for process optimization. Based on the results of quantitative and qualitative analyses, a conceptual model of the framework has been developed. The evaluations support that the DL integrated DT model will incorporate cognitive abilities to detect complex and unpredictable actions and reasoning about dynamic process optimization strategies to support decision-making in smart planning and construction.

Keywords: Digital Twins, Deep Learning, IoT, Decision support, Smart planning and construction, Process optimization, Construction 4.0.

1

Introduction

The architecture, engineering, and construction (AEC) industry is known to be overwhelmed with resource planning, risk management, and logistic challenges, which often result in design defects, project delivery delays, cost overruns, and contractual disputes. These challenges have instigated research in the application of advanced machine learning algorithms such as Deep learning (DL) to help with diagnostic and prescriptive analysis of causes and preventive measures. The AEC industry has shown an unparalleled level of resiliency over the past few years. AEC is a highly competitive industry, and the firms that embrace the latest technologies, specifically during Pandemic period, will position themselves ahead of the competition due to their willingness to take advantage of and adapt to these technologies. During the recent years, companies have been encouraged to adapt to new tools, techniques, processes, and ways of working to keep/increase their projects’ performance [1-3]. As the current pandemic forced the AEC firms forced to plan, design, monitor, and manage their projects remotely, moving to digital transformation has been an accelerator faster than most had planned [4]. Industry 4.0 in the AEC industry has been outlined as “a name for the current trend of automation and data exchange of technologies, including cyber-physical systems CPS), the Internet of things (IoT), cloud computing, cognitive computing and creating the smart industry” [5]. In this context, construction engineering and management are going through constant innovations towards digitalization and more intelligence systems, in order to realize a considerable boost in automation, productivity, and reliability [6].Cyber-physical Systems (CPSs) are defined as a systems which work via understanding the [6].Cyber-physical components by different sensors, automatically transferring the captured data to the cyber components, analyzing these data, and then converting them into required information through cyber processes that can be used to get required decision and actions. An example of CPSs is seen in intelligent building systems. In such a system, components and elements of

building and air conditions constitute the physical resources, and data are collected from sensors of these resources, constituting the cyber part of the system. Often a communication channel is involved in transmitting data used to monitor and control the physical resources. On the cyber side, computations are carried out to maximize the utilization of sources, and a suitable decision is taken, based on which the physical resources are further controlled. CPS comprising interconnected and integrated smart systems can transform the AEC industry and contribute to the development of Construction 4.0. CPS applications are predicted to significantly improve the approach in construction projects that are planned, managed, built, and connected to other autonomous systems [7]. Currently, the processes involved in the design, construction, and operation of built assets are more and more influenced by technologies dealing with value-added monitoring of data from sensor networks, management of this data in secure and resilient storage systems underpinned by semantic models, as well as the simulation and optimization of engineering systems [8].

CPS outlines the ways that different physical systems can combine sensors, communication, computing, and control in a large-scale cyberinfrastructure. On the other hand, Digital Twin (DT) construction is a new engineering model for managing production in construction that leverages data streaming and drives novel capabilities from various site-monitoring technologies. A DT in the AEC industry artificially intelligent functions to provide accurate status information, proactively analyze and optimize ongoing design and planning, and create new services to maximize its value [9]. Researchers in the AEC industry has made several remarkable attempts to keep up with the pace of applying DL [10-13]. The rapid advancement of Graphics Processing Unit (GPU)-accelerated computation techniques and availability of structured and labeled data has contributed to the adoption of DLs within the AEC industry [14].

Although the current level of advancement in enabling technologies and the state-of-the-art applications and implementations of DT in the AEC industry regarding real-time monitoring, performance prediction, and decision-making, there still exist several key knowledge gaps that must be addressed through continued research to make DT more capable, reliable, and practical for real-world applications [15, 16]. Some of these challenges are the cost of having technologies, software, hardware, hiring and training expert employees; lack of fully automated systems, codes, computing, storage, network bandwidth; and lack of rules, policies, securities, and procedures [15]. Despite mature IoT techniques, data loss during the transfer process is still a problem due to various reasons such as software incompatibility and data fading due to external environment interferences, and current simulation methodologies for the built environment are generally not correlated with the real-time environmental data, i.e., building performance simulations are typically carried out based on historical or synthetic data instead of seeding models with current or real conditions in the environment being simulated [17, 18]. The next generation of DT includes not only real-time visualization and prediction to support decision-making but also support automatic feedback and control of the built environment [19].

Based on previous researches, there is still a lack of awareness regarding the real potential impact of DT integration, DL, and IoT, all connected to self-learning hybrid models with proactive cognitive capabilities for smart planning and construction [15, 16, 19, 20]. The purpose of this study is to investigate the potential integration of DT and DL to facilitate smart planning and construction through an explorative analysis to identify and close this gap. In alignment with the study's purpose, mainly three research questions are posed:

i. What constitutes technically (components, characteristics, and requirements) justifiable for a digital platform integrating DT and DL to facilitate smart planning and construction?

ii. How can capacity be developed in order to seize opportunities and overcome constraints on implementing DL integrated DT applications to simulate and optimize planning and construction processes autonomously and collaboratively?

iii. How can this integration of DT and DL become successful in addressing the potential values to be created for the construction companies, engineering consulting firms, facility operators, real estate agents, and owners (clients) when utilizing such a DT model?

The main contribution to the knowledge domain is an insight into the DL integrated DT model that will establish an interoperable functionality and develop typologies of models described for autonomous real-time interpretation and decision-making support of complex building systems development based on cognitive capabilities of DT.

The rest of the paper is structured as follows: Section two depicts the theoretical background involving Smart planning and construction, DT, DL, IoT, and process optimization. In Section three, the applied research method, including a mixed approach of quantitative and qualitative analyses are described. Section 4 presents the findings and

analysis of results. In Section five, discussions on decision support capabilities, integrability enablement, and practical implications are presented. Section six draws the conclusions and recommendations.

2

Theoretical Background

2.1 Smart planning and construction

Construction 4.0 is the process of implementing cyber-physical systems to encourage the digitization of the construction industry with the intention of achieving optimum performance of the sector. Construction 4.0 includes the combination of technology supporting smart construction site, simulation and virtualisation with the intention for ensuring optimum project performance. Construction 4.0 mainly involves three scenarios (1) Physical Domain/Automation referring to the digital end to end engineering integration, considering technologies for the automation of the physical construction environment, (2) Simulations and Modelling referring to modeling and simulation tools for the design, construction, and operation of buildings and infrastructures and (3) Digitalization and Virtualization referring digitalization and virtualization tools for construction planning and design processes [21]. Construction 4.0 will enable construction companies to improve productivity, reduce project delays and cost overruns, manage complexity, and enhance safety, quality, and resource efficiency [22].

2.2 Digital Twin (DT)

DT is a realization of the cyber-physical system for visualization, modeling, simulation, analysis, prediction, and optimization [23, 24]. It incorporates three main components to create a practical loop: a physical entity, a virtual entity, and a data link. There are usually two methods for dynamic mapping in the DT. Data from inspections are obtained in the real world and then moved to the simulated space for an additional review [25-27]. The virtual model performs simulations to acquire optimized predictions to offer prompt solutions that adapt natural processes to the evolving environment [6]. DT integrates historical and real-time data obtained from physical systems with physics-based models and advanced analytics to create digital counterparts with high integrity, awareness, and adaptability to provide predictive services to planning and construction entities. It enhances transparency and feasibility of functions in CPS and facilitates real-time monitoring, simulation, optimization, and control of cyber-physical elements. A DT-based CPS should constantly acquire, integrate, analyze, simulate, and synchronize data across multiple stages of the product life cycle to provide on-demand predictive services to different users in both physical and cyber spaces. The key characteristics and requirements for integration of DT in CPS are ubiquitous connectivity and smart objects, advanced analytics, cooperative decision making, autonomous and rapid model building and updates, and autonomous disturbance handling and resilience control [28]. According to Deng et al. [19], five-level ladder taxonomy was developed to reflect the evolution from BIM to DT. These levels indicate BIM/ Level 1, BIM/Level 2 supported simulations, BIM/Level 3 integrated with IoT, BIM/Level 4 integrated with AI techniques for predictions, and Level 5 – ideal DT. Based on the building life cycle, each level of the ladder taxonomy was divided into different sub-categories focusing on separate research areas allocated into the design stage, construction phase, operation phase, and demolition phase [24]. Therefore, BIM/Level 4+AI illustrates the integration of BIM and AI techniques to enhance decision-making and database predictions; also, Level 5 ideal Digital Twins reflects the interaction and optimization [19].

Boje et al. [8] reviewed BIM literature on construction applications and examined DT uses in adjacent fields to identify differences and to formulate and describe "Digital Twin Construction (CDT)." They proposed the development of a CDT in three generations. The first generation is represented as an improved version of BIM on construction sites up to date; the second generation incorporates semantics, defining CDTs as 'enhanced restricted intelligence monitoring platforms where a common web-language system is deployed to represent the DT with all its integrated IoT devices, thus forming a knowledge base'; and the third generation.' Machine learning, deep learning, data mining, and analysis capabilities are essential to construct a self-reliant, self-updatable, and self-learning DT" [9]. Rausch et al [29] demonstrate how computational algorithms can support digital twins in construction and how these workflows can be used to converge on optimal and heuristic solutions to challenging problems.

2.3 Deep Learning (DL)

DL at the forefront of machine learning (ML) in AI has networks capable of learning unsupervised from unstructured or unlabeled data. Learning at DL can be supervised, semi-supervised, or unsupervised [30]. Systems can be trained to behave with human brain-like thinking, using DL algorithms [7]. DL is part of a broader family of ML methods that have the capability to use raw data and automatically provide the representations required for various applications such as classification, regression, clustering, and pattern recognition. DL is very powerful in discovering complex structures in high-dimensional data. It allows higher levels of abstraction without manual feature engineering, and its high performance has been validated in different domains [28]. There are many applications of DL, particularly within the AEC in areas such as site planning and management. Still, the level of efficiency achievable with the available unlabelled data remains unclear even though DL is good at supporting this kind of data [14].

2.4 Internet of Things (IoT)

According to the definition provided by the International Organization for Standardization (ISO 2018), IoT is "an infrastructure of interconnected objects, people, systems and information resources together with intelligent services to allow them to handle information of the physical and the virtual world and react." Hence IoT is the mixture of physical and virtual states, which carries physical entities such as sensors, actuators, cloud service, communication, and protocols with many specific architectures, to provide a framework and explication for IoT Systems. In recent years, a dramatic expansion in sensor and modern communications has assisted the growth of IoT. An increasing number of devices and sensors are being deployed in construction and industrial sectors such as transportation, security, health, smart building, and automotive. The vision of the Internet of Things is to make things more intelligent and more connected; thus, a variety of technologies are being used to help enhance management efficiency in both the virtual and physical worlds [31].

2.5 Process Optimization

Optimization is decision-making process for pursuing and providing feasible, sustainable solutions to the construction project. By maximizing the anticipated impacts, optimization can make a process completely follow a set of criteria and constraints. At the phase of performing construction activities in a complex site, optimization supports in improved allocation of resources, organizing crews determining layouts of facilities, and making consistent modifications in a reasonable and timely manner. DT involves simulation, prediction, and optimization that are performed in the virtual model by learning data from multiple sources, which can offer instant solutions to manage the realistic process and make it adapt to the changeable environment [6]. In Cognitive Digital Twin and analytics for the process simulation phase, optimization tools will support process optimization through real-time data and Cognitive Digital Twin models. The result of this optimization is applied to make decisions for physical entities controlling [24].

3

Research methodology

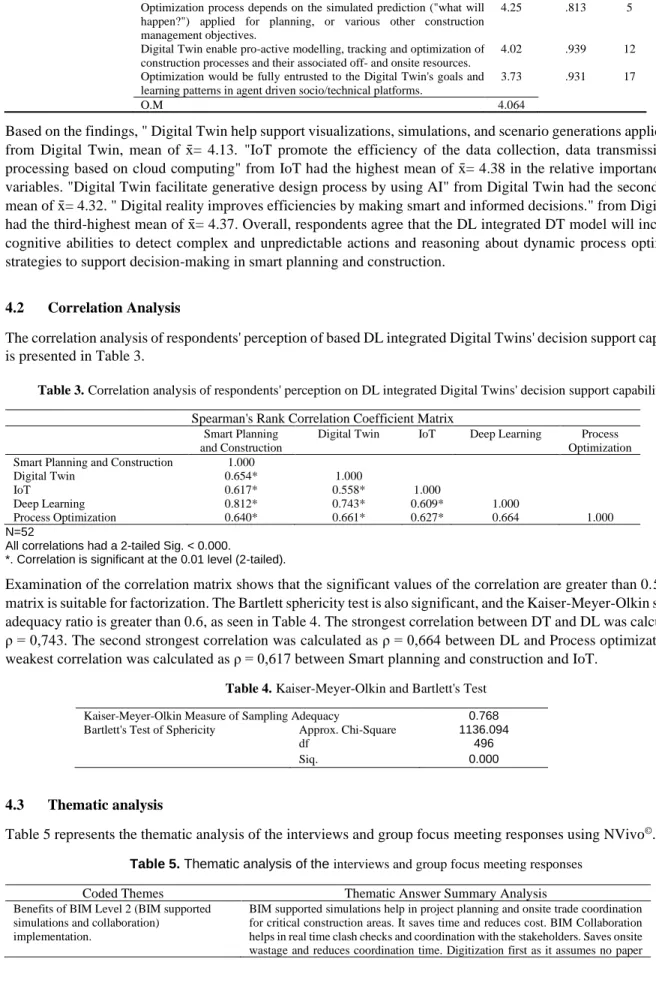

A mixed approach was applied to collect data from global industry experts with interviews, focus groups, and a survey focusing on the applicability and interoperability of DL integrated DT with decision-support capabilities for process optimization. Based on the results of quantitative and qualitative analyses, a conceptual model of the framework has been developed. The research methodology involving three main steps is shown in Figure 1.

Fig. 1. The research methodology.

Data Collection - Interviews - Survey - Focus Group

Empirical Data Analysis - Qualitative

- Quantitative

Framework of DL integrated DT Model for smart planning and construction

3.1 Sampling and data collection

Survey. The survey population included professionals from design firms, project management consulting firms,

contracting firms, and IT firms operating in North America, South America, Europe, Scandinavia, Asia-Pacific, and the Middle East. The sample includes large (>250 employees), medium (50-250 employees), and small (<50 employees) firms. A total of 150 firms were communicated through LinkedIn, and one representative from each was invited to participate in the computerized self-administered questionnaire (CSAQ). The participants were informed of the research objectives as well as of the confidentiality and anonymity of their answers. Fifty-three completed questionnaires were returned, resulting in a response rate of 35 percent. The participants were asked to share information about their current role, expertise, experiences, and the company they work for. To what extent they agree with the items describing their organization's view on the integration of DT and DL for facilitating smart planning and construction statements have been positioned on a five-point Likert scale of 1 (strongly disagree) to 5 (strongly agree). The proportions of firm positions, experiences, sizes, and regions are shown in Table 1.

Table 1. Company region, size, and role in percentage.

Thematic Analysis. Using the qualitative data analysis software NVivo© and a Grounded theory coding approach,

the interview responses and focus group meeting data were analyzed thematically, identifying patterns of themes. An iterative process was followed from disorganized data to a map of the most important themes in the data. Profiles of interviewees and interview details are presented in Table 2. Preliminary codes were assigned to the data in order to describe the content. Themes were searched in the codes across the different interviews and focus group discussions. Afterward, themes were reviewed, defined, and named. The themes defined in interviews were:

i. Benefits of BIM Level 2 (BIM supported simulations and collaboration) implementation. ii. Challenges for the implementation of BIM Level 3 (BIM integrated with IoT)

iii. Integration of IoT and AI agents (data analytics, ML, DL) through semantic models iii. DT promise progressing towards Construction 4.0

iv. Role of AI for prediction and optimization in DT realization v. Challenges in construction process optimization abilities of DT

vi. Achievable level of interoperability between DT and DL towards Construction 4.0 vii. Added value of DT and DT for process optimization in construction.

Firm Type Design Firm Project Management

Firm

Contracting firm IT firm

Role Design

Manager

2% BIM Manager 19% Project Manager 4% Product Manager 4% Design Coordinator 14% BIM Coordinator 8% Construction Manager 8% Platform Developer 6% Project Manager 6% Digitalization Specialist 23% BIM Manager 6% Experience >5 years 2% 15% 0% 0% 5>x>10 years 15% 21% 2% 0% 20<years 8% 10% 17% 10% Company size Large (>250 employees) 4% 21% 6% 0% Medium (50-250 employees) 8% 13% 10% 4% Small (<50 employees) 11% 15% 2% 6%

Region USA and Canada 2% 15% 0% 0%

UK Asia Europe except 2% 19% 2% 2% 10% 21 4% 6% 2% 2% 0% 2% Sweden 0% 2% 2% 6%

Table 2. Profiles of interviewees and interview details.

ID Position Organization Location Interview type*

Interview duration** 1 BIM Specialist IT firm California, USA CSAQ 20 2 BIM Specialist Project Management

Firm

Dubai, UAE CSAQ 20 3 BIM Manager Design firm Vancouver, Canada CSAQ 20 4 BIM Manager Project Management

Firm

Sydney, Australia Online meeting 55 5 BIM Specialist IT firm Tehran, Iran CSAQ 20 6 Project Manager Project Management

Firm

Tehran, Iran CSAQ 20 7 Construction

Manager

Contracting firm Tehran, Iran CSAQ 20 8 Digitalization

specialist

Design Firm Tehran, Iran CSAQ 20 9 Digitalization

specialist

Design Firm Tehran, Iran CSAQ 20 10 Digitalization

specialist

Design Firm Tehran, Iran CSAQ 20 11 Digitalization

specialist

Design Firm Tehran, Iran CSAQ 20 12 Construction

Manager

Contracting firm Tehran, Iran CSAQ 20

Focus Group Meeting. A focus group meeting was organized digitally at House of Digital Twins hosted by Christina

Savian, founder of Digital Twins Club on ClubHouse (

www.houseofdigitaltwins.club

), focusing on an achievable level of interoperability between DT and DL towards Construction 4.0 and what eventual added value of integrating DT and DL are for constructing process optimization in construction. As it shown in Table 3. Guests of professionals ranging from both the manufacturing industry and construction industry participated in the meeting.Table 3. Profiles of focus group meeting and participants' details.

ID Position Organization Location Interview type* Interview duration** 1 BIM Specialist IT firm California, USA Online meeting 75

2 BIM Specialist IT firm SJ, Costa Rica Online meeting 75 3 Design Manager Design firm Sydney, Australia Online meeting 75 4 BIM Manager Project Management

Firm

Sydney, Australia Online meeting 75 5 BIM Manager IT firm DC, USA Online meeting 75 6 BIM Specialist IT firm DC, USA Online meeting 75

4

Findings and analysis of results

The results are broken down into three parts, and a model of the framework is presented. The first two sections present the survey results, while the third section focuses on interviews and focus group meeting outcomes. The fourth section discusses a framework for DL integrated DT model.

4.1 Descriptive statistics

Descriptive statistics reporting the mean values and standard deviations of questionnaire responses are presented in Table 2. The summarized statistics indicate noteworthy understandings as an overview of the industry professionals' perception of the concepts. According to the results, the mean scores for 22 of the 32 questions were higher than 4.00 out of 5.00. The proposed model's overall mean rating was 4.064, which means that industry professionals support approaching DL integrated DT development for process optimization and decision-making purposes and that integrability enablers confirm progression towards Construction 4.0.

Table 4. Descriptive statistics analysis.

Factors/References Questionnaire Statement Mean SD Rank

Smart Planning and Construction [32-35]

BIM Level 2 "BIM supported simulations and collaboration" is implemented as collaborative working and information exchange methods.

4.15 .894 9

Cloud-based Common Data Environment is one of the main challenges for the full implementation of BIM Level 3 "BIM integrated with IoT".

3.88 1.060 14 BIM clash detection and resolution reduce rework and delayed

schedules.

4.25 .947 5

4D BIM planning and scheduling are used for progress monitoring. 3.71 1.289 18 Reality capture technologies are used for automated data collection from

site.

3.71 1.073 18 From 3D point clouds to as-built models are used to revise design and

update the progress of construction.

3.88 1.215 14 Digital reality improves efficiencies by making smart and informed

decisions.

4.37 .841 3

Digital Twin [15, 16, 19, 24, 36]

Digital Twin help to formulate a data-centric mode of smart planning and construction.

4.21 .848 6

Digital Twin facilitate generative design process by using AI. 3.79 1.073 16 Digital Twin help to optimize creativity in design process. 3.85 1.073 15 Digital Twin help support visualizations, simulations, and scenario

generations applications.

4.42 .801 1

Digital Twin leverages the data streaming from a variety of site monitoring technologies and artificially intelligent functions.

4.13 .950 10 Digital Twin provides accurate status information to proactively analyze

and optimize ongoing design, planning, and construction.

4.13 .971 10 A Digital Twin provides real-time and effective decisions based on

well-informed and reliable what-if scenario assessments.

4.27 .910 4

Digital Twin provide long-term feedback for design and planning. 4.23 .942 6 IoT

[37-40]

IoT is included in Digital Twin as connecting the physical and virtual worlds.

4.17 1.004 8 IoT facilitate to integrate and share data by a network of interconnected

physical devices.

4.19 .841 7

IoT promote the efficiency of the data collection, data transmission, data processing based on cloud computing.

4.38 .771 2

IoT solution support real-time data transformation and instantaneous data analysis.

4.25 .860 5

IoT-based sensing systems help feasibly track the progress and monitor the worksite.

3.96 1.102 13 IoT help to automate the real-time decision making. 4.19 .886 8 Deep Learning

[10, 30, 41, 42]

Current challenges promote exploiting the use of Deep Learning in tackling construction problems.

3.87 .950 13 Deep Learning facilitate the huge amount of recorded data to analyzed

and offer actinal insights for better supervision and decision making.

4.02 .918 8

Deep Learning is required to construct a self-reliant, self-updatable and self-learning Digital Twin.

3.96 .928 13 Deep Learning enables autonomous Digital Twin that generates

predictive insights and foster continuous optimization processes.

4.10 .934 11 Deep Learning facilitate to automate generative design process. 3.79 .997 16 Deep Learning support to solve cash flow prediction, onsite safety, and

project risk mitigated analysis in construction

4.06 .873 10 Process Optimization

[42-44]

The simulation, prediction and optimization abilities of a Digital Twin are inter-dependent and act in unison in solving the problems in planning, design, and construction.

4.02 .874 12

Digital Twin facilitate dynamic optimization technologies that enable real-time system reflections and automatic model evolvement with updated data feed.

Optimization process depends on the simulated prediction ("what will happen?") applied for planning, or various other construction management objectives.

4.25 .813 5

Digital Twin enable pro-active modelling, tracking and optimization of construction processes and their associated off- and onsite resources.

4.02 .939 12 Optimization would be fully entrusted to the Digital Twin's goals and

learning patterns in agent driven socio/technical platforms.

3.73 .931 17

O.M 4.064

Based on the findings, " Digital Twin help support visualizations, simulations, and scenario generations applications." from Digital Twin, mean of x̄ = 4.13. "IoT promote the efficiency of the data collection, data transmission, data processing based on cloud computing" from IoT had the highest mean of x̄ = 4.38 in the relative importance of the variables. "Digital Twin facilitate generative design process by using AI" from Digital Twin had the second highest mean of x̄ = 4.32. " Digital reality improves efficiencies by making smart and informed decisions." from Digital Twin had the third-highest mean of x̄ = 4.37. Overall, respondents agree that the DL integrated DT model will incorporate cognitive abilities to detect complex and unpredictable actions and reasoning about dynamic process optimization strategies to support decision-making in smart planning and construction.

4.2 Correlation Analysis

The correlation analysis of respondents' perception of based DL integrated Digital Twins' decision support capabilities is presented in Table 3.

Table 3. Correlation analysis of respondents' perception on DL integrated Digital Twins' decision support capabilities Spearman's Rank Correlation Coefficient Matrix

Smart Planning and Construction

Digital Twin IoT Deep Learning Process Optimization Smart Planning and Construction 1.000

Digital Twin 0.654* 1.000

IoT 0.617* 0.558* 1.000

Deep Learning 0.812* 0.743* 0.609* 1.000

Process Optimization 0.640* 0.661* 0.627* 0.664 1.000

N=52

All correlations had a 2-tailed Sig. < 0.000.

*. Correlation is significant at the 0.01 level (2-tailed).

Examination of the correlation matrix shows that the significant values of the correlation are greater than 0.5, so this matrix is suitable for factorization. The Bartlett sphericity test is also significant, and the Kaiser-Meyer-Olkin sampling adequacy ratio is greater than 0.6, as seen in Table 4. The strongest correlation between DT and DL was calculated as ρ = 0,743. The second strongest correlation was calculated as ρ = 0,664 between DL and Process optimization. The weakest correlation was calculated as ρ = 0,617 between Smart planning and construction and IoT.

Table 4. Kaiser-Meyer-Olkin and Bartlett's Test

Kaiser-Meyer-Olkin Measure of Sampling Adequacy 0.768 Bartlett's Test of Sphericity Approx. Chi-Square 1136.094

df 496

Siq. 0.000

4.3 Thematic analysis

Table 5 represents the thematic analysis of the interviews and group focus meeting responses using NVivo©.

Table 5. Thematic analysis of the interviews and group focus meeting responses Coded Themes Thematic Answer Summary Analysis

Benefits of BIM Level 2 (BIM supported simulations and collaboration)

implementation.

BIM supported simulations help in project planning and onsite trade coordination for critical construction areas. It saves time and reduces cost. BIM Collaboration helps in real time clash checks and coordination with the stakeholders. Saves onsite wastage and reduces coordination time. Digitization first as it assumes no paper

model anymore. Collaboration is easier, but reconciling each party's model can certainly be a challenge.

Challenges for the implementation of BIM Level 3 (BIM integrated with IoT)

Gives the full perspective of the process and brings all the disciplines on the same round. It helps a lot in reducing the clashes that might happen during the construction process.

Integration of IoT and AI agents (data analytics, ML, DL) through semantic models

Specifications or dimensions are set for each object and standards are set for the production, exchange and archiving of information in one package.

DT promise progressing towards Construction 4.0

Involves developing building information in a collaborative 3D environment with data attached, but created in separate discipline models.

Role of AI for prediction and optimization in DT realization

Improving processes and increasing the efficiency of the construction industry in an intelligent environment.

Challenges in construction process optimization abilities of DT

Attaching data in a smart environment. Achievable level of interoperability between

DT and DL towards Construction 4.0

Implementing, improving processes and increasing the efficiency of the construction industry. Discipline in the building design environment.

Added value of DT and DT for process optimization in construction.

Partitioning the data with related parts and optimizing the conclusion.

4.4 Model of framework

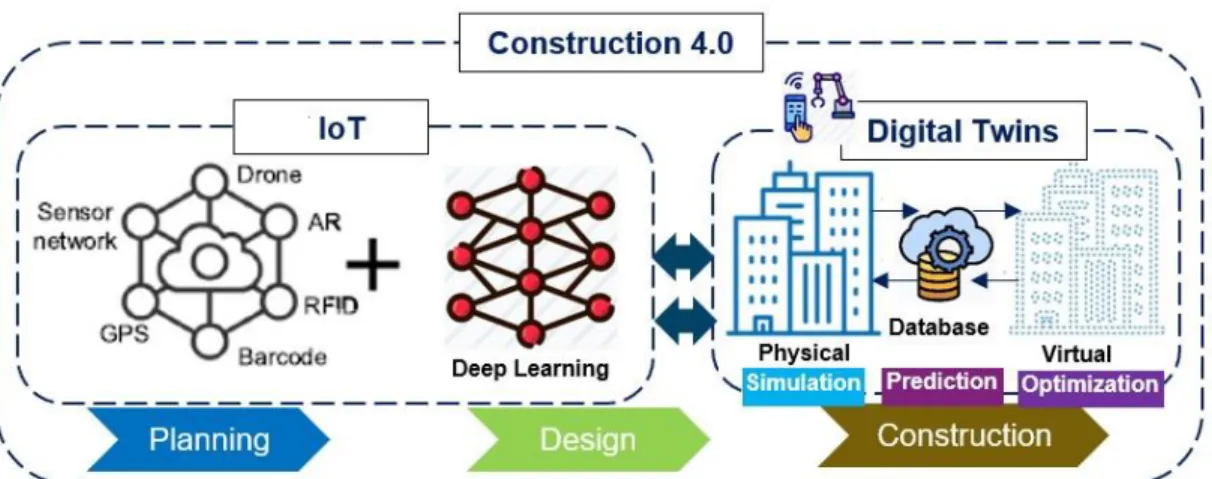

The development of a management system for any practical purpose should be based on understanding the process details. The framework of the DL integrated DT model in different stages of planning, design, and construction is exhibited in Figure 2. The framework model is a step for the next level of DT involving process automation and control towards Construction 4.0 to be implemented for different phases of the project lifecycle (planning-design-construction). DT integration with IoT, DL, and big data is all connected to self-learning hybrid models with proactive cognitive capabilities for smart planning and construction. DL integrated DT model will incorporate cognitive abilities to detect complex and unpredictable actions and reasoning about dynamic process optimization strategies to support decision-making better decisions in real-time through the interplay of the optimization and simulation.

Fig. 2. DL integrated DT model of framework.

5

Discussion

The motivation for this research originated from the novelty of the next level of DT concept to be integrated with DL and leveraged in the construction domain as it has been in other sectors. There are currently insufficient DL applications in DT compared to the applications of other digital technologies like BIM and other machine learning algorithms [14]. This study investigates what constitutes technically (components, characteristics, and requirements) justifiable for a DT platform integrating DT and DL to facilitate smart planning and construction, how the capacity can be developed in order to seize opportunities and overcome constraints on implementing DL integrated DT applications to simulate and optimize planning and construction processes autonomously and collaboratively, and how this integration of DT and DL can become successful addressing the potential values to be created for the construction

companies, engineering consulting firms, facility operators, real estate agents, and owners (clients) when utilizing such a DT model.

The quantitative and qualitative analyses of the data collected from the surveys, interviews, and group focus meetings indicated that DL integrated DT model facilitating smart planning and construction will incorporate cognitive abilities to detect complex and unpredictable actions and reasoning about dynamic process optimization strategies to support decision-making. DL integrated DT model will facilitate semantic-driven detection, learning, prediction, inference, estimation, and decision capabilities consisting of a series of predictive ML models developed using the data from multiple sources, such as physical counterparts and sensors from all aspects in the operational conditions of the industrial systems [24]. DL integrated DT model will enable cognitive abilities, including anomaly detection and behavioral learning during the construction process, and the capability to decide on the actions of physical twin to improve the measures defining its state or function [45].

DT leverages the data streaming from a variety of site monitoring technologies and artificially intelligent functions. IoT promotes the efficiency of data collection, data transmission, data processing based on cloud computing [46]. DT help to formulate a data-centric model of smart planning and construction. DT facilitates the generative design process by using AI. IoT solutions support real-time data transformation and instantaneous data analysis. DT enable pro-active modeling, tracking, and optimization of construction processes and their associated off- and onsite resources. Optimization would be fully entrusted to the DT's goals and learning patterns in agent-driven socio/technical platforms [46].

A DT provides real-time and effective decisions based on well-informed and reliable what-if scenario assessments [6]. DT provides long-term feedback for design and planning. IoT is included in DT as connecting the physical and virtual worlds. IoT facilitates to integration and shares data by a network of interconnected physical devices [46].

6

Conclusions and recommendations

This study presented DL integrated DT model of framework. It arrays processes on how these technologies work collaboratively to manage data and information in AEC projects. The results strongly prove that there is awareness regarding the real impact of DT integration with DL and IoT to resolve previously unknown situations in an efficient way. The benefits to be derived from the introduction of this model of the framework are better decisions in real-time through the interplay of the optimization and simulation during planning and construction.

This study reveals various potential opportunities for future research areas, but it has some limitations as well. A limited number of specialists from different industry sectors restrained the insight of this study's findings. An increased number of samples on a larger scale and response rate are recommended to improve the future study's reliability. Future research recommendations include how to design the system's structure and workflow of a DL and IoT and integrated DT model that can help to automate the real-time decision making at an operational level to remotely control the construction worksite, optimize the project performance, and predict future conditions.

7

References

1. Wang, W., et al., Exploring the adoption of BIM amidst the COVID-19 crisis in China. Building Research & Information, 2021: p. 1-18.

2. Fitria, H., S. Ahmad, and D. Novita, The Effectiveness of Internet-Based Supervision on The Covid 19 Pandemic Situation. Tadbir: Jurnal Studi Manajemen Pendidikan, 2021. 5(1): p. 19-32.

3. Cardno, C.A., Companies Offer Free Tech during COVID-19 Slowdown. Civil Engineering Magazine Archive, 2020. 90(5): p. 40-43.

4. Alizadehsalehi, S., A. Hadavi, and J.C. Huang, From BIM to extended reality in AEC industry. Automation in Construction, 2020. 116: p. 103254.

5. Sawhney, A., M. Riley, and J. Irizarry, Construction 4.0: An innovation platform for the built environment. 2020: Routledge, Taylor & Francis Group.

6. Pan, Y. and L. Zhang, Roles of artificial intelligence in construction engineering and management: A critical review and future trends. Automation in Construction, 2021. 122: p. 103517.

7. Yitmen, I. and S. Alizadehsalehi, Overview of Cyber-Physical Systems and Enabling Technologies in Cognitive Computing for Smart Built Environment, in BIM-enabled Cognitive Computing for Smart Built Environment. CRC Press. p. 1-20.

8. Boje, C., et al., Towards a semantic Construction Digital Twin: Directions for future research. Automation in Construction, 2020. 114: p. 103179.

9. Sacks, R., et al., Construction with digital twin information systems. Data-Centric Engineering, 2020. 1.

10. Hou, L., et al., Deep Learning-Based Applications for Safety Management in the AEC Industry: A Review. Applied Sciences, 2021. 11(2): p. 821.

11. Galanos, T. and A. Chronis, A deep-learning approach to real-time solar radiation prediction, in The Routledge Companion to Artificial Intelligence in Architecture. 2021, Routledge. p. 224-231.

12. Alawadhi, M. and W. Yan, BIM Hyperreality: Data Synthesis Using BIM and Hyperrealistic Rendering for Deep Learning. arXiv preprint arXiv:2105.04103, 2021.

13. Ma, J.W., T. Czerniawski, and F. Leite, Semantic segmentation of point clouds of building interiors with deep learning: Augmenting training datasets with synthetic BIM-based point clouds. Automation in Construction, 2020. 113: p. 103144.

14. Akinosho, T.D., et al., Deep learning in the construction industry: A review of present status and future innovations. Journal of Building Engineering, 2020: p. 101827.

15. Alizadehsalehi, S. and I. Yitmen, Digital twin-based progress monitoring management model through reality capture to extended reality technologies (DRX). Smart and Sustainable Built Environment, 2021.

16. Yitmen, I. and S. Alizadehsalehi, Towards a Digital Twin-based Smart Built Environment, in BIM-enabled Cognitive Computing for Smart Built Environment. CRC Press. p. 21-44.

17. ur Rehman, M.H., et al., The role of big data analytics in industrial Internet of Things. Future Generation Computer Systems, 2019. 99: p. 247-259.

18. Wang, J., et al., Data communication mechanism for greenhouse environment monitoring and control: An agent-based IoT system. Information Processing in Agriculture, 2020. 7(3): p. 444-455.

19. Deng, M., C.C. Menassa, and V.R. Kamat, From BIM to digital twins: A systematic review of the evolution of intelligent building representations in the AEC-FM industry. Journal of Information Technology in Construction (ITcon), 2021. 26(5): p. 58-83.

20. Alshammari, K., T.H. Beach, and Y. Rezgui, Cybersecurity for digital twins in the built environment: current research and future directions. J. Inf. Technol. Constr., 2021. 26: p. 159-173.

21. Munoz-La Rivera, F., et al., Methodological-technological framework for Construction 4.0. Archives of Computational Methods in Engineering, 2021. 28(2): p. 689-711.

22. Craveiroa, F., et al., Additive manufacturing as an enabling technology for digital construction: A perspective on Construction 4.0. sustainable development, 2019. 4: p. 6.

23. Tao, F., et al., Digital twins and cyber–physical systems toward smart manufacturing and industry 4.0: Correlation and comparison. Engineering, 2019. 5(4): p. 653-661.

24. Yitmen, I., et al., An Adapted Model of Cognitive Digital Twins for Building Lifecycle Management. Applied Sciences, 2021. 11(9): p. 4276.

25. Aheleroff, S., et al., Digital twin as a service (DTaaS) in industry 4.0: an architecture reference model. Advanced Engineering Informatics, 2021. 47: p. 101225.

26. Qi, Q., et al., Digital twin service towards smart manufacturing. Procedia Cirp, 2018. 72: p. 237-242.

27. Pan, Y. and L. Zhang, A BIM-data mining integrated digital twin framework for advanced project management. Automation in Construction, 2021. 124: p. 103564.

28. Lee, J., et al., Integration of digital twin and deep learning in cyber‐physical systems: towards smart manufacturing. IET Collaborative Intelligent Manufacturing, 2020. 2(1): p. 34-36.

29. Rausch, C., et al. Computational algorithms for digital twin support in construction. in Construction Research Congress 2020: Computer Applications. 2020. American Society of Civil Engineers Reston, VA.

30. Zhang, S., et al., Deep learning based recommender system: A survey and new perspectives. ACM Computing Surveys (CSUR), 2019. 52(1): p. 1-38.

31. Lin, Y.-C. and W.-F. Cheung, Internet of Things (IoT) and internet enabled physical devices for Construction 4.0, in Construction 4.0. 2020, Routledge. p. 350-369.

32. Li, C., et al., Evaluation system: Evaluation of smart city shareable framework and its applications in China. Sustainability, 2020. 12(7): p. 2957.

33. Wu, Z., Intelligent City Evaluation Indicator Systems in China, in Intelligent City Evaluation System. 2018, Springer. p. 67-85.

34. Kumar, K., The 4th Industrial Revolution. CIGFARO Journal (Chartered Institute of Government Finance Audit and Risk Officers), 2018. 18(3): p. 16-21.

35. Hong, M., et al., Research on the Construction Effect Evaluation System of Smart CBD: A Case Study in Jiangbei New District, Nanjing, China. Advances in Civil Engineering, 2021. 2021.

36. Meža, S., et al., Digital twins and road construction using secondary raw materials. Journal of Advanced Transportation, 2021. 2021.

37. Mahmud, S.H., L. Assan, and R. Islam, Potentials of internet of things (IoT) in malaysian construction industry. Annals of Emerging Technologies in Computing (AETiC), Print ISSN, 2018: p. 2516-0281.

38. Woodhead, R., P. Stephenson, and D. Morrey, Digital construction: From point solutions to IoT ecosystem. Automation in Construction, 2018. 93: p. 35-46.

39. Gamil, Y., et al., Internet of things in construction industry revolution 4.0. Journal of Engineering, Design and Technology, 2020.

40. Oke, A.E. and V.A. Arowoiya, Evaluation of internet of things (IoT) application areas for sustainable construction. Smart and Sustainable Built Environment, 2021.

41. Darko, A., et al., Artificial intelligence in the AEC industry: Scientometric analysis and visualization of research activities. Automation in Construction, 2020. 112: p. 103081.

42. Akanbi, L.A., et al., Deep learning model for Demolition Waste Prediction in a circular economy. Journal of Cleaner Production, 2020. 274: p. 122843.

43. Matar, M., et al., Sustainable construction modelling: a systems engineering approach. Smart and Sustainable Built Environments, 2013: p. 383.

44. Oprach, S., et al., Building the future of the construction industry through artificial intelligence and platform thinking. Digitale Welt, 2019. 3(4): p. 40-44.

45. Eirinakis, P., et al. Enhancing Cognition for Digital Twins. in 2020 IEEE International Conference on Engineering, Technology and Innovation (ICE/ITMC). 2020. IEEE.

46. Turner, C.J., et al., Utilizing Industry 4.0 on the Construction Site: Challenges and Opportunities. IEEE Transactions on Industrial Informatics, 2020. 17(2): p. 746-756.