Evaluating the Environmental

Impact of a Product

RESEARCH WITHIN: Industrial Engineering and Management AUTHOR: Lina Ek & Sanna Ström

SUPERVISOR: David Eriksson

JÖNKÖPING May 2020

Address: Visiting address: Phone number:

Acknowledgements

We would like to take this opportunity to thank everyone who made this final thesis possible. To begin with, a big thank you to ITAB Shop Concept who initially believed in us. Furthermore, a big thank you to ITAB Guidance for making it possible to conduct our investigation at ITAB. Especially, thanks to Henrik Wettegård for all your support and helpfulness.

The warmest and most humble thank you to our supervisor David Eriksson. Thank you for believing in us, we could not have done this without you. Throughout the whole process you have contributed with valuable opinions and advices, as well as encouraged and challenged us to drive the process towards our final goal. Finally, we want to raise your constant commitment to us students, it is admirable.

Jönköping May 2020

Lina Ek Sanna Ström

This thesis has been carried out at the School of Engineering in Jönköping in the subject area Industrial Engineering and Economics, Logistics and Management. The authors take full responsibility for options, conclusions and findings presented.

Examiner: Leif-Magnus Jensen Supervisor: David Eriksson Scope: 15 credits

Abstract

Purpose – The purpose of this research is to investigate how manufacturing

organisations can decrease their environmental impact in the supply chain. To meet the purpose, two research questions were formulated:

1. How can a manufacturing organisation reduce its environmental impact caused by transportation?

2. How can a manufacturing organisation reduce its environmental impact caused by production?

Method – To provide the opportunity to reach a conclusion and to create a basic

understanding of the research area, a literature review was conducted, which formed the basis of the theoretical framework. Through a case study at a manufacturing organisation, interviews and document analyses were used as sources for empirical data. In order to develop solutions and recommendations, collected data and theoretical framework were analysed and discussed.

Findings – The research findings indicate that there are several possible measures to

implement to reduce an organisation's environmental impact in the supply chain. A decisive factor is creating a holistic and fundamental understanding of sustainability and enabling everyone involved to work according a common view and in the same direction. In addition, a requirement to pursue the same goal is that all stakeholders are involved where a prerequisite is a well-functioning internal communication.

Implications – The research did not contribute to any new theories, but through the

research analysis, statements and theories from previous research were strengthened. The research suggests actions that can be used for organisations to reduce their environmental impact, but also to increase the understanding of why actions should be implemented. Society has an important responsibility for motivating and provide conditions for manufacturing organisations to reduce their footprint. This research is considered to lead to an improved environment in the form of lower emission levels where both organisations and the entire community take responsibility for the planet.

Limitations – The case study is designed as a single-case study which, from a validity

perspective, is not considered as advantageous as a multiple case study because the results are difficult to generalize. In order to strengthen the study's reliability, several functional units and / or organisations could have been included in the study.

Keywords – CO2-eq, climate change, cradle-to-grave, environmental impact, footprint, functional unit, green production, LCA, new product development, supply chain, sustainability, sustainable transport.

Contents

1 Introduction ...1

1.1 Background ...1

1.2 Problem Definition ...3

1.3 Purpose and Research Questions ...3

1.4 Delimitations ...4

2 Research Methodology ...6

2.1 Connection between Research Questions and Method ...6

2.2 Research Approach ...6 2.3 Research Design ...7 2.4 Research Process ...7 2.5 Literature Review ...9 2.6 Data Collection ...9 2.6.1 Interviews ...10 2.6.2 Document Analysis ...11 2.7 Data Analysis ...12 2.8 Trustworthiness ...12 3 Theoretical Framework ...14

3.1 Connections between Research Questions and Theory ...14

3.2 Life Cycle Assessment ...15

3.2.1 Stages in a Life Cycle ...15

3.2.2 LCA according to ISO 14040:2006 ...16

3.2.3 Phases of an LCA ...17

3.2.4 Types and extent of an LCA ...18

3.2.5 Key Issues with an LCA ...19

3.3 Classification Climate Change ...20

3.4 Sustainable Transport ...21

3.4.1 Factors to Consider when Choosing Transport Mode ...22

3.4.2 Strategies to Reduce the Environmental Impact of Transport ...23

3.5 Green Production ...23

3.6 New Product Development...24

3.6.1 Developments of New Product Development ...25

4 Empirical data ...28

4.1 Case Company ...28

4.1.1 Situation Assessment in relation to Sustainability ...28

4.1.2 New Product Development ...29

4.2 LCA of Transport and Production ...30

4.2.1 Goal and Scope Definition ...30

4.2.2 Inventory Analysis ...32

4.2.2.2 Climate Change of Production Phase ...33

4.2.3 Impact Assessment ...35

4.2.4 Interpretation...37

4.2.4.1 Identification of Significant Findings ...37

4.2.4.2 Uncertainty Analysis ...40

4.2.5 Conclusions, Limitations and Recommendations from the LCA ...40

4.2.5.1 Conclusions ...41

4.2.5.2 Limitations ...41

4.2.5.3 Recommendations ...41

5 Analysis ...43

5.1 Comparing Findings with Theory ...43

5.2 Answering the Research Questions ...47

6 Discussion and Conclusions ...48

6.1 Discussion of Results ...48 6.2 Discussion of Methodology ...48 6.3 Implications ...50 6.3.1 Theoretical Implications ...50 6.3.2 Practical Implications ...50 6.3.3 Social Implications ...50 6.4 Conclusions ...51 6.5 Recommendations ...52 6.6 Further Research ...53 References ...54

List of Figures

Figure 1.1: Scope and delimitations of the research ...5

Figure 1.2: Delimitation of environmental impact categories ...5

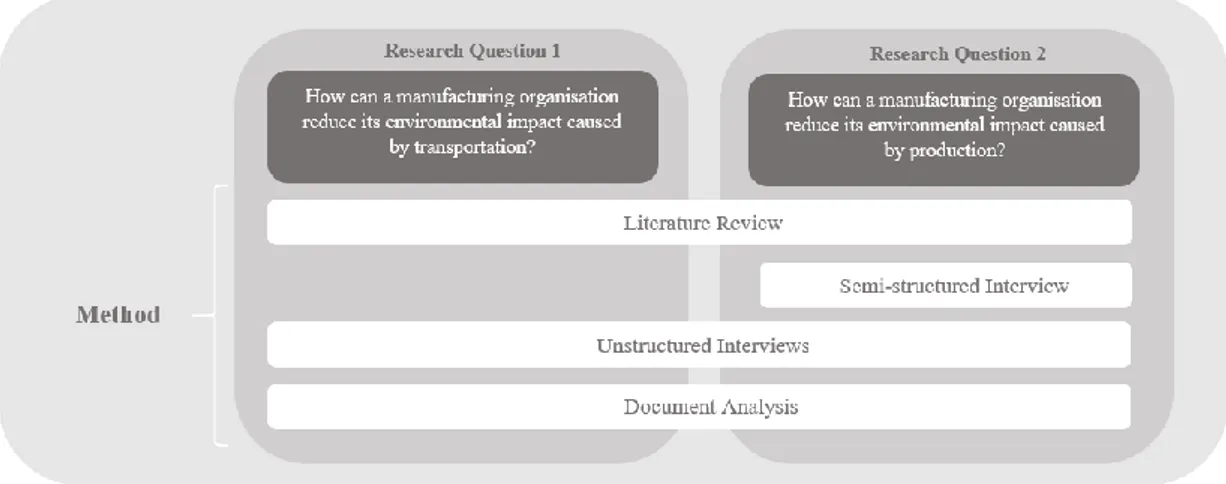

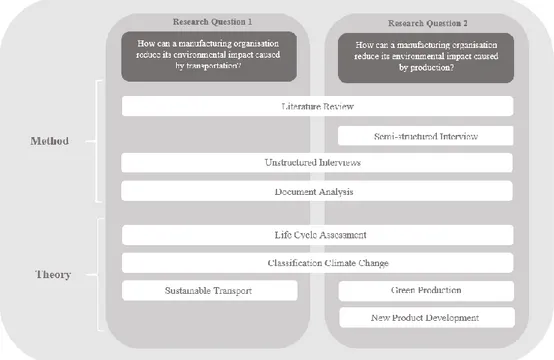

Figure 2.1: Method used for research questions ...6

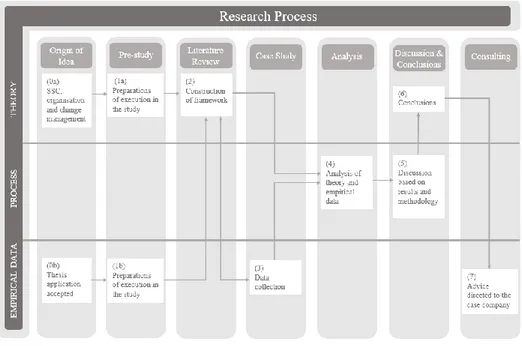

Figure 2.2: Research process ...8

Figure 2.3: The process and implementation of the data analysis ...12

Figure 3.1: Theories used for answering the research questions ...14

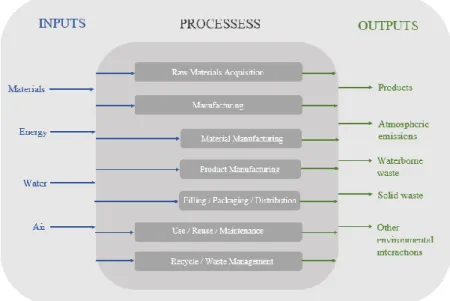

Figure 3.2: Stages in a life-cycle from raw materials to end-of-life ...15

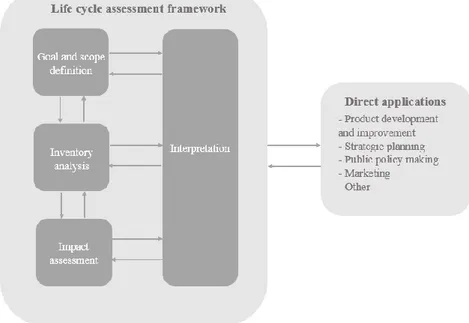

Figure 3.3: Phases in an LCA ...17

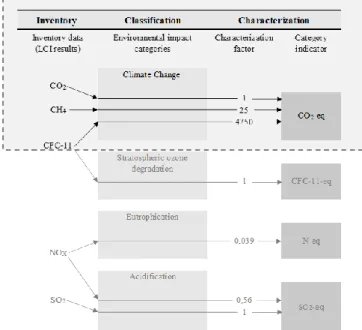

Figure 3.4: Classification climate change. ...20

Figure 3.5: CO2-eq emissions by transport mode ...22

Figure 3.6: 3-D concurrent engineering. ...26

Figure 4.1: Functional unit, SigmaGate ...30

Figure 4.2: Material allocation ...32

Figure 4.3: Emission and allocation of raw materials ...34

Figure 4.4: Emission and allocation of production ...35

Figure 4.5: Emission level and allocation of the phases included* ...35

Figure 4.6: Emission level and allocation of the phases included ** ...36

Figure 4.7: Emission level and allocation of the phases included *** ...36

Figure 4.8: Total emission level and allocation for the phases included in the LCA ...37

Figure 4.9: Comparison of emissions between the company's various modes of transport ....38

Figure 4.10: Comparison of emissions between air and ocean as mode of transport ...39

List of Tables

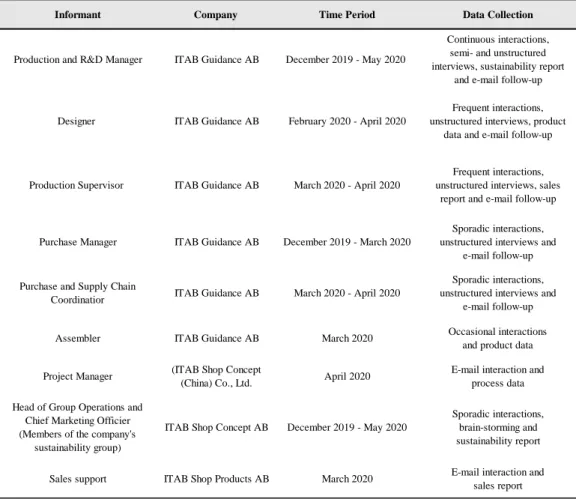

Table 2.1: Literature search with examples of keywords ...9Table 2.2: Summary of data collection ...10

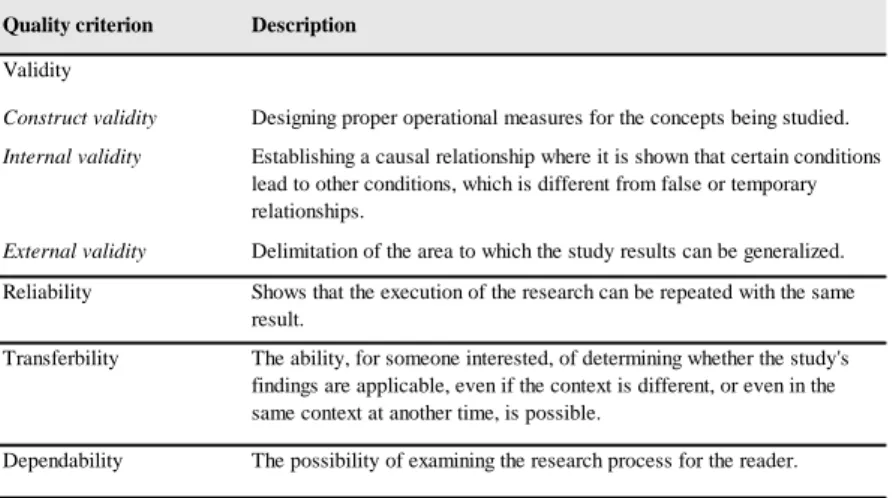

Table 2.3: Quality criterion described ...13

Table 3.1: Different extent of an LCA methodology depending on the purpose ...19

Table 3.2: Factors to consider when choosing transport mode...22

Table 4.1: System boundary ...31

Table 4.2: Data requirements ...32

Table 4.3: Total emission level for the phases included in the LCA ...37

Table 6.1: Quality criterion and application ...49

List of Appendices

Appendix A: Interview questions: Production and R&D manager Appendix B: Product structure, SigmaGate

Appendix C: Components, SigmaGate (excluded packaging) Appendix D: Emission level supply

Appendix E: Emission level distribution Appendix F: Processes

Introduction

1

Introduction

In this chapter, background and problem definition of the research are introduced with main focus on sustainability in supply chains. The importance of manufacturing organisations understanding their environmental impact and how they can take action to reduce global warming are also introduced. The purpose and research questions of the study are then presented followed by delimitations.

1.1 Background

Over the next coming years sustainability will be one of the leading trends. Industries need to change towards circularity, need to make sustainable choices and must increasingly reduce the internal and external environmental footprints of their operations (Naidoo & Gasparatos, 2018). To meet new challenges and trends, organisations must constantly change and find new solutions (e.g. Eriksson & Hilletofth, 2011). However, it is challenging for organisations to implement sustainability in their supply chain, as it requires manpower, effort, and knowledge. Accordingly, small companies often have limited resources required to implement sustainability.

Sustainability has become a global corporate mandate. With the recognition that global supply chains have a great impact on sustainability, “greening” the entire supply chain is required (Sanders, Boone, Ganeshan, & Wood, 2019). Organisations that choose to develop a sustainability strategy will be at the forefront in the transformation towards a more sustainable supply chain, while those who use a "wait and see" method run the risk of falling behind and losing stakeholders (Naidoo & Gasparatos, 2018).

Bentahar and Benzidia (2018, p. 202) define a sustainable supply chain as:

The integration of economic, environmental, and social dimensions into the management of intra- and inter-organisational flows, through innovative and collaborative approaches, with the objective

of creating sustainable value.

Min, Zacharia and Smith (2019) state that global supply chains are seen as strategic assets and sources of competitive advantage. Due to the intensive globalization of supply chains, where the raw material can cross the globe several times before the final product reaches its end customer (Wood, Stadler, Simas, Bulavskaya, Giljun, Lutter & Tukker, 2018), it is important to understand the contribution of emissions caused by international transport in the dynamic of the total footprint for final consumption (Hu, Wood, Tukker, Boonman, & de Boer, 2019). It is crucial for organisations to consider possible choices to face the future and participate in the development towards the change to a more sustainable supply chain.

The current population and economic growth in the world have been linked to increases in carbon dioxide (CO2) emissions. Asia accounts for more than 40 percent of the total

current global CO2 emissions, where China is the country with highest global emissions

level. China is also known to have generated 28.7 percent of global CO2 emissions in

Introduction

CO2 emissions and will play an important role in estimating and reducing emissions for

minor climate change (Yoshizaki, Yamada, Itsubo, & Inoue, 2016).

Kokubu, Itsubo, Nakajima and Yamada (2012) assert that for the industrial sector, it is important to estimate and visualize the reduction of CO2 emissions for the entire supply

chain to develop global low-carbon supply chain. Sustainable production amount to the efficient use of resources, services that are necessary for supply and the reduced impact of critical chemicals. Such efficiency improvements would mean environmental benefits, but also social and economic benefits such as increased competitiveness, business development in a global market and improved quality of life. One of the UN's global goals for sustainable development is to promote sustainable consumption and production patterns. By 2030, a milestone is to ensure that people around the globe have the information and awareness needed for sustainable development and lifestyle in harmony with nature (Regeringskansliet, 2015). Sustainable production processes are thus a prerequisite for “greening” the entire supply chain.

To quantitatively estimate and visualize CO2 emissions, life cycle assessment (LCA) is

an advantageous tool to use (Klöpffer, 1997; Rebitzer et al., 2004). LCA is a structured framework and tool used to identify sustainable choices in the supply chain with consideration for environmental impacts (Ibn-Mohammed, Greenough, Taylor, Ozawa-Meida & Acquaye, 2013; Hellweg & Canals, 2014). The method relates to environmental aspects and potential environmental impact throughout a product's entire life cycle, from cradle-to-grave (Swedish Standards Institute, 2006). In 1993, a standardization process was started for LCA by the International Organization for Standardization (ISO), which resulted in a common framework and fundamental principles. In the beginning of the 21st century, the standard was developed and updated to the current version ISO 14040:2006 (Hauschild & Huijbregts, 2015). When applying an LCA, there is an aim for environmental improvements, which is also in focus of the ISO 14000 series. The series contains international standardizations where an LCA is based on the requirements of ISO 14040:2006 and 14044:2006 (Swedish Standards Institute, 2006).

The LCA method is commonly used for the evaluation of environmental impacts throughout the supply chain in an activity, product, or process (Ibn-Mohammed et al., 2013; Hellweg & Canals, 2014). In previous research, the production, disposal, or transport phase have been shown to contribute with the main environmental impact (Ibn-Mohammed, Koh, Reaney, Acquaye, Wang, Taylor & Genovese, 2016; Guinée et al., 2011). Smith, Ibn-Mohammed, Koh and Reaney (2019) mean that there is no doubt that it is the manufacturing organisations that are responsible for reducing the carbon footprint of the product.

Luthra, Garg and Haleem (2016) state that organisations nowadays work hard to maintain and improve their sustainability through various strategies, such as environmental management systems, environmental efficiency, and green production. Environmental awareness is growing all over the world, consumers’ demands are increasing, and organisations are facing severe pressure to reduce emissions throughout the supply chain. As mentioned, “greening” the supply chain has been identified as a crucial element in encouraging organisational sustainability. There are different ways of dealing with environmental issues, where one is to work with new product development.

Introduction

As mentioned, transport and production are the two major phases in the supply chain that contribute to the greatest environmental impact. As the world's population continues to rise, the environmental burden for these phases will grow. In order to reduce the environmental impact, organisations need to identify and evaluate the environmental impact of the systems in which they are involved.

1.2 Problem Definition

The world's population continues to grow and as more and more complex products and systems, that increase people’s quality of life, are developed the environmental burden will continue to increase. Organisations must counteract this development with sustainability principles in order to constantly evolving products and services with an optimal balance between increased quality of life and environmental impact (Smith, Ibn-Mohammed, Koh, & Reanny, 2019).

To be able to develop sustainability principles within an organisation, transport and production are two stages that should be analysed since these are the ones that contributes with most emissions in the supply chain. Hu, Wood, Tukker, Boonman and de Boer (2019) state that transport might be one of the more difficult sources of emissions to deal with. Although there are possibilities available such as electrification of road vehicle fleets, air transport and long-distance freight transport are more challenging due to a higher dependence on fossil fuels. Countless manufacturing organisations use a global supply chain and it is therefore difficult to avoid material crossing the globe several times.

Production is also a major part of the supply chain in a manufacturing organisation and is also an important part of an LCA. The first, and most important, step in an LCA for the organisation is to provide a deep understanding of the materials and energy input, as well as other related resources required to manufacture the product or system that is being considered (Smith et al., 2019).

At the same time as the trend towards a more sustainable supply chain is increasing, the demand for lean, fast and profitable new product development has never been greater. Product life cycles are shorter, customers are more demanding and competition is more intense. Organisations that are not successful in their innovations are facing a bleak future. The challenge with new product development is that it is not easy to be profitable and competitive. Research has shown that leading companies have improved their product development processes and included critical success factors, in form of a stage-gate new product development process (Stage-Gate International, n.d).

It is inevitable that transport and production will contribute to the consumption of energy and emissions. The European Commission (2015) believes that organisations need to change their behaviour. It is essential to create more value with fewer resources, at a lower cost and with the least possible environmental impact. Simply, produce more with less.

1.3 Purpose and Research Questions

As stated in the background and the problem definition, sustainability is one of the leading trends and is becoming a great competitiveness. Naidoo and Gasparatos (2018) believe that organisations run the risk of falling behind in the transformation towards a more sustainable supply chain when using a "wait-and-see" approach. Furthermore, it is of great importance for organisations to understand their environmental impact in

Introduction

order to reduce their global environmental impact. Thus, the purpose of this research is to:

Investigate how manufacturing organisations can decrease their environmental impact in the supply chain.

While the purpose is to investigate on how manufacturing organisations can decrease their environmental impact caused by their supply chain, it necessitates that they first understand their environmental impact. To create an understanding of the organisation's environmental impact, an LCA can be implemented. An LCA provides a comprehensive picture of the total environmental impact during a product's life cycle, which includes production and transport. Moreover, the thesis will primarily focus on organisations that are not yet as mature in their sustainability efforts. The research will be operationalized through two research questions. The questions were formulated to achieve an understanding of the extent to which a manufacturing organisation’s transport and production emissions affect the environment. Thus, the questions are:

1. How can a manufacturing organisation reduce its environmental impact caused by transportation?

2. How can a manufacturing organisation reduce its environmental impact caused by production?

While the research questions are focused on identifying how to reduce emissions and environmental impact, the first step is to deal with current emissions as well as to investigate the conditions of producing sustainably. A case study will be carried out in a manufacturing organisation in Sweden with most of the production in China.

1.4 Delimitations

This research will examine the importance of creating an understanding of organisations environmental impact, both how an understanding can become a competitive advantage but also to meet future challenges and trends. The delimitations drawn are aimed at reducing complexity and scope.

A product's life cycle consists of different phases, from raw materials to end-of-life. The two phases that contribute to the main environmental impact are transport and production and the study is therefore limited to these phases (Figure 1.1). The study seeks to help manufacturing organisations understand their environmental impact. Manufacturing organisations have the opportunity to make environmentally conscious choices, such as choice of materials. Since the focus is on transport and production, the research does not include energy consumption for the customer's use of the product, nor does it include recycling or disposal. The main focus is not on the emissions that come from the extraction of raw material, but it is included in the research because examination of the production phase requires information on the constituent raw material.

Introduction

Figure 1.1: Scope and delimitations of the research

Production and transportation of goods contributes to environmental emissions, which in turn contributes to global warming (Naturskyddsföreningen, 2020). Transport contributes to wear on roads and emissions of sulphur dioxide (SO2). It also wears on tires which is made of rubber and therefore leads to plastics in nature and ocean. In production, energy consumption is linked to the use of electricity and water. Understanding the organisation's environmental impact is endless work (Grant, Trautrims, & Wong, 2017). Due to the complexity and comprehensively of understanding the environmental impact, the emissions that come from production and transport are in this study limited to carbon dioxide equivalent (CO2-eq) emissions (Figure 1.2).

Figure 1.2: Delimitation of environmental impact categories, modified from (Wendin, 2019,

p. 21)

CO2-eq was considered most relevant since it is the largest source of emissions with a negative environmental impact (Naturskyddsföreningen, 2020).

Research Methodology

2 Research Methodology

The aim of this chapter is to create an understanding of the researcher’s assumptions about methods and provides an overall description of the research process. The following chapter is important to establish an understanding for the reader about how the research was conducted and the reason why the approach was chosen. It is also important for the reader to be able to determine trustworthiness of the study. First, a summary of the connection between research questions and method is introduced. Furthermore, the research approach, design and steps in the research process are presented in chronological order. The chapter concludes with methods used for data collection together with the data analysis performed, as well as quality criteria of the study.

2.1 Connection between Research Questions and Method

Saunders, Lewis and Thornhill (2009) claims that combining the right method with each research questions have a significant role, which either enables or prevents the study from achieving high reliability and validity of the results. Interviews, both semi-structured and unsemi-structured, and document studies have been conducted to collect empirical data for the research questions (Figure 2.1).

Figure 2.1: Method used for research questions 2.2 Research Approach

The aim of the study was to create an understanding for organisations about how they can reduce their environmental impact. To provide the opportunity to reach a conclusion, a literature study was conducted in the beginning of the study to investigate and evaluate previous research on sustainable supply chains. The literature study led to significant knowledge when collecting empirical data. The empirical data collected was analysed together with the theoretical framework and based on the analysis, general conclusions connected to the research area of the study were formulated. According to Patel and Davidson (2011), this type of research approach is characterized as an inductive research process, which is also the reasoning used in this study. Further, it is stated that induction makes it possible to learn from what is happening in the world. It is suitable when researchers want to orient themselves in an area, or when there are no prerequisites or opportunities to test theories.

Research Methodology

Patel and Davidson (2011) argue that most of the research conducted today consists of simultaneous use of both quantitative and qualitative approaches, which also characterizes the approach of this study. The terms "quantitative" and "qualitative" refer to how the information collected is generated, processed, and analysed. Quantitative focused research means that measurements are performed during the data collection and statistical processing and analysis methods are used, while qualitative data collection focuses on soft data such as interviews and interpretive analyses (Patel & Davidson, 2011). Mainly, this study has a quantitative approach as the research questions are designed as “how” questions, but also for the reason that the analysis is partly based on the measurements in the data collection. The reason why this study also has a qualitative approach is because interviews and analytical interpretation of literature have been conducted.

2.3 Research Design

The investigation method used to answer the study's purpose and questions was a case study. A case is a delimitation of the real world, to make it possible to operationalise the research. In this research, the case was a company, but it can also be, for example an individual, an event, or a neighbourhood (Yin, 2019). Case studies are based on holistic perspectives to obtain an as comprehensive information as possible and are best suited when processes and changes are to be studied (Patel & Davidson, 2011). Once the suitable strategy was identified for this research project, the design of the case study was formed. According to Yin (2007), design in a basic sense, is a logical sequence that links empirical data with the research questions in order to lastly be linked to the conclusions. The main purpose to form a design is to not end up in a situation where empirical data has no connection to the research questions. The questions were designed as “how” questions, which as stated by Yin (2007) are appropriate in a case study. The study examined one unique organisation in its specific context, which means that the study was designed as a single-case study. A single-case study can be characterized either by one unit of analysis or several units of analysis (Yin, 2019). This study examined one product family, and only one unit that represents the product family is included, which according to Patel and Davidson (2011) results in a distinct view of the individual case. The case company studied in the research suited the purpose and research questions of the study since it is a revelatory case. It is a manufacturing organisation that in recent years has started to develop a sustainability strategy where one cornerstone of the strategy is “efficiency in the value chain”. In order to advance the organisation’s work in that area, they need to understand their environmental impact, which was relevant to the purpose of the study. The product that represents the product family was considered to have the greatest sales potential in the future and was thus selected for the research.

2.4 Research Process

The research process was divided into seven general activities: origin of idea, pre-study, literature study, case study, analysis, discussion, and consulting. Figure 2.2 illustrates if the activities were either a process, a theoretical or an empirical basis and in which order the activities are executed. Activity two and three were performed in parallel, hence the double arrow between them. To achieve high clarity, the activities will be presented with the numbering found in the figure (0-7).

Research Methodology

Figure 2.2: Research process

(0a) The idea of the research arose through a discussion about the researchers’ common interests and areas. Sustainability within the supply chain, efficiency, change management and operational management were some of the topics that occurred. Meanwhile, a thesis project was introduced at an organisation that reflected the areas discussed. (0b) An application was sent by the researchers, which got accepted and assigned to the researchers.

(1a) The second activity in the process was a pre-study which was carried out to create a basic knowledge and understanding of previous research regarding LCA and sustainable supply chain. The theoretical pre-study contributed to relevant keywords to the literature review. During the pre-study, the problem definition was formulated, and the method choices were made. (1b) During the empirical pre-study, an introductory meeting was held with the case company to discuss the problem area, set relevant delimitations and to preliminary plan parts of the data collection. (2) In conjunction with the completion of the pre-study, a literature review begun, which later formed the basis of the theoretical framework. More in-depth information on how the literature studies were conducted can be found under heading 2.5.

(3) During the design of the theoretical framework and data collection, the researchers felt that the results of the study may become too narrow. The researchers thus reached a crossroads (see Alvesson & Sandberg, 2011), which meant either continuing on the same track, with focus on LCA, or choosing to add new theories, concerning new product development as well as collection methods. A decision was made to choose the second alternative and the data collection was conducted in forms of interviews and document analysis. (4) The data collected then constituted the empirical analysis which was analysed together with the theoretical framework. (5) The study was discussed based on the results and methodology, followed by conclusion drawn. (6) Based on the discussion, conclusions were also drawn. (7) Finally, to reach a conclusion with the thesis project, the researchers consulted the case organisation regarding conclusions and advice.

Research Methodology

2.5 Literature Review

The literature selected aimed to be used as research overview in the study. The searches were made in appropriate databases, such as Scopus and ScienceDirect, and the selected literature was considered to fall within the subject area of the thesis and was therefore of relevance. The reason why the databases mentioned were used was because they included the subject area logistics and business management, which also was the area for research. All scientific literature used were referee-reviewed. Table 2.1 shows examples of keywords used and in which different combinations.

Table 2.1: Literature search with examples of keywords

The focus was on sustainable supply chains, transport, production, and new product development. For example, transport and production contribute to large amounts of different emissions, but a delimitation was made to CO2-eq emissions. Therefore, distinctive words were selected as keywords and the different combinations were set to limit the number of hits. To make the selection of articles, the searches were screened exclusively on the title. Articles whose title captured the researchers’ interest, the summary was read to screen further. If the article was still considered applicable, it was studied in full text. An article was considered applicable when the content was considered useful.

2.6 Data Collection

The data collection of this research was based on a case study in which both primary and secondary data have been collected (Table 2.2). Primary data of studies refers to empirical data collected through interviews and observations by researchers themselves (Lundahl & Skärvad, 2016). In order to provide a broad and deep knowledge in the research area, primary data was collected through interviews. Secondary data refers to data that has already been collected, compiled, analysed, documented and presented by other researchers, organisations or investigators (Lundahl & Skärvad, 2016). Document studies were used as secondary data for this study and was collected to make use of already documented research and thus create a holistic view. Patel and Davidson (2011) believes that secondary data serves the purpose of adding context to the collected data. They, like Lundahl and Skärvad (2016), also emphasize the importance of having a critical approach and examine if the secondary sources contribute information that is correct and up to date. Finally, according to Yin (2019), comparison and analysis of the collected data will contribute to a trustworthy result. Therefore, the collected empirical data was analysed in relation to theoretical frameworks.

Keyword Database Number of hits Year

"supply chain" AND footprint AND freight Scopus 22 2014-2019

"carbon footprint" AND manufacturing AND steel Scopus 33 2015-2019

"sustainability strategy" AND retail Scopus 10 No limit

sustainability AND trend AND "supply chain" AND manufacturing Scopus 33 2016-2020

"sustainable supply chain" AND trend Scopus 53 2017-2020

Research Methodology

Table 2.2: Summary of data collection

2.6.1

InterviewsYin (2007) describes interviews as one of the most important sources of information in case studies. Interview is a data collection method with the purpose of gathering information based on questions. There are a variety of variations and combinations of interviews that are structured according to the particular need. Interviews enable flexibility for the interviewer where flexibility consists of the concepts standardization and structuring. Furthermore, the standardization refers to the interviewer's responsibility, in terms of how the questions are designed and in what sequence they are asked. Structuring refers to which extent the interviewee can interpret the questions freely and how large the respond space is (Patel & Davidson, 2011).

A structured interview is based on questions that are asked in identical order to all respondents, with fixed response alternatives. The space for the respondent to reply within is limited, which makes it possible to predict which potential answers are to be provided. In an unstructured interview, the questions are formulated during the interview and put in the order that is considered appropriate. There is maximum with space for the respondent to answer within. A semi-structured interview leaves room for follow-up questions and is easier to analyse than an unstructured interview. The answers obtained by a semi-structured interview can vary widely depending on the respondent and the situation (Patel & Davidson, 2011).

One interview was conducted at the case company. The interview was structured as a variant of semi-structured interview, with high standardization and low structuring

Informant Company Time Period Data Collection

Production and R&D Manager ITAB Guidance AB December 2019 - May 2020

Continuous interactions, semi- and unstructured interviews, sustainability report

and e-mail follow-up

Designer ITAB Guidance AB February 2020 - April 2020

Frequent interactions, unstructured interviews, product

data and e-mail follow-up

Production Supervisor ITAB Guidance AB March 2020 - April 2020

Frequent interactions, unstructured interviews, sales

report and e-mail follow-up

Purchase Manager ITAB Guidance AB December 2019 - March 2020

Sporadic interactions, unstructured interviews and

e-mail follow-up Purchase and Supply Chain

Coordinatior ITAB Guidance AB March 2020 - April 2020

Sporadic interactions, unstructured interviews and

e-mail follow-up

Assembler ITAB Guidance AB March 2020 Occasional interactions and product data

Project Manager (ITAB Shop Concept

(China) Co., Ltd. April 2020

E-mail interaction and process data Head of Group Operations and

Chief Marketing Officier (Members of the company's

sustainability group)

ITAB Shop Concept AB December 2019 - May 2020

Sporadic interactions, brain-storming and sustainability report

Sales support ITAB Shop Products AB March 2020 E-mail interaction and sales report

Research Methodology

(Patel & Davidson, 2011). The questions were put in a specific order and the interviewee was given room to answer in own words. The interviewee was contacted via e-mail where the purpose of the interview was clarified, and the date and time was determined. The predetermined questions together with the subjects of the interveiw were attached to the interviewee a few days before the interview was held with the purpose of preparing the interviewee. The interview was conducted with the production and R&D manager of the case company. The purpose of the interview was to gather information about the company's routines regarding new product development and how the process takes sustainability into account. Both researchers attended at the interview which was conducted at the case company. Each researcher asked questions in the area each researcher was responsible for and the interview followed the predetermined standardization (Appendix A), with some influences of new questions considered relevant. The entire interview was, with approval from the interviewee recorded and lasted for 36 minutes. The day after, the interview was transcribed.

Several unstructured interviews were also conducted at the case company, with different employees (Table 2.2). The reason why most of the interviews where unstructured was due to that one of the researchers has a long-standing relationship with the case company. This also implies that a certain basic understanding of various areas and the product existed in advance. As reflections and questions emerged, it was directly addressed to the person at the company who had knowledge of it. If the long-standing relationship and knowledge would not exist, more interviews and contact would have been needed with the case company.

2.6.2

Document AnalysisDocument analysis is a data collection method that, according to Bell and Waters (2016), can be used either as a complement to other data collection methods or as main method. It is further believed that it is important to use a source-critical approach, when using documents. Yin (2007) argues that documents can be useful in case studies but that they not always are accurate and should therefore be used with caution. The most important role of documents is to strengthen data and evidence obtained from other sources.

The documents used in this study were constructional drawings, bill-of-material (BOM) lists, a list of all ingoing physical parts and the number of parts used (McKay, Stiny, & de Pennington, 2015), the transport route, sustainability report for 2019 and sales statistics. The documents were collected from databases and the enterprise resource planning (ERP) system of the case company and were used to gather important information for the study. The constructional drawings and BOM lists were used to compile all the components of the product with material and weight. Transport documents were used to map the product's transport route. The sustainability report helped the researchers to obtain an overview of the sustainability work and the sales report was used to generate statistics for the number of products sold per customer.

When all documents were compiled and structured, the LCA experts Miljögiraff was contacted to receive guidance and tools for the analysis of materials and transport. The analysis was performed using Ecodesign Studio, an LCA software. The software is a simplified LCA database, recommended for students, which Miljögiraff has the agencies in Sweden. Ecodesign Studio is a tool for projecting product development while combining it with life cycle and cost perspectives. The tool allows the user to

Research Methodology

review the recycling rate, and compare the environmental impact of the product (s) with different material choices, weight and use to find the best environmentally combination (Miljögiraff, n.d.). Before using the database, the researchers conducted a three-hour course to create a basic understanding of the database.After the course, all the collected and relevant data were put into the software. The database provided information on the emission levels for the product's constituent materials, processes and modes of transport.

2.7 Data Analysis

Collected empirical data formed the basis for the research process of the study, which was further analysed with the theoretical framework of the study. To ensure that no data was lost, the data analysis was performed continuously by collecting and documenting data simultaneously. To ensure the relevance, transparency and quality of the data, it was collected with constant consideration for the purpose of the study. By conducting a pre-study of both the organisation and of previous research, an understanding of the subject and the problem area were obtained. Thenceforth, the collection and compilation of relevant theories and empirical data were carried out and further investigated in the data analysis. The theoretical framework was continuously supplemented with new theories to support the collected empirics. The theory and empirical data were analysed and compared with each other, which according to Yin (2007) is called pattern matching. The advantage of pattern matching, when the comparison corresponds to each other, is that the results can enable a strengthened internal validity. The process and implementation of data analysis made in the study is illustrated in Figure 2.3.

Figure 2.3: The process and implementation of the data analysis

2.8 Trustworthiness

According to Lincoln and Guba (1985), the most important criterion in evaluating qualitative research is that the reader is given the opportunity to evaluate the research path and determine whether the study's results are reliable. Therefore, the study focuses to enable transparency to the processes for the reader. A research design contains a logical set of statements and therefore it is possible to judge the quality of a given research design based on certain logical criteria (Yin, 2019). Credibility, reliability, ability to coat results, and data reliability are concepts proposed for such an assessment

Research Methodology

(U.S. General Accounting Office, 1990). According to Yin (2019), there are in particular four criteria that are usually used when assessing the quality of a study: construct validity, internal validity, external validity and reliability (Table 2.3).

Furthermore, Lincoln and Guba (1985) suggest that there are criterions to fulfil to achieve reliability, where credibility is considered the most important criterion. Credibility consists of seven activities that are divided into five main techniques that make it more likely that credible findings and interpretations are produced. The first technique consists of three activities: prolonged engagement, persistent observation, and triangulation. The other four techniques consist of the following activities: peer debriefing, negative case analysis, referral adequacy and member checks. Two other quality criteria are transferability and dependability (Table 2.3). Several authors provide a more in-depth explanation (e.g. Eriksson, 2014, p. 42-44; Yin, 2019, p. 54-60).

Table 2.3: Quality criterion described, based on (Lincoln & Guba, 1985; Yin, 2019) with

inspiration from (Eriksson, 2014)

The application of quality criteria is presented at the end of the research, under the sub-heading 6.2. It will form the basis for the reader to determine the trustworthiness of the study.

Quality criterion Description

Validity

Construct validity Designing proper operational measures for the concepts being studied. Internal validity Establishing a causal relationship where it is shown that certain conditions

lead to other conditions, which is different from false or temporary relationships.

External validity Delimitation of the area to which the study results can be generalized. Reliability Shows that the execution of the research can be repeated with the same

result.

Transferbility The ability, for someone interested, of determining whether the study's findings are applicable, even if the context is different, or even in the same context at another time, is possible.

Dependability The possibility of examining the research process for the reader. Credibility

Prolonged engagement Invest enough time to get involved in the situation of the study as well as to appreciate and understand the context correctly.

Persistent observation Widening the depth of the study, invest the time considered necessary to reach a sufficient depth.

Triangulation Several data collection methods are used, which strengthens and ensures the study's data collection.

Peer debriefing The process of exposing the study to an uninterested peer, with the aim of discovering aspects of the research that would otherwise remain incomprehensible to the peer.

Negative case analysis A review process to test hypotheses with hindsight, with the purpose to continuously refining a hypothesis until it stands for all known cases without exception.

Referential adequacy Maintain some of the raw data unprocessed to allow the data to be revisited.

Member checks Data, analytical categories, interpretations and conclusions are tested by the member (s) who are the source of origin.

Theoretical Framework

3

Theoretical Framework

This chapter contains the theoretical framework that forms the basis for answering the study’s research questions. The main theories addressed are life cycle assessment and new product development. The reason for including life cycle assessment as a theoretical area is because of its usefulness when examining a product's environmental impact from raw materials to end-of-life. It gives organisations a good basis for creating an understanding of how they affect the environment and what potential measures may be needed to reduce environmental impact. Climate change classification is included as a theory to give the reader a basic understanding of the emissions included in the study. Sustainable transport and green production are stated as theories to determine in concrete terms what previous research provides as possible alternatives that may lead to a reduction in environmental impact. The motivation for including new product development is for the reason that many see new product development as a strategically important key activity. It is thus considered advantageous to include in both the sustainability strategy and the supply chain, in order to achieve long-term success, both in a sustainable and economic perspective.

3.1 Connections between Research Questions and Theory

The purpose of this study was to investigate how organisations can act to create an understanding of how they can reduce their environmental impact and hence the focus was on implementing part of an LCA. In order to enable a credible result, the theoretical framework was constructed through conscious choices with connection to the research questions. The theoretical framework formed the basis for answering and supporting the research questions, as well as meeting the purpose. Figure 3.1 illustrates the connections between the study’s research questions and theoretical framework.

Theoretical Framework

3.2 Life Cycle Assessment

Life cycle assessments (LCA) is a holistic environmental strategy to assess a product’s or a service’ impact on the environment and human health, in conjunction with the entire life cycle, from creation to use to end-of-life of products, processes and activities (Curran, 2015). An LCA enables modelling of the entire system from which products come from or from which processes and / or activities work (Ibn-Mohammed et al., 2013; Hauschild & Huijbregts, 2015; Hellweg & Canals, 2014). A properly implemented LCA identifies and quantifies the potential effects of an industrial system, but perhaps more importantly, an LCA identifies the potential transfer of environmental impact from one media to another and / or from one stage of a life cycle to another (Curran, 2015). The main objective of an LCA is often to determine which of several compared alternative products is preferable. This is commonly done from an environmental perspective, or in order to find out where the greatest environmental impacts can be found in a product's life cycle. Using an LCA can help decision makers to choose the product or process that has the least environmental impact. This knowledge can also be used in conjunction with other factors, such as cost and performance data, in selecting the best alternative from a sustainable perspective (Hauschild & Huijbregts, 2015).

LCA as an evaluation method is based on two basic concepts. The first involves taking a given account of the product or material system of interest and mapping out all activities or processes associated with its production, operation, and final storage - the life cycle. The second concept is to take a list of life cycle activities, while considering the associated environmental impact across the entire supply chain (Smith et al., 2019).

As an LCA is an important part of this research, the stages included in a life cycle will be described in detail below.

3.2.1 Stages in a Life Cycle

A life cycle is based on a number of stages, from raw materials to end-of-life, which in turn are based on a number of factors including utilization of raw materials, energy and water utilization, conveyor, waste production, waste management and its associated impact on air, water, soil and underground (Figure 3.2) (Smith et al., 2019).

Theoretical Framework

The general scope for each stage of a product's life cycle can be described as follows (Curran, 2015):

Raw Materials Acquisition. This step includes extraction of raw materials and energy sources from earth, such as harvesting trees or extracting crude oil. Land disruptions as well as transport of raw materials from the point of acquisition to processing of raw materials are considered as a part of this step.

Manufacturing. The manufacturing stage produces the product from raw materials and delivers it to the consumers. Three stages are involved in this transformation: (i) material manufacturing, (ii) product manufacturing and (iii) filling / packaging / distribution.

(i) This step involves converting raw materials into a form that can be used to make a finished product. Transport between manufacturing operations and product manufacturing should also be reported in the inventory, either as part of material manufacturing or separately.

(ii) Processing of the manufactured material, to create a product that is ready to be filled or packaged. For example, forming a bottle or forming an aluminium can is involved in this step.

(iii) This step includes all manufacturing processes and shipments required to fill, package, and distribute a finished product. Energy and environmental waste that comes from transporting the product to stores or to consumers is reported here.

Use / Reuse / Maintenance. This is the phase that consumers are most familiar with, actual use, reuse, and maintenance of the product. Energy requirements and environmental waste in connection with product storage and consumption are included in this step.

Recycle / Waste Management. Energy requirements and environmental waste that are associated with product disposition are included here, as are alternatives for handling waste after consumer such as recycling, composting and incineration.

3.2.2 LCA according to ISO 14040:2006

An LCA is one of several environmental management tools. The first set of international guidelines for the implementation of an LCA was published in 1997 by ISO. Today, the ISO 14040 series is widely accepted among LCA practitioners and is continuously being developed with new methods. The ISO standardizations from the 14000 series that are connected to an LCA are 14040 and 14044. ISO 14040:2006 contains principles and structures about how to implement an LCA which are specified in detailed requirements and recommendations in ISO 14044:2006 (Wendin, 2019).

According to ISO 14040:2006, an LCA does not usually handle the economic and social aspects of a product and is thus not always the most appropriate method to use in all

Theoretical Framework

situations considering sustainability. In line with the standard an LCA is useful and directly applicable to:

▪ Product development and improvement, ▪ strategic planning,

▪ public policy making, ▪ marketing, and

▪ other.

Organisations that have an interest in becoming more sustainable can apply the standards and thus assist in identifying opportunities to improve the environmental performance of products and select relevant indicators for environmental performance and marketing (Swedish Standards Institute, 2006).

3.2.3 Phases of an LCA

As highlighted, an LCA is a scientific analysis that assesses the environmental effects of a product system. It is an environmental assessment method with two unique characteristics, cradle-to-grave analysis, and functional unit. Cradle-to-grave means that all steps in a product's life cycle are analysed. The steps involve extraction of raw materials, production of materials, production of final product, use, recycling, or removal. The transport that exists between all stages is also reported (Klöpffer, 2014). The functional unit defines what is being studied and its primary aim is to provide a reference to which inflows and outflows are related (Swedish Standards Institute, 2006; Wendin, 2019).

An LCA consists, according to the international standard ISO 14040:2006, of four phases, (i) goal and scope definition, (ii) inventory analysis, (iii) impact assessment and (iv) interpretation (Figure 3.3).

Theoretical Framework

(i) The first step involves goal and scope definition depending on the topic area and the intended use of the study. The selection of the functional unit is also included in this phase. The width and depth of an LCA can vary considerably depending on the objectives of each individual analysis.

(ii) The life cycle inventory analysis (LCI) is the second step in an LCA. Data for inflows and outflows are invented in relation to the system studied. The step requires collecting data needed to achieve the objectives of the study. Inventory and calculation of data collected is compiled and presented.

(iii) The third phase is the life cycle impact assessment (LCIA), which aims to provide additional information and data. The information should facilitate the assessment of a product system's LCI performance to create a better understanding of its environmental significance. Therefore, the importance of potential impact is assessed in this phase, using the results of an LCI. The process involves linking inventory data to specific environmental impact categories, category indicators and characterization factors.

(iv) The final phase of an LCA is life cycle interpretation. In this phase, the results of an LCI and / or an LCIA are summarized and discussed in relation to the study's goal and scope. According to ISO 14044:2006, this step aims to create and increase confidence and reliability in the results of the LCA. The results should be presented in a way that gives the client or other stakeholders a clear and understandable picture of the outcome. Furthermore, Curran (2015) believes that an uncertainty analysis, sensitivity analysis and / or contribution analysis are three techniques that can be used in the evaluation of the LCA performed.

The concluding phase should begin with an identification of significant findings to highlight and identify the most important issues in accordance to the goal and scope definition. The phase should be completed with conclusions, limitations and recommendations with the purpose to form the basis for decision-making (Swedish Standards Institute, 2006).

3.2.4 Types and extent of an LCA

An LCA can be divided into two main types which are "attributional" and "consequential". Attributional is a retrospective study that is suitable when examining the environmental impact of a specific product or service, or when comparing the environmental impact of different products, or services with the same functional unit. A consequential LCA is a forward-looking study that is used in an examination of the consequences of a change based on different scenarios (Wendin, 2019). The two main types can, in turn, be implemented to varying extent depending on the purpose of the study (Table 3.1).

Theoretical Framework

Table 3.1: Different extent of an LCA methodology depending on the purpose of the study,

modified from (Wendin, 2019, p. 7).

As previously mentioned, the scope of studies should be defined in a way that the goal of the study can be achieved (Wendin, 2019).

3.2.5 Key Issues with an LCA

Smith et al., (2019) assert that to successfully perform an LCA, the first and most important step is to gain an understanding of the product, process, or activity for which the environmental profile should be assessed. Further, it is argued that the step includes a deep understanding of the materials and energy requirements as well as other resources required for the production of any given material. In order to create this understanding, a calculation of materials and energy input to the entire manufacturing process should be constructed. This material calculation can be either primary sources, where the information is provided directly by manufacturers, or through secondary sources, such as the use of various databases. After the material calculation, the following step is to determine how outputs and potential environmental impacts will be evaluated over various indicators. This step, in turn, requires understanding and access to relevant databases for which the emission intensity for different processes and materials can be assessed (Smith et al., 2019).

Performing an LCA includes various simplifications of assumptions and value-based assessments throughout the process. Although the same product seems to be the focus of the study, differently performed LCAs can give different results. These variations can be caused by several factors, such as different objectives, different functional units, different boundaries, and different assumptions. A desirable situation is to keep these differences to a minimum and the key is to maintain openness and transparency as well as to be clear in the reporting phase regarding which assumptions and values were used. This is necessary as it is not a single prescription process, but a process that contains several decision points that can affect the outcome of the LCA (Hauschild & Huijbregts, 2015).

Description Area of Use ISO terminology

A tt ri but iona l Cons e que nt ia l A t t he poi nt of subs ti tut ion Cut -off by c la ss ifi c a ti on P roc e ss da ta Input /out put

Simplified method that quickly provides an overview of a product's environmental impact throughout its life cycle. Not enough data for external communication.

DfE - Design for Environment IPP - Integrated Product Policy

Complete overview with specific information on all environmental aspects in a product's life cycle. Adequate support for external communication.

EPD - Environmental Product Declarations

R&D - Research and Development LCA according to ISO 14040

Internal R&D - Research and Development

External EIA - Environmental Impact Assessment

Overall LCA for an entire organisation, environmental impact is allocated to all products produced within the organisation.

Strategy/Management/Accounting GRI - Global Reporting Intiative CFA - Carboon Footprint Analysis

Organisational LCA

Suitable for studies to be used as a basis for the introduction of new rules affecting entire regions or sectors.

Policy, directive - Region/sector

Method Allocation Data

Screening

Extent

Complete

Scenario Comparative studies for

communication Compare several scenarios for a product to

gain in-depth information on the effects of different options. Based on either screening or complete.

Theoretical Framework

It has been proven over the years that the main environmental impact of a product is determined in the production, disposal, or transport phase. It is key for both researchers and industry to implement the LCA method as a decision-making tool in the early development phases. This, to avoid any unpredictable costs required to reduce the environmental impact of a product or service (Smith et al., 2019).

3.3 Classification Climate Change

One of the world's most pressing challenges is climate change (Ritchie & Roser, 2017). The earth is heated by direct solar radiation. When the earth's crust is heated, it emits heat radiation partially absorbed by greenhouse gases, into the earth's atmosphere. The heat then radiates back to the earth, which results in the temperature of the earth becoming higher and more even compared to if these greenhouse gases were not present in the atmosphere. This is part of the natural greenhouse effect which is a prerequisite for life on earth (Wendin, 2019). The presence of greenhouse gases in the atmosphere, such as carbon dioxide (CO2), methane (CH4) and trichlorofluoromethane (CFC-11), has increased the global temperature by around 1°C since pre-industrial times, due to human activity (Ritchie & Roser, 2017). The increase affects the radiation balance, which means that the natural greenhouse effect is enhanced, and global warming and climate change is a fact. The climate change causes several environmental problems that affect both ecosystems and human health (Franchini & Mannuccio Mannucci, 2015; Wendin, 2019).

In order to create a holistic view of how the environment is affected by the different emissions, they are bundled together according to the type of impact they cause (classification). The ability of the classification to affect the environment is then translated into the corresponding emission of a common substance which is seen as a reference for the environmental impact investigated (characterization). Figure 3.4 illustrates the emissions classified as climate change and its characterization.

Figure 3.4: Classification climate change, modified from (Wendin, 2019, p. 21).

The most common greenhouse gas emitted by human activities is CO2. Worth noting is

that the term CO2 is sometimes used as a summary term for all greenhouse gases,

leading to global warming. This, of course, can cause confusion and a more correct way to refer to a number of greenhouse gases in common is to use the term carbon dioxide equivalents (CO2-eq). The term is used to describe different greenhouse gases in a

common unit (Brander, 2012). Climate change is usually characterized in the form of

CO2-eq. Examples of three emissions that contribute to climate change and that can be

combined into CO2-eq are CO2, CH4 and CFC-11. CH4 is a 25 times more powerful

Inventory Classification Inventory data (LCI results) Environmental impact categories Characterization factor Category indicator CO2 1 CH4 25 4750 CFC-11 Characterization Climate Change CO2-eq

Theoretical Framework

greenhouse gas compared to CO2, which gives CH4 characterization factor 25. Potentially, 1 kg of CH4 can cause as much climatic change as 25 kg CO2 and therefore

becomes 25 kg CO2-eq. A very potent greenhouse gas is CFC-11, 1 kg CFC-11

contributes to the same climate change as 4750 kg CO2. To calculate the total climate

change in CO2-eq, all emissions are added. Thus, in Figure 3.4, the total amount of

CO2-eq becomes 1 + 25 + 4750 = 4776 kg CO2-eq (Wendin, 2019). For a more general

case, the following formula can be used

𝐺𝑊 = ∑ 𝐺𝑊𝑃𝑠 𝑠

× 𝑚𝑠

where GW represents the total amount of global warming, s the substance (the different greenhouse gases), GWPs the global warming potential of substance s and ms the

emitted amount of substance s in kg. A further generalization thus becomes

𝐼𝑐 = ∑ 𝐶𝐹𝑐,𝑠 𝑠

× 𝑚𝑠

where c stands for impact category, I the indicator result for category c and CFc,s the

categorization factor that links substance s to impact category c. This formula serves as the operational formula for categorization (Curran, 2015).

3.4 Sustainable Transport

Martins, Gonçalves Quelhas and Anholon (2019) define sustainable transport as transporting in accordance with the principles of sustainability, which, for example, means as little CO2 emissions as possible in process management in organisations. Furthermore, Wiederkehr, Crist, Gilbert and Caïd (2004) describe sustainable transport according to four criterions: provides for security, economically sustainable and socially acceptable access to people, plastics, goods and services, meets widely accepted health and environmental quality goals, protects ecosystems and does not aggravate negative global phenomena such as climate change, and stratospheric ozone depletion.

Trautrims (2017) claims that transport is undoubtedly the most obvious problem in the discussion of making logistics activities in supply chains greener. The percentage environmental impact of transport varies widely between different supply chains, but it cannot be ignored that every goods’ supply chain and almost every services’ supply chain contains transport activities. Freight transport has in recent decades disproportionately outgrew economic development, and in line with an increasingly global supply chain it will, despite temporary declines related to economic downturn continue to grow (FTA, 2015; OECD, 2015). The increased international trade can primarily be related to offshoring and other specialization in supply chains. What could mitigate the trend of strong growth of transportation, and thus reduce the environmental impact of it, is the ongoing debate about the disadvantages of globalization, supply chain risks and the higher responsiveness of the local supply (Grant et al., 2017).

Theoretical Framework

The various modes of transport available for organisations to transport goods are ocean freight, rail freight, road freight and air freight.

Figure 3.5: CO2-eq emissions by transport mode, modified from (Grant et al., 2017, p. 69)

Emissions vary considerably between the available modes of transport, with the slower ones generally emitting less CO2-eq than the faster ones (Figure 3.5).

3.4.1 Factors to Consider when Choosing Transport Mode

Although some modes of transport are obviously more detrimental to the environment compared to others, there must be an understanding that organisations need to make both commercial and logistical considerations before making a choice. Organisations must take consignment factors, operational factors, cost and service requirements, and product characteristics into account (Table 3.2) (Grant et al., 2017).

Table 3.2: Factors to consider when choosing transport mode, based on (Grant et al., 2017) Factors to consider

Consignment factors ● Carbon dioxide emissions,

● type of fuel,

● the use of already planned transport instead of a new one (both environmentally and economically more attractive),

● whether a consignment can fill the size of a standardized transport unit (also linked to price), ● the load factor (utilization) is important from an environmental assessment perspective, ● electrified transport modes.

Operational factors ● The availability and quality of infrastructure, vehicles and logistics service providers differ

between countries and modes of transport, ● local rules and laws,

● costs,

● emissions effects (i.e. fuel tax, aviation tax, tax cuts for environmentally friendly choices), ● nature and climate.

Cost and service requirements ● Customer cost and service requirements,

● size of orders, ● requested delivery time, ● storage space and storage costs.

Product characteristics ● Value density and weight density,