ISSN 0347-6049

i V//särtryck

153

Resilientmodulus byindirect tensile test

SafwatF. Said

PreparedforpresentationandpublicationattheFourthInter-nationalSymposiumRULEM,24-26thOctober, 1990in

Budapest, Ungern

Vag-och Trafik-

Statens väg- och trafikinstitut (VT!) * 581 01 Linköping

ISSN 0347-6049

___ K1/särtryck

153

1990

Resilient modulus by indirect tensile test

Safwat F. Said

Prepared for presentation and publication at the Fourth

Inter-national Symposium RIÅLEM, 24 - 26th October, 1990 in

Budapest, Ungern

f, Väg" 00h a /(' Statens vag- och trafikinstitut (VTI) * 581 01 Linkoping

RESILIENT MODULUS BY INDIRECT TENSILE TEST"

SAFWAT F. SAID

Swedish Road and Traffic Research Institute Linköping, SWEDEN

Abstract

With developments in analytical design of pavement structu-re, there is an increasing demand for knowledge of the

mechanical properties of various pavement elements under different conditions encountered in roads, such as tensile strength, stiffness modulus, and repeated-load fatigue re-sistance of the asphalt concrete mixtures. These parameters provide a good basis for analytical design and performance evaluation of flexible pavements.

In this study, Indirect Tensile Test has been conducted because of its validity and simplicity. However, modifica-tions of the test apparatus and test procedure have been introduced.

Three different types of asphalt concrete mixtures have been examined using indirect tensile method. Two of the mixes are blended with 3% rubber content by total weight.

i.e. Rubit (RUBI2), which is a dense asphalt concrete used for surfacing, and a porous mix called Rubdrain (RUBD12) . The third mix is a conventional dense asphalt concrete

(HAB12T) used for surfacing. The maximum size of the aggre-gate was 12 mm for all types.

Stress-deformation-strain relationships have been estab-lished in order to examine the effect of stress and/or

strain level on the resilient modulus found by the indirect tensile test and to define an approximate linear viscoelas-tic zone for bituminous mixtures at different temperatures. Resilient modulus has been measured using the modified in-direct tensile method for mixtures studied at four different temperatures.

Keywords: Asphalt Material, Rubberized Asphalt, Indirect Tensile Test, Resilient Modulus, Linear Viscoelastic, Stress-Strain Relation, Temperature.

*This job has been conducted by the Dept. of Highway

Engineering, Royal Inst. of Technology in cooperation with the Swedish Road and Traffic Research Inst.

1 Introduction

With developments in analytical design of pavement structu-re, there is an increasing demand for knowledge of the

mechanical properties of various pavement elements under different conditions encountered in roads, such as tensile strength, stiffness modulus, and repeated-load fatigue re-sistance of the asphalt concrete mixtures. These parameters provide a good basis for analytical design and performance evaluation of flexible pavement.

In the last three decades a lot of research has been

focused on the response of various layers and materials sub-jected to possible conditions in the field by using a wide variety of methods and apparatus, which have a provided valuable knowledge platform for further investigation. Indirect tensile test has been conducted in this study

because of its validity and simplicity. However, modifica-tions of the test apparatus and test procedure have been introduced.

Three different types of asphalt concrete mixtures have been examined using indirect tensile method. A conventional mix HABl2T, which is a dense asphalt concrete used for

surfacing, Rubit (RUBI2)], which is a rubber granular blended asphalt mix with 3% rubber content, and a porous mix, called Rubdrain (RUBD12) also containing 3% rubber used as a drain-age layer, have been used. The maximum size of the aggregate was 12 mm for all types. Rubit and Rubdrain mixtures are marketed by the ABV (NCC) company. The specimens were supplied by the ABV laboratory.

Stress-deformation-strain relationships have been estab-lished in order to examine the effect of stress and/or

strain level on the resilient modulus found by the indirect tensile test and to define an approximate linear viscoelas-tic zone for bituminous mixtures at different temperatures.

Resilient modulus has been measured using the modified indirect tensile method for mixtures studied at four

different temperatures.

2 Test apparatus

Due to its simplicity and validity the Repeated-1load Indi-rect Tensile Test [1-8], with modification in test apparatus and test procedure, has been used to study the mechanical properties of bituminous mixtures. The principle of this test is that a cylindrical specimen is loaded in the verti-cal diametral plane, the compressive load is applied through a couple of curved loading strips. The resultant deformation is measured at horizontal diameter.

The expressions given by Schmidt [2] andKennedy et .al. [1] for tensile stress at the center of specimen, resilient modulus, Poisson's ratio and strain across horizontal diame-ter are the following:

. + v v + + + + k k k k k k k k W k ok WoW k ok k k k k k ok k k k k d k k k k k k k k (1) Q [1 5 11 3.4 [ÄH/AV]- 0427 4 v 4 4 v k kW kk kk kk k k k k k k k k k k k k k k k k k (2) (P/t. AH)[4/n+n-1] = P(n+0.27)/t.AH. . . .. . + + + ++ + ++. (3) Mr E. =(2P/MantD)[ (4D*n-16D?x2)/(D2+4x2)2+(1-n)]. .... . + +. (4 )

Tensile stress (MPa) Applied load (N)

specimen thickness (mm) specimen diameter (mm) Poisson's ratio

Total resilient horizontal deformation (mm) Total resilient vertical deformation (mm) Resilient modulus (MPa)

Tensile strain at horizontal diameter

S U ct U Q AH NV Mr Ex d

By substituting Equation (1) in Equation (3) and solving for

resilient modulus:

Mr = (KD/2) (0/AH)]) (n+0.27) i i i v v v v k k k k k k k k k k k k e k k k k k k a (5)

To find the tensile strain at the center of the specimen (x=0), substituting Equation (3) in Equation (4) and solving for strain we get:

Co = (2AH/D)[(I+3n)/(4+KM+T)] ] + + + + + + + + + + + * + & * k ok k k k k k k k a (6 )

If n = 0.35 then

Co = 2.1 (AH/D) ... (7) where, AH and D are defined as before.

The testing machine is capable of applying compressive pulse loads over a range of frequencies and load durations for repeated load testing.

In this investigation the repeated load pulse was applied at a frequency of 0.33 Hz with 0.2 sec loading time and 2.8 sec rest period. The load applied in the vertical diameter plane is sensed by a load cell under the specimen. Deforma-tion across the horizontal diameter of the specimen is

sensed by one extensometer instead of two LVDTSs, which are normally used. Instron dynamic strain gauge (2620-601, with resolution of 20+*107-5 mm and weight 20 grams), and MTS

extensometer (632-11l1c, resolution 8*10-7-5 mm and weight 25 grams) have been shown to be adequate. The strain gauge is fixed to two curved zinc strips (2 mm thick, i0 mm wide and 80 mm long) which are glued at opposite sides of the hori-zontal diameter. The total weight of extensometer and the

two deformation strips is less than 75 gm (See Plate 1 and Figure 1). However, a couple of LVDTs with the frame which carry out the two LVDTs is more than 700 gm which might influence the recorded deformation.

Plate 1. Horizontal] extensiometer mounted on the specimen.

_| (ts d U S I f 4) FPL /_/_ __J

The deformation is measured at the same points where the two zinc strips are glued in order to avoid any error in re-cording deformations due to specimen movement or inadequate contact between extensometer (strain gauge) and specimen. Brown and Cooper [9] have mentioned the shortcomings of indirect tensile test, using LVDTs, in deformation measure-ment. The recorded deformation was found to be influenced by the strength of the spring used to keep the LVDT core in contact with the specimen, and by the vibration of the frame which carries the deformation transducers. In addition, it is easier to use just one extensometer rather than two

LVDTS .

The loading device is shown in Plate 2 and Figure 2. The upper steel loading strip is not fixed on the upper platen of loading device in order to bring a good contact between loading strips and specimen even at low stresses and high stiff asphalt specimens. An alignment bar is fixed to the upper aluminum platen to bring the loading strips into the same vertical plane. Figure 3 shows three different cases which could happen depending on the contact between loading strips and specimen when the loading strips are fixed on the platens. Case 1 shows a good contact, while cases 2 and 3

show insufficient contact which is a result of a rough surface. For more details see reference 22.

Plate 2.

Loading device and specimen in place.

0 sug: Z 12

©

organ

%& /

C

J_

©

7/77

NZ

/

.

-/// /" , z* sär \ ( \| 22 _£ _/ __ z Im O_ y k 0 | [ Å, di / en _ _ /|

\

//

9)

GRK

w ]

&

|- 1

#NWM

r

®\\\

n

Xskäl

.

o

s

I _._]

|

210

All dimensions in mm

1 Precision Pillar

2 Ball Bushing

3 Upper Plate

4 Float Loading Strip

Fig. 2.

tw

CO

-I

Oy

Un Specimen

Alignment Bar

Fixed Loading Strip

Bottom Plate

Hardened Disk

Case 1 0 Case 2 Case 3

Fig.3. Contact between strips and specimen.

3 Viscoelastic property of bituminous materials

Various investigators have emphasized the effects of stress or strain levels on the modulus of asphalt concrete mixtures

[2,10-21]. The increasing use of elastic theory in pavement evaluation and for comparing various asphalt materials in terms of their rheological characters makes the fundamental properties in stress-strain relationship an important param-eter [16]. With regard to the non-linear viscoelastic behav-ior of bituminous materials, the stress or strain level has an essential influence when measuring the moduli. Sayegh

[17] does not exceed a strain value of 4.107* when measuring moduli. Monismith et. al. [11] consider the stiffness of asphalt mixtures independent of applied stress at strains less than 1.1073 in/in. Bonnaure et .al. [13] determine stiffness modulus for strains 5.107 at -159C and +92C; 20.107 at +302C. Bonnaure et .al. also report that the phe-nomenon of non-linearity appears at strains close to

100.107. Kennedy and Anagnos [1] and ASTM [3] recommend a load range to induce 10 to 50 percent of the tensile

strength as determined in the static indirect tensile test, or in lieu of tensile strength data, loads ranging from 4 Ib

(25 Ib according to Kennedy) to 200 Ib per inch of specimen thickness can be used. Schmidt [2] uses a stress range from about 1 psi up to 15 psi at the specimen center at 73 PF (24 °C). So a wide variety of limits have been recommended. Therefore, an approximate linear zone (the resilient modulus is independent of applied stress or strain level)

should be well defined to make the modulus more reliable.

4 Linearity

The test series consist of testing three specimens from each type of asphalt mixture at temperatures of -10, +5, +25 and +40 degrees Celsius and at a loading frequency of 0.33 Hz. Totally, 36 specimens have been tested with this method. The test procedure is the following:

* The test specimens were stored in a temperature cabinet for 24 hours at testing temperature. ( A dummy specimen has shown that it takes at least four hours to bring the specimen from room temperature to -10eC) .

* Repeated-load pulse, at a frequency of 0.33 Hz, was ap-plied with 0.2 sec loading time and 2.8 sec rest period

* The load level was increased gradually up to a level which resulted in a recordable deformation by

extensometer.

* -A minimum of 50 load repetitions were applied before the first reading.

* The load level was increased gradually to a higher level with about 25 load repetitions at each load level. The maximum load level used was about 4000 N.

* Stresses and strains were calculated at each load level, a curve was fitted by regression analysis for all three specimens, which represent the material response at de-fined temperature. The zero point has normally been ad-justed due to surface irregularities.

The isochronous stress-horizontal deformation-strain diagrams were produced for bituminous mixtures to study the stress and strain effect on resilient modulus using repeated load indirect tensile test. Figure 4 shows isochronous dia-gram for HABl27T mix. Similar curves have been found for the other two mixtures (See Figure 5 and 6). The stress was calculated at the center of the specimen by Equation 1. These diagrams are represented by stress-deformation-strain

0.40 aoe |

//l

|

+5 °C

0.35

s

l/ ///

"(u gset

0.30

TE

NS

IL

E

ST

RE

SS

(M

Pa

)

"7

a

|

\

0.20

sl

|/

_-|/

s

I

//+40°C 0.10 | pameM .////

///////,/

/ / o L-- . -o ul 0 50, 100. 150, 200. 250, 300 x10 OEFORMATION (mm) (0 " 200 / 5,00 " 600 x 10% STRAINFig.4. Stress-deformation-strain relationships for HABl27T.

curves and not only by the more familiar stress-strain

curves, hence the deformation distribution on the horizontal

diameter is not uniform [2,4,5,23]. This is done in order

to eliminate the effect of using an assumed value for the

Poissons ratio for strain calculation at the center of the

specimen, which might affect the strain value. However, for

the sake of comparison, the tensile strain at the center of

the specimen is calculated by Equation 7.

The correlation coefficients (R) are higher than 0.94,

except for the porous graded mix tested at 25 degrees

Celsius, which is 0.83. In all the cases, the

stress-deformation relationships show curves which are concave

downwards. This means that strain increases faster than

stress and results in a reduction in resilient modulus. The

nonlinearity relationships are obvious even at low stress

and deformation levels. The non-linear viscoelastic

rela-tionships confirm the importance of stress and deformation

levels when measuring the resilient moduli of asphalt

mixtures .

The above discussion shows the dominance of viscous

prop-erties at high strain and stress levels. Therefore, and in

order to measure the resilient moduli of bituminous

materi-als with consistent in results, a viscoelastic linear zone

should be defined in which the effect of stress or strain

levels on the resilient modulus is negligible. If resilient

modulus is measured at higher stresses or strains, it could

- 0.40 & 0 0.35 E 3 n 10°C //+S°C / -§ 0.30 o % / *ZSOC - 025

/////,////

0.15

/

///

A

I|

|

aoe _|_

0.10

7

Tee

|__---*x

0.05

; *

// /

A

___/_l",////

/ / 0 - -4 0 50 100 150. 200. 250, 300. 350 400. x10 JEFORMATION(mm) -- } + i } -6 0 200 400 600 800 x10 STRAINFig.5. Stress-deformation-strain relationships for RUB1l2.

0.40 0.35 0.30 T E N S I L E S T R E S S ( M P a ) 0.25 020 015 010 0 05 Fig.6. Stress-deformation-strain relationships 10 |

1

~10°C

/

¥ +5 °C

//

/////

//

/

e

/ _- 25°C / _ l /| / c V/ // 7/ ________._ 4 |U/ //

/ / nona---|_| see

fuse //L-/"/ Louk 0 50 100 150. 200, 250 300 350 500 x 10 DE FOR2MATION (mm) 0 200 400 600 800 = 10 STR AIN for RUBD12 .p Linear zone is at o=A/B *100 © 10%

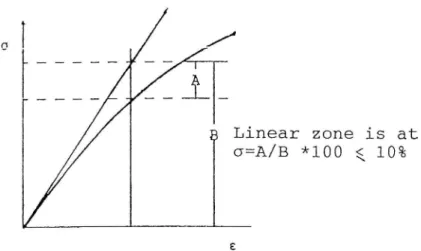

Fig.7. Isochronous stress-deformation curve.

conditions, in this case the stress or strain level should be reported.

The viscoelastic linear zone is defined, in this study, as the zone where stress in the stress-deformation curve divergqges with less than 10 percent from the rectilinear stress-deformation relation shown in Fiqure 7. The recti-linear stress-deformation relation is represented by the slope of the curve at the origin.

The 10 percent divergence of stress cause a 10 percent reduction in resilient modulus from the initial modulus value (modulus at origin). This variation is believed to be acceptable because of the hetrogeneity and unisotropy of asphalt concrete mixtures.

Figure 4 through 6 also show the limits of deformations and stresses at 10 percent reduction of resilient modulus. The stress limits decrease with increased temperatures but for deformations it is the opposite, i.e., the deformation limits increase with increased temperatures. A similar con-clusion is reported by other investigators [24,25 ,26] when exposing asphalt mixture specimen to different deformation rates, using the tensile strength method, higher elongation is reported at lower deformation (high temperatures

correspond to low deformation rates) and vice versa. At low temperatures the bituminous mixtures are stiff and brittle. They tolerate low strains with high stresses. At high

temperatures these mixtures have low stiffness and high flexibility. They tolerate high strains but with very low stresses.

Figure 8 shows a relation between temperatures and the logarithm of deformation limits, as defined before for

- 1000

600 - I 300

Log(D) = exp(0.0138T+0.313) &g | e00

2007 -400 mm -6 TE NS IL E ST RA IN x 10 - - 200 80 -D ]x 10 60 7 - 100 0 7 - 80 DE FO RM AT IO N ( 60 ad - 40 - 30 - 10 0 10 20 e TEMPERATUR (T) 2C

Fig.8. Relationship betweenn the logarithm of deformation and temperature.

tested mixtures (with 0.2 sec loading time, and a frequency of 20 cycle/min.).The correlation coefficient (R) for all materials together is 0.986, using regression Equation 8.

Log(D) = exp(0.0138T+0.,313) . | / . v v v v v & v k k v k k k k k k k k k k a k a (8 )

where

D= Horizontal deformation in mm x 107-74 T= Temperature in Celsius.

5 Resilient modulus

In accordance with the discussion in the above section regarding stress-strain relationships and the effect of irregularites of specimen surface the following procedure has been used for resilient modulus measurement. Indirect tensile test has been used on cylindrical bituminous sample.

* The test specimens were stored in a temperature cabinet to the proper temperature.

* Repeated-load pulses at a frequency of 0.33 Hz were applied with 0.2 sec loading time.

Ä minimum of 50 load repetitions were applied before the first reading and until the resilient deformation became constant .

The resilient horizontal deformation were measured at the maximum allowable load level and at 50 and 75% of this value. The test began at the lowest load level and increased gradually to higher load levels with about 25 load repetitions at each load level.

After the test had been completed, the tensile stress was calculated at each load level according to Equation

(1) .

Stress-resilient horizontal deformation curve was plotted. Curve fitting by linear regression analysis was used. In such cases, the zero point was adjusted as

shown in Figure 9 to compensate for surface irregulari-ties and insufficient contact between loading strips and specimen .

The resilient modulus was calculated with constant Poisson'!s ratio according to Table 1 at different temperatures by Equation 5:

/

LN

Fig.9. Correction of the stress-strain curve.

Table 1. Constant Poisson's ratio TeC n - 1 0 0 . 20 d- 55 0 . 25 +2 0 0 . 35 +4 ( 0 . 4 0 10000 + 8000 6000 $ 4000 -£ 92) -3 D CM 2 - 2000 + C

gä

[I x 1900 ---HAB12T n 1000 - - - RUBA2 ä - - -RUBD 12*xgjxx

500

he

~10

0.0

+10

+20

+30

+40

TEMPERATURE °C

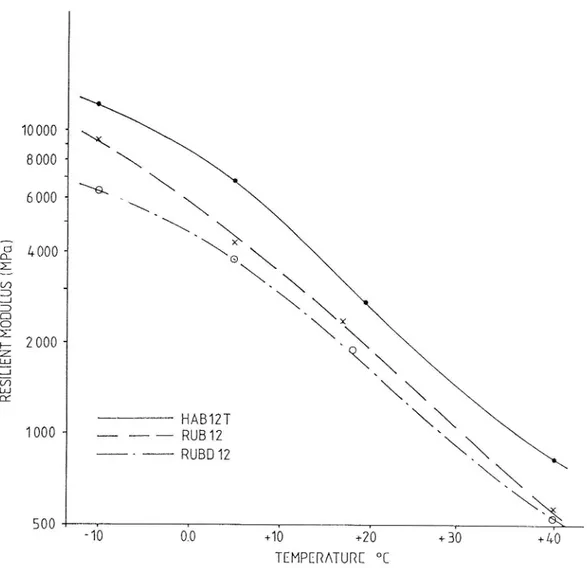

Fig.l10. Effect of temperature on resilient modulus.

Figure 10 shows the resilient modulus at different temperatures. The relationship between temperature and the log of resilient modulus is not linear. The rubberized mix

(RUB1I2) shows lower moduli than conventional mix (HABl27T), a fact which indicates the higher flexibility of the rubber-ized mix. The porous mix (RUBD12) has shown, as expected, the lowest moduli. Furthermore, there were no problems in measuring resilient modulus for the porous mix.

Conclusions

An approximate linear viscoelastic zone for practical use has been defined for asphalt mixtures at different

temperatures (with 0.2 loading time and 20 cycles/min.).

The upper loading strip should be free in order to create satisfactory contact between loading strips and specimen even at low stresses and stiff asphalt specimens.

One extensometer may be used instead of two LVDTs with carryirig frame. In that case the recorded deformation will not be influenced by the following: (1) the strength of the spring that keeps the LVDT cores in contact with the specimen, (2) the vibration of the frame which car-ries the deformation transducers, and (3) the extensive load on the specimen.

References

Kennedy T.W and Anagnos J.N, "Procedures for the Static and Repeated-Load Indirect Tensile Tests, "Research Re-port 183-14, Center for TransRe-portation Research, The Uni-versity of Texas at Austin, 1983.

Schmidt R.J, "A Practical Method for Measuring the Resil-ient Modulus of Asphalt-Treated Mixes", Highway Research Record, 404, 1972 .

; American Society for Testing and Materials,

ASTM D 4123-82, Method of Indirect Tension Test for

Re-silient Modulus of Bituminous Mixtures, 1984.

Wallace K. and Monismith C.L, "Diametral Modulus Testing

on Nonlinear Pavement Materials", Proceedings, The

Asso-ciation of Asphalt Paving Technologists, Vol. 49, 1980,

p. 633.

. Kennedy T.W, "Characterization of Asphalt Pavements

1 0 1 1 1 2 1 3 1 4 15 16

rials Using the Indirect Tensile Test" Proceedings of the Association of Asphalt Paving Technologists, Vol. 46.

1977 .

Baladi G.Y, Harichandrun R.S and Lyles R.W, "New Rela-tionships Between Structural Properties and Asphalt Mix Parameters", Paper presented at the Transportation

Research Board, 67Jth Annual Meeting, Jan 1988.

Hondros G., "The Evaluation of Poisson's Ratio and the Modulus of Materials of a low Tensile Resistance by the

Brazilian (Indirect Tensile) Test with Particular Refe rence to Concrete", Australian Journal of Applied Sci ence, Vol. 10, No. 3, 1959.

Baladi G.Y., Harichandrun R. and De Foe J.H., "The Indi-rect Tensile Test, a New Apparatus". Interim Report, College of Engineering, Michigan State University 1987.

Brown S.F and Cooper K.E, "The Mechanical Properties of Bituminous Materials for Road Bases and Base courses" Proceedings of the Association of Asphalt Paving

Technologists, Vol. 53, 1984.

. Pell P.58 and Taylor I.F, "Asphaltic Road Materials in Fatigue", Proceedings of the Association of Asphalt Paving Technologists, Vol. 38, 1969.

. Monismith C.L, Epps J.A and Finn F.N, "Improved Asphalt Mix Design" Proceedings, The Association of Asphalt Paving Technologists, Vol. 54, 1985, p. 347.

.Deacon J.A and Monismith C.L, "Laboratory FlexuralFatigue Testing of Asphalt-Concrete with Emphasis on Compound-Loading Tests", Highway Research Record, No. 158, 1967.

. Bonnaure F., Gest G., Gravious A. and Uge P., "A new Method of Predicting the Stiffness of Asphalt Paving Mixtures" Proceedings, The Association of Asphalt Paving Technologists, 1977, p. 64 .

. Kallas B.F. and Riley C., "Mechanical Properties of As-phalt Pavement Materials", Proceedings, 2nd International Conference on the Structural Design of Asphalt Pavements, Ann Arbor 1967, p. 931.

. Kallas B.F and Puzinauskas V.P, "Flexure Fatigue Tests on Asphalt Paving Mixtures", American Society for Testing

and Materials, STP 508, 1972, p. 47.

. Witczak M.W. and Root R.E., "Summary of Complex Modulus Laboratory Test Procedures and Results", American Society for Testing and Materials, STP 561, 1973, p.67.

17 . 18 . 19 20 21 22 . 23 24 25 . 26

Sayegh G., "Viscoelastic Properties of Bituminous Mixtures", Proceedings, 2nd International Conference

on the Structural Design of Asphalt Pavements, Ann Arbor 1967, p. 743.

Takallou H.B., McQuillen J. and Hicks R.G., "Effect of Mix Ingredients on Performance of Rubber Modified Asphalt Mixtures", FHWA-AK-RD-86-05, Federal Highway

Administration, May 1985.

.Lee M.A. and Emery J.J., "Improved Methods for Character-izing Asphaltic Concrete", Proceedings, Canadian Techni-cal Asphalt Association, Vol. 22, 1977, p.109.

.Vinson T. "Fundamentals of Resilient Modulus Testing" Workshop on Resilient Modulus Testing, Oregon State University, Corvallis, OR, 1989.

. Furber B. "Strain and Temperature Effects on Resilient Moduli" Workshop on Resilient Modulus Testing, Oregon State University, Corvallis, OR, 1989.

Said S.F, "Tensile and Fatigue properties of Bituminous Mixtures Using Indirect Tensile Method", Ph.D.

Dissertation, Department of Highway Engineering Royal Inst. of Technology, 1989.

. Kennedy T.W and Hudson W.R, " Application of the Indirect Tensile Test to Stabilized Materials", Highway Research Record 235, 1968.

. Eriksson R. "Dragprov på sandasfalt", Meddelande 85, Statens Väginstitut, Stockholm, 1954 .

Sugwara T. "Mechanical Response of Bituminous Mixtures under Various Loading Condations", Proceedings, 3rd In-ternational Conference on the Structural Design of As-phalt Pavements, London 1972, p. 343.

. Linde S. "Investigations on the Cracking Behavious of Joints in Airfields and Roads" SP Rapport 1988:23, Polymerteknik, Borås 1988.

L" ANALYSE D'EXTENSION INDIRECTE DES MODULES RESILIENTS

SAFWAT FP. SAID

L' Institut National Suédois de Recherches Routiéres et de la Circulation

Linképing, Suéde

Résumé

Les progrés faits dans le domaine du design analitique des structures de pavé ont rendu necessaire un croissant besoin de connaissances sur les propriétés mécanique des différents composants du pavé dans les conditions des routes; telles que la résistance a l'extension; la rigidité des modules et la résistance a plusieures réprises des mélanges de pavé en bé-ton. Ces paramétres constituent une base convenable pour le design analytique et l'évaluation des performances du pavé flexible.

Dans ce rapport-ci on a choisi l'analyse d'extension indi-recte a cause de sa validité et simplicité. En tout cas; on a éffectué des modifications de l' appareillage et des

procedures d'analyse.

On a examiné trois types différents de mélanges de pavé en béton par utilisant la méthode d'extension indirecte. Deux d'entre les mélanges sont mélés a 3% de contenu de caoutchouc par le poids total, c'est a dire le Rubit (RUB12), qui est un asphalt dense en béton, utilisé pour la réféction des routes, et un mélange poreux appéllé Rubdrain (RUBD12) . Le troisiéme mélange est un asphalt dense conventionnel en béton (HABI2T), utilisé pour la réféction des routes. La dimension maximum de l' aggrégat a été 12 mm pour tous les types.

La relation entre la tension et la déformation (stress-de-formation-strain) a été établie pour examiner l' influence du niveau de la tension et/ou la déformation sur le module rési-lient trouvé par l'analyse d'extension indirecte et pour dé-finir une zone viscoélastique approximativement linéaire pour les mélanges de bitume a temperatures différentes. Les modu-les résilients ont été mésurés par utilisant la méthode d'ex-tension indirecte, modifiée pour les mélanges analysés a 4 temperatures différentes.