Mälardalen University Press Licentiate Theses No. 218

DESIGN PROCESS OF FLEXIBLE ASSEMBLY SYSTEMS

Natalia Svensson Harari 2015

School of Innovation, Design and Engineering

Mälardalen University Press Licentiate Theses

No. 218

DESIGN PROCESS OF FLEXIBLE ASSEMBLY SYSTEMS

Natalia Svensson Harari

2015

Copyright © Natalia Svensson Harari, 2015 ISBN 978-91-7485-233-2

ISSN 1651-9256

Printed by Arkitektkopia, Västerås, Sweden

i

Abstract

Flexible assembly systems have emerged in response to changing markets and increased variety in form of demands of new products and manufacturer’s need for differentiation. Assembly systems play a critical role in handling great variety and adapting to dynamic changes at the same time as securing product quality and productivity. Therefore, assembly systems should be designed to be able to handle changes. However, the design of flexible assembly systems is a challenge because it involves several subjects such as the configuration of the flow, the material handling and the flexibility to handle future changes and adjustment. In addition, time-to-market and time-to-volume are important which means that faster assembly systems designs are required.

The design process of assembly systems concerns the procedures that guide the design work to achieve an assembly system proposal. The design process is divided into a number of stages/phases describing the activities that should be done and when they should be performed as well as the expected result after each phase supporting the decision-making process. Research argues that working in a systematic and structured way is important in order to achieve better assembly systems in shorter time.

However, even though there is extensive research work in regard to flexibility, knowledge is limited concerning the design process of assembly systems. Therefore, the objective of this thesis has been to increase the knowledge about the design of flexible assembly systems by investigating the relation between the assembly system design process and flexibility. The characteristics of flexible assembly systems and how flexibility is considered during the design process have also been studied in this thesis.

Literature reviews were conducted as well as three case studies and one exploratory survey in the manufacturing industry of heavy vehicles. Study I concerns the results of having studied an industrial international project of the design process of a flexible assembly system during two years. In study II, flexibility needs, enablers and challenges in assembly systems were identified. In study III, the mechanism used to achieve flexibility in the assembly systems of two companies were investigated. The exploratory survey study IV, was a pilot study to investigate the relationship between the design process of assembly systems and flexibility based on the association of different variables involved in the design process of flexible assembly systems.

From the holistic perspective adopted in this thesis, the results showed that flexibility should be considered in a comprehensive way during all the design process. The design process of flexible assembly systems is iterative, circumscribed by different conditions, and requires support as well as the participation of different roles and functions to achieve a solution. The increased knowledge generated in the research is expected to lead to future development of working procedures that better can support the design process of flexible assembly systems.

i

Abstract

Flexible assembly systems have emerged in response to changing markets and increased variety in form of demands of new products and manufacturer’s need for differentiation. Assembly systems play a critical role in handling great variety and adapting to dynamic changes at the same time as securing product quality and productivity. Therefore, assembly systems should be designed to be able to handle changes. However, the design of flexible assembly systems is a challenge because it involves several subjects such as the configuration of the flow, the material handling and the flexibility to handle future changes and adjustment. In addition, time-to-market and time-to-volume are important which means that faster assembly systems designs are required.

The design process of assembly systems concerns the procedures that guide the design work to achieve an assembly system proposal. The design process is divided into a number of stages/phases describing the activities that should be done and when they should be performed as well as the expected result after each phase supporting the decision-making process. Research argues that working in a systematic and structured way is important in order to achieve better assembly systems in shorter time.

However, even though there is extensive research work in regard to flexibility, knowledge is limited concerning the design process of assembly systems. Therefore, the objective of this thesis has been to increase the knowledge about the design of flexible assembly systems by investigating the relation between the assembly system design process and flexibility. The characteristics of flexible assembly systems and how flexibility is considered during the design process have also been studied in this thesis.

Literature reviews were conducted as well as three case studies and one exploratory survey in the manufacturing industry of heavy vehicles. Study I concerns the results of having studied an industrial international project of the design process of a flexible assembly system during two years. In study II, flexibility needs, enablers and challenges in assembly systems were identified. In study III, the mechanism used to achieve flexibility in the assembly systems of two companies were investigated. The exploratory survey study IV, was a pilot study to investigate the relationship between the design process of assembly systems and flexibility based on the association of different variables involved in the design process of flexible assembly systems.

From the holistic perspective adopted in this thesis, the results showed that flexibility should be considered in a comprehensive way during all the design process. The design process of flexible assembly systems is iterative, circumscribed by different conditions, and requires support as well as the participation of different roles and functions to achieve a solution. The increased knowledge generated in the research is expected to lead to future development of working procedures that better can support the design process of flexible assembly systems.

ii iii

Acknowledgements

There are numerous people that have contributed in various ways to this thesis and my research process so far. I particularly want to thank:

My supervisors, Professor Mats Jackson, Dr Jessica Bruch, Dr Anna-Lena Carlsson and Hans Wikstrand. I would like to express my deepest gratitude to you for your guidance through this research process and your help in completing this licentiate thesis.

Colleagues at Mälardalen University, IDT and Innofacture Research School who have supported me in one way or another.

Mona Lindberg, Jennifer Persson, and Lasse Frank for helping me with the cover of this thesis.

Colleagues at Volvo CE and all the people at the different factories that participated and allowed me to conduct my research studies.

My friends and family from the deepest of my heart, with a special thanks to my husband Joakim, because you have always been there for me.

Finally, this research work has been funded by the Knowledge Foundation within the framework of the INNOFACTURE Research School, the participating companies and Mälardalen University, Sweden. The research work is also part of the initiative for Excellence in Production Research (XPRES) which is a joint project between Mälardalen University, the Royal Institute of Technology, and Swerea. XPRES is one of two governmentally funded Swedish strategic initiatives for research excellence in Production Engineering.

Natalia

ii iii

Acknowledgements

There are numerous people that have contributed in various ways to this thesis and my research process so far. I particularly want to thank:

My supervisors, Professor Mats Jackson, Dr Jessica Bruch, Dr Anna-Lena Carlsson and Hans Wikstrand. I would like to express my deepest gratitude to you for your guidance through this research process and your help in completing this licentiate thesis.

Colleagues at Mälardalen University, IDT and Innofacture Research School who have supported me in one way or another.

Mona Lindberg, Jennifer Persson, and Lasse Frank for helping me with the cover of this thesis.

Colleagues at Volvo CE and all the people at the different factories that participated and allowed me to conduct my research studies.

My friends and family from the deepest of my heart, with a special thanks to my husband Joakim, because you have always been there for me.

Finally, this research work has been funded by the Knowledge Foundation within the framework of the INNOFACTURE Research School, the participating companies and Mälardalen University, Sweden. The research work is also part of the initiative for Excellence in Production Research (XPRES) which is a joint project between Mälardalen University, the Royal Institute of Technology, and Swerea. XPRES is one of two governmentally funded Swedish strategic initiatives for research excellence in Production Engineering.

Natalia

iv v

Publications

Appended papersPaper I – Svensson Harari, N., Bruch, J., Jackson, M. (2013)Flexibility Needs and Enablers in Assembly Systems. 22nd International Conference on

Production Research, ICPR22, Iguassu Falls, Brazil.

Contribution: The authors initiated and wrote the paper together. Svensson

Harari presented the paper.

Paper II – Svensson Harari, N., Bruch, J., Jackson, M. (2014) Mixed-Product

Assembly Line: Characteristics and Design Challenges. 6th Swedish Production Symposium, SPS14, Gothenburg, Sweden.

Contribution: The authors initiated the paper together. Svensson Harari and

Jackson wrote the paper together. Bruch supported with ideas about the content and structure of the paper. Svensson Harari presented the paper.

Paper III – Svensson Harari, N., Osterman, C., Bruch, J., Jackson, M. (2014)

Flexibility in Lean Mixed Model Assembly Lines. Advances in Production

Management Systems Conference, APMS 2014, Ajaccio, France.

Contribution: Svensson Harari wrote the paper together with Osterman. Bruch

and Jackson supported with structure and readability of the paper. Svensson Harari presented the paper.

iv v

Publications

Appended papersPaper I – Svensson Harari, N., Bruch, J., Jackson, M. (2013)Flexibility Needs and Enablers in Assembly Systems. 22nd International Conference on

Production Research, ICPR22, Iguassu Falls, Brazil.

Contribution: The authors initiated and wrote the paper together. Svensson

Harari presented the paper.

Paper II – Svensson Harari, N., Bruch, J., Jackson, M. (2014) Mixed-Product

Assembly Line: Characteristics and Design Challenges. 6th Swedish Production Symposium, SPS14, Gothenburg, Sweden.

Contribution: The authors initiated the paper together. Svensson Harari and

Jackson wrote the paper together. Bruch supported with ideas about the content and structure of the paper. Svensson Harari presented the paper.

Paper III – Svensson Harari, N., Osterman, C., Bruch, J., Jackson, M. (2014)

Flexibility in Lean Mixed Model Assembly Lines. Advances in Production

Management Systems Conference, APMS 2014, Ajaccio, France.

Contribution: Svensson Harari wrote the paper together with Osterman. Bruch

and Jackson supported with structure and readability of the paper. Svensson Harari presented the paper.

vi vii

Table of contents

Abstract ... i

Acknowledgements ...iii

Publications ... v

Table of contents ... vii

1. Introduction ... 1

1.1 Background ... 1

1.2 Problem description ... 2

1.3 Objective and research questions... 3

1.4 Scope and delimitations ... 4

2. Theoretical framework ... 5

2.1 Systems theory and assembly systems ... 5

2.2 Flexibility and flexible assembly systems ... 6

2.3 Flexibility and reconfigurability ... 12

2.4 Assembly systems design process ... 13

3. Research methodology ... 17

3.1 Research approach ... 17

3.2 Research design ... 17

3.2.1 Literature reviews ... 18

3.2.2 Conducted research studies... 18

3.3 Research process ... 22

3.3.1 Case study I ... 22

3.3.2 Case study II ... 23

3.3.3 Case study III ... 24

3.3.4 Explorative survey study IV ... 26

3.4 Cross-study analysis ... 34

3.5 Role of the researcher ... 34

3.6 Research quality ... 36

4. Results ... 37

4.1 Case study I ... 37

4.2 Case study II ... 48

4.3 Case study III ... 50

4.4 Exploratory survey study IV ... 52

5 Analysis... 75

5.1 Characterising flexible assembly systems ... 75

5.2 The design process of assembly systems and flexibility ... 81

5.3 Summary ... 88

6. Conclusion and future research ... 93

6.1 General conclusion ... 93

6.2 Research contributions ... 93

6.3 Research method discussion ... 94

6.4 Future research ... 95

vi vii

Table of contents

Abstract ... i

Acknowledgements ...iii

Publications ... v

Table of contents ... vii

1. Introduction ... 1

1.1 Background ... 1

1.2 Problem description ... 2

1.3 Objective and research questions... 3

1.4 Scope and delimitations ... 4

2. Theoretical framework ... 5

2.1 Systems theory and assembly systems ... 5

2.2 Flexibility and flexible assembly systems ... 6

2.3 Flexibility and reconfigurability ... 12

2.4 Assembly systems design process ... 13

3. Research methodology ... 17

3.1 Research approach ... 17

3.2 Research design ... 17

3.2.1 Literature reviews ... 18

3.2.2 Conducted research studies... 18

3.3 Research process ... 22

3.3.1 Case study I ... 22

3.3.2 Case study II ... 23

3.3.3 Case study III ... 24

3.3.4 Explorative survey study IV ... 26

3.4 Cross-study analysis ... 34

3.5 Role of the researcher ... 34

3.6 Research quality ... 36

4. Results ... 37

4.1 Case study I ... 37

4.2 Case study II ... 48

4.3 Case study III ... 50

4.4 Exploratory survey study IV ... 52

5 Analysis... 75

5.1 Characterising flexible assembly systems ... 75

5.2 The design process of assembly systems and flexibility ... 81

5.3 Summary ... 88

6. Conclusion and future research ... 93

6.1 General conclusion ... 93

6.2 Research contributions ... 93

6.3 Research method discussion ... 94

6.4 Future research ... 95

viii

Appendix A ... 103

Appendix B ... 104

Appendix C: Questionnaires ... 114

viii

Appendix A ... 103

Appendix B ... 104

Appendix C: Questionnaires ... 114

Appendix D: Questions variables ... 170

1

1. Introduction

This chapter presents the background of the research that is presented in this thesis. Two subjects have been central in the research: the design process of assembly systems and flexible assembly systems. Furthermore, this chapter outlines the research problem as well as the objective and research questions. The chapter ends with the scope and delimitations of the thesis.

1.1 Background

Nowadays, assembly systems need to be designed and operated to handle great variety (Hu et al., 2011) and to be flexible, adapting to dynamic change (ElMaraghy et al., 2013). According to ElMaraghy et al. (2013), some of the reasons behind the need for increased variety concern the demand for new products, regional requirements, emergence of new technologies and manufacturers’ need of differentiation. This is also argued by Wiendahl et al. (2007), who state that dynamic markets have impacted product and process life cycle- characteristics.

Hu et al. (2011) indicate that assembly is one of the most cost-effective approaches to handle product variety. To emphasise the importance of assembly for manufacturing industries, Lotter and Wiendahl (2009, p. 127) point out that “the assembly of industrially produced products requires anywhere from 15 to 70% of the total manufacturing time”. Furthermore, assembly systems bring together processes such as design, engineering, manufacturing and logistics in order to consolidate varieties of objects that perform a function based on different configurations (Whitney, 2004). Thus, understanding the design process of flexible assembly systems is important in order to cope with greater varieties in the form of, for example, handling demands of different products with shorter life cycles in dynamic markets.

The International Academy of Production Engineering (CIRP, 2014) states that the assembly system plays a critical role in product quality, system productivity and cost, and in order to respond to changing markets and increasing variety, flexible assembly systems have been introduced. However, the design of flexible assembly systems is a challenging task because it involves several interrelated subjects like material handling and process flow configuration as well as the flexibility to handle future changes or capacity adjustments (Heilala and Voho, 2001). In addition, time-to-market is critical, which means that a faster assembly system design process is required (ibid.) and time-to-volume is also important (Terwiesch and Bohn, 2001). Consequently, research into design processes of assembly systems reveals the importance of working in a systematic and structured way in order to achieve better assembly systems in shorter time (Bellgran, 1998).

2

To summarise the background to this thesis, it is clear that there is an industrial need to manage variations and changes in order to be competitive and knowledge in this area is important. Flexibility in assembly systems is in this thesis seen in the context of the ability and capability to adapt and to handle changes regarding to, for instance, volume or product changes within the system. Finally, to address the need for flexibility within assembly, it is critical to take flexibility into consideration during the assembly system design process. Based on this, the two subjects that are central in this thesis are the design process of assembly systems and flexible assembly systems.

1.2 Problem description

‘Flexibility’ is a broad term and several different definitions of flexibility exist in literature. There are differences in meanings and interests (Allvin and Aronsson, 2013) as well as variation in perspectives (D’Souza and Williams, 2000). While on one hand the vast literature about flexibility have made contributions to an increased understanding of this important concept, it is at the same time difficult to obtain a unitary framework (Toni and Tonchia, 1998). Flexible assembly system has been related to for example the use of all-purpose machines or robots to perform variety of tasks for multiple products (CIRP, 2014) as well as the sum of flexibility in individual equipment, products, processes and operations (Heilala and Voho, 2001). In order to better support industry in the development towards flexible assembly systems it seems important to establish an increased understanding of the characteristics of flexibility in assembly from a system perspective. Characteristics of flexible assembly systems is here understood as what makes them able to handle changes and therefore different from other assembly systems.

The assembly system design process concerns the activities performed when designing, i.e., the way or the procedure that guides the work performed to achieve an assembly system proposal (Bellgran, 1998). Rösiö and Bruch (2014, p. 106) state that “there is a lack of focus on production system design and projects are mainly owned by as well as focused on product design”. Research provides valuable contributions regarding the design process of assembly systems (Rampersad, 1994, Nof et al., 1997, Bellgran, 1998) and production systems (Bennett, 1986, Wu, 1992, Bennett and Forrester, 1993, Pisano, 1997, Ruffini, 1999, Christmansson and Rönnäng, 2003, Bellgran and Säfsten, 2010, Wiktorsson, 2012) as well as flexibility in production systems (Jackson, 2000, Petersson, 2000, Rösiö, 2012). However, even though there exist extensive work in regard to flexibility, knowledge is limited when linked to the design of assembly systems (Terkaj et al., 2009). In addition, industrial problems when designing assembly systems often include unclear objectives when developing the systems and their subject to change, meaning that designing flexibility is important (Chryssolouris, 2006). Accordingly, there is a need to study how the

3

design process of assembly systems is related to flexibility in assembly and analyse how flexibility could be considered in the design process.

Terkaj et al. (2009) suggest that it is fundamental to find ways to express flexibility needs of the companies from the production problem in an operative and pragmatic way. Furthermore, even though flexibility has been said to be an increasingly important attribute to manufacturing, it is also mentioned that it is often a problem to properly consider it in the decision making process if it is not properly defined in a quantitative way (Chryssolouris, 2006). In fact, recent studies consider it an unsolved problem to define precisely and in quantitative terms the required forms of flexibility (Terkaj et al., 2009), thus, it appears necessary to look for methodological approaches that could help to obtain also quantitative information of flexibility that could work as input to the design processes.

Finally, one trend is that assembly systems often need to be designed to handle fluctuating demand of diversified products, still utilising the same facilities and resources (for example mixed-model/mixed-product assembly). During the design work it is often a challenge to make trade-offs between efficiency and flexibility (Magnusson et al., 2009). Therefore it is necessary to comprehend the conditions that circumscribe the decisions about flexibility in the design process in regard to the wanted solution. Condition is in this thesis understood as the way in which flexibility could be introduced and evaluated during the design process in form of requirements, problems or challenge.

In summary, the main problem area addressed in this thesis is to understand how the design process of assembly systems is related to the need of flexibility in assembly. In order to address this problem area it is necessary to first understand the characteristics of flexible assembly from a system perspective. Second, it is important to comprehend how flexibility could be considered during the design process, and finally it is necessary to understand the conditions that circumscribe the decisions about flexibility in the design process. An expected result is increased knowledge to contribute to the development of working procedures that can lead to an effective flexible assembly design process.

Based on the problem described above, the objective and formulated research questions are presented below.

1.3 Objective and research questions

The objective of this thesis is to increase knowledge about the design of flexible assembly systems by studying the relation between the assembly system design process and flexibility.

In consequence, to meet this objective the following research questions have been formulated:

4

RQ1 What characterises flexible assembly systems?

Different definitions of flexibility are mentioned in the literature. Therefore, this question focuses on studying flexibility in assembly from a system perspective to identify characteristics that makes assembly systems flexible e.g. able to handle changes and therefore different from others.

RQ2 How is flexibility considered during the design process of assembly systems? There is extensive work in regard of flexibility, but knowledge is limited when linked to the design process of assembly systems. Supported by RQ1, this question will be answered by analysing the design process of assembly systems and studying how flexibility is considered in this design work. In addition, there will be analysis made of conditions that circumscribe the assembly systems design process in relation to flexibility e.g. requirements, problems, and challenges.

1.4 Scope and delimitations

During this research study, the researcher has had a role of an industrial PhD student within the Innofacture Research School with access to one manufacturing company in the automotive sector for heavy vehicles and therefore this research has been focused on this particular industry. Only one case study was made outside this company and this study was facilitated via Innofacture.

Since the design of assembly systems in Sweden has faced transitions from “non-traditional assembly systems designs” during the 1970s–1990s to the reintroduction of assembly lines in recent years (Blomquist et al., 2013), the assembly systems design processes accessible and studied at the companies have been in the form of assembly lines.

Flexibility and reconfigurability are both concerned with changes when analysing the assembly system (ElMaraghy and Wiendahl, 2009), therefore characteristics of reconfigurability are mentioned and discussed in this thesis, but the main focus is on flexibility within the assembly system. Accordingly, literature about transformability and agility which concerns changeability of the designed system has not been the focus of the conducted studies described in this thesis.

The focus of this research work so far is on the assembly system design process, and not on the product development process. Still, the products assembled have been taken into account in the sense that they are considered during the design process of flexible assembly systems. However, in accordance with the focus of this thesis no deep analysis of the impact of the design of the product is presented. Lean and the company’s production principles are not studied as such, but considering the increased number of company-specific production systems created on the basis of Toyota Production Systems (TPS) (Netland, 2012), these have been considered as a context of the design process of flexible assembly systems. This helps to understand the framework in which the assembly system operates.

5

2. Theoretical framework

This chapter presents the theoretical framework for the conducted research. The first section covers theory about systems theory and assembly systems. A holistic view has been adopted in this thesis and its justification is included in this section. Thereafter, theory on flexibility, flexible assembly systems and reconfigurability is presented. The last section concerns theory on the assembly systems design process.

The theory presented in this chapter helps to interpret the results from different conducted studies in connection to the research questions. It also represents the choices that have been made to approach the subjects of study in this research.

2.1 Systems theory and assembly systems

According to Skyttner (2001, p.53) “[a] system is a set of interacting units or elements that form an integrated whole intended to perform some function”. The assembly system can be seen as a collection of interrelated components such as people and machines organised to work together towards an end (Wu, 1992). The assembly system can be considered as an open system that has a dynamic relation with the environment, that adapts to changes and a competitive market, and with several factors that might affect the output (Bellgran and Säfsten, 2010). In this thesis, assembly is seen as an open system1 where the collection of its elements and their interaction form the whole and its function. Wu (1992) mentions that the system approach should be seen as appropriate for analysing problems generated in modern manufacturing operations, and by studying assembly as a system, a holistic perspective could be achieved (Bellgran and Säfsten, 2010).

Bennett and Forrester (1993) state that the elements of the assembly system are characterised by the organisation of work and the choice and arrangement of the physical facilities and human resources. Expanding on observations from other authors, Rösiö (2012) defines the elements of the assembly system as the technical system (hardware directly related to the assembly process), the human system (direct and indirect labour), the material handling system (hardware related to operations at or between stations), the computer and information system (hardware and software to be used to communicate information) and the building and premises. Hubka and Eder (1984) also mention the management and goal system. In addition, the socio-technical concept have emerged as a way to include the technical as well as the social system and their relation. The socio-technical school can, according to Johansson and Abrahamsson (2009), be viewed as a combination of the human relation school and scientific management, to which the system-theoretical approach is added. “The human relation school provides an

1 The openness of the system is the reason why financial issues sometimes is relevant to include,

6

analysis of the social system, while the scientific management school’s rational production technology constitutes the groundwork” (Johansson and Abrahamsson, 2009, p.84). In this thesis assembly is studied as a system and a holistic view has been adopted because it gives a wider margin for also incorporating elements of other theories such as the socio-technical one, which facilitates new interpretations.

In systems theory from a manufacturing context, Seliger et al. (1987) indicate that a complete description of a system is required to conduct a successful analysis, and three different system aspects are indicated; functional, structural and hierarchical. The functional aspects concern the behaviour of the system. The transformation of inputs into outputs is the function of the system (ibid.). The assembly system consists of the aggregation of processes to build a complete product by individual, batch or continuous process (Nof et al., 1997).

Structural aspects are used to describe the system. A system could be seen as a set of elements interlinked by relations given the structure of a system. An example of this in assembly systems is operators that assemble an object using production means such as tools at a determined station. The hierarchical aspects relate to the parts of the system as subsystems or components. Also, the system itself is part of a more comprehensive system called supersystem or hypersystem (Seliger et al., 1987). From this view the assembly system can be seen as a part of the production system and the production system as a part of the whole factory.

In this thesis, assembly concern the elements of the system which are the technical system, the human system, the material handling system, the information system, the buildings and premises, and the management system. These elements exert an impact on the operands to accomplish a desired transformation process; thus the product is also taken into account.

2.2 Flexibility and flexible assembly systems

There are different definitions of flexibility in the literature. Sethi and Sethi (1990, p. 295) defined “flexibility of a system as adaptability to a wide range of possible environments that it may encounter. A flexible system must be capable of changing in order to deal with a changing environment”. Another definition of flexibility is “the ability to change or react with low penalty in time, effort, cost or performance” (Upton, 1994, p. 73). The common indicator between the different definitions of flexibility is that they deal with a nature of change of the assembly system, see also Slack (1983, p. 7), Browne et al. (1984, p. 114), Gupta and Goyal (1989, p. 119), Olhager (1993, p. 69).

7

The emergence of production paradigms such as flexible assembly systems has also generated interest in flexibility. There are two aspects that revolve around the rise of flexible assembly systems; 1) changes in market demand and differentiation (Owen, 1984) and 2) the emergence of programmable automation, assembly cells and robotics (Owen, 1984, Nof et al., 1997). Referring to other authors Matt (2007) indicates that assembly systems allowing a mixed model at a certain level of variation and without interruptions for changeover are called flexible assembly systems. However, the flexibility of the assembly systems has been described concerning assembly system automation level, as well as volume, product variety, and batch size (see Figure 1.).

Figure 1 shows how different authors discuss and classify assembly systems according to the level of automation and its relation to flexibility. All of them indicate that manual assembly seems to be the more flexible with more variants or diversity in small quantity or small batch size. Lotter and Wiendahl (2009) refer to a certain productivity while the others refer to a certain production volume. Lotter and Wiendahl (2009) indicate that a classification of industrial assembly systems concepts is divided into rigid (predominantly automated) and flexible (predominantly manual) assembly systems. Heilala and Voho (2001) denote assembly systems as semi-automatic modular systems by combining flexible workstations of differing degrees of automation and material handling with operators’ skills. They also indicate that flexibility in production corresponds to the sum of the flexibility in individual equipment, products, process and operations as well as transport system (Heilala and Voho, 2001). This highlights that the flexibility of a system does not only correspond to the level of automation but to the flexibility of constituents of the system, processes and products. Recently, scholars have proposed the concept of fully flexible assembly systems (F-FAS), indicating that one major difference between the automated assembly station and the traditional FAS design is in the feeding subsystem (Rosati et al., 2013).

8 Fig ur e 1. A ss em bl y sy st em s a ut om at ion lev el , v ol um e, pr odu ct v ar iet y, b at ch si ze and f lex ibi lit y ac co rd ing to di ff er ent au thor s f rom 1994 unt il 20 13. (L otter an d W ien dah l, 20 09 ) (R os ati et al. , 2 01 3) (Heilala an d Vo ho , 2 00 1) Pr od uction Vo lu m e Fix ed sp ec ial p ur po se au to m at io n Flex ib le Au to m atio n M anua l Ass em bl y Lo w Hig h Fe w Lo w La rg e Hig h Ma ny Sm all Nu m ber o f Var ia nt s B atch Size Flex ib ili ty Se m ia uto m atio n (R am pe rs ad , 1994 ) Pr od uction Vo lu m e Me ch an ized Ass em bl y R ob otic Ass em bl y M anua l Ass em bl y Lo w Hig h Lo w Lo w La rg e Hig h Hig h Sm all Pr od uct Var iet y B atch Size Flex ib ili ty Pr od uctiv ity Au to m ated Ass em bl y H yb rid Ass em bl y M anua l Ass em bl y Lo w Hig h Lo w Lo w Hig h Hig h Hig h Lo w Qu an tit y Var ian t D iv er sit y Flex ib ili ty Pr od uc tio n Vo lu m e Ded icate d (au to m ated ) Ass em bl y S ys te m s Flex ib le ( au to m ated ) A ss emb ly S ys te ms M anua l A ss em bl y Sys te m s Lo w Hig h Lo w Hig h Nu m ber o f Var ia nt s B atch Size Flex ib ili ty F-FAS

9

Requirements of flexibility in assembly systems have been discussed with regard to the ability of the system to handle change, that is, for example, requirements in the form of capability, capacity and error recovery; this is summarised as the “ability to adapt to varying product life-cycle volumes, product variants and new products within the same system” (Heilala and Voho, 2001, p. 21). Also, different dimensions of flexibility correspond to the ability to change in determined time-frames when changes are needed (ElMaraghy and Wiendahl, 2009). In the literature concepts have been introduced to characterise flexibility, such as time, range and cost (Slack, 1983). Upton (1994) went further, stating that there are flexibility dimensions, time horizon and flexibility elements:

Dimensions are related to the required flexibility and need to change. There are different dimensions of flexibility described in the literature, see Browne et al. (1984), Atkinson (1985), Atkinson and Meager (1986), Sethi and Sethi (1990), Gupta and Somers (1992), Chryssolouris (1996), and Koste & Malhotra (1999).

Time horizon is related to the timeframe in which the change should occur, corresponding to operational, tactical or strategic flexibility.

Elements of flexibility are referred to as range, uniformity or mobility. The elements of flexibility are defined by Koste and Malhotra (1999) as range-number (R-N) related to a range-number of operations, tasks, products, etc.; range-heterogeneity (R-H) related to differences in operations, task, products, etc.; mobility (M) referred to as transition penalties like time, cost and effort; and uniformity (U) as the similarity of performance outcomes such as quality, cost and time within a range.

Flexibility is constituted by a requirement on the ability of the system to change, which corresponds to the different dimensions of flexibility; these dimensions in turn constitute a certain range in number or heterogeneity, mobility, which refers to the transition and uniformity that denotes the result.

In this research, the framework of Koste and Malhotra (1999) is adopted because it incorporates previous research in the field as well as new definitions of flexibility that include elements which are useful in order to understand characteristics of flexible assembly systems. These definitions are presented in Table 1.

10

Table 1. Flexibility definitions by (Koste and Malhotra, 1999)

Flexibility Definition

Machine Number and variety of operations that the machine can

perform.

Labour Number and variety of operations/tasks that workers can perform.

Material handling Number of paths and variety of material.

Routing Number of products with alternate routes and extent of variation between routes.

Operation Number of products with alternate sequencing plans and variety of plans.

Expansion Number and variety of expansions.

Volume Extent of change and degree of fluctuations on output level. Mix Number and variety of products that can be produced. New product Number and variety of products that can be introduced. Modification Number and variety of product modifications.

Product flexibility consists of new product flexibility and modification flexibility.

All of them without incurring high transition penalties or great changes in performance outcomes.

Furthermore, Koste and Malhotra (1999, p. 81) state, with regard to labour flexibility, that “conceptual and empirical literature is remiss in addressing this dimension”, however, the labour market and workforce has been one critical aspect related to assembly systems design in Sweden (Blomquist et al., 2013). Given that labour flexibility also has social implications other than those described in the framework, the works of Atkinson (1985), Atkinson and Meager (1986) and Allvin and Aronsson (2013) have also been used as a reference (see Table 2).

11

Table 2. Flexibility dimensions and definitions according to (Atkinson, 1985, Atkinson and Meager, 1986, Allvin and Aronsson, 2013)

Flexibility dimension Definition

Functional* Capacity of the job and the organisation of work such as teamwork. It implies a reorganisation and conversion of the operators to new work tasks.

Numerical* Adaption of the workforce to changes in production

not related to the performance of work. Some examples of this are temporary employment, outsourced personnel and staffing agencies.

Financial*2 Adjustment of working time or labour cost. It could also include variable salaries.

Time** Rules specifying the extent and location of the time

of work.

Space** Rules specifying the extent and location of the space

of work for the different tasks, for the assignment as a whole and for the workplace as a whole.

Horizontal organisation** Rules specifying the performance of work, i.e., rules making up the labour process as such.

Vertical organisation** Rules specifying the cooperation surrounding work, i.e., rules establishing control and an organisational structure.

Employment** Rules specifying the terms of employment,

formalised either in contract between the employer and employee or as laws and other legislative instruments.

*(Atkinson, 1985, Atkinson and Meager, 1986) ** (Allvin and Aronsson, 2013, p. 424)

The main idea of these definitions is that there are dimensions of flexibility that concern the design of the work and others that concern the employment.

Principles of the design of the work organisation such as versatile work content, and where the operators should plan, perform and monitor the production tasks (Mårtensson, 1995) have also been taken into account. These principles have also

2 Financial Flexibility was included but as mentioned earlier no financial analysis were performed because they are not within the scope of this thesis.

12

been part of theories about proactive assembly work settings, which are those able to adapt to dynamic changing environments in real time where the operators have active participation (Bruch, 2009, Dencker, 2011).

Considering the holistic view applied in this research, flexible assembly systems are seen as assembly systems that are able to handle changes based on different dimensions which take into account the role of the elements of the system and the products.

2.3 Flexibility and reconfigurability

In order to achieve flexibility, the concept of reconfigurability and reconfigurable manufacturing systems – RMS has appeared (Terkaj et al., 2009). Rösiö (2012, p.17) defines reconfigurability as “the ability to add, remove, and/or rearrange the production system elements in a timely and cost-effective manner which can result in a desired set of alternative configurations”. According to Koren et al. (1999), an RMS is designed to adjust production capacity and functionality within a part family by changing the structure as well as hardware and software components, due to market changes or regulatory requirements. RMS were introduced with a view to economic benefits obtained by increasing reusability and reducing excess capacity and/or excess functionality (ElMaraghy, 2005). However, Terkaj et al. (2009) argue that reconfigurability should be designed to accomplish the change, and there is an installation and operating cost. ElMaraghy (2005) describes RMS as a system that provides customised flexibility of demand in a short time. Some of the characteristics of RMS are scalability, convertibility, modularity, integrability, diagnosability, automatibility, customisation and mobility (Koren et al., 1999, Rösiö, 2012).

According to the definitions of reconfigurability characteristics presented by (ElMaraghy, 2005), it can be argued that reconfigurability is in some way similar to volume flexibility and mix flexibility. RMS considers scalability as increasing capacity and capability through hardware, and convertibility allows quick changeover between products.

ElMaraghy (2009) differentiates the characteristics of reconfigurability by delimiting that flexibility is related to changes of the system behaviour without changing its configuration, while reconfigurability would change the system behaviour by changing its configuration. Also, Jackson (2000) mentions that flexibility relates to the system being designed to deal with changes effectively, while reconfigurability deals with change of the system; it can be deconstructed and reconstructed as needed. Reconfigurability does not contradict flexibility; it can be seen as a capability to achieve flexibility (Rösiö, 2012). This is how reconfigurability is understood in this thesis, e.g. considered as the ability to achieve alternative desired configurations based on their characteristics.

13

2.4 Assembly systems design process

Slack et al. (2007, p.90) define design as “to conceive the looks, arrangement and working of something before it is constructed” and the design activity can be approached at different levels of detail. According to Blessing and Chakrabarti (2009, p.2), “design is a complex, multifaceted phenomenon, involving: people, a developing product, a process involving a multitude of activities and procedures; a wide variety of knowledge, tools and methods; an organisation; as well as micro-economic and macro-micro-economic context.” A process can be defined as “a series of activities, changes or functions which lead to a result” (Karlsson et al., 2009, p.569).

An assembly system design process involves the activities performed when designing e.g. it concerns the way or the procedure that guides the design work that is performed to fulfil the selected assembly system proposal, but not its realisation, while the development of assembly systems involves its realisation (Bellgran, 1998). The design of the assembly system can then be seen as a part of the development of the assembly system.

A design process is divided into a number of stages/phases, some of them iterative. It refers to the activities that should be done and when they should be performed as well as the expected result after each phase supporting the decision-making process. It can also incorporate methods and tools (Rösiö and Bruch, 2014).

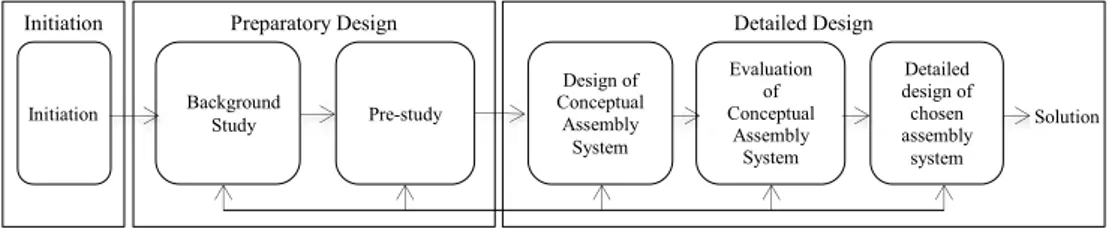

Different proposals for assembly systems design processes have been found in the literature (Rampersad, 1994, Nof et al., 1997, Engström et al., 2001) as well as proposals regarding production system design (Bennett, 1986, Wu, 1992, Bennett and Forrester, 1993, Pisano, 1997, Ruffini, 1999, Christmansson and Rönnäng, 2003, Bellgran and Säfsten, 2010, Wiktorsson, 2012, Karlsson et al., 2009). There are also generic design methods and approaches (Rao and Gu, 1997, Suh et al., 1998, Cochran et al., 2001, IEEE, 1998). Bellgran (1998) developed a method supporting planning of an assembly system design process where different phases and activities are specified in detail. This work was further developed into a framework for a structured way of working with assembly systems development (Bellgran and Säfsten, 2010). Based on this framework and other authors, Bruch (2012) and then Rösiö (2012) compiled the typical activities carried out when designing the assembly system. These are framed in phases of initiation, background study, pre-study, design of conceptual assembly system, evaluation of conceptual assembly system and detailed design of the assembly system, see Figure 2.

According to Rösiö and Bruch (2014), the former phases of a design processes, also called early phases, are considered crucial because they allow the creation of the preconditions for the following phases, comprising an initiation stage, project

14

definition and design of conceptual assembly systems, while the phases that follow are design, implementation, launch and disposal.

Figure 2. Phases of the assembly system design rocess (Bellgran, 1998, Bellgran and Säfsten, 2010, Bruch, 2012, Rösiö, 2012)

The design work is carried out in the form of a project work involving different parties such as users, designers, economists and union representatives (Karlsson et al., 2009). Bellgran (1998) states that the project organisation when designing is a matter of strategic concern and suggests that the competence required for the assembly system design should be identified in order to establish the existence or need of education or recruitment of new employees. She also recommends that those who will eventually work in the assembly system should participate in the problem analysis, requirement specification and maybe also (at least by representation) when formulating the assembly system proposal (Bellgran, 1998). The development of assembly systems has over time been affected by factors summarised by Bellgran and Säfsten (2010, p.34) into three categories: external influences (history, trends, globalisation, company structure), strategies and fundamental attitudes among the individuals involved in the development of the assembly system (management strategies, production philosophies, company culture) and actual options (technology, work environment and organisation, planning and control).

In Sweden socio-technical theories have affected the design of assembly systems away from traditional assembly lines implying increased work content for assemblers. The organisation of the production and work has over the years included discussions about working conditions and work environment (Johansson and Abrahamsson, 2009). Many cases of experiences of assembly system design in Sweden have been further studied and described by Berggren (1992). In those analyses the way in which equipment and workstation are grouped and how the physical flow is organised has been one central dimension. Forces driving the reintroduction of the assembly line in Sweden can be found in Blomquist et al. (2013). This analysis addresses a number of additional issues: productivity, ergonomics, standardisation of production system, labour market situation, etc. A framework of assembly system design has been presented by Bennett (1986), who states that the design of assembly systems is influenced by a number of factors, some of them “visually apparent” like the layout together with the work organisation (product-oriented, i.e. position layout, process-oriented, i.e. batch

Initiation Initiation Preparatory Design Background Study Pre-study Detailed Design Design of Conceptual Assembly System Evaluation of Conceptual Assembly System Detailed design of chosen assembly system Solution

15

production, functional layout, task-oriented, i.e. continuous or flow, line layout) but also by motivational, technological, environmental and legal considerations. With regard to flexibility and the design process of assembly systems, different kinds of flexibility have been found in work of Bellgran (1998). Design option guides featuring flexibility have been presented by Bennett and Forrester (1993). Flexibility and reconfigurability have been considered in a model proposed by Jackson (2000), and a support for reconfigurability in the production systems design process was developed by Rösiö (2012). These contributions provide valuable information that has been taken into account to answer the research questions in this thesis.

A general synthesis of the theoretical framework:

As mentioned at the beginning of this chapter, the theoretical framework presented the foundation of the choices that have been made to approach the subjects of study. These are summarised below.

In this thesis a holistic view, incorporating socio-technical elements, is adopted since it facilitates new interpretations and allow to study the subjects in question. The contributions of flexible assembly systems are seen as important in this thesis because they incorporate considerations pertaining to this work as well as aspects of reconfigurability.

Flexible assembly systems are seen as assembly systems that are able to handle changes based on different dimensions that take into account the role of the elements of the system and the products.

The framework of Koste and Malhotra (1999) is adopted, incorporating flexibility dimensions and definitions according to Atkinson (1985), Atkinson and Meager (1986), and Allvin and Aronsson (2013). Principles of design of the work organisation (Mårtensson, 1995) and proactive assembly work settings (Bruch, 2009, Dencker, 2011) have also been taken into account.

Reconfigurability is considered as a capability to achieve flexibility; it is seen as the ability to achieve alternative desired configurations based on their characteristics.

The design process proposed by (Bellgran, 1998) and then extended by Bellgran and Säfsten (2010), Bruch (2012), and Rösiö (2012) is adopted in this thesis because it is detailed for the study of assembly systems design. It includes defined design phases; the work of Bellgran (1998) incorporates aspects of flexibility that are also relevant for this thesis.

Additionally due to the specific characteristics of study IV, theories from this chapter have been used to identify variables within assembly and from there

16

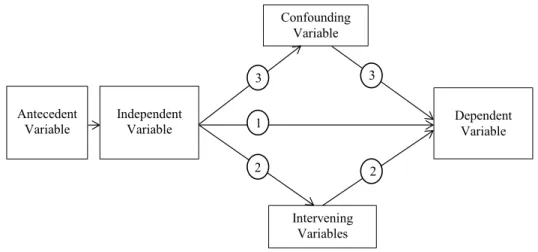

indicators and scales have been derived in the operationalisation in the study. This is described in more detail in the following chapter and can be seen in Figure 4 Diagram of Association of Variables and in the Operationalisation in Appendix B. The identified variables are:

Antecedent variable corresponding to the company strategy and production principles.

Independent variable corresponding to the design process of assembly systems, including product design, recruitment of personnel, and reconfigurability.

Intervening variable corresponding to the organisation of the project and competence, who is involved in the project, union, working conditions, training and education, reconfiguration of times, legislation, safety, environment and health, available technology, economic/labour situation. Dependent variable corresponding to the flexible assembly systems

including the already mentioned flexibilities.

Confounding variable including cultural aspects, those that describe the studied population such as age, and others.

17

3. Research methodology

This chapter presents how the research in the thesis has been conducted. It describes and motivates the research design and the methods used. It also presents the role of the researcher and research quality.

3.1 Research approach

The problem description presented at the beginning of this thesis called for methodological approaches that could contribute to increased knowledge in the area of design processes of flexible assembly systems. As motivated in chapter 2, a system approach has been adopted in this thesis.

Based on the systems approach and the formulated objective and research questions, mixed-method approaches have been used which involves the collection and analysis of both qualitative and quantitative data (Creswell, 2013). A quali-quantitative approach has been applied in this thesis and is intended to help to achieve, from the qualitative part, a deeper understanding of the problem studied as well as to help to describe for example the context in which the assembly system operates or is designed. With the quantitative part it is possible to achieve a more structured analysis, comparisons and measures (Holme and Solvang, 1997).

In this thesis the relation between the design process of assembly systems and flexible assembly systems is studied and therefore it is relevant to incorporate, for example, the opinion of the people involved in the process and the users of the assembly systems as well as cultural3 characteristics. These cannot be quantified but can be qualified, while with the quantitative approach it is possible to obtain numerical results to compare, contrast and create scores.

3.2 Research design

The research design is conducted to plan a structured process for collecting data, perform the analysis, and draw conclusions (Yin, 2014). Inspiration has been found in the research design components described by Maxwell (2005) taking into account the objective of this thesis and defining the research questions from the problem description already presented in chapter 1, determining the theoretical framework which has been presented in chapter 2, and determining the methods and validity. The methods and the quality of the research are presented in this chapter. This thesis is based on theory and the data from the conducted studies in order to answer the research questions. The studies are described next.

3‘Culture’ is understood as acquired characteristic realisations of human groups such as

language. Culture can be incorporated in social traditions of groups, for example, knowledge, ideas, beliefs, and norms (Fairchild, 2010).

18

3.2.1 Literature reviews

Literature reviews have been conducted concerning system theories, assembly systems, design and design processes of assembly systems/production systems, flexibility, reconfiguration and flexible assembly systems. A couple of the databases used have been Scopus and Web of Science. MDH and KTH library databases have also been visited. Google scholar was used to identify articles that may not be visible in the databases visited. In addition, some operations management journals have been searched for papers: International Journal of Operations & Production Management, International Journal of Production Economics, International Journal of Production Research, Journal of Operations Management and Global Journal of Flexible Systems Management. Books and theses have also been reviewed.

The following keywords were primarily used for searching in databases: systems theory, assembly, assembly systems, design, assembly/production system design, design process, design process of assembly/production systems, assembly/production system development, flexibility, flexible assembly system, flexible production system, flexible manufacturing systems, reconfiguration, reconfigurable manufacturing/production systems, product development process, lean, stage-gate model, assembly system design methods, design methods.

To determine if a publication was relevant or not, the steps suggested by Blessing and Chakrabarti (2009, p.52) were followed: read the abstract, if the abstract is interesting then read the introduction and the conclusions, if these are interesting and relevant in relation to the research questions and objective, then read the results, and if these are relevant read the background, objectives and setup. The quick read is aimed to determine what the objective is, why the authors have done what they did, what research methods were used, what the findings are and what the quality of the research is (ibid., 2009).

3.2.2 Conducted research studies

As seen in the theoretical framework, the design process of flexible assembly systems is complex and involves a number of interrelated subjects. In this thesis three case studies and one exploratory survey study were conducted.

These studies are connected by the common denominator of flexibility in assembly systems. In each of the studies, particular aspects were considered and required specific approaches. The studies can be linked together under the common denominator of flexibility within assembly systems.

The selected cases considered different aspects of flexibility and were chosen because they corresponded to situations where it was feasible to gather the necessary information to obtain reasonable results.

The case studies have been designed to be used in investigations of contemporary phenomena in real industrial contexts pertinent to this research (Yin, 2014) and

19

allowed the use of different techniques for data collection. Case studies, allow in-depth analysis of a case such as a design process and to delimit the subject of study and specify the scope of the study which helps to answer the formulated research questions (Creswell, 2013). The exploratory survey study was designed based on the association between variables using quali-quantitative methods. It allows a study of the relation between the design process of assembly systems and flexibility in assembly in line with the objective of this thesis. It provides a picture of the outcome (flexible assembly systems) and the characteristics associated with it at the specific point in time when the study was conducted. According to Forza (2009), exploratory surveys allow to gain preliminary insight into a topic and provides the bases for more in-depth survey research. It can help for example to determine the concepts to measure providing preliminary evidence of association among concepts.

The studies conducted and their units of analysis were:

Single longitudinal embedded case study I: an industrial project of a design process of an assembly system. Flexibility is the embedded unit of analysis. The longitudinal nature of the case allowed covering trends over an extended period of time, following the unit of analysis in depth. This study is mainly descriptive.

Single case study II: an industrial project with focus on achieving flexibility in assembly systems, it involved 7 assembly systems of different factories.

Multiple-case Study III: design of five assembly lines in two factories (3 lines in one and 2 line in the other one), the unit of analysis was flexibility in assembly systems.

The application of a multiple-case study allows the inclusion of two cases with the aim of achieving more compelling results.

In case studies II and III semi-structured interviews were considered appropriate because they allowed a combination of open and closed questions (Lantz, 1993) to gather the necessary data.

The contribution of case study I and II to RQ2 is also based on the identification of conditions (requirements, problems and challenges) that circumscribed flexibility in assembly.

The first three studies contributed to partially answer the research questions repectively, and gave important understanding and knowledge. However to be able to fullfill the main objective of this thesis further understanding about the relation between the design process of assembly systems and flexibility in assembly was necessary. Based on the experience and understanding gained from the first three studies and since, as mentioned by Chryssolouris (2006) and Terkaj

20

et al. (2009), there are many studies of flexibility but a limited number of contributions that consider also the quantitative part. Thus, a study IV was designed as a pilot with the aim to face these limitations. The pilot study primarily helps addressing the general objective of this thesis which is to study the relation between the design process of assembly systems and flexibility in assembly and it also contributes to answer RQ1 and RQ2:

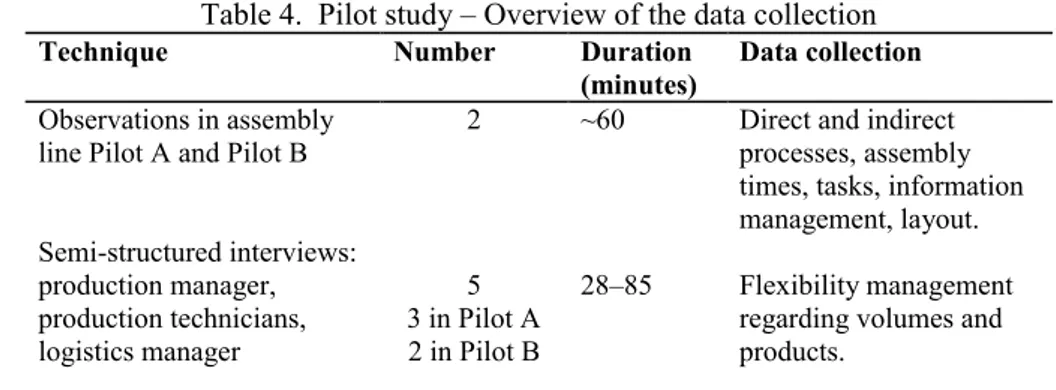

Exploratory Survey Study IV: 2 Industrial projects of the design process of flexible assembly systems where reconfigurability and flexibility are the embedded unit of analysis; and 2 assembly lines to study flexibility and reconfigurability in assembly systems.

An overview of the research questions and conducted studies is presented in Table 3 and a description of each study is provided in the following sections.

21 Table 3. Ov erview of th e r es ea rc h q ue st io ns a nd th e s tu di es C ont rib ut io n o f t he s tu dies to a ns w er th e resear ch q uest io ns Un it o f a na lys is Em bed ded u nit o f a na lys is Par ticip atin g f ac to ries an d l oca tio n B ran ch o f t he in dus try / p rodu ct Pu blis hed p ap er RQ Stu dy RQ 1 ,2 Lo ng itu din al em bed ded ca se st ud y I An in du str ial pro je ct Proj ec t o f ass em bl y sy ste m desig n p ro ce ss Flex ib ili ty 2 Sw ed en , 1 P ol an d, 1 USA , 1 Ko rea, 1 Fra nce , 1 Ger m an y Au to m oti ve/ hea vy veh ic les ( fin al pr od ucts) II* * RQ 1 ,2 Sin gle c ase st ud y I I An in du str ial pr oj ec t * Flex ib ili ty in th e ass em bl y sys te m - 2 S w ed en *, 1 P ol an d, 1 USA , 1 Ko rea , 1 Fra nce , 1 Ger m an y Au to m oti ve/ hea vy veh ic les ( fin al pr od ucts) I RQ 1 ,2 Mu ltip le -ca se st ud y III Fiv e as se m bl y lin es a t t w o dif fer en t fac to ries Fiv e as se m bl y li nes, fle xib ilit y in t he ass em bl y sys te m - Sw ed en Au to m oti ve/ hea vy veh ic les a nd au to m oti ve/tr uck s an d bu se s (c om pon en ts ) III RQ 1 ,2 Ex plo rato ry su rv ey s tu dy I V Tw o in du str ial pr oj ec ts in two fac to ries Tw o ass em bl y lin es Tw o pr oj ec ts of a ss em bl y sy ste m d es ig n p ro ce ss Flex ib ili ty an d r ec on fig ur ab ili ty Sw ed en Au to m oti ve/ hea vy veh ic les (f in al p ro du ct an d co m po ne nt ) - Two ass em bl y li nes, fle xib ilit y an d rec on fig ur ab ilit y i n th e ass em bl y s ys te m - * Fo r th is s tu dy o ne in du str ial p ro jec t r elate d t o f lex ib ilit y w as id en tif ied in o ne of th e fa cto ries in S w ed en alr ea dy p ar ticip atin g in th e pr oj ec t m en tio ned in ca se stu dy I. Data fr om th e pr oj ec t m en tio ned in ca se st ud y I w as als o i nc lu ded in th is st ud y. ** R es ult s p ar tiall y p resen ted in P ap er II .

22

3.3 Research process

This research started with literature reviews in parallel with the design of case study I. The literature has been reviewed along the whole licentiate process as long as more knowledge was obtained and in order to be updated in the fields of study. In parallel with this, other studies, case study II, case study III and exploratory survey study IV were designed and conducted. Some of the studies resulted in publications. A description of this process is presented in Figure 3.

Figure 3. General description of the studies presented in this thesis. This thesis was written until September 2015. A description of the studies conducted is presented below.

3.3.1 Case study I

An industrial project regarding the design process of a mixed-product assembly concept with a focus on flexibility was actively studied through the author’s participation as an industrial PhD student in the project, which allowed following the design process closely from the time it started in September 2012 until its end in December 2014.

The purpose of this study was:

To study an industrial assembly system design project to learn how flexibility was considered in the design process and to identify the conditions (requirements, problems and challenges) that circumscribed how flexibility was taken into account in the project.

To study the characteristics of the assembly system design concerning flexibility.

This study contributes to answer the research questions RQ1 by analysing what characterises flexible assembly systems as well as RQ2 by analysing how flexibility is considered during design process of assembly systems.

The project was international but managed from Sweden. The project group consisted of a project manager, a consultant, production engineers from the different factories involved, a logistics developer and PhD students.

Sept 2012 Sept 2013 Sept 2014 Mars 2015

Review of literature, company documents, books, as well as previous works such as thesis. Also continuous observations in assembly.

Exploratory survey study

IV Case Study II

Paper I Case Study III Paper III

23

3.3.1.1 Data Collection

Multiple techniques for data collection were used in this study, which gave a broad picture of the project. Data were gathered from the beginning through participant observations in the design activities. This means that the project and design activities were followed through the weekly project meetings and workshops where, in addition to the access to the presentations and documents, notes were taken. Observations were also conducted in different assembly systems settings of the corporation in Sweden as well as three overseas (South Korea, USA and Brazil). The observations in the assembly systems included the support of production engineers and workers at the stations who explained about the systems. Continual formal and informal conversations with project members and experts of the company about the design process and assembly systems were held.

Documents about the company and the project as well as the presentations, photos and films were accessible and reviewed. The reports of the project were reviewed and approved by the project group. These reports have also been reviewed and used as sources of information, in some cases also compared with the researcher’s notes.

3.3.1.2 Data Analysis

Collected data have been organised chronologically and analysed with regard to the theoretical framework. As mentioned before, this study is mainly descriptive. Design challenges and characteristics of the mixed-product assembly line concept under study are presented in Paper II. The results were continuously discussed with the project manager, who is also the researcher’s supervisor. The industrial supervisor representative of the company was involved in the discussions.

3.3.2 Case study II

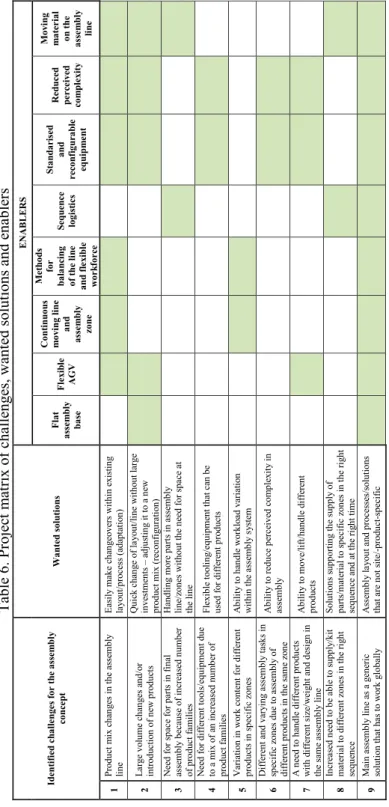

The purpose was to study flexibility in assembly systems by investigating the needs, enablers and challenges at the case company. This study contributes to answer RQ1 by answering what characterises flexible assembly systems as well as RQ2 by identifying conditions (requirements, problems and challenges) that circumscribed designing in flexibility in assembly.

One industrial project of increasing flexibility in assembly in a factory in Sweden was identified, and studied. The industrial project of flexibility at the factory had the aim of analysing the flexibility of the assembly system which included an assembly area composed of two assembly lines and a workshop. The assembly lines were of interest to the study due to the quantity of product variants assembled: five product variants are assembled in the first assembly line and ten in the second one. The industrial project included members with for example, different roles such as engineering, planning, and logistics.