School of innovation, design and engineering

Toward an energy

self-sufficient paint shop

Bachelor Thesis

15 credits, C-level

Product and process development Production and logistics

Violet Mohammadpour

Oskar Hane

Supervisor (Company): Niclas Forsman

Supervisors (Mälardalen University): Viktorija Badasjane, Natalie Agerskans Examiner: San Giliyana

ABSTRACT

As manufacturing is creating welfare and prosperity, it is important for humankind. Nevertheless, manufacturing is causing the depletion of natural resources, environmental burdens affecting the health of animals, humans and eco-systems, and social conflicts. Thus, it is essential to implement sustainability into manufacturing. Paint shops are however known for being liable for a big part of the large energy consumptions within manufacturing. Therefore, it is necessary to investigate what cost-effective solutions can be implemented in paint shops in order to reduce the energy consumption in a sustainable manner. Hence, the aim of this study was to, from a manufacturing perspective identify possible cost-effective solutions for lowering energy consumption within paint shops. The aim was further divided into two research

questions:

• RQ1: What are the enablers for energy efficient paint shops? • RQ2: What are the challenges for energy efficient paint shops?

The research approach used to answer the aim and research questions were a literature review and a case study. The literature review was performed to get a deeper understanding of the subject and was then complimented with the findings from the case study. The case study was performed at the paint shop of a global automotive manufacturing company in Sweden, which currently have a high energy consumption.

The enablers identified were (1) implementation of solar photovoltaic, and an energy storage system, which enables an environmentally friendly way of generating energy on-site and store excess energy for later use. The energy storage system can also be used to save money by utilizing the fluctuating electricity market prices, charging the battery when the energy price is at its lowest. (2) Implementation of an UV-curing system and paint, which is an

environmentally harmless method of curing paint. (3) Reducing or disabling the heating, ventilation and air conditioning system of a building when it is not a necessity. (4) Workers commitment and motivation towards sustainability, to ensure everyone’s participation. The challenges identified were (1) the expensiveness of sustainability, allocating and prioritizing it in budgets is challenging for a company since profitability is always a major concern that often overshadows sustainability. (2) The risk of modifying the processes within the paint shop, as the consequences are unexplored. (3) In its current state, the energy

consumption of the paint shop is very high, it is hence difficult to provide the whole paint shop with solely solar photovoltaic. (4) An energy storage system requires space and freeing up that space is a challenge without reconstructing existing facilities. (5) With implementation of UV-curing, the paint used must be curable with UV-light. Additionally, complex three-dimensional shapes make it challenging to properly cure evenly with UV-curing. (6) It is not guaranteed whether it is possible to completely shut down heating, ventilation and air conditioning since industrial equipment in general is designed to always run. (7) Sustainability is not a focus and even if it is increasingly requested by society, the commitment of companies is experienced as low. It is challenging to motivate all the employees to work towards sustainability and find ways to always keep sustainability in mind and to prioritize it over other alternatives.

Key words: Paint shop, Energy efficiency, Self-sufficient manufacturing, Sustainability, Variable renewable energy, Solar photovoltaic, UV-cure paint, Energy storage system

SAMMANFATTNING

Eftersom tillverkningsföretag skapar välfärd och välstånd är det viktigt för mänskligheten. Ändå bidrar tillverkningsföretag till att naturresurserna blir utarmade, miljöbördan som

påverkar djurens, människors och ekosystemens hälsa samt social konflikt. Därav är det viktigt att implementera hållbarhet i tillverkningsföretag. Målerier är dock kända för att stå för en stor del av den höga energiförbrukningen inom tillverkningsföretag. Av den anledningen är det nödvändigt att undersöka vilka kostnadseffektiva lösningar som kan implementeras i målerier för att minska energiförbrukningen på ett hållbart sätt. Följaktligen var syftet med denna studie att från ett tillverkningsperspektiv identifiera möjliga kostnadseffektiva lösningar för att sänka energiförbrukningen inom målerier. Målet delades vidare upp i två frågeställningar:

• RQ1: Vilka möjliggörare finns för energieffektiva målerier? • RQ2: Vilka utmaningar finns för energieffektiva målerier?

Forskningsmetoden som användes för att besvara syftet och frågeställningarna var en litteraturöversikt och en fallstudie. Litteraturöversikten genomfördes för att få en djupare förståelse av ämnet och kompletterades med resultaten från fallstudien. Fallstudien utfördes på ett måleri hos ett globalt fordonstillverkningsföretag i Sverige, som för närvarande har en mycket hög energiförbrukning.

De identifierade möjliggörarna var (1) implementering av solceller och ett

energilagringssystem, vilket möjliggör ett miljövänligt sätt att generera energi på plats och lagra överskottsenergi för senare användning. Energilagringssystemet kan även användas för att spara pengar genom att använda de fluktuerande elmarknadspriserna, att ladda batteriet när energipriset är som lägst. (2) Implementering av ett UV-härdningssystem och färg, vilket är en miljövänlig metod för att härda färg. (3) Minska eller inaktivera värme-, ventilations- och luftkonditioneringssystemet i en byggnad när det inte är nödvändigt. (4) Arbetarnas engagemang och motivation mot hållbarhet, att säkra allas deltagande.

De utmaningar som identifierades var (1) det dyra priset på hållbarhet, att fördela och prioritera det i budgetar är utmanande för ett företag eftersom lönsamhet ofta överskuggar hållbarhet. (2) Det är riskabelt att modifiera processerna i måleriet eftersom konsekvenserna är okända. (3) I sitt nuvarande tillstånd är energiförbrukningen i måleriet för hög, därmed täcks inte behovet av enbart energi från solceller. (4) Ett energilagringssystem kräver utrymme och att frigöra det utrymmet är en utmaning utan att behöva rekonstruera befintliga anläggningar. (5) Vid implementering av UV-härdning måste den använda färgen vara härdbar med UV-ljus. Dessutom kan komplexa tredimensionella former göra det utmanande att UV-härda ordentligt och jämnt. (6) Det är inte nödvändigtvis möjligt att helt stänga av värme-, ventilations- och luftkonditioneringssystemet eftersom industriell utrustning i allmänhet är utformad för att alltid vara igång. (7) Hållbarhet är inte ett fokus och även om det alltmer efterfrågas av samhället, upplevs företagens engagemang som lågt. Det är utmanande att motivera anställda att arbeta mot hållbarhet, att alltid ha hållbarhet i åtanke och prioritera det framför andra alternativ. Nyckelord: Måleri, energieffektivitet, energioberoende produktionsenhet, hållbarhet, förnybar

ACKNOWLEDGEMENTS

This thesis was performed during Oskar’s studies in Bachelor’s in Engineering – Innovation and Logistics and Violet’s studies in Master of Science in Engineering – Production and Logistics at Mälardalen university.

We want to thank everyone who have contributed to this thesis work. Firstly, we want to thank everyone at Scania and their ability to welcome us with openness and enthusiasm during our stay. We would also like to extend our thanks to our department for receiving us as a part of the group. Additionally, we would like to thank all the interviewees at the case company, who took their time to answer our questions. Lastly, we would like to express the deepest gratitude to our supervisors at Mälardalen university, Viktorija Badasjane and Natalie Agerskans, who helped us improve our work through always being available and providing feedback.

TABLE OF CONTENTS

1. INTRODUCTION ... 1

1.1. BACKGROUND... 1

1.1. PROBLEM FORMULATION ... 2

1.2. AIM AND RESEARCH QUESTIONS ... 2

1.3. PROJECT LIMITATIONS ... 2

2. RESEARCH METHOD ... 3

2.1. RESEARCH APPROACH ... 3

2.2. LITERATURE REVIEW ... 3

2.3. CASE STUDY... 4

2.3.1. Empirical data collection ... 4

2.3.2. Secondary data collection ... 5

2.4. DATA ANALYSIS ... 5

2.4.1. Validity and Reliability ... 7

2.4.2. Source criticism ... 8

3. THEORETICAL FRAMEWORK ... 9

3.1. DEFINITION OF ENERGY EFFICIENCY ... 9

3.2. ENERGY FLEXIBILITY ... 9

3.2.1. Level 1 – Energy demand flexibility ... 10

3.2.2. Level 2 – balanced energy self-sufficiency ... 10

3.2.3. Level 3 – real energy self-sufficiency ... 11

3.3. VARIABLE RENEWABLE ENERGY (VRE) ... 11

3.4. ENERGY STORAGE SYSTEMS ... 13

3.4.1. Lead-Acid Batteries ... 13

3.4.2. Flow Batteries ... 13

3.4.3. Vanadium-Redox Flow Batteries ... 13

3.4.4. Lithium-Ion Flow Batteries ... 14

3.5. UV-CURING PAINT ... 14

3.5.1. Different UV-lamps ... 14

3.5.2. Radical or cationic mechanism ... 15

3.5.3. Photo initiators ... 15

3.5.4. Benefits and drawbacks ... 16

3.6. HEATING,VENTILATION AND AIR CONDITIONING (HVAC) ... 16

3.7. EMPLOYEE COMMITMENT TOWARDS SUSTAINABILITY ... 17

4. CASE COMPANY PRESENTATION ... 18

4.1. SCANIA ... 18

4.2. VISION AND GOALS ... 18

4.3. CASE DESCRIPTION ... 19

5. EMPIRICAL FINDINGS ... 20

5.1. THE CURRENT PROCESSES WITHIN THE PAINT SHOP... 20

5.2. THE PAINT CURING PROCESS ... 21

5.2.1. UV-cure paint ... 21

5.3. THE VIEW OF SUSTAINABILITY ... 22

5.3.1. The price of sustainability ... 22

5.3.2. Employee commitment ... 22

5.3.3. Goals and visions ... 23

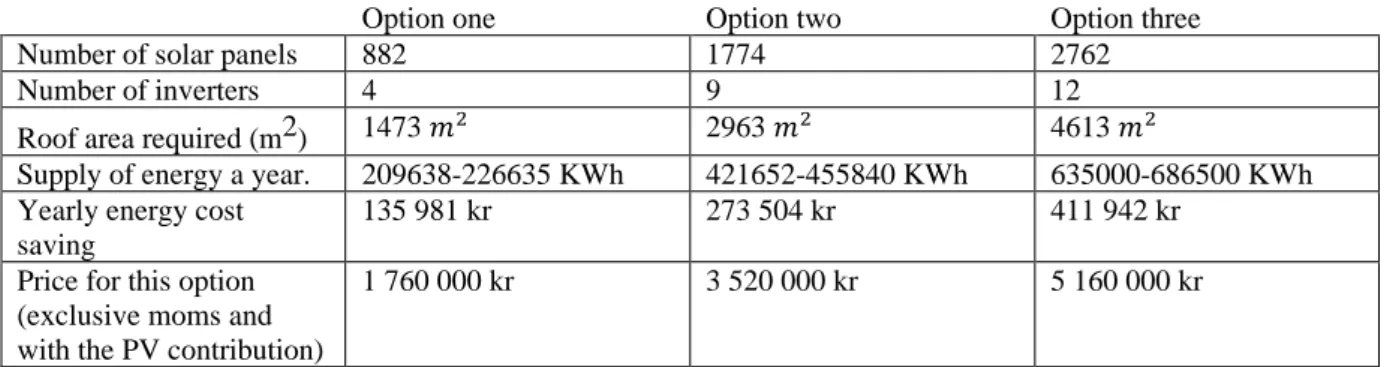

5.4. THE COMBINATION OF SOLAR PV AND ESS... 23

5.5. HVAC ... 23

6. ANALYSIS AND DISCUSSION ... 24

6.2. SELECTION OF VRE-SOURCE ... 26

6.2.1. Solar PV... 27

6.3. ESS ... 28

6.4. UV-CURING PAINT ... 29

6.5. HVAC ... 32

6.6. MOTIVATION AND COMMUNICATION ... 32

7. CONCLUSIONS AND RECOMMENDATIONS ... 34

7.1. FURTHER RESEARCH ... 35

8. BIBLIOGRAPHY ... 36

List of figures

Figure 1 Steps taken during Analysis ... 6

Figure 2 The development path from energy flexibility to energy self-sufficiency for manufacturing systems, modified from Schulze, et al. (2019)... 10

Figure 3 The process-steps in the paint shop. ... 20

List of tables

Table 1Methods of non-empirical data collection... 3Table 2 Details of the semi-structured interviews ... 5

Table 3 Describes how the relationship between change in input and output affects the energy efficiency, modified from Pérez-Lombard, et al. (2013). ... 9

Table 4 Benefits and drawbacks of different VRE sources. ... 12

Table 5 Specifications of the three batteries modified from May, et al., (2018) ... 13

Table 6 Differences between the two lamp types, modified from Wagner (2006). ... 15

Table 7 Positive attributes of each acrylate group, modified from Wagner (2006). ... 15

Table 8 Benefits and drawbacks of UV-cure paint. ... 16

Table 9 The 16 process steps in the axle paint shop. ... 21

ABBREVIATIONS

ESS Energy Saving System

HVAC Heating, Ventilation and Air Conditioning PV Photovoltaic

VOC Volatile Organic Compounds VRE Variable Renewable Energy

1

1. INTRODUCTION

The following chapter begins with the background, which opens to problem formulation to be stated, as well as an Aim and Research Questions. Furthermore, the project limitations are presented.

1.1. Background

As known, manufacturing is the main driving force for welfare and prosperity of humankind. Nevertheless, manufacturing is the main cause of the depletion of natural resources,

environmental burdens affecting the health of animals, humans and eco-systems as well as to social conflict. These damaging effects increase together with the worldwide demand for industrial goods, which will continue expanding together with the continuously growing world population. Even though human beings are aware of the planet´s prevailing limitations of natural resources and emission capacities, the demand for resources and related pollution to the environment has continued increasing drastically (Jingshan, 2017). Consequently, it is more important and urgent than ever to find solutions towards a more sustainable development of global manufacturing (Jingshan, 2017; Jawahir, et al., 2005). Sustainable manufacturing is the creations of manufactured products that use processes that minimize negative impacts on economic, environmental and social objectives, thus preserving the environment, while continuing to improve the quality of human life (Garetti & Taisch, 2012).

It is agreed in majority of literature that sustainability should include economic, environmental and social dimensions (Digalwar, et al., 2019). However, it is explained in studies made by the European Association of the Machine Tool Industries on the separate part of manufacturing, how electrical consumption is responsible for more than 99 percent of the environmental impacts (Cecimo, 2009). As around 40 percent of the utilization of electricity corresponds to activities of manufacturing (Administration, 2016), the adverse impact manufacturing has on the environment, cannot be ignored (Garetti & Taisch, 2011). In a manufacturing system, the consumption of energy depends on several factors, such as equipment technology, the

processes and control strategies (Renna, 2018; Dahmus & Gutowski, 2010; Gutowski, et al., 2006).

Specifically, automotive manufacturing is an energy-intense process which consumes a

significant quantity of raw materials and water (Giampieri, et al., 2019). With paint shops being responsible for the highest energy consumptions in the manufacturing process, it is essential to investigate its energy consumption in order to attain sustainable manufacturing (Giampieri, et al., 2019; Wang & Li, 2011; Systems, et al., 2010). Two of the highest energy consuming activities are curing processes and paint deposition. Paint deposition and curing processes include several operation steps and components (paint booths, scrubbers, Volatile Organic Compounds removal system, etc.). These processes also include significant consumption of electricity, fuel, compressed air, as well as hot and chilled water (Streitberger & Dossel, 2008). A main issue in fact, is that the energy sources manufacturing primarily use industrially are exhaustible. A supply shortage, both from a technical and economic point of view, in easily extractable oil and natural gas reserves is anticipated in the first thirds of the century. Even if large new reserves were discovered, fossil fuels would still only last for a few more years (Romagnoli, 2016).

2

1.1. Problem formulation

Apart from being an important element in vehicle production, the paint shops are liable for a big part of the large energy consumptions within manufacturing (Giampieri, et al., 2019; Systems, et al., 2010), and consequently need to be taken into account. In fact, paint shops are the largest energy consuming unit throughout the automotive assembly plant. About two thirds of the energy cost is electricity, while the third part is on fuel used to generate hot water and steam for painting booths and heat in ovens. Hence, energy reduction in paint shops has noticeable importance, even if it is a small percentage (Wang & Li, 2011).

In addition to the energy consumptions, the painting process causes atmospheric emissions where several gases, including carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O),

are released into the atmosphere. Also, the cleaning of sticky residues on the walls, robots, fixtures etc. caused by over spray and purge, will result in evaporation of Volatile Organic Compounds (VOC) emissions. In turn, VOC emissions will contribute to unfavorable impact to environment and the greenhouse effect (Wang & Li, 2011).

Reducing energy consumption and carbon emissions is critical in order to achieve sustainable manufacturing. Besides, due to growing energy prices and climate concern, it is important to consider the impacts the manufacturing has on global warming by contributing to the

greenhouse effect, on waste generation of toxic release, water emissions and floating end-of-life implications. Additionally, working conditions is for manufacturing considered as an important part of the sustainability picture (Garetti & Taisch, 2011). The paint shops are hence required to adapt to increasing energy costs and ever more stringent emission regulations in order to sustain a successful coating operation and remain competitive (Systems, et al., 2010). Thus, it is necessary to investigate possible cost-effective solutions able to implement in paint shops in order to reduce the energy consumption in a sustainable manner.

1.2. Aim and research questions

The aim is to from a manufacturing perspective identify possible cost-effective solutions for lowering energy consumption within paint shops.

RQ1: What are the enablers for energy efficient paint shops? RQ2: What are the challenges for energy efficient paint shops?

1.3. Project limitations

The focus on this bachelor thesis is to investigate the possibilities to increase sustainability in paint shops through lowering the energy consumption of the activities within paint shops. The study is limited by the vast gap between the energy consumption in paint shops currently, until paint shops can be completely energy self-sufficient.

The case study was conducted in the paint shop department of a global automotive

manufacturing plant in Sweden. The result was furthermore limited by a main investigation on the processes within the paint shop, whilst remaining parts of the manufacturing plant was not taken into consideration. Thus, this study mainly focusses on potential improving steps of development needed in order to attain a completely self-sufficient paint shop.

3

2. RESEARCH METHOD

This chapter is initiated with information regarding the method used for Research approach, how the Literature review and Case study was performed. Thereafter, the method used for Data Analysis is being described.

2.1. Research Approach

When conducting a research study, it is imperative to follow a clear and structured research process (Yin, 2014). For an understanding of the broad topic, a literature review was

conducted. Since the topic covered a wide range of different processes and methods, the area was narrowed down, energy saving methods in manufacturing processes at an automotive paint shop have been examined. Data for energy consumption, processes, currently implemented or at the point of implementing improvements have been collected through semi-structured interviews, and case documents was used as empirical secondary data.

The literature review was based on keyword searches, by utilizing the snowball method, more articles relevant to the keywords was collected. The semi-structured interviews were conducted on-site or through telephone, recorded, transcribed, and analyzed. Secondary data was collected as documents provided by the case company, publicly available information online, or through direct contact with other companies.

2.2. Literature Review

When conducting a case study research, it is necessary to undertake a comprehensive literature review to properly understand the existing body of research. To provide the reader with a background of connections between the researched area and other relevant subjects the literature review provides a basis for the research projects structure, design, and scope as well as where the investigated area belong within a broader context (Williamson & Bow, 2002). A literature review utilizes multiple sources for gathering information regarding a particular topic, contains few if any personal biases, and contains a clear search and selection strategy (Cronin, et al., 2008).

The first step of this study was identifying keywords relevant to the aim and RQ´s, keywords such as energy efficiency, self-sufficient manufactory, environmentally friendly, sustainable

automotive industry etc. in the later phases more specific literature was gathered with focus on

long-term solutions. Keywords at that time were variable renewable energy sources, energy

storage systems, and UV curing paint. Based on articles relevant to the research questions, the

snowball sampling method was used. Some books and articles were identified through recommendations. Table 1 shows which kind of data was collected and with which method it was identified.

Type of data Identified through

Scientific articles • Literature database search

• Course literature • Snowball sampling • Recommendations

Books • Course literature

• Library

• Recommendations

4 According to Bryman (2001) a problem with qualitative research is the transparency, which is extra clear when it comes to selection. For the relevancy of this study, literature published after 2010 is the main source of data, however, due to the snowball method, some articles published before 2010 were deemed relevant and therefore not excluded. In this literature review the main method for non-empirical data collection was searching in scientific databases, the main being ScienceDirect, also complimented with searches on the database Scopus and Mälardalen University library database Primo.

2.3. Case study

Case study research is an empirical enquiry where multiple sources of data are used to understand and evaluate a real-life phenomenon. Because of the detailed empirical findings, case studies are a reliable research method when there is a need to understand a complex phenomenon. Case studies are particularly appropriate for situations in which the examinations and understanding of context is important (Williamson & Bow, 2002). This work focused on theoretical data concerning paint shops and energy reduction, this was then complimented with empirical data collected from interviews and documents.

2.3.1. Empirical data collection

Interviews are an important method for collecting data and in a case study, interviews are performed in a manner of guided conversation (Yin, 2014). Semi-structured interviews apply a questionnaire as the foundation of the interview, a so-called interview guide. Unlike the

structured interview, a semi-structured interview provides the respondent with adequate freedom when answering. The semi-structured interview also provides the interviewer with more freedom as he or she can ask to follow up questions that are not included in the interview guide, based on the respondent's answers (Williamson & Bow, 2002).

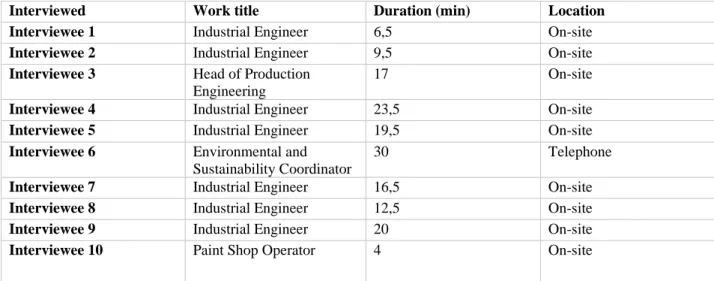

The interviews conducted in this thesis were made on-site or over the phone and recorded for transcribing. The recording was made through software installed on the phone and only after gaining approval from the interviewee. Before scheduling any interviews, an interview guide was written based on the RQs of this study see Appendix 1. Details of the interviews are found in Table 2. The interviews were conducted on 2020-04-29. Properly in-depth interviews require more time with each interviewee, however, in this thesis multiple semi-structured, short

interviews were chosen over a few in-depth interviews. This provided a context to the study from an inside perspective.

5

Interviewed Work title Duration (min) Location Interviewee 1 Industrial Engineer 6,5 On-site

Interviewee 2 Industrial Engineer 9,5 On-site

Interviewee 3 Head of Production Engineering

17 On-site

Interviewee 4 Industrial Engineer 23,5 On-site

Interviewee 5 Industrial Engineer 19,5 On-site

Interviewee 6 Environmental and Sustainability Coordinator

30 Telephone

Interviewee 7 Industrial Engineer 16,5 On-site

Interviewee 8 Industrial Engineer 12,5 On-site

Interviewee 9 Industrial Engineer 20 On-site

Interviewee 10 Paint Shop Operator 4 On-site

Table 2 Details of the semi-structured interviews

Every interviewee answered the goals and visions category, however, due to the workload and pressure from lead times, the paint shop operator was not asked about challenges and

opportunities.

2.3.2. Secondary data collection

Official and publicly available documents from private sources such as annual reports, target documents, press releases, adverts, and PR material are a common form of documentation originating from companies and organizations in general and tend to produce many documents. Such documents have the probability of being authentic and meaningful, however, questions about credibility and representativeness are cause for a more rigorous analysis (Bryman, 2001). Data from documents was provided by the case company and covered information regarding energy consumption and energy expenses, layout of the paint shop facility, roof size, and processes. Secondary empirical data was gathered from companies other than the case

company. Such data was gathered through email contact, phone conversations, and published materials on webpages such as documents and product specifications. Through contacts with different companies, prices quote, and performance specifications were presented. To ensure the credibility of the collected secondary data, no consideration or attention towards claims from companies was made, the focus was solely to retrieve performance specifications and offers on products and services.

2.4. Data Analysis

The foundation of data analysis lies in the research questions, informing the reader of the level and scope for the case study. For the research questions to be adequately answered, the case study must provide enough breadth and depth of data collected. To help selection from various data analysis techniques, a general data analysis strategy is an important part of the case study design. The strategy will indicate what to analyze and why, as a major practical difficulty of analysis of case study research is dealing with the amount and variety of data collected (Williamson and Bow, 2002).

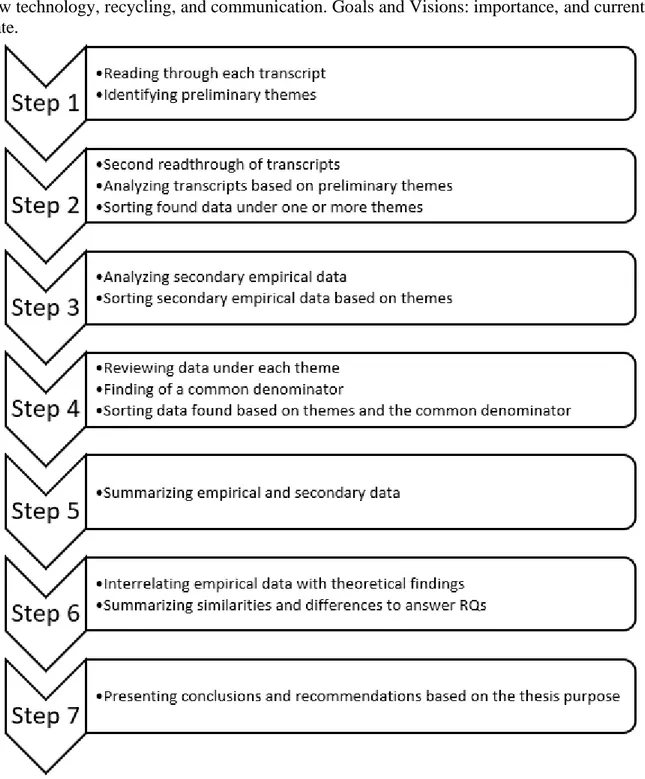

The interview guide was divided into three categories, Challenges, Opportunities, and Goals and Visions. Figure 1 shows the seven steps taken during data analysis. In step 1 the analysis was initiated by reading through each transcript of the interviews. During the read through, similar patterns were identified and categorized as themes under each interview subject.

6 In step 2 the themes were headlined in a Word document and a second read through of the transcriptions was conducted, this time analyzing the information from the interviews based on the identified themes, connecting the information with which theme it fit under. This was done until all information had been placed under one or several themes and information deemed unnecessary was sorted out. The themes identified for each category was, Challenges: energy consumption, prices, the bigger picture, knowledge, and space requirements. Opportunities: new technology, recycling, and communication. Goals and Visions: importance, and current state.

Figure 1 Steps taken during Analysis

During step 3 secondary data was analyzed, gathering it with empirical data sorted under the identified themes. In step 4 a common denominator was identified by carefully reviewing the data under each main theme.

7 Every theme had the common denominator of commitment, whether it was commitment

towards prices or commitment towards sustainability. The empirical data was then sorted according to the identified themes and the common denominator. In step 5 the empirical and secondary data was summarized. In step 6 the empirical findings were interrelated with theoretical findings using the research questions as guidance, searching for similarities and differences between these data by taking notes while reading. This was then summarized to provide answers to the research questions. In step 7 conclusions were presented based on the purpose of this thesis which was, from a manufacturing perspective identify possible cost-effective solutions for lowering energy consumption within paint shops.

2.4.1. Validity and Reliability

To ensure that the adequacy and validity of evidence collected is established, the design of case study research requires suitable data collection methods and data analysis strategies. By clearly demonstrating the processes in which the research results are arrived, the research findings validity can be demonstrated (Williamson and Bow, 2002).

Williamson and Bow (2002) further explains case studies with strengths and weaknesses. Particularly that case study research is appropriate for situations where examination and understanding of context is important. However, the validity of the research findings is heavily dependent of the researcher´s interpretation of events, documents, and interview material. That the data collection and data analysis processes are both subjects to the influence of the

researcher´s characteristics and background. This thesis included previous research that both concurs and contradicts with empirical findings. By identifying relations and thoroughly scrutinizing the correlations to identify unbiased patterns and openly discussing the findings added validity.

External validity is the extent to which the results generalizability to other social environments and situations. External validity poses a problem for researchers that tend to use case studies and limited selections (Bryman, 2011). Based on the case company´s situation, to ensure validity, a workable result of a general nature providing any company striving towards

sustainability, and sustainability in paint shops foremost was presented. However, this study´s generalization could have been improved through methods such as observations, and

benchmarking could have further validated this thesis.

With internal validity however, to have good consistency between the researcher’s observations and the theoretical ideas he or she develops internal validity. Because the prolonged presence and participation in a social group enables the researcher to secure a high level of conformity between concepts and observations, internal validity tends to become a strength within qualitative research (Bryman, 2011).

According to Bryman, (2001) reliability stands for the width in which a research can be repeated. However, it is difficult to meet this criterion within qualitative research since it is impossible to “freeze” a social environment and the social stipulations which applies at an initial study. By transparently presenting how the case study was conducted to achieve

reliability to the greatest extent, interview approach and data management followed by a rigid structure of analysis was presented. Recording and transcribing the interviews to further add replicability while providing an established framework for the research approach, adding to the reliability.

8 The interviewees were selected at random depending on who had time to spare during the day when the interviews were conducted, however, every interviewee was known by the authors beforehand, adding a bias element to the reliability. Documenting theoretical data collection provided performance traceability of data collection.

2.4.2. Source criticism

Critical thinking is part of the foundation of science and in the academic context that means explaining, interpreting, and striving to understand the meaning of what is to be critically examined. When working with a literature study it is required to have a critical approach and a questioning attitude to what is read. By ordering the sources and continuously adapting a reflective writing style the author is able to conduct a source critical literature study. In the method section, research design, data collection method, and analysis method justify how the study was conducted and marks the critical approach. Critical thinking also applies when judging whether information provided by informants is truthful (Blomkvist & Hallin, 2014). By striving to clearly showcase what the comments from the study are, and what has been used from different scientific sources, the critical attitude throughout the thesis is shown.

9

3. Theoretical Framework

This chapter provides the theoretical data for this study. It is initiated with the concept of energy efficiency and methods to generate and store electricity on-site. Thereafter, it is followed with different methods used to increase energy-efficiency in order to attain sustainable manufacturing.

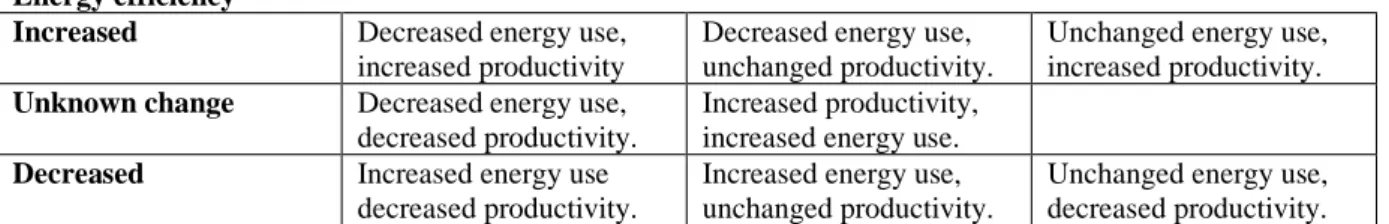

3.1. Definition of energy efficiency

Efficiency is a term used in several contexts and may generally be described as the resources required (input) in order to perform a service or function (output). The term energy efficiency hence describes the amount of energy required in relation to the service or function intended to be performed. Table 3 describes how the relationship between change in input and output affects the energy efficiency.

Energy efficiency

Increased Decreased energy use, increased productivity

Decreased energy use, unchanged productivity.

Unchanged energy use, increased productivity.

Unknown change Decreased energy use, decreased productivity.

Increased productivity, increased energy use.

Decreased Increased energy use decreased productivity.

Increased energy use, unchanged productivity.

Unchanged energy use, decreased productivity.

Table 3 Describes how the relationship between change in input and output affects the energy efficiency, modified from Pérez-Lombard, et al. (2013).

Increased energy efficiency is therefore not the same as reduced energy use, but rather a description of the relationship between input and output. Reduced energy use may, but need not, mean increase of energy efficiency. How energy efficiency is affected also depends on how the performed function changes in connection with the changed use of energy. In the same way, a change in the service performed can have an impact on energy efficiency, but it does not necessarily have to do so even if energy use is affected (Andersson & Arfwidsson, 2016).

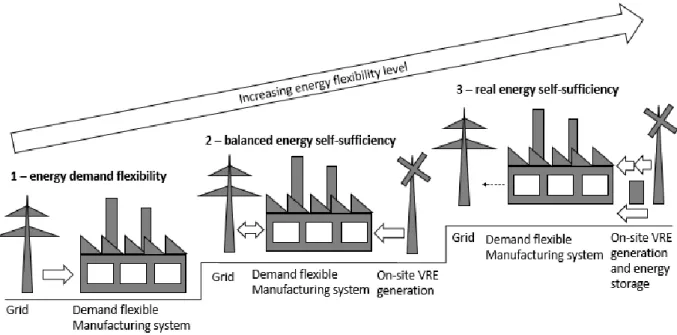

3.2. Energy Flexibility

Energy flexibility require a manufacturing system’s ability to adapt energy demands fast and without high expenses (Sethi & Sethi, 1990). The potential to flexibilize the energy demand depends on two factors. The first factor is the technical aspects, e.g. efficiency of used equipment. The second factor is organizational aspects, e.g. working times and production schedule (Yusta, et al., 2010; Popp & Zaeh, 2014). Manufacturing systems energy load profiles expose typical patterns for productive and non-productive times, e.g. base loads and load peaks, based on used machinery, infrastructure and their operation (VDMA, 2015; Dehning, et al., 2019). High potentials of flexibility could be identified on several plant levels such as machine tools, process chains as well as technical building services (Popp, et al., 2017; Moog, et al., 2017; Stoldt, et al., 2018). The overall potential for energy flexibilization is however highly individual in terms of machinery, addressed plant level and branches (Kneiske & Hoffmann, 2013; Lund, et al., 2017).

10

Figure 2 The development path from energy flexibility to energy self-sufficiency for manufacturing systems, modified from Schulze, et al. (2019).

The state of research proposes that there are three main development levels for energy flexible manufacturing systems. Various challenges, but also opportunities within companies are related to all three levels of flexibility (Graßl, et al., 2014). Figure 2 shows the development path from energy flexibility to energy self-sufficiency for manufacturing systems.

3.2.1. Level 1 – Energy demand flexibility

Flexible energy demand, no on-site generation. The companies being described in this level are the ones with energy flexible production machinery that may adapt its energy consumption to the actual energy availability on the grid, that is by either instantly reducing or increasing the energy demand according to market needs (Graßl, et al., 2014). Many companies have already discovered lucrative new business models by providing ancillary services for the electricity market, as a respond to the volatile electricity prices (Pechmann & Zarte, 2017).

3.2.2. Level 2 – balanced energy self-sufficiency

Flexible energy demand, on-site generation of (at least) same energy amount. On-site energy generation from variable renewable energy (VRE) is extending the energy supply of the demand flexible manufacturing system. The aim for it, is to, by consuming the self-generated electricity, partly cover the present energy demand. Contrary to level 1, various additional aspects, which are concerning the generation and usage of on-site energy have to be

considered, e.g. the size and type of VRE as well as the installation of energy storage (Kneiske & Hoffmann, 2013). If the total on-site generated energy is equal or higher than the total energy demand during a certain period of time, e.g. one year, then balanced energy self-sufficiency is achieved (Deutschle, et al., 2015).

11 However, the temporal distribution of generation and demand is not considered by this metric. Because of VRE's intermittent nature, an on-site generation from e.g. photovoltaics (PV) and wind power strongly depends on the conditions of the environment, like local solar radiation or the intensity of the wind. Usually, the top PVs generation is achieved at noontime, whilst wind power is generated at night-time as well. For that reason, it is recommended to combine two or more VRE types with comprehensive character to a hybrid renewable system (Al-falahi, et al., 2017; Zahraee, et al., 2016).

3.2.3. Level 3 – real energy self-sufficiency

Flexible energy demand fully synchronized with and covered by on-site energy generation. In order to achieve this level, the on-site generated energy needs to fully cover the energy demand from a related manufacturing system (Deutschle, et al., 2015). An actual self-sufficient

manufacturing system only relies on internal resources and is always completely autarkic from external supply (Müller, et al., 2011) Since there are uncertainties in the predictions of demand and supply, it is common to over-dimension on-site VRE. Therefore, temporally more energy is generated than demanded by the manufacturing system. This excess energy is commonly fed into the grid (Unterberger, et al., 2014)

Unlike balanced self-sufficiency, this flexibility level is usually not feasible due to economic reasons (Deutschle, et al., 2015). Actual self-sufficiency is rather implemented at locations, where grid connection is not accessible or very unstable, e.g. on isolated islands or regions of developing countries. The purpose of those off-grid energy supply systems is to cover

electricity demand with on-site generated energy, while the maximum energy generated limits the consumption. Therefore, real energy self-sufficiency might cause a forced limitation of productivity. Hence, high energy demand processes might end up as outsourced, while machinery and processes with lower energy demand could be favorable (Müller, et al., 2011; McKenna, et al., 2015; Schulze, et al., 2019).

3.3. Variable Renewable Energy (VRE)

In order to meet the growing demands of power and combat the ongoing climate change, the global energy structure is experiencing a fundamental change. Renewable energy is bringing a great expectation in this transition procedure, where electricity generation is predicted to reach 25%-41% of the total energy by 2040 (Bazilian, et al., 2013; IPCC, 2014).

For recent years, and in many countries, electricity generation from VRE sources, in particular solar energy and wind power, has been growing rapidly. It is driven by technological progress, economies of scale, and deployment subsidies (REN21, 2014; Commission, 2012; EIA, 2018; Sawin, et al., 2017). In fact, VRE sources generate energy with the least negate impact on the environment and are characterized by great resource potentials. In the sustainable development scenario, solar energy and wind power is able to reshape the global power sector, and their installed capacity could reach 7059 GW accounting for 49,21% of the total in 2040 (Can, et al., 2018).

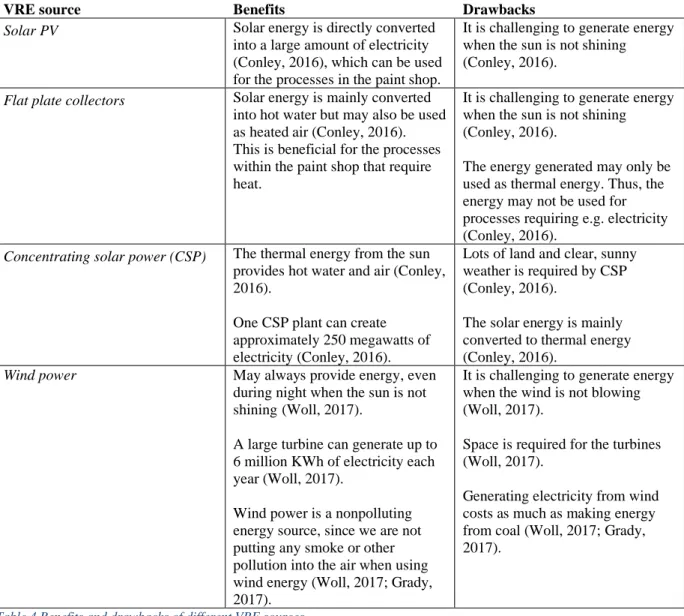

Solar energy is a renewable energy source, which means that it cannot be used up. As the sun shines, its energy may provide power (Grady, 2016). In Table 4 the benefits and drawbacks of different VRE sources are described briefly, highlighting solar photovoltaics (PV).

12

VRE source Benefits Drawbacks

Solar PV Solar energy is directly converted

into a large amount of electricity (Conley, 2016), which can be used for the processes in the paint shop.

It is challenging to generate energy when the sun is not shining

(Conley, 2016).

Flat plate collectors Solar energy is mainly converted

into hot water but may also be used as heated air (Conley, 2016). This is beneficial for the processes within the paint shop that require heat.

It is challenging to generate energy when the sun is not shining (Conley, 2016).

The energy generated may only be used as thermal energy. Thus, the energy may not be used for processes requiring e.g. electricity (Conley, 2016).

Concentrating solar power (CSP) The thermal energy from the sun

provides hot water and air (Conley, 2016).

One CSP plant can create approximately 250 megawatts of electricity (Conley, 2016).

Lots of land and clear, sunny weather is required by CSP (Conley, 2016).

The solar energy is mainly converted to thermal energy (Conley, 2016).

Wind power May always provide energy, even

during night when the sun is not shining(Woll, 2017).

A large turbine can generate up to 6 million KWh of electricity each year (Woll, 2017).

Wind power is a nonpolluting energy source, since we are not putting any smoke or other pollution into the air when using wind energy (Woll, 2017; Grady, 2017).

It is challenging to generate energy when the wind is not blowing (Woll, 2017).

Space is required for the turbines (Woll, 2017).

Generating electricity from wind costs as much as making energy from coal (Woll, 2017; Grady, 2017).

Table 4 Benefits and drawbacks of different VRE sources.

The two main ways to harvest energy from the sun discovered by scientists is either through solar cells (solar PV) or through solar thermal collectors (flat plate collectors and concentrating solar power). The two methods are useful in different areas (Conley, 2016). Wind power is partly a form of solar energy and consist of energy of motion, kinetic energy. Wind turbines convert kinetic energy into electricity. (Woll, 2017; Grady, 2017).

The term photovoltaics means the direct conversation of light into electrical energy using solar cells (Anon, 2013). Most solar cells are made from silicon. Silicon wafers are made and treated with chemicals, which give the silicon an electric charge. Each cell has two layers, one with a positive charge and the other a negative charge. When the two layers are hit by sunlight, it generates electricity which is generated by thin metal wired in the cell. In order to make the cell even more efficient, an antireflecting coating is added in order to counteract the cell from being shiny and prevent sunlight from reflecting off it. This allows more sunlight to be converted into electricity. Layers of glass is covering the cells in order to protect them. Joining solar cells creates more electricity and when cells are connected, they form a solar panel. When panels are joined, they form an array. The more panels in an array, the more electricity may be produced. Arrays can be quite powerful, they can even provide enough electricity to power plants

13

3.4. Energy Storage Systems

Energy storage systems (ESS) ensure the continuity of energy supply, improve the reliability of the system and are an essential part of the renewable power system (Li and Wang, 2018;

Rashid, 2016). Electricity is commonly charged depending on the time of use, usually divided in two rates: the high rate, during daytime, and the low rate, during night-time. Large

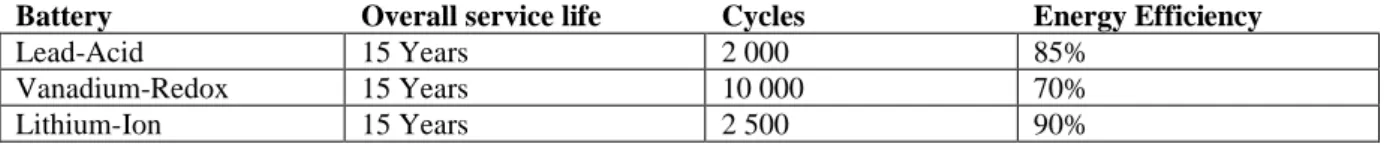

consumers also pay a fee per kilowatt kW of peak demand on top of regular payments. Because of that, installing ESS can reduce payments in two ways: by reducing the peak demand and shifting consumption from daytime to night-time (Pandžić, 2018).According to Mahlia, et al., (2014) ESS can be divided into four main categories: Electric, Thermal, Mechanical Storage, and Chemical, all with their own benefits, drawbacks, and sub-categories. The category commonly combined with VRE sources is battery storage systems, and commonly found already implemented in different systems around the world are lead-acid, vanadium-redox, and lithium-ion are (Yamamura, et al., 2011; Chen, et al., 2009). See Table 5 below for

specifications and differences of flow batteries and lead-acid batteries.

Battery Overall service life Cycles Energy Efficiency

Lead-Acid 15 Years 2 000 85% Vanadium-Redox 15 Years 10 000 70% Lithium-Ion 15 Years 2 500 90%

Table 5 Specifications of the three batteries modified from May, et al., (2018) 3.4.1. Lead-Acid Batteries

Lead-acid batteries are a rechargeable electrochemical device that is well established around the world. Lead-acid batteries are a popular storage choice for power quality, uninterruptible power supply and reserve applications (Chen, et al., 2009; Beaudin, et al., 2010). While usually coupled with wind and solar energy harvesters to stabilize the unpredictable behaviors of weather elements (Mahlia, et al., 2014), lead-acid batteries have also been used in a few commercial and large-scale energy management applications (Chen, et al., 2009; May, et al., 2018).

May, et al. (2018) explains the importance of sustainability and how recycling of lead-acid batteries is a well-established practice with recycling rates approaching 100% in Western countries. This becomes important since lead-acid batteries uses heavy metal components that are toxic and hazardous to the environment (Poullikkas, 2013; Mahlia, et al., 2014; Yamamura, et al., 2011). Typically, 65% of a lead-acid battery weight is lead and most of it can be

recovered in recycling. The greenhouse gas emissions produced when manufacturing lead-acid batteries is 3kg/kg and energy used is 30MJ/kg or 0,6MJ/Wh (May, et al., 2018).

3.4.2. Flow Batteries

In contrast to conventional batteries, flow batteries store energy in one or more dissolved electroactive materials that flow through a power cell/reactor converting chemical energy into electricity (Chen, et al., 2009; Poullikkas, 2013). Flow batteries utilizes remote storage of the electroactive materials, allowing the possibility of very large capacities, in principle limited only by the tank size containing the electroactive material (May, et al., 2018). Flow batteries can continuously release energy for up to 10h with a high rate of discharge (Chen, et al., 2009).

3.4.3. Vanadium-Redox Flow Batteries

Vanadium-redox batteries are suitable for a wide range of energy storage applications for electricity utilities and industrial end-users. Applications include enhanced power quality, uninterruptable power supply, increased security of supply and integrations with renewable

14 energy systems. However, since it is a system with low energy density, mobile applications become limited and it is best used in stationary applications. Vanadium sulfate solution is stored in tanks, and therefore there is in principle no limit to the quantity and subsequently the capacity of the battery (May, et al., 2018; Mahlia, et al., 2014).

3.4.4. Lithium-Ion Flow Batteries

Lithium-ion batteries have drawbacks regarding sustainability since there is an uneven distribution of lithium in the world and the use of flammable organic electrolytes affect the safety and environmental friendliness of the battery (Yamamura, et al., 2011). According to May, et al. (2018) recycling of lithium-ion batteries is virtually non-existing, as the packaging and transport regulations are very strict, adding costs, and damaged batteries makes the requirements very burdensome.

3.5. UV-Curing paint

The UV-curing systems and its economic feasibilities has been successfully approved in industrial businesses such as wood paints and printing inks. Although, recently, UV cure paint has become an alternative for the traditional curing within the automotive paint and coating industry. Since the new combination of raw materials with brand new UV flash technology, now provides a big step forward for the automotive refinishing applications, as it is rapidly becoming a very popular technique in the paint and coating industry. However, the high-quality demands of the customer must be satisfied by the resulting film properties as well as

appearance (Stropp, et al., 2006; Maag, et al., 2000). Also, one of the most important

requirements for a broad use of UV cure paint in the paint and coating industry is that paints and coatings are stable against degradation caused by atmospheric influences, since weathering leads to a degradation of the polymeric binder (Valet, 1999).

UV-curing paint is a process to cross-link (cure) coatings by a chemical process, which is initiated and sustained by UV energy. Consequently, rather than going into a thermal oven after the painting application, the paint is cured with UV energy, generated by UV lamp systems. The UV lamp systems are organized in a way which illuminates the paint with minimum amount of energy required to achieve cure. Also, with UV-curing, it takes less than a minute to convert the coating from a liquid to solid (Awokola, et al., 2002; Maag, et al., 2000; Seubert & Nichols, 2004). Although, as the coating is required to receive UV energy in order to be cured successfully, the placement of the UV lamps need to be planned in detail and leave no

shadowed areas under-exposed. Additionally, the distance between the lamp and the surface can make a vast difference in the efficiency of the curing process. The further the surface is from the bulb, the more UV-intensity will decrease. Also, it is beneficial to run a proper radiometry in order to ensure that optimum UV energy is reached. Apart from that, it is essential to decide the lamp type, mechanism and the photo initiator, which is a part of the formulation. Furthermore, the formulation and application go hand in hand, and developing the right formulation is important to achieve a proper UV-curing process (Wagner, 2006).

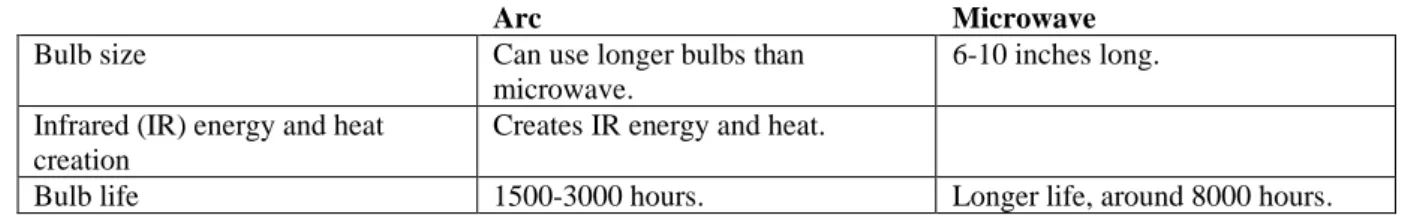

3.5.1. Different UV-lamps

There are two main types of lamps being used when curing paint and coatings with UV-light, these are arc and microwave. There is not much difference between these lamps when they are operating. However, they do differ in how UV-light is powered and the time it takes to reach the optimum operating condition when initiating the system. They also differ regarding the bulb size, bulb life and amount of heat produced (Wagner, 2006). Table 6 shows the difference between the last-mentioned properties.

15

Arc Microwave

Bulb size Can use longer bulbs than microwave.

6-10 inches long. Infrared (IR) energy and heat

creation

Creates IR energy and heat.

Bulb life 1500-3000 hours. Longer life, around 8000 hours.

Table 6 Differences between the two lamp types, modified from Wagner (2006).

Both of the lamp types require regular maintenance (reflector and bulb cleaning and rotation) to ensure the proper UV output for curing to be performed (Wagner, 2006).

3.5.2. Radical or cationic mechanism

The first choice to make regarding the formulating is the oligomers (Wagner, 2006), which are low molecular weight polymers comprised with a small number of repeating units. Its physical properties are noticeably dependent on the length of the chain (Klaerner & Padmanabhan, 2016). UV-curing paint can however be cured by either free radical or cationic mechanism. As, the cationic-cured coatings usually do not have great weathering characteristics, free radical formulation is a better fit in the automotive paint and coating industry. The free radical formulations are based on acrylate chemistry and can be urethane acrylates, epoxy acrylates, polyester acrylates or acrylic acrylates (Wagner, 2006). The positive attribute of each group is highlighted in Table 7.

Acrylate group Positive attribute

Urethanes Weather well.

Epoxies Cure quickly.

Polyesters Wet pigments well. Acrylics Improve adhesion.

Table 7 Positive attributes of each acrylate group, modified from Wagner (2006).

Based on the general descriptions, formulating a coating for metal application can use any of these groups. In order to find the best oligomers for the application, an extensive screening is required. Also, a blend of chemistries can optimize the performance characteristics in most formulas (Wagner, 2006).

3.5.3. Photo initiators

After the oligomers, the most crucial choice of formulating is photo initiator, since this is the component making UV-curing possible. As UV coatings cure by line of sight, it is essential to balance the throughout cure with the surface cure. Meaning that the curing starts from the surface of the coating and works its way down to the substrate interface. Commonly, a package of two or more photo initiators is used to cure both the surface and the substrate interface. There is a risk of wrinkled or pinched appearance if the surface is cured too quickly. Also, the surface might be cured and tack-free, while the paint underneath will not have the chance to cure properly and remains wet. Vice versa, if the amount of surface cure used is insufficient, the surface of the coating could end up tacky or wet, and the gloss would be reduced, while the substrate interface will be cured (Wagner, 2006).

These risks can be reduced with the proper selection of bulb. A prime example of the

formulation and application working together in order to optimize the cure process would be as followed. Initially, penetrating deeper into the coating with the UV energy from a gallium-doped bulb, which emits a longer wavelength region. Thereafter, follow up the gallium-gallium-doped bulb with a standard mercury bulb, which emits shorter wavelength UV energy which can finish the curing at surface level. However, the thicker the coating is, the deeper the UV energy required to penetrate to cure the substrate (Wagner, 2006).

16

3.5.4. Benefits and drawbacks

UV-cure paint is certainly playing an important role in the future of the paint industry, especially as a means of overcoming solvent emission limitations and energy savings.

Basically, UV-cure paint may be used in all applications if the performance requirements are fulfilled (Valet, 1999). Many potential advantages are held by the UV cure paint for use as automotive painting and coating. Among these advantages, one is the fact that UV cure paint has the potential to hold very low VOC contents, which may be used as the key to implement more environmentally friendly painting processes in the future (Seubert & Nichols, 2004). Table 8 describes benefits and drawbacks of the UV-cure paint process.

Benefits Drawbacks

Saved energy and increased productivity due to fast process (Stropp, et al., 2006).

Excellent scratch and mar resistance, improved initial appearance, and potential first time through

improvements (Stropp, et al., 2006).

Contains several concerns for the automotive industry, such as ozone production, power consumption, worker safety (Seubert & Nichols, 2004).

It is challenging to cure pigment less colors, e.g. white, with UV-curing (Wagner, 2006).

Possesses very low VOC contents. UV-cure paint has the least possible environmental impact (Seubert & Nichols, 2004).

It’s challenging to ensure achievement of complete through-cure, since complex three-dimensional vehicle parts prevent the supply of even amount of light on the whole body (Awokola, et al., 2002). Heavy investment costs are earned back relatively

quickly with the reduced process time, less energy cost, reduced destructive management, lower labor costs, less physical machine space on the industrial floor (Gawalewicz, u.d.).

Usually, relatively large investments are required in suitable curing equipment. Especially in larger projects where a lot of light is needed (Gawalewicz, u.d.).

There is no need for large industrial ovens, therefore floorspace required for the process is reduced (Gawalewicz, u.d.).

Oxygen might influence the process (Awokola, et al., 2002).

Table 8 Benefits and drawbacks of UV-cure paint.

However, if UV cure coatings eventually will be used as automotive topcoats, the process is required to adapt to current automotive paint application infrastructure and process (Seubert & Nichols, 2004).

3.6. Heating, Ventilation and Air Conditioning (HVAC)

Air quality and the condition of the air are two factors that affect working environments. With commercial heating, ventilation, and air conditioning (HVAC) systems, a safe and comfortable work environment can be established (Sugarman, 2007).

When designing a building, the HVAC system should provide thermal comfort, have minimal investment, running, maintenance and replacements costs, and energy use or environmental impact, all whilst meeting the building owners' specific requirements (Picard & Helsen, 2018). The HVAC system is a heavy load on a building´s energy usage, and accounts for

approximately 25% of a building´s energy usage. A typical HVAC system operates to keep the indoor temperature constant which causes the HVAC system to produce a constant output even at peak load times. Most of the recent research available regarding HVAC systems is focused on reducing the load by modifying indoor temperature constraint during the demand response time. Significant work has also been put in managing the peak load through the usage of ESS (Nam-Kyu & Won, 2018).

17

3.7. Employee commitment towards sustainability

Employee participation and commitment towards improvement initiatives is key for successful implementation of management initiatives (Baird, et al., 2011; de Menezes, 2012; Lagrosen & Lagrosen, 2005). However, the actions and behaviors to reach employee participation and commitment is the subject of many different researches, Temminick, et al. (2015) claim that actions such as rewards, promotions or penalties are perceived as the least motivationally effective strategies, while encouraging employee participation and commitment towards

management initiatives are the most effective incentives. Lam, et al. (2015) finds collaboration, consultation, ingratiation, inspirational appeals, and rational persuasion being five strategies that are significant and strong predictors of strong employee commitment. While Kamphorst and Swank (2018) research the effects that performance based feedback from management has on employees motivation, finding that while positive feedback is a good incentive, it could become obsolete if the management is afraid of also providing negative feedback when required.

Sustainability is continuously being an increasing pressure subject for organizations to reduce the use of resources, and in order to respond to the expectations it is imperative to address how employees can contribute in the work for increased sustainability (Temminck, et al., 2015). However, so far companies have mainly focused on reducing emissions within production and service processes rather than motivating employees to obtain a more sustainable and climate aware behavior (Klade, et al., 2013).

Implementing sustainability goals and changes in general typically poses a problem with engaging and encouraging employees to adapt to these changes. To counteract these problems, important determinants such as employees attitude and commitment towards the company’s organizational performance need to be enhanced and encouraged by the management to successfully implement changes (Temminck, et al., 2015).

18

4. CASE COMPANY PRESENTATION

This section provides information about the case company and a description of its vision and goals. Finally, the case description is presented.

4.1. Scania

Scania was founded 1891 and established 1900 in Malmö, Sweden for the production of bicycles. Two years later, the first truck was produced, and Scania soon began to produce cars as well as trucks. In 1911, the first bus was manufactured, and production of cars, trucks and buses continued in both Malmö and Södertälje. Scania became a wholly owned subsidiary of the German Volkswagen AG in 2014. Currently, Scania is conducting a business that will make Scania the market leader in sustainable transport. With sales and service in a total of 100

countries, Scania is strategically placed for customer operations worldwide. Scania is a Swedish truck and bus manufacturer. In fact, Scania is one of the world’s leading

manufacturers of heavy trucks and buses. The company is headquartered in Södertälje, Sweden (Scania, 2019).

4.2. Vision and goals

It is important for Scania to have complementary long-term perspectives in order to continue being a profitable company. Scania’s long-term perspectives are driving costumer profitability through sustainable solutions and pursuing responsible business. Although the core of Scania’s contribution to society is delivering sustainable transport solutions by improving customer profitability, it does not mean that the responsibility ends there. According to Scania, sustainable transport is all about contributing to economic and social development, when moving people and goods. Scania aims to not negatively influence human health and safety or endangering the environment when fulfilling its business strategy. Scania states that it is all about “doing the right things” (Scania, 2019).

Scania suggests that there is more than one solution to consider in order to transform the transport system to more sustainable. Rather, a holistic approach is called for, considering the specific transport assignment and the maturity of the transport and logistics infrastructure in different parts of the world. Scania’s strategy is based on three pillars: Energy efficiency, Alternative fuels and electrification and Smart and safe transport (Scania, 2019).

Complementary sustainability is about how Scania operate the business, manufacturing and about the employees. Thus, it is about being responsible and delivering value across the value chain and in the relationships. Scania simply call this “Doing things right”. Six business responsibility areas are identified by Scania, these are environmental footprint, diversity and inclusion, health and safety, human and labor rights, business ethics and community

19

4.3. Case description

In 2015 Scania’s paint shop wasted 11 800 MWh electricity, 4 485 MWh district heating, 4330 MWh hot water and 1400 m3 city water. The plant is satisfied with how the processes currently used within the paint shop of the production are working, there have however been some modifications during the years to optimize the painting process. The plant is now requested to become an environment friendly industry and reach the goals of the Paris agreement. Hence, the opportunities to lower the energy consumption through modifying one or more of the paint shop process steps should be investigated.

20

5. EMPIRICAL FINDINGS

The data in this section was collected from the case company and companies delivering appropriate solutions to the case company. This chapter begins with a description of the paint shop section at the case company and is followed by the employees view of sustainability. Finally, possible measures that can be taken to achieve sustainability in a paint shop are presented.

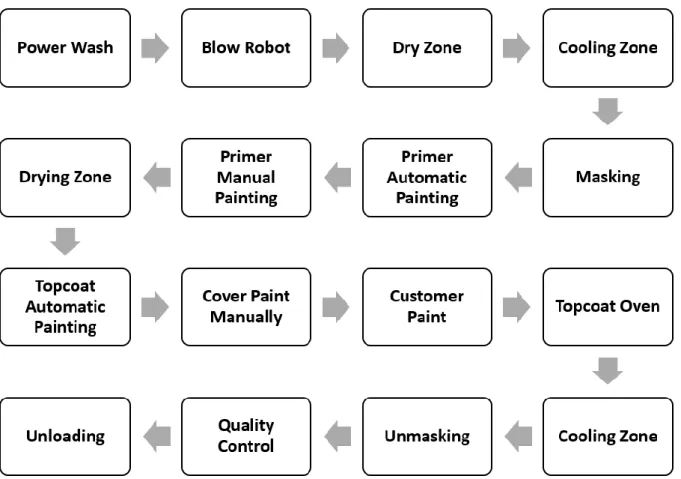

5.1. The current processes within the paint shop

The axles are assembled in the assembly line before they are transported to the paint shop. The painting process is the last manufacturing process for axels at the case company, before

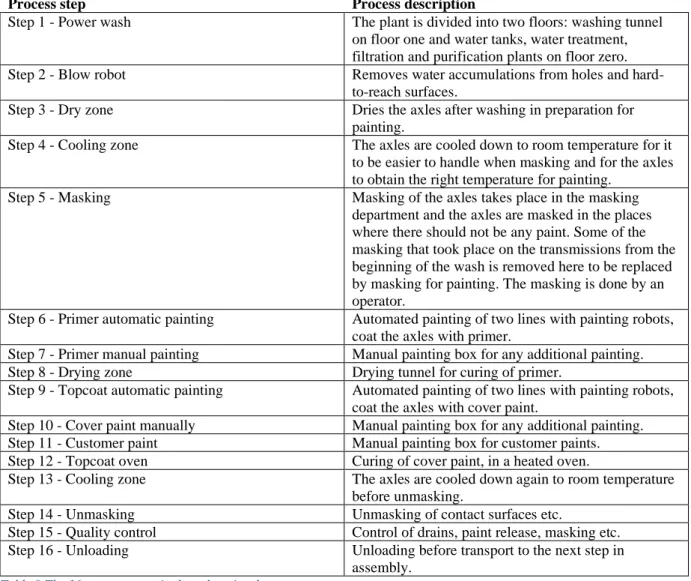

packaging and shipping to truck assembly. There are lifts, a laundry department, masking stations, several ovens and cooling zones, robotic painting stations, a manual painting box, an improvement box and a packaging department. The axles are transported hanging to the paint shop and throughout the paint shop processes. Also, transmissions need to be masked before entering the paint shop to prevent water leakage into sensitive components during washing. Each article goes through several different steps before considered finished. Figure 3 shows the process steps within the paint shop, which are further described in Table 9.

21

Process step Process description

Step 1 - Power wash The plant is divided into two floors: washing tunnel on floor one and water tanks, water treatment, filtration and purification plants on floor zero. Step 2 - Blow robot Removes water accumulations from holes and

hard-to-reach surfaces.

Step 3 - Dry zone Dries the axles after washing in preparation for painting.

Step 4 - Cooling zone The axles are cooled down to room temperature for it to be easier to handle when masking and for the axles to obtain the right temperature for painting.

Step 5 - Masking Masking of the axles takes place in the masking department and the axles are masked in the places where there should not be any paint. Some of the masking that took place on the transmissions from the beginning of the wash is removed here to be replaced by masking for painting. The masking is done by an operator.

Step 6 - Primer automatic painting Automated painting of two lines with painting robots, coat the axles with primer.

Step 7 - Primer manual painting Manual painting box for any additional painting. Step 8 - Drying zone Drying tunnel for curing of primer.

Step 9 - Topcoat automatic painting Automated painting of two lines with painting robots, coat the axles with cover paint.

Step 10 - Cover paint manually Manual painting box for any additional painting. Step 11 - Customer paint Manual painting box for customer paints. Step 12 - Topcoat oven Curing of cover paint, in a heated oven.

Step 13 - Cooling zone The axles are cooled down again to room temperature before unmasking.

Step 14 - Unmasking Unmasking of contact surfaces etc.

Step 15 - Quality control Control of drains, paint release, masking etc. Step 16 - Unloading Unloading before transport to the next step in

assembly.

Table 9 The 16 process steps in the axle paint shop.

When the equipment used in the paint shop was purchased, sustainability and energy consumption was not considered, and the main factor mattering was the price. However, processes always have capacity to be improved, technology is quickly developing and there is hence a vast potential to improve the energy efficiency within the paint shop.

5.2. The paint curing process

Currently, there are two paint curing processes (step 8 and step 12, described in Table 9) within the pain shop. The curing of the topcoat (step 12 described in Table 9) is more critical

regarding energy consumption. In fact, the topcoat oven alone consumes 1 500 MWh a year.

5.2.1. UV-cure paint

The current paint system does not have the properties required to cure with UV-light, therefore it is not possible to implement UV-paint curing without changing the paint system to one that is appropriate to cure with UV-light. An UV-cured paint option is UVMax®, which is a powder

coating from Keyland Polymer and is both durable and functional for a variety of products and applications. The UV-cured powder is mainly for metal and considered to be an excellent coating for applications in transportation, building materials, industrial products, among other markets. Keyland Polymer is able to develop a wide range of powders to match to any RAL color chart, Pantone or supplied color standard. The benefits with this UV-cured powder is the