VTI rapport 1069A Utgivningsår 2020 vti.se/publications

Development of advanced

evaluation and construction

methods for asphalt joints

Ehsan GhafooriVTI rapport 1069A

Development of advanced evaluation and

construction methods for asphalt joints

Author: Ehsan Ghafoori, VTI, http://orcid.org/0000-0002-5526-5896 Reg. No., VTI: 2019/0252-9.2

Publication: VTI rapport 1069A Published by VTI, 2020

VTI rapport 1069A 3

Publikationsuppgifter – Publication Information

Titel/Title

Utveckling av avancerade utvärderings- och konstruktionsmetoder för asfaltfogar/Development of advanced evaluation and construction methods for asphalt joints

Författare/Author

Ehsan Ghafoori (VTI, http://orcid.org/0000-0002-5526-5896)

Utgivare/Publisher

VTI, Statens väg- och transportforskningsinstitut

Swedish National Road and Transport Research Institute (VTI) www.vti.se/

Serie och nr/Publication No.

VTI rapport 1069A

Utgivningsår/Published

2020

VTI:s diarienr/Reg. No., VTI

2019/0252-9.2 ISSN 0347–6030 Projektnamn/Project Asfaltfogar/Asphalt joint Uppdragsgivare/Commissioned by Trafikverket Språk/Language Engelska/English

Antal sidor inkl. bilagor/No. of pages incl. appendices

4 VTI rapport 1069A

Abstract

Asphalt pavement joints are one of the weakest parts of an asphalt pavement and require much attention during construction to avoid short pavement lifespans. Despite of their importance, there are no standardized performance-based evaluating tools and not much is known about the impact of different construction parameters on the quality of the asphalt pavement joints. Building up a better fundamental understanding of the joints construction and developing evaluating methods based on their expected fracture mechanisms in the field can help counteracting the premature failure of asphalt joints. Therefore, in this project, the impacts of different construction parameters on the quality of the joints were fundamentally studied. Besides, possibility of using shear testing as an evaluating method for asphalt joints was examined. The obtained results clearly highlighted the superiority of

constructing asphalt joints with inclined geometry to the vertical one and also indicated the importance of compacting the joints from the hot side. In addition, it was shown that using proper surface

preparation for maintenance joints can help improving the quality of asphalt pavement joints. Finally, the developed shear tests in this project showed their efficiency of being used further on for evaluating asphalt pavement joints.

Keywords

VTI rapport 1069A 5

Referat

Fogarna är en av de svagaste delarna av en asfaltbeläggning och kräver stor omsorg under läggningen för att förhindra förkortad livslängd på asfaltbeläggningen. Trots deras betydelse finns det inga standardiserade utvärderingsverktyg för hur de presterar och man vet inte mycket om effekterna av olika konstruktionsparametrar på den slutliga kvalitén på fogarna. Att bygga upp en bättre

grundläggande förståelse för konstruktionen av fogarna och utveckla utvärderingsmetoder baserat på deras förväntade brottmekanismer i fältet kan bidra till att motverka det för tidiga felet i asfaltfogar. Därför studerades i grunden effekterna av olika konstruktionsparametrar på fogarnas kvalitet. Dessutom undersöktes möjligheten att använda skjuvningstest som en utvärderingsmetod för asfaltfogar. De erhållna resultaten visade tydligt överlägsenheten av att konstruera asfaltfogar med lutande geometri jämfört med vertikala fogar. Försöken indikerade också vikten av att börja packning av fogarna från den heta sidan. Dessutom visades att användning av lämplig förberedelse av ytan för underhållsfogar kan bidra till att förbättra kvaliteten på fogarna. Slutligen visade de utvecklade skjuvningstesterna i detta projekt deras förmåga att utvärdera asfaltbeläggningsfogar.

Nyckelord

VTI rapport 1069A 7

Förord

This is the final report regarding the BVFF project with the title of “Development of advanced evaluation and construction methods for asphalt joints” funded mainly by the Swedish road administration. The main applicant and the project leader of this project was KTH, whereas VTI, Skanska, NCC, Atlas Copco and Peab acted as supporters and co-financers of this work. The project tasks were carried out by Ehsan Ghafoori mainly during his employment at KTH and finalized during his employment at VTI. Therefore, this report was written as a VTI report.

Stockholm, March 2020

Manfred N. Partl Projektledare, KTH

8 VTI rapport 1069A

Quality review

A review seminar was held on 12 November 2020 with Manfred Partl and Björn Kalman as reviewer. Ehsan Ghafoori has made adjustments to the final report. Research director Björn Kalman has

thererafter reviewed and approved the report for publication on 12 November 2020. The conclusions and recommendations in the report are those of the author and do not necessarily reflect VTI as a government agency.

Kvalitetsgranskning

Granskningsseminarium har genomförts 12 november 2020 där Manfred Partl och Björn Kalman var lektör. Ehsan Ghafoori har genomfört justeringar av slutligt rapportmanus. Forskningschef Björn Kalman har därefter granskat och godkänt publikationen för publicering 12 november 2020. De slutsatser och rekommendationer som uttrycks är författarens egna och speglar inte nödvändigtvis myndigheten VTI:s uppfattning.

VTI rapport 1069A 9

Contents

Publikationsuppgifter – Publication Information ...3

Abstract ...4 Referat ...5 Förord ...7 Quality review ...8 Kvalitetsgranskning ...8 Summary ...11 Sammanfattning ...13 1. Background ...15

2. Methods and materials ...16

2.1. Laboratory simulation ...16

2.1.1. Materials ...17

2.1.2. Influence of layer thickness on asphalt joint quality ...17

2.1.3. Influence of static and vibratory compaction on asphalt joint quality ...18

2.1.4. Impact of bottom surface roughness on asphalt joint quality ...18

2.2. Discrete element simulation ...18

2.3. Test developments ...20

2.3.1. Investigating the shear capacity of asphalt joints ...20

3. Findings ...21

4. Recommendations ...22

VTI rapport 1069A 11

Summary

Development of advanced evaluation and construction methods for asphalt joints

by Ehsan Ghafoori (VTI)

Asphalt pavement joints are formed during the construction of new asphalt surfaces wider than the paving machine or the maintenance of deteriorated pavement sections. In many cases, asphalt pavement deterioration is caused by poorly constructed joints and can result in a significant lowering of the pavements service life. The purpose of this project was to investigate possible impacts of construction concepts and techniques on the quality of the asphalt pavement joints and to provide recommendations for constructing joints with appropriate interaction at their interfaces. An additional aim of this study was to examine the possibility of using shear tests to evaluate asphalt joints. Hence, experimentations and discrete element simulations were carried out with respect to the possible impacts of geometry, asphalt mixture type, compaction techniques, lift thickness, and bottom surface roughness at the asphalt joint interface. In addition, two shear test methods were successfully

developed and utilized for evaluating the quality of asphalt joints.

The results obtained from this study suggest constructing joints with inclined interfaces and also compact the joints from its hot side with few static and follow it with vibratory roller passes. The results also indicated that the bottom surface milling based on the maximum aggregate size of the asphalt mixture can help maximizing the density of the joint at its interface. The shear tests developed in this project showed their capability for being used along with other specified test methods for providing a better picture of the mechanical properties of joints.

VTI rapport 1069A 13

Sammanfattning

Utveckling av utvärderings- och konstruktionsmetoder för asfaltfogar

av Ehsan Ghafoori (VTI)

Beläggningsfogar i asfalt bildas vid anläggning av nya asfalterade ytor som är bredare än läggaren och vid underhåll av beläggningar. I många fall börjar nedbrytningen av asfaltbeläggningar på grund av dåligt konstruerade fogar. Syftet med detta projekt har varit att undersöka effekterna av olika konstruktionskoncept och tekniker på fogarnas kvalitet och att ge rekommendationer hur fogar ska konstrueras för att få lämplig interaktion i gränssnittet. I denna studie har vi också undersökt möjligheten att använda skjuvningstester för utvärdering av asfaltfogar. I studien har vi dels utfört experiment men också kompletterat med diskreta elementsimuleringar för att studera möjliga effekter med avseende av geometri, asfaltsmassor, packningstekniker, tjocklek och bottenytans struktur vid asfaltfogen. I projektet utvecklades två skjuvningstester som användes för att utvärdera kvaliteten på asfaltfogarna.

Resultaten som erhållits från denna studie gör det möjligt att ge några praktiska förslag för att förbättra kvaliteten på asfaltfogar i fältet. Resultaten föreslår också att man konstruerar fogar med lutande gränssnitt och även packar fogarna från dess heta sida med få statiska och följer den med vibrerande rullpassager. Resultaten indikerade också att bottenytfräsning baserat på asfaltblandningens maximala aggregatstorlek kan hjälpa till att maximera fogens densitet vid dess gränssnitt. De skjuvtest som utvecklats i detta projekt visade att de kunde användas tillsammans med andra specificerade testmetoder för att ge en bättre bild av fogarnas mekaniska egenskaper.

VTI rapport 1069A 15

1.

Background

Asphalt pavement joints are formed during the construction of new roads and the repair of deteriorated pavement sections. In many cases, asphalt pavement deterioration starts at poorly constructed joints and can result in a significant lowering of the pavements service life. Such joints may also raise the traffic noise level (in particular in urban areas with increased concentration of pavement repair patches) and cause serious safety issues especially for two wheeled vehicles. Despite of their key role, joints are nowadays characterized in a very simplistic empirical way (density measurements) without fundamentally understanding the mechanisms of compaction and material interlock during and after the joint construction. This calls for appropriate tests and numerical models for evaluating the joint interlocking properties and the pavements structural strength at joint locations.

Deterioration of joints may be caused by various effects such as insufficient compaction, construction without suitable preparation of the joint surfaces, and weak pavement bedding. Mechanical loading, temperature variation, and the intrusion of oil and de-icing substances may also accelerate

deterioration.

In an earlier study at the Swedish Royal Institute of Technology (KTH), possibilities of using alternative tests for capturing the mechanical properties of the joints were examined [Ghafoori R., et al., 2013]. Three test methods were chosen and adjusted for specifically measuring joint properties. Based on literature and expert interviews, some of the frequent and recommended joint interface treatments and geometries as well as frequent and recommended compaction methods were

investigated. These test methods showed their capability of producing reasonable rankings among the different joint concepts.

The results of that study suggested that not only one but also a combination of parameters, such as geometry and treatment, may have a great impact on joint performance. Moreover, changing the compaction method only may have a prominent influence on the performance level of joints. Based on the finding from this earlier study, focus was directed on the compaction process and the material flow during compaction of mixtures. Therefore, a simple lab-scale compaction simulator for studying the particle flow during compaction (Compaction Flow Test) was developed at KTH. Mixtures were tested with variations in binder content, temperature, and gradations [Ghafoori Roozbahany and Partl, 2016]. The compaction effort was recorded by a dynamic load frame and the particle flow was closely observed using X-ray Computed Tomography (CT).

The aforementioned studies were used as a basis in this project to provide construction recommendations and develop test methods for evaluating asphalt pavement joints.

16 VTI rapport 1069A

2.

Methods and materials

This project consisted of laboratory and discrete element simulations and is discussed in detail in the following paragraphs.

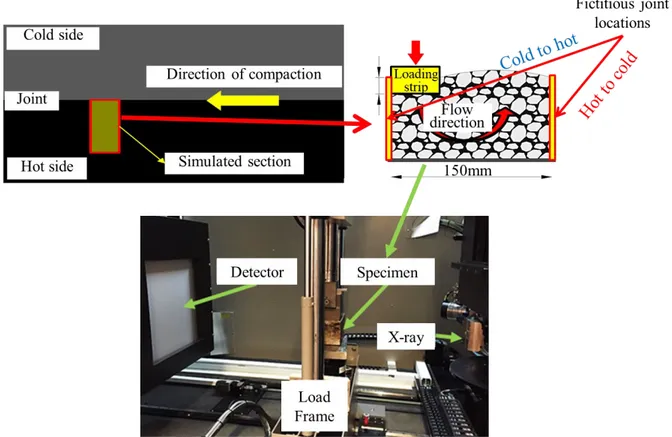

2.1. Laboratory simulation

In the experimental part, the impact of flow near the joint location on the interlock at the joint interface was investigated. A laboratory scale investigation was carried out to determine possible impacts of construction parameters such as lift thickness, bottom surface roughness and compaction modes on the flow behavior of the asphalt mixtures close to the interface of asphalt joints during compaction. To achieve this, it was required to take a close look at the changes in aggregate arrangement, due to compaction loads, in an asphalt mixture layer near the joint. Hence, a test method recently developed at KTH, Compaction Flow Test (CFT), was utilized along with X-ray computed tomography (CT) for investigating the flow behavior of two commonly used wearing course asphalt mixtures near the potential joint location. Figure 1 demonstrates the test setup and shows the assumptions made in this part of investigation.

Figure 1. Test setup for simulating asphalt mixture flow during compaction (Photographer: Ehsan Ghafoori).

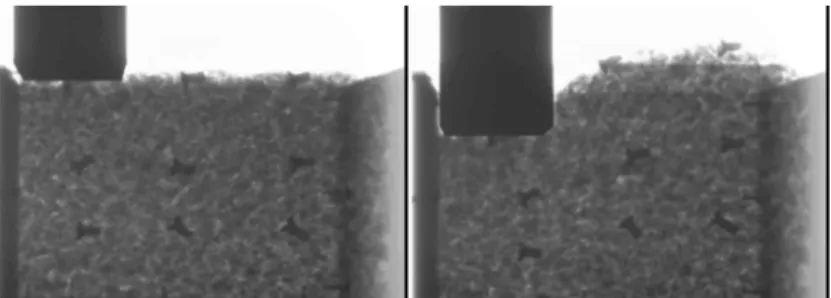

All tests were carried out at compaction temperatures between 120°C and 140°C in displacement control mode with a loading rate of 15 mm/min. To obtain the flow patterns, two-dimensional (2D) X-ray CT images were taken during the CFT. For an in-depth study on the asphalt mixtures flow pattern during the test, some embedments with minor disturbance to the flow were utilized (Figure 2).

VTI rapport 1069A 17 Figure 2. Example of X-ray CT images obtained during the CFT (Screws were embedded in the specimens and used as flow indicators during the test). (Photographer: Ehsan Ghafoori).

2.1.1. Materials

This project focused on the surface course layer. Therefore, a coarse-graded mixture (stone mastic asphalt, SMA), and a fine-graded mixture (asphalt concrete, AC), were selected for testing. Both had a nominal maximum aggregate size (NMAS) of 11 mm and were either laboratory prepared or collected from a Skanska asphalt plant. For the SMA mixture, 70% of the aggregates were between 11 mm and 4 mm as compared to 42% in case of the AC mixtures. The mixtures were prepared to fulfill the requirements of the Swedish standard [TRVKB 10, 2011] as shown in Figure 3. Both mixtures were prepared using the commonly used binder type in Sweden for wearing course layers, i.e. bitumen 70/100 pen.

Figure 3. Upper and lower limits of the gradation curves according to the Swedish standard for SMA and AC.

2.1.2. Influence of layer thickness on asphalt joint quality

To investigate the possible impact of thickness on the quality of asphalt joints, three different

thicknesses were investigated: 45 mm, 75 mm, and 100 mm. Thanks to the flexible design of the CFT setup, only minor adjustments regarding mold depth were made. During each test, after filling the mold with the asphalt mixture, one third of the specimen was subjected to a vertical compaction load (Figure 1) until the loading strip was vertically displaced as much as 30% of the initial specimen thickness. The maximum particle movement of each specimen during loading was measured and compared to examine whether there were meaningful differences between the cases. Details of the test setups and results of this part the study have been published elsewhere [Ghafoori Roozbahany et al., 2017a].

18 VTI rapport 1069A

2.1.3. Influence of static and vibratory compaction on asphalt joint quality

The possible impacts static and vibratory compaction modes have on asphalt joints quality were also investigated. Even though these two modes of compaction have been used for a long time, their influence on the structural changes of an asphalt layer are yet to be fully understood. Hence, the impact of these two compaction modes on the internal movements of aggregates during compaction was investigated. To achieve this, 50 mm thick CFT specimens were prepared and loaded down to 20% of their initial lift thickness (10 mm). Similar to section 2.1.2, each test was carried out inside the X-ray CT system for acquiring images of the aggregate movements within the mixtures during the compaction process.

Based on the literature [Bahia & Paye, 2001], pavements with lift thicknesses up to 60 mm can be compacted with high efficiency under a vibration mode of low amplitude and high frequency. Therefore, an amplitude of 0.25 mm and a frequency of 70 Hz were chosen as input values for the loading. Details of the test setups and results of this part of the study have been published elsewhere [Ghafoori Roozbahany et al., 2017b].

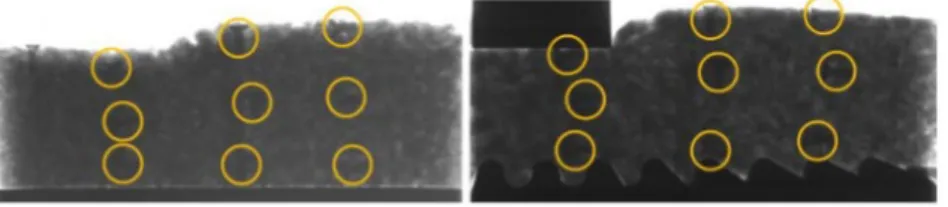

2.1.4. Impact of bottom surface roughness on asphalt joint quality

In the third part of this project, possible impacts of a milled and un-milled surface on the flow pattern of an overlay near joints were investigated. Similar to the previous section, 50 mm thick specimens were prepared and loaded to a displacement of 20% of their initial thickness. To simulate the milled bottom surface, a grooved metal surface was prepared and placed at the bottom of the CFT mold then filled with the asphalt mixture (Figure 4). Test setup details and the results of this part of the study is presented in Ghafoori Roozbahany et al., 2017c.

Figure 4. Examples of CFT X-ray images used for determining possible impact of flat and grooved bottom surfaces on the flow of asphalt mixtures under compacting loads. (Photographer: Ehsan Ghafoori).

2.2. Discrete element simulation

Due to uncertainties concerning the influence of construction parameters on the quality of the finalized joints, and to eliminate the influence of human error in the laboratory, asphalt joint construction was numerically simulated. Hence, the possible impacts of thickness, bottom layer roughness, joint interface geometries, and compaction techniques on the particle flow of a coarse structured mixture were investigated using discrete element method. Figure 5 shows the variations used for simulating the asphalt joint construction. Details of the assumptions and results of this study have been published in a journal paper [Ghafoori Roozbahany, Partl, 2019].

VTI rapport 1069A 19 Figure 5. Examples of variations used for simulating asphalt joint construction: bottom roughness, joint geometry, and compaction methods [Ghafoori Roozbahany and Partl 2019]

In addition, the influence of the distance from the joint interface, when compacting from the hot side towards the joint, was also investigated (Figure 6).

Figure 6. Examining the maximum efficient distance from the joint interface when compacting hot-to-cold [Ghafoori Roozbahany and Partl 2019].

20 VTI rapport 1069A

2.3. Test developments

2.3.1. Investigating the shear capacity of asphalt joints

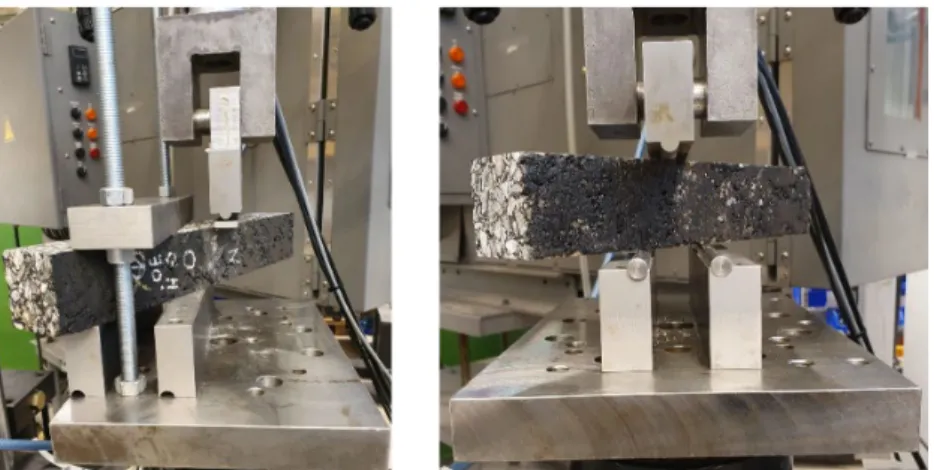

As mentioned in the background section, in an earlier study mainly carried out by the author of this report, three mechanical-based test methods: indirect tension, direct tension, and 4-point bending, were successfully utilized to identify construction parameters and techniques that have a high potential for improving asphalt joint quality. Since the joint shear capacity at interface also plays a vital role in its quality, the possibility of using shear tests to evaluate the interaction of the joints two sides at its interface was investigated. This was achieved by developing two new shear test devices and are presented in Figure 7.

Figure 7. The test setups (left): cantilever test, (right): 3-point bending shear test (Photographer: Ehsan Ghafoori).

To prepare specimens for evaluation, asphalt joints with three different geometries: 0°, 45°, and 60° (Figure 8) were formed. Specimens were prepared using the two compaction techniques: one from hot towards cold and the other from cold to hot side of the joints (Figure 9). Specimen slabs were

produced in a laboratory and cut into beams. Shear capacity tests were carried out at 25°C under displacement control with a loading rate of 5 mm/min.

Figure 8. Geometry of the asphalt joints produced in the laboratory in form of slabs

Figure 9. The Compaction setup used for simulating (left) cold-to-hot and (right) hot-to-cold. (Photographer: Ehsan Ghafoori).

The results of this investigation have also been written in form of a scientific paper and will soon be submitted to a scientific paper in a pavement related journal.

VTI rapport 1069A 21

3.

Findings

The results of the investigation provided reasonably useful input for building up a better understanding of the behavior of mixtures under compaction loads, especially near the asphalt pavement joints. The suggested method successfully revealed structural re-arrangement differences within the asphalt mixtures for different lift thicknesses, bottom roughness, and compaction modes. Besides, discrete element simulations of the asphalt joint construction revealed possible reasons that could explain the differences in mechanical properties. The simulations have also helped to explain results from previous research studies in a more comprehensive way. The findings of this project suggest the following:

The CFT setup along with the X-ray imaging appeared to be an effective laboratory method for investigating possible impacts from construction parameters as well as how mixture characteristics affect the internal flow behavior of asphalt mixtures during the compaction phase.

Based on the experimental part, test mixtures during vertical compaction loading showed vertical and horizonal aggregate flow. Similar movements can also be recognized if the compaction in the field is closely observed. However, under similar compaction conditions, mixtures with coarser gradations seem to show higher horizontal flow. This means that compacting asphalt mixtures from the cold side of the joint may produce asphalt joints with lower density and poorer mechanical properties than when compacting from the hot side. This is especially so in case of coarse graded mixtures such as SMA. Changes in lift thickness appeared to have a very high impact on the interlock of aggregates at the joint interface; the higher the lift thickness the larger the horizontal flow, especially in case of SMA mixtures.

Both experimental results and discrete element simulations suggest that the roughness of the bottom surface can influence the flow of aggregates during the compaction phase. The milled surface appeared to limit the flow. When compared to the flat bottom surface it seemed to help keep the mixture aggregates closer to the joint interface, particularly when compacting from the cold side of the joint.

When compared to the vibration compaction mode the static compaction mode caused more overall flow during the CFT for the tested surface course test mixtures. The vibration compaction mode seemed to lower the intensity of aggregate to aggregate interactions. Hence, using vibration mode might not be a very good option when large deformations are expected especially when starting the joint compaction from the hot side towards the joint. However, as the compaction continues and the compactor gets closer to the joint interface, the vibratory compaction can create turns in aggregates in such a way that the interlock at the joint is increased.

Both experiments and simulations demonstrated that interface geometry seems to have a very high contribution towards improving the mechanical properties of the asphalt pavement joints. The investigated asphalt joints with inclined interfaces showed a higher interaction at their interfaces than those with vertical interface. This is because of their larger interface areas.

Results also suggest that combining inclination at the joint interface with the hot to cold compaction technique can increase the quality of the asphalt joints.

In order to apply the hot to cold compaction method on an asphalt pavement layer with maximum thickness of 5·NMAS, 150 mm distance for the initial passes seemed to be appropriate.

Suggested shear test methods enabled evaluating the shear capacity of asphalt joints. Results obtained from the developed shear tests also indicated great impacts from geometry and compaction on the asphalt joints shear capacity.

22 VTI rapport 1069A

4.

Recommendations

Results obtained from the CFT and X-ray image analysis successfully demonstrated the influence of different modes of compaction on the chosen mixtures. Therefore, it is recommended to consider these tools for studying a wider range of mixtures, construction options, and vibration variations. In this way, this study can be taken as a basis for improving road compaction as a key factor for constructing better performing roads and encouraging a more efficient use of material resources.

To obtain a better interaction at the joint interface, it is recommended to construct asphalt joints with an inclined interface rather than a vertical one. Obviously, too much inclination can make the existing side of the joint prone to breakage and poor interaction at the joint interface. Therefore, to obtain an optimum interaction at the joint interface, the inclination ought to be chosen carefully and based on the NMAS of the mixture. So, it is recommended to choose the inclination in such a way that the coarse aggregates of the two sides of the joint can interact with each other for more than 80% of the total joint interface area.

It is highly recommended to start compacting asphalt joints from the hot side towards the joint with a few static roller drum passes, especially when using coarse graded mixtures. It is also suggested to follow the static passes from the hot side with a few vibratory passes for maximizing the interaction between the two sides of the joint at its interface.

In case of maintenance work, depending on the mixture gradation and based on the expected material flow near asphalt joint locations, minimum groove size for milling should be carefully chosen in a way that the milled bottom surface help keeping coarse aggregates of the mixture near the joint interface to provide an appropriate interlock at the joint interface between the aged and the newly laid side of the joint.

It is also recommended to use mechanical testing along with density measurements for an effective evaluation of asphalt joints particularly for the roads of high importance. Obviously, the type of test should be chosen depending on the expected mechanism of the failure for the asphalt joint that is evaluated. The adjusted and developed tests specifically for evaluating the quality of joints, i.e. indirect tensile, direct tension, 4-point bending, and cantilever shear test, are recommended to be used for this purpose.

VTI rapport 1069A 23

References

Bahia, H. U., and B. C. Paye. ‘Minimum Pavement Lift Thickness for Superpave Mixtures’. No. WHRP 03-02, 2001.

Ehsan Ghafoori Roozbahany, Manfred N. Partl & Patryk Jakub Witkiewicz, “Fracture testing for the evaluation of asphalt pavement joints”, Road Materials and Pavement Design, Volume 14, Issue 4, pages 764-791, 2013

Ghafoori Roozbahany, E., and Part M. N. "A new test to study the flow of mixtures at early stages of compaction." Materials and Structures 49.9 (2016): 3547-3558.

Ghafoori Roozbahany, E. and Partl M. N. "Investigation of asphalt joint compaction using discrete element simulation." Road Materials and Pavement Design 20.7 (2019): 1722-1734.

Ghafoori Roozbahany E., Partl M. N. and Jelagin, D. “Modelling the flow behaviour of asphalt under simulated compaction using discrete element” Construction and Building Materials 227 (2019): 116432

Ghafoori Roozbahany E., Partl M. N. and Guarin A. "Influence of layer thickness on the flow of asphalt under simulated compaction”, 10th international conference on the bearing capacity of roads, railways and airfields, Athens, Greece, June 28-30, 2017a.

Ghafoori Roozbahany E., Guarin, A., Partl M. N. "Influence of static and vibratory compaction on the flow behaviour of asphalt surface courses" 71st Rilem week and international conference on advances in construction materials and systems, Chennai, India, September 3-8, 2017b.

Ghafoori Roozbahany, E., Partl, M. N., and Guarin, A. "Monitoring the flow of asphalt mixtures compacted on two different rough surfaces", 4th conference on smart monitoring, assessment and rehabilitation of civil structures, Zurich, Switzerland, September 13-15, 2017c.

ABOUT VTI

T

he Swedish National Road and Transport Research Institute (VTI), is an independent and internationally prominent research institute in the transport sector. Our principal task is to conduct research and develop-ment related to infrastructure, traffic and transport. We are dedicated to the con-tinuous development of knowledge pertaining to the transport sector, and in this way contribute actively to the attainment of the goals of Swedish transport policy. Our operations cover all modes of transport, and the subjects of pavement technology, infrastructure maintenance, vehicle technology, traffic safety, traffic analysis, users of the transport system, the environment, the planning and deci-sion making processes, transport economics and transport systems. Knowledge that the institute develops provides a basis for decisions made by stakeholders in the transport sector. In many cases our findings lead to direct applications in both national and international transport policies.VTI conducts commissioned research in an interdisciplinary organisation. Employ-ees also conduct investigations, provide counseling and perform various services in measurement and testing. The institute has a wide range of advanced research equipment and world-class driving simulators. There are also laboratories for road material testing and crash safety testing.

In Sweden VTI cooperates with universities engaged in related research and education. We also participate continuously in international research projects, networks and alliances.

The Institute is an assignment-based authority under the Ministry of Infrastruc-ture. The Institute holds the quality management systems certificate ISO 9001 and the environmental management systems certificate ISO 14001. Certain test methods used in our labs for crash safety testing and road materials testing are also certified by Swedac.

![Figure 6. Examining the maximum efficient distance from the joint interface when compacting hot-to- hot-to-cold [Ghafoori Roozbahany and Partl 2019]](https://thumb-eu.123doks.com/thumbv2/5dokorg/4746608.126001/21.892.160.762.114.434/figure-examining-efficient-distance-interface-compacting-ghafoori-roozbahany.webp)