Postadress: Besöksadress: Telefon:

Box 1026 Gjuterigatan 5 036-10 10 00 (vx)

A MORE EFFICIENT WAY OF BUILDING IN

A DEVELOPING COUNTRY, INFLUENCED

BY INDUSTRIALIZED BUILDING

- A case study in Leticia, Colombia

Sanna Ahlstrand

Johanna Bender

Linn Nordström

BACHELOR THESIS 2015

This bachelor thesis has been carried out at Jönköping School of Engineering within the field of Building Technology. The authors take full responsibility for result, opinions and conclusions presented in this thesis.

Examiner: Peter Johansson Supervisor: Martin Lennartsson Credits: 15 ECTS

Abstract

Purpose: The purpose of this study is to approach a solution to reduce housing shortage, by using inspiration from an industrialized building concept, which can lead to the opportunity for underprivileged people to get a livable housing.

The aim is to study how knowledge from industrialized building could be used for a more efficient way of building in developing countries similar to Colombia.

Method: Utilizing literature studies for achieving abutment to published research also giving the authors an observant mind. With this knowledge, participatory observations were made as action research to explore the prevailing procedure when establishing a house. Operating analyzes, interviews were held in Leticia for understanding observed decisions. To be able to critically analyze the results from the interviews and observations, collected data were compared with knowledge based on the authors’ reference frames.

Findings: Keystones identified as the overall concept are applicable on establishments in the western world, since the concept is designed after similar conditions. Capital is required designing a building system as well as establishing a factory for prefabrication of elements, conditions limited in developing countries. Climate conditions and prevailing corruption prevents implementation of the concept. Identified weaknesses during the observations, noted repetition of unnecessary and non-value adding activities. One conclusion is not to implement the entire industrial building system, only practice the mindset. Initially keystones are implemented such as planning, exchange of information and reflection of performed projects, in order to improve upcoming projects. These keystones require no direct capital, merely a mindset that should be implemented.

Implications: The outcome of this study is to enlighten the subject, since obvious weaknesses were noticed, with capacity for development. Further research is realistic because, in a long term it will help solving the housing situation. For example, using this result as underlay for education like creating more efficient building, enlightening planning for reducing unnecessary non value-adding activities. As a conclusion of the study, identified weaknesses during the establishment affects the efficiency, creating unnecessary costs. A developing country should focus upon emphasizing reduction of costs, since their economic status is already declining.

Limitations: The observations during the case study have been concentrating on one small-scaled project in Leticia, Colombia. No further observations have been made but complements such as literature studies and interviews. Due to lack of time and language barrier, the amount of collected empirical data was too limited to provide durable conclusions for question formulations. Since only observations were performed on one establishment, a general result cannot be submitted.

Keywords: Industrialized building, developing country, efficiency, rationalization, value-adding, weaknesses, ICT, standardized elements, prefabrication, implementation, planning.

Sammanfattning

Syfte: Syftet med denna studie är att närma sig en lösning för att minska rådande bostadsbrist i utvecklingsländer genom att använda inspiration från ett industriellt byggsätt. Detta kan i sin tur leda till möjligheten, för underprivilegierade personer, till ett drägligt boende.

Målet är att studera hur kunskap från industriellt byggande kan användas för ett effektiviserat byggande i utvecklingsländer som Colombia.

Metod: Litteraturstudier genomfördes för att sätta sig in i ämnet samt ge stöd till aktionsforskningen som bedrevs genom deltagande observationer under etableringen av en byggnad i Leticia. Som komplement till observationerna utfördes intervjuer. För att kritiskt kunna analysera dessa resultat jämfördes insamlad empiri med kunskap från teoretiskt ramverk.

Resultat: De identifierade nyckelpunkterna i konceptet industriellt byggande är applicerbara på byggnadsprojekt i västvärlden och dess förutsättningar. Finansiellt kapital krävs vid både utformning av byggsystem samt vid uppförande av fabrik för tillverkning av förtillverkade element, förutsättningar som är begränsade i utvecklingsländer.

Klimatförhållanden samt rådande korruption förhindrar implementering av konceptet. Identifierade svagheter under observationerna var upprepning av icke värdeskapande aktiviteter. En slutsats är att inte implementera hela konceptet men delar av det så som planering, informationsutbyte samt återkoppling och uppföljning för att förbättra kommande projekt. Dessa nyckelpunkter kräver inget större finansiellt kapital, snarare ett tankesätt skulle implementeras.

Konsekvenser: Resultatet av denna studie är att belysa ämnet då tydliga svagheter, med kapacitet för förbättring, har noterats. Vidare forskning är realistiskt då det, på längre sikt, kan hjälpa till att lösa boendesituationen. Exempelvis kan resultatet användas som underlag vid utbildning, att skapa effektiviserat byggande, med belysning på planering med minskade icke värdeskapande aktiviteter. En slutsats är att identifierade svagheter under byggprocessen påverkar effektiviteten och skapar onödiga kostnader. Ett utvecklingsland bör fokusera på att betona innebörden att minska kostnader på grund av redan låg ekonomisk status.

Begränsningar: Observationer under fältstudien har utförts på ett mindre projekt i Leticia, Colombia. Inga ytterligare observationer har utförts och därför har kompletterande data insamlats via intervjuer och litteraturstudier. På grund av bristande planering samt språkbarriär kunde mängden insamlad data inte generera ett starkt resultat. Då observationer endast utförts på ett projekt kan inte ett generellt resultat redovisas.

Nyckelord: Industrialized building, developing country, efficiency, rationalization, value-adding, weaknesses, ICT, standardized elements, prefabrication, implementation, planning.

Content

1

Introduction ... 1

1.1 BACKGROUND ... 1

1.2 PROBLEM FORMULATION ... 1

1.3 AIM AND QUESTION FORMULATIONS ... 2

1.3.1 Aim of Study ... 2

1.3.2 Question formulations ... 2

1.4 DELIMITATIONS ... 2

1.5 DISPOSITION ... 3

2

Method and Implementation ... 4

2.1 RESEARCH STRATEGY ... 4

2.2 CONNECTION BETWEEN QUESTION FORMULATIONS AND METHODS FOR DATA COLLECTION ... 5

2.3 METHODS FOR DATA COLLECTION ... 6

2.4 WORK PROCESS ... 7

2.5 VALIDITY ... 7

3

Theoretical framework ... 9

3.1 CONNECTION BETWEEN QUESTION FORMULATIONS AND THEORY ... 9

3.2 INDUSTRIALIZED BUILDING ... 9

3.2.1 History of the concept industrialized building ... 10

3.2.2 Significant areas of an industrialized building ... 10

3.2.3 Advantages and disadvantages with industrialized building ... 12

3.3 CONCEPTS SIGNIFICANT FOR AGGRADATION OF INDUSTRIALIZED BUILDING ... 13

3.3.1 Lean Construction ... 13

3.3.2 The Toyota Production System ... 14

3.3.3 Supply Chain Management ... 15

3.4 ORIGIN OF CASE STUDY:COLOMBIA AND ITS CONDITIONS IN A DEVELOPING COUNTRY ... 16

3.5 SUMMARY OF THEORIES ... 16

4.1 OBSERVATIONS ON-SITE ... 18

4.2 INTERVIEWS ... 20

4.2.1 Interview with manager on-site ... 20

4.2.2 Interview with architect ... 21

4.3 SUMMARY OF COLLECTED EMPIRICAL DATA ... 21

5

Analysis and result ... 23

5.1 ANALYSIS ... 23

5.2 HOW DOES THE OVERALL CONCEPT FOR INDUSTRIALIZED BUILDING LOOK LIKE? ... 25

5.3 WHICH WEAKNESSES CAN BE IDENTIFIED IN THE ESTABLISHMENT OF A HOUSE IN A DEVELOPING COUNTRY? ... 26

5.4 WHAT KNOWLEDGE FROM INDUSTRIALIZED BUILDING COULD BE USED IN THE ESTABLISHMENT OF BUILDINGS WITH LIMITED RESOURCES? ... 27

5.5 CONNECTION TO THE AIM ... 29

6

Discussion and Conclusion ... 31

6.1 DISCUSSION OF RESULT ... 31

6.2 DISCUSSION OF METHOD ... 31

6.3 LIMITATIONS ... 32

6.4 CONCLUSION AND RECOMMENDATIONS ... 32

6.5 SUGGESTION FOR FURTHER RESEARCH ... 33

References ... 34

1

Introduction

As a part of the Bachelor of Science in Civil Engineering, specialisation Architectural

Engineering, Department of Civil Engineering and Lighting Design at Jönköping

School of Engineering, a bachelor thesis of 15 ECTS points has to be carried out. The purpose of assembly this thesis is to demonstrate skills and knowledge gained during the program through an independent study of a current problem.

The purpose of this study is to give underprivileged people the opportunity to get a livable housing by using inspiration from an industrialized building concept.

This thesis was made in collaboration with the Swedish Ancla Foundation, which has been working in the Amazonas region for 20 years, mostly building schools. A local orphanage in the town Leticia, La Aljaba, recently sent a request for support to rapidly erect a new center. La Aljaba bought a piece of land in a newly exploited part of Leticia that in the future will accommodate three buildings for housing, each house accommodating twelve children. The site will also accommodate schools, administration building, playgrounds, soccer field as well as garden. This case study will take place during the establishment of the first house at the center.

1.1 Background

All around the world, people are living in slum-like conditions, according to the Millennium Development Goals report (2014). In the year of 2012, approximately 863 million people were living in slum-like conditions and the number has been increasing since 1990 with its 657 million. Despite improved building standard the people still living in slum-like conditions has not decreased. This proves that the need to improve people’s housing situation is genuine.

Environmental issues are highly topical in today’s society and the use of the earth’s resources is a major problem for the underprivileged parts on our planet (Globalis, 2015a). The building sector has a great impact on the climate change and stands for 40% of the resource consumption (Offerman, 2014). When improving living conditions, it is important to build in a way that does not harm the environment. An efficient way of building contributes to a minimized waste of resources.

This thesis was carried out by a scholarship from Sida which is the Swedish International Development Cooperation Agency, providing funding or knowledge to developing countries. Performing this thesis is topical since statistics (UNEP, 2014) indicates a growth of 7.9 to 10% in the building sector, one of the main economic drivers, in Colombia. To help further development, it is relevant to assist with knowledge how to create a more efficient and profitable building.

1.2 Problem formulation

Industrialized building might be a concept that could be utilized for improving the housing situation for underprivileged people. Colombia suffers from a housing shortage of 13% (1.2 million) and the government implemented a National Development Plan suggesting 1 million housing units, for low income families, should be built until 2019 (UNEP, 2014). Similar projects have been done elsewhere, for example in Sweden during the 1960’s and 70’s, where the Million programme (Miljonprogrammet) were used as an action to solve housing shortage. A solution like

this is good in a short-term perspective, but the speed of the mass-production affected the house’s quality, not sustainable seen through a long-term perspective. By preventing same faults occurring again, it is of importance sharing experiences from projects accomplished with industrialized building (Engström, 2012).

One hypothesis for the housing shortage is that the way of building is inefficient, which results in unnecessary costs. Assuming the building could be more efficient by using knowledge from industrialized building, where the idea is to create a more economical production (Fernström & Kempe, 1998). Improved efficiency of industrial processes in planning, construction and property management is needed for increased productivity to meet requirements of housing (Andersson, Engström, Johnsson, Löfsjögård, Stehn & Söderqvist, 2013).

The building sector in Colombia has not been making use of its total capacity; nevertheless a growing rate of 16.9% indicates an advancing country (UNEP, 2014). By using knowledge from the industrialized building strategy, it is possible to create a base to a more efficient building production (Gerth, 2008). Efficiency in the building process is desirable nevertheless; reality usually looks completely different (Buser, 2013). In developing countries, the workforce is commonly uneducated and by practicing an inefficient traditional way of building, an inability to meet the increasing demands for housing arises (Lee, Nawi & Nor, 2011). It is of great importance promoting an industrialized way of building to all parts, from large companies to the single individual, within the construction sector for increased efficiency and quality.

1.3 Aim and Question formulations

How the purpose of the question formulations supports the report towards the aim is presented below.

1.3.1 Aim of Study

The aim is to study how knowledge from industrialized building could be used for a more efficient way of building in developing countries similar to Colombia.

1.3.2 Question formulations

1. How does the overall concept for industrialized building look like?

2. Which weaknesses can be identified in the establishment of a house in a developing country?

3. What knowledge from industrialized building could be used in the establishment of buildings with limited resources?

1.4 Delimitations

The observations during the case study have been concentrating on one small-scaled project in Leticia (the Amazon region). No further observations outside Leticia has been made. As the building process has been studied, parts as property management and demolition have been disregarded.

1.5 Disposition

Chapter two presents performed methods; literature studies for gathering knowledge of the concept industrialized building, interviews with participants in the building sector in a developing country. To get an explication of how the establishment of a house in a developing country could proceed observations was made through a case study performed as action research.

Chapter three support answers for question formulations. The theoretical framework contains inter alia parts from the licentiate thesis by Lessing (2006), theories for industrialized building such as Supply Chain Management and the Toyota Production System.

Chapter four handle the outcome of empirical data carried out as interview and observations which strived to identify weaknesses during an establishment.

Chapter five presents answer to the questions as a result of the study, by analyzing the empirical data together with facts from the theoretical framework.

Chapter six includes a discussion, conclusion and suggestions for future research within the field.

2

Method and Implementation

This study takes place as a case study in the beginning of 2015, during eight weeks in Leticia, Colombia. The case study is performed as an action research based upon interviews and observations when studying the establishment of a one-story house. This opportunity was carried out through the scholarship MFS (Minor Field Study) received from Sida, who provides developing countries with funding and knowledge. Thereby the chosen methods for this case study is consulting and relevant to reach the aim.

2.1 Research strategy

A qualitative approach is used in this report to understand the big picture. The research focuses on conditions for building in developing countries and its possibilities for adapting an industrialized building concept. This report will be carried out through qualitative research methods since no measurable results were to be analyzed (Kvalitativ metod, 2015).

The question formulations affiliate each other where the first two questions exceed into the third question (Q.3). Aiming to provide with consultation regarding Q.3, participatory observations during the case study as chosen method, is suitable. Action research in this case study as method is used for two reasons, partially for projects not properly fulfilling requirements of scientific research but concentrating on consultancy. Secondly, when usage of traditional methodology derives from the positivistic paradigm. Regarding the observations, rationality is a large part compared to scientific research (Gummesson, 2000). Action research is, according to Gummesson (2000), a way of learning about a social system and simultaneously trying to change it. The traditional action research is societal where underprivileged groups are supported by achieving knowledge which makes this method relevant for the questionnaires.

A case can be illuminated from different angles through a combination of different methods, which is called to triangulate. This study combines methodologies, empirical data were collected through interviews and observations. A case study is expected to capture the complexity and focuses on one particular case, including many variables and qualities. A case study investigates a complex functioning unit, on-going or a contemporary phenomenon in its natural context, therefore a case study cannot be repeated acquiring an identical result, (Johansson, 2005).

By studying the establishment of a house, critical moments were identified and analyzed. Through the case study one part of the process was investigated where the result later applies on the entirety, (Ejvegård, 2009). To obtain comprehension of procedures, in an environment that distinguishes from an industrialized country, observations were made. To get an extended view, interviews were held with two involved persons. Literature studies of industrialized building were used as a complement to link empirical data to the current field, also giving a background of the concept. The chosen empirical methods helped reaching the qualitative inspired aim while collecting knowledge of advantages and disadvantages supported the analysis.

2.2 Connection between question formulations and methods

for data collection

1. How does the overall concept for industrialized building look like?

The purpose of this question is to introduce the subject and get a more profound picture. Material can be found through literature studies of previous research which is compiled to give an explanation of the concept. The concept is complex and to comprehend it, a great amount of reading was required which makes a summary desirable.

2. Which weaknesses can be identified in the establishment of a house in a developing country?

This question will be answered through interviews, observations and literature studies. To get an insight of weaknesses occurring in the establishment of a house, observations were made on-site, complemented with interviews. Applied empirical methods were chosen since it gives direct access to the problem. For obtaining knowledge of the concept, literature studies supported the analysis when finding improvements for observed weaknesses.

3. What knowledge from industrialized building could be used in the establishment of buildings with limited resources?

Question number three was answered through literature studies, supported by observations and interviews. Literature studies were beneficial for highlighting previous faults, like consequences from the Swedish Million programme. Sharing knowledge creates awareness for developing countries not making the same faults, which contributes to their rate of development. Observations on-site were carried out to get a profound picture of how an establishment in a developing country precedes. Interviews helped obtaining a comprehension if implementation of the concept could be possible. The connection between empirical methods and theories supporting the reasoning towards the aim of the study is illustrated in the figure 1.

Figure 1. Connection between empirical methods and theories, towards the aim.

2.3 Methods for data collection

The purpose of chosen methods is: utilizing literature studies to achieve abutment to published research also giving the authors an observant mind. The field of industrialized building holds a lot of previous published material, which needed screening. To simplify this process tools were used such as reviewing the table of content and abstract (Ejvegård, 2009). Used literature are referred as the Harvard system (Carlstein, 2015.)

Observations were made to explore the prevailing procedure when establishing a house. Participatory observations has been carried out with intention to collect material for question formulations (Bengtsson, Hjorth, Sandberg, Tehlander, 1998). As a complement to participatory observations, interviews or protocol is recommended to implement (Ejvegård, 2009). To operate analysis based upon more than opinions from an industrialized country, interviews were held in Leticia for understanding observed decisions. Pure knowledge does not exist it is only a socially constructed knowledge (Bengtsson et al., 1998).

The further analysis was primarily based on literature studies and observations supported by interviews, which later on were compared with knowledge based on the authors’ reference frames. Foundational values for the reference frames originated from knowledge obtained from the Bachelor of Science in Civil Engineering, specialisation Architectural Engineering. The analysis also got influenced by the impressions of Leticia. It was a new environment to the authors where conversations with inter alia the board of the orphanage helped to a more profound understanding, see appendix 1.

EMPIRICAL METHOD QUESTION FORMULATION THEORY

AIM

The figureXXXX present used empirical methods and theories which supported the reasoning towards the aim of the study.

Observation

Interview

How does the overall concept for industrialized

building look like? (Q1)

Which weaknesses can be identified in the establishment of a house in

a developing country? (Q2)

[Q.2] What knowledge’s from industrialized building could

be used in the establishment of buildings

with limited resources? (Q3)

Industrialized building

Origin of field study: Colombia and conditions

in a developing country

(3.4) Concepts significant for

aggradation of industrialized building

The aim is to study how knowledge from industrialized building could be used for a more efficient way of building in developing

2.4 Work process

Since the authors received a MFS scholarship as a group the interviews were performed with all members attending, to get everyone involved although recommendations considering interviewing are to only have one interviewer (Ejvegård, 2009). Interviews were held in an early phase of the case study, see table 1. They were carried out with one respondent at a time and held in an office environment where two interviewers asked questions and one interviewer took notes. Because of language barrier an interpreter translated from Spanish to English. Two respondents were interviewed, manager on-site and architect from the city council in Leticia. Qualifications within the current field made the respondents suitable for interviewing. Manager on-site have practical experienced knowledge within the project. The architect clarified the planning phase and brought another point of view of the process as an academic. Before the interviews, the respondents were assured the material is handled confidentially (Ejvegård, 2009). The interviews were prepared in advance with open questions and recorded to make sure answers were captured. The recording were replayed for analyze and compilation of the material, see appendix 2-4.

Table 1. Summary of interviews.

Observations were carried out as a case study during four weeks at a building site for a future one-story orphanage in Leticia. Observations were made in a participatory way, where the authors worked alongside three employees, commanded by the manager on-site. To support the compilation, thoughts from observations were written down afterwards, see appendix 5. Observations of the working procedure were made to identify faults deviating from the efficiency theories presented in theoretical framework. Proposals of improvements arose as a result from actions provoked through comparison between the reference frames and the actual project. Observations and interviews overlapped each other where interviews were performed during an early stage of the study. Literature studies were initially made before leaving for Colombia, but the majority was collected when writing the theoretical framework.

2.5 Validity

Interviews were used as complement to the observations to prevent authors’ own interpretation distorting the collected material which strengthen the reliability (Ejvegård, 2009). Both respondents are professionals with years of experience in the business. During the interviews an interpreter was involved, with no experience of the subject. This may affect the validity of the answers, since the interpreter may misstate, misinterpret or otherwise affect the answers with own interpretation. The answers were not reviewed by the respondent which may affect the validity; misstatements could otherwise have been corrected. Answers from respondents might not be fully reliable due to the present corruption. Observations are relevant as an empirical method for understanding the situation. By obtaining another perspective also enables

triangulation that could explain the level of reliability in the analysis. Using action research, the authors’ paradigm influences the empirical data, generating diversity and the results’ validity might be affected if replicating the study. Literature studies were used to critically analyze collected data.

3

Theoretical framework

In following chapters, theory supporting the thesis and its result can be found. To complement the answers, empirical data is declared in chapter 4 Empirical data.

3.1 Connection between question formulations and theory

1. How does the overall concept for industrialized building look like?

To obtain a general comprehension of the development of industrialized building as a concept, eight significant principles defined by Lessing (2006), Lean Production and the Toyota Production System have been studied.

2. Which weaknesses can be identified in the establishment of a house in a developing country?

To collect supporting material for this question, general literature about the concept was studied as well as significant concepts that aggravated industrialized building. To understand the reasons for identified weaknesses literature focusing on Colombia and its conditions were studied.

3. What knowledge from industrialized building could be used in the establishment of buildings with limited resources?

References from Sweden have been studied since it is in the frontier of using industrialized building system, IBS, based on history with improvements of the concept. To prevent recurrence in the implementation of IBS in developing countries today, both contemporary and historical knowledge have been studied. To obtain a profound comprehension of IBS, significant areas which developed the concept were studied such as Lean Construction, Supply Chain Management and the Toyota Production System.

3.2 Industrialized building

The purpose of industrialized building is to simplify and make the work at the building site more effective (Ballard & Howell, 1998). It is a combination of the traditional on-site construction with classic handcraft and artisanal assembly of prefabricated elements. Depending on the company’s ability to adjust their focus from unique projects to a continuous process increases their productivity (Lessing, 2006). Industrialized building affects more than just the product and the building on-site and should be differentiated from the traditional building process (Gerth, 2008). The traditional process has transformed to achieve rationalization where the whole chain has become more efficient by prefabrication of components and elements (Sebestyén, 1998). The repetitive effect is pursued at all stages such as efficient management, projection and control of the activities and resources within the project (Ekholm, Lessing & Robertsson, 2005).

Currently, industrialized building is highly topical in the Swedish building society, (Johnsson, 2012), with expectations that development leads to solutions for many of today’s problems within this area. Many companies have a strategic development area for industrialized building, with expectations to create new business opportunities and better methods for an efficient building.

Experiences from industrialized building system in developed countries such as Japan, Sweden, Germany and the U.K has great potential to development and if a developing country such as Malaysia wants to grow, imitating industrialization of building and construction should be pursued (Jaafar, Kadir, Peng, Salit & Thanoon, 2003).

3.2.1 History of the concept industrialized building

During the period 1960-1970, 1 million tenements were built by an initiative from the parliament to solve the 1940-50’s housing shortage (Statistiska centralbyrån, 2013). The Million programme required development of automated building systems that lead to developing industrialized building as a concept. The programme were focusing on industrial principles such as mass-production with large series, limited choice and variation, technological standardization and coordination of tasks and people (Lessing, 2006). Engström (2012) already targets matters for improvements, only 50 years from the start of the programme. When investigating the possibilities for restoring the programme, it appeared that waste originated from the industrial process. Engström also studied conditions using an industrial way of thinking while performing restorations. By mass-producing housings in a short time left the quality suffering. The outcome from the programme changed the way of building today, above all the focus on diversity and design (Industrialismen, 1970).

3.2.2 Significant areas of an industrialized building

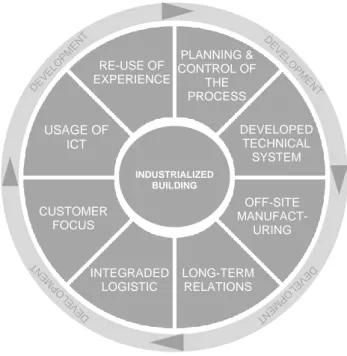

In the licentiate thesis written by the Swedish researcher Lessing (2006), eight characteristic areas present definitions industrialized building. The eight parts shown in figure 2 created the industrialized approach, where all parts co-operate to achieve an efficient process.

Figure 2. The eight characteristic areas of industrialized building (Boverket, 2008).

Planning and control of the processes

Planning and controls creates a structured project where unnecessary work and none-value adding activities eliminates. Maximized efficiency is reached by defined guidelines, permeated within the entire project from first idea to final building. From

DEVELOPED TECHNICAL SYSTEM OFF-SITE MANUFACT-URING LONG-TERM RELATIONS INTEGRADED LOGISTIC CUSTOMER FOCUS USAGE OF ICT RE-USE OF EXPERIENCE PLANNING & CONTROL OF THE PROCESS INDUSTRIALIZED BUILDING

projection, manufacturing, mounting to complementary work on-site, an accurate method of planning is required for creating a smooth process without errors and faults.

Developed technical systems

To rationalize the assembling, technical building systems with a high level of detailing has been developed within groups of products. The systems have standardized solutions for frameworks and technical solutions used in the projection and establishment. Standardized solutions are used largely but to adopt requirements from customers there has to be levels of flexibilities within the system. By using knowledge collected from former projects the systems can be justified and improved.

Off-site manufacture of building parts

Elements manufactured in a factory with optimal and controlled conditions results in a component with reduced errors. To minimize the work on-site components should be as complete as possible before leaving the factory. The components should also be produced in a way that simplifies the transport.

Long-term relations between participants

Long-term and close relationship between participants gives good qualifications for dedication and possibilities to create a unified collection of knowledge for future projects. Participants should be involved early to match competences and systems considering interfaces, avoiding further interruptions. With a long-term constellation, projects can start quicker since structure and organization already is established.

Logistics integrated in the construction process

The project puts high demands on the supply chain since it has to collaborate with logistic from the factory, as well as delivery of material to the site. When using industrialized building, deliveries should be planned pursuant to the JIT- concept (Just-In-Time). To make this possible it is important that all participants are updated and involved in the flow of information.

Customer focus

Customer focus is important; if requirements are not reached it proves an incorrect constructed system. By investigations of customer’s demands, systems could be formed creating guidelines for industrialized building. All customers do not require the same final result and to meet different needs, the market gets divided into sectors. It eases to secure that a building, with the right quality to the right cost, is built.

Use of information and communication technology

Decreasing the amount of errors requires a usage of modern ICT-systems (Information and Communication Technology) where information gets easy to handle and quality-secure. It is a smooth way to communicate the latest updates within the project to participants. By using 3D-projection, eventual errors could be discovered in an early phase. To the 3D-model is it also possible adding project-specific information like time schedules and economical calculations.

Systematic performance measurement and re-use of experience

Industrialized building is largely about using a traditional technique, where methods and solutions has been developed to be more efficient. To be aware of parts needing improvements, it is important to measure and document processes within the project.

Documentation could be used to gather experiences for future decisions whether to change methods or technical solutions in upcoming projects. Participants contributing with reflections create a comprehensive analysis.

3.2.3 Advantages and disadvantages with industrialized building

There are both advantages and disadvantages, see table 2. The Swedish Construction Federation, BI, represents interests in the Swedish construction industry and regulates the relationship between client and entrepreneur, for instance ABT06. It can lead to negative consequences in industrialized building because habit of the usage of regulations. In a traditional way of building, alteration and additional work

(Ändrings- och tillägsarbeten, ÄTA) is common and causes supplementary costs. The

process in industrialized building is included in a predefined way; therefor alteration and additional work are not necessary. One advantage with industrialized building is the absence of additional costs. Usage of alteration and additional work is substantial, clients establish routines and operating systems but it is problematic to declare the financial benefit of industrialized building. If the planning were performed as predefined, the alteration and additional work would not occur (Johnsson, 2012). Using prefabricated components and the repeating effect reduces the time on-site. This can reduce production and building costs, in terms of material and employees (Höök, 2005). Manufacturing in factory result in products with higher quality, the components can be optimized and the working environment is more suitable according to weather conditions and available equipment. Operators in the building sector indicate that industrialized building requires more planning than a traditional way of building. Late changes can be problematic and complications in the attachment of the prefabricated components occur. Some operator’s claim that professional qualifications are bereaved and montage work of prefabricated components may result in monotonous work (Johnsson, 2012). Enclosed industrialized systems, building methods and components within the company, requires a determine structure in an early stage and limit the varieties. Development of industrial systems involves a large amount of resources regarding time and financial capital.

Table 2. Advantages and disadvantages within industrialized building.

3.3 Concepts significant for aggradation of industrialized

building

The philosophies described below were chosen since their way of thinking inspired and formed today’s industrialized building.

3.3.1 Lean Construction

Lean Production is based on continuous improvement of processes and larger production with fewer resources. The concept Lean Construction were developed based on Lean Production, aiming to decrease waste and maximize value to customers by streamlined building; optimized resource utilization and improved quality. It implies continuous collaboration between entrepreneur and constructor leading to qualifications for continual improvement and exchange of experience. Lean principles are applied to make a complex environment, with unique products and teams, more efficient by planning and control methods (Lessing, 2006). By using Lean Construction (Toolanen, 2007):

Advantages Disadvantages

· Faster mounting at building site by using prefabricated components

· Problems in attachment of components due to faults in the projection

· Faster profits when building time shortens · Difficulties for a developed industrialized building when planning unique projects

· Higher quality of prefabricated components when producing in a factory

· Inflexible for changes in the production

· Cheaper products by optimizing and limiting the selection of products when manufacturing in a factory

· Too enclosed industrial systems limit the choices

· Reduced stock, waste- and stealing costs by good logistics at building site

· Requires more planning than traditional way of building

· Better working environment when manufacturing in a factory

· Bereaves professional qualifications when work at the building site is replaced by montage work

· Reduced production costs due to repeating effect, leads to increased efficiency, reduced material and salary costs by manufacturing, results in lower costs for the customer

· Requires large amount of resources regarding time and money developing industrial systems

· An industrial production in a factory leads to more efficient and simple logistic considering purchases and coordination of transports

· Requires determined structure for the project’s design

· Reduced production costs leads to a wider market by reaching further target groups

· Manipulability of prefabricated elements

· Better construction solutions · Difficult to make complex prefabricated constructions

· Opportunity to handle larger and heavier components in a factory by taking advantage of machines

· Harmful environmental aspects due to international transports

The building and its process for delivery are designed together to present and maintain customer purpose.

Work is organized for maximized value and reduced waste at project delivery stage.

Aiming for improvement of the performance of the total project since it is more preferentially than increasing the speed of any specific activity or reducing costs.

Performance of planning and control systems is improved. From “monitoring results”, the new definition of control is “make things happen”.

Two parts implicate Lean Construction of the lean approach, first of all the investigation of opportunities for adapting advantages from developed manufacturing techniques. The second part is development of lean techniques (Lessing, 2006). Two strategies appearing in Lean Construction that influences the concept is the product

strategy and the process strategy (Bertelsen, 2004).

The product strategy; progressively transfer construction work to manufacturing off-site. The building site will become a final-assembly site.

The process strategy; a dynamic complicated system focusing on improvement of flow and value creating, to develop methods based on the idea that large- scaled products are constructed on-site.

Manufactured housing is an initiative within industrialization described as the product strategy (Lessing, 2006). For standard buildings, product and process design can be standardized, in relation to manufactured housing. For non-standard buildings, standardization of planning and control is necessary.

3.3.2 The Toyota Production System

The Toyota Production System focuses upon reduction of waste and an achievement of stockless production (Ohno, 1988). The system constitutes parts which contribute to the entire system (Bröms & Johnson, 2000). Ohno (1988), states that the customer’s wishes exercise great influence for identifying value-adding factors and waste. The organization must have a philosophy that permeates the whole company. Responsible employees who strive to improve their abilities and create value for the society, customer and economy. Emphasize the importance of supply chains, employees and receive help to partners since their improvement benefits partnering companies. To guarantee a secure production where correct quality is obtained by different methods, optimized workflow, efficient processes for reducing waste is necessary. The concept has proved to be successful in the development for not only Toyota Motor Company.

The TPS constitutes the foundation for the entire system and the “TPS House” see

figure 3, illustrates how the philosophy is connected to the production and the system

for the company. All parts cooperate to achieve a common goal and customer value. JIT represents one of the columns and is a central method for maintaining a pull system. Inside the process flow, problems and waste elements is created which prevents the process value-adding factor. The opposite column Jidoka represents quality, including searching for errors on operating level to secure the production and thereby the quality, using methods and asking ‘why’ five times. Constant improvement requires competent employees who strive after achieving the same goal,

and solving waste problems; the center part. These parts rest on the foundation; the philosophy embraced by the company, the standardized processes and the management’s work. The roof represents the goal: Best quality – Lowest cost – Shortest lead-time – Best safety – High morale (Liker, 2004).

Figure 3. "TPS House" illustrates the connection between elements in TPS (Liker,

2004).

3.3.3 Supply Chain Management

A supply chain constitutes several stages of the product processing, processes with information, physical products, organizations and activities. Helping steering the chain and making it efficient is Supply Chain Management frequently used (Larsen & Schary, 2003). To achieve an efficient supply chain is it important to consider the whole chain (Hines, Jones & Rich, 1997), improvements in one link might result in deterioration in another (Larsen & Schary, 2003). Through an efficient supply chain costs could be reduced.

Close interaction by suppliers, distributors and customers helps designing an efficient, reliable chain without errors (DeWitt, Keebler, Mentzer, Min, Nix, Smith & Zacharia, 2001). Information technology enables sharing information which contributes to efficient response for customers, where proper information helps achieving JIT. Continuous improvements are important, and elimination of unnecessary work and activities enables concentration of time that generates in greater efficiency. By keeping products in their un-configured state increase their flexibility and utilizing technical platforms achieves a decrease of the complexity. Evaluation of the customer’s wishes contributes to a flexible chain, and also the prevention of sup-optimization in one link.

To achieve efficient processes within a company, thorough planning and sharing information is required, which logistics aims to fulfill through collaboration and synchronization between the company’s departments (Christopher, 2005).

3.4 Origin of case study: Colombia and its conditions in a

developing country

The Republic of Colombia had a population of approximately 47.7 million in the year of 2012 (Sida, 2014). Leticia has a population of approximately forty thousand people. No roads extends from the more populated north to the region around the Amazon, to get there is either by boat or airplane The Amazon region with its rainforest is characterized by high humidity. In the year of 2013 (The World Bank, 2015), Colombia had a gross national income (GNI) per capita of 7590 US$. The same year, reached the Internet use 51.7% (Globalis, 2015b). In 2009 Colombia faced a national housing shortage of 13% or 1 200 000 houses. Approximately 15% of Colombia’s houses are built on informal settlements without sanitation or basic service (UNEP, 2014).

Colombia newly incorporated a concept of sustainability for the national environmental policy with major challenges connected to the countries social and economic development. Through a national development plan, NDP, Colombia created a strategy which contributes to economic growth meanwhile opposing poverty. This plan is supposed to be accomplished in 2019 according to NDP 2010-2014; all aligned with the Millennium Development Goals (UNEP, 2014). The government utilizes five sectors ("government engines of growth"), housing is one of these sectors where goal is to produce affordable housing for the underprivileged. One action from the government was to provide one million new housings by the year of 2019, which 500 000 of these units would be classified as affordable social housing (Lugari, 2013).

The building sector represents one of the biggest economic incentives in Colombia and during the last years, the growth level has risen from 7,9% to 10%. In the year of 2013 the building sector grew 16,9% in relation to GDP (UNEP, 2014).

3.5 Summary of theories

In the developing country Colombia, there is a housing shortage of 13 % (1.2 million) that the government is trying to solve through a National Development Plan similar to the Million Programme (Miljonprogrammet) that was carried out in Sweden during the 1960’s. Sweden went through the industrialization that originated from Great Britain in the beginning of the 19th century this was the start for the industrialized production within manufacturing. Later on even the building sector adopted this concept. Theories such as Lean Production, Toyota Production System and Supply Chain Management developed and influenced the construction process to become more efficient. By using an industrialized building concept the quality of the project is carried out in a reliable way since the prefabricated elements are manufactured in a controlled process. Industrialized establishment creates automatized processes, which depraves qualified workforce. When utilizing an industrialized concept one area out of eight significant, defined by Lessing (2006), is Planning and control of the

processes. This area contributes to an eliminations of wasted time and resources

which is more economical profitable. Even though it is advantageous in long-term, the implementation is often an expensive procedure for the society and its companies. It

takes time to adopt and requires immense of planning where late changes are difficult to execute.

4

Empirical data

The empirical data has been collected in Leticia, through a case study using observations and interviews as methods. The established building will become an orphanage for La Aljaba, financed by Ancla. The original technique performed by Ancla is casted on-site and time saving. Concrete planks and pillars were used and erected as the Swedish shiftwork technique, see appendix 6 for descriptive photos. The first phase of the case study focused upon the establishment of a one-story house, see figure 4, where also observations were performed. Preparation drawings of the orphanage were created at the university in Sweden before leaving for Colombia.

Figure 4. Floor plan of the new orphanage.

4.1 Observations on-site

The concrete foundation was casted when arriving in Leticia on constructor’s directive with manager on-site as responsible at the building site. Measurements for the casted foundation were not equal to measurements of drawings made by neither the authors nor drawings handed in for the building permit. The concrete foundation was solid and casted with no preparation for piping. The foundation’s surface was irregular because of weather conditions and unwelcomed treading. Testing officer made topology studies six weeks after building start. Placement of foundation in the fringe of the lot, adapted to a natural source of water. During precipitation large bodies of water occurred, which led to uneven and muddy soil around the foundation. No motor-able road for deliveries, connected to the building site, was available. Material was carried by hand from the unloading place, approximately 100 meters. The path was complemented with stones and wooden planks but is planned to become a main road paved with asphalt. Material was stored in an unlocked, non-completed adjacent building.

Casting of planks and pillars were done to produce elements for the technique implemented by Ancla. For producing the elements; sand, cement and water, collected from adjacent water well, were mixed. A power-driven pump, daily brought to the building site, mortised water. When casting pillars, damaged aluminum frames were used and for the planks, formwork with shims of wood to delimit the concrete for each module length, see figure 5 and 6. The wooden shims were 230 millimeters without right-angled corners, which resulted in unstableness. The concrete contained 130 paddles of sand, 5 bags of cement and 15 buckets of water. Two persons were mixing the formula by hand, directly on the foundation, with shuffles for approximately 20 minutes. The texture differentiated for every batch.

Figure 5. Wooden splines separating planks from the frames (Private photo). Six persons participated when casting concrete; one person filled buckets with concrete, three persons carried these from the preparation area to the fifth person who filled the formwork. After filling the formwork, reinforcement were placed in the concrete and unwrinkled by the sixth person. Reinforcement bars were cut and bent in advance by hand, without precision with unsuitable tools. The elements were burning unprotected and unattended during night-time. Due to heavy rainfall, this procedure took two weeks. Completed elements were stored on the field next to the foundation. Subsequently, position for the pillars were measured and before rising, scoops in the foundation was made without carefulness. The pillars were fixed with wooden splines, after adjustments with a plumb and thereafter planks were threaded in. The floor plan was not available during the first three weeks of the establishment. Adjustments of the plan were made as the establishment was running by adapting to the generated design. The general work procedure was disrupted, one task was commenced and before finishing, another task was launched. Absent planning appeared when employees were left passive, while waiting for another task.

Figure 6. Casting concrete planks (Private photo)

When planks were threaded in, complication proceeded as slits on the pillars were too narrow, which caused every plank’s edge had to be chopped off using a spatula. The 200 pieces of concrete planks had been casted as 2000 millimeters instead of the intended 1900 millimeters. Every plank, including reinforcement bars, had to be cut off with a deficient angle grinder. Confusion appeared when assembling planks because of limited directives.

Manager on-site with trainee had been attending at the site during the observations. Beyond these occasions, different employees with different educations concurred which led to confusion in disposing work tasks.

4.2 Interviews

The empirical data collected during interviews helps support the analysis. 4.2.1 Interview with manager on-site

Collected material from interview with manager on-site informs that the most common way of learning the profession is to work alongside a manager on-site during six years. The manager acquired experience in the construction sector when starting as a trainee alongside another manager on-site within Ancla. Today working as a manager on-site for projects in the Amazon region with his own trainee. Traditional projects within the organization are schools for indigenous tribes. Manager on-site has been active since the beginning, 20 years ago, using the unmodified building technique for 70 built schools. The most common technique in the region is using bricks but he claims that this pertained method is cheaper and faster. Implementation of the technique to the general public would be possible since it is easily performed according to him. The method itself is cheap to use but the market price of prefabricated concrete planks decides if implementation of the concept is successful. Regarding the planning phase, the culture in Leticia indicates that concerned actors have meetings when problems occur not scheduled for regular check-ups. The only fixed meeting was the introduction meeting before start-up between constructor, manager on-site and financier. Relationship between constructor and manager on-site

is static, where the constructor plans the work although not actively present at the building site. Manager on-site is not privileged to make own decisions regarding adjustments for the working process. Estimated time for constructing a school is approximately 20 days. The constructor manages the labor but manager on-site can provide recommendations. Labor differs with each project nevertheless the manager prefers to have the same workers since they are familiar with the technique. The constructor places the order while the manager is responsible for weekly material calculations. Material such as sand, reinforcement and water is accessible in Leticia; cement is transported by boat from Manaus in Brazil. Material transportation to the building site is by van, without complications.

Manager on-site indicates that better tools are needed like a concrete mixer instead of mixing by hand which is utilized today. To improve the technique formwork for casting pillars and planks were brought from Bogota three years ago but got damaged along the transport. The formwork has not been replaced and are still used which, according to him, affects the workflow. Besides damaged formwork no other critique is expressed about the building technique.

4.2.2 Interview with architect

Any kind of construction demands license from the local authority according to the architect. The time and cost for the procedure applying for a building permit depends on the project’s complexity. First of all, clients certify ownership of the land by a license to gain approval for permit, thereafter complementing with drawings. Processing an application for building permit must meet requirements stated in the national regulation plan. Despite these requirements houses are built without permit in Leticia, the architect claims that one reason is the deficient financial wealth. To prevent buildings being erected without permit, controls should be made by the authorities but due to lack of employees it is usually overlooked. Controls are supposedly performed before moving in to check that the final building equals to the drawings. When building without a permit, the police can interrupt the establishment, a fee from the authorities can be inducted or, in worst case, the building is tore down.

“… it could get very expensive. The thing is, it’s a small city - everybody knows everybody, so you can probably make an agreement” Of the 120-150 houses built per

year in Leticia about two are tore down according to the architect.

Architects often draw by hand during the projection phase and thereafter use computer programs. Printed versions are brought to presentations and project meetings, because of the heavy computer files format. The lack of Internet complicates sending drawings to others involved.

The architect is aware of the concept industrialized building and believes it would minimize costs, but claims it is difficult to implement it in Leticia because of problematic location where the only transport is by boat.

4.3 Summary of collected empirical data

During observations faults were noticed like the order of performed phases, which led to inefficiency. For example, the foundation was casted solid before the set layout and given building permit. The actual foundation did not match the original layout and required modification even though the establishment already had begun. To gain knowledge of the permit procedure, an architect from the city council was

interviewed. The architect claimed that permit is necessary but the majority evades applying because of high costs. Since personnel at the office are limited, controls of erected buildings are often neglected. If knowledge about unauthorized erected buildings reaches the council, police department is utilized for handing out warnings or fees.

Utilized technique during the establishment could be compared to an industrialized building concept. Planks and pillars casted on-site were used in a system mounted as Swedish shiftwork technique. Due to weather conditions the time of casting got delayed. Ancla has used the technique for 20 years with only minor adjustments. Lately one adjustment was made; formwork for creating straight pillars were bought but got demolished during transport and never replaced. Resulting in additional work since the joint’s measurements no longer was compatible. To continue the work, individual adjustments of the planks needed to be made by hand. Communication between manager on-site and contractor was infrequently and meetings were held only when problems occurred. Lack of reviewing and planning were frequently noticed and unnecessary procedures were occurring. Material were purchased weekly accessible in Leticia. Transportation from the unloading place to the site was inconvenient, because of a substandard path.

5

Analysis and result

The first part of this chapter presents a major analysis and its structure. Followed by the thesis’s result where a deeper analysis takes place.

5.1 Analysis

It might seem irrelevant trying to implement knowledge from industrialized building built upon western conditions to a developing country. But it is topical since Colombian government is operating a programme, similar to the Swedish Million programme, trying to ease the housing shortage (UNEP, 2014). Studies done in Malaysia refers to education as one of the barriers when trying to implement an industrialized way of building (Lee et al., 2011). Assuming the barriers are equal in Colombia, it is adequate performing this study. To introduce knowledge from the concept for individuals in developing countries, this thesis could be used as a transition of knowledge. Breaking down knowledge from PhD level, to undergraduate level where it finally could reach underprivileged people. During observations numerous weaknesses were identified, mostly associated with ineffective methods and poor education. To be able to make professional analysis of the observations, the purpose of the first question (Q1) is to create a reference frame for further analysis. The reference frame is built upon exploration of important literature presented in the theoretical framework, see figure 7. The literature focused upon the philosophies of efficiency which represents the foundation in the concept. These are relevant to study to get a profound understanding of the concept. Like the concept of today has evolved through central projects such the Swedish million programme the authors gathering knowledge from the concept to evolve a more efficient way of building in developing countries.

Figure 7. Process to gain result for answering question 1.

The result of question two (Q2) is centered on observations where numerous weaknesses were identified when differing from the core of efficiency philosophies. To support the analysis complementary interviews were held, see figure 9. TPS highlights the importance of a permeating mutual mindset which keeps participants striving for a higher purpose of working, creating value for the society (Liker, 2004). Manager on-site ascertain that the reason of working is to get a salary, the actual result is not the primary motivation. This is an obvious point where the implementation of an industrialized mindset could change the attitude, adding value to projects and finally the society. During observations double work occurred; the planks needed to be individually truncated to fit the pillar tracks. Demolished formworks were used even awareness of the problem. This costly extra work, concerning time and material waste, could be reduced by introducing lean principles which strives to reduce waste and maximized value (Toolanen, 2007).

THEORETICAL

Analysis and result

Figure 9. Process to gain result for answering question 2.

Question three (Q3) unify the study and the previous results towards the aim. Discussed fragments which could be brought from the concept to prevent the identified weaknesses, were found by an analysis structured as picture 10.

During observations the work stagnated completely when awaiting material, by an adequate planning these could be enlightened. Preparing the daily work of upcoming activities creates a smoother process assigned by supply chain management (Larsen & Schary, 2003). The purpose of using industrialized building, as a device improving the way of building in developing countries, is not to implement the entire concept even though Lessing (2006) claims all significant areas area important to consider for an efficient and profitable project. According to the authors some areas are more important initially and easier to implement, such as feedback on finished project in order to improve upcoming ones. A proof where implementations of the concept could have increased the efficiency is where demolished formworks are utilized even awareness of upcoming double work.

Figure 10. Process to gain result for answering question 3.

The studied literature within this thesis originated from the western world with different conditions from the ones in developing countries, especially concerning available capital. The concept is designed to be applied on large-scale projects not individual. The authors kept this in mind when analyzing but claims there are fragments which could be used to improve efficiency and increase the financial profit and furthermore the speed of developing countries' development.

OBSERVATION S

INTERVIEWS

5.2 How does the overall concept for industrialized building

look like?

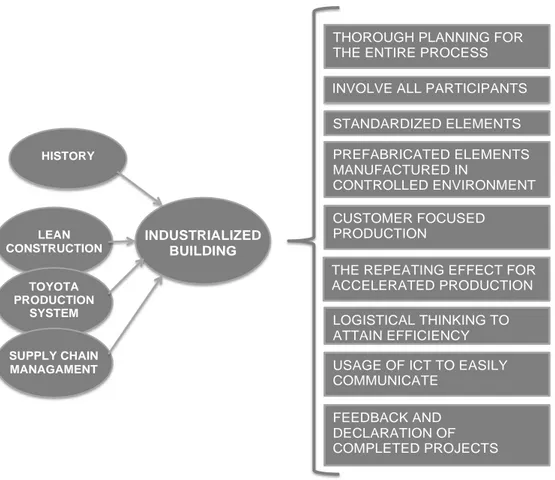

One persistent apprehension for industrialized building is a production method that creates value by more efficient processes, covering all phases from idea generation to completed product (Boverket, 2008). Reducing unnecessary consumption of time and resources, enables attaining efficient productions (Christopher, 2005). Achieving such a process, an industrialized concept is recognized by:

Substantial work is required for establishing complete planning covering all phases.

Preventing errors during the building process and involving participants in an early phase, creates a project-specific system where standards and joints are corresponding.

Standardized elements are used to streamline assembly work and reduce complement work on-site.

Prefabricated elements produced in an organized environment with suitable equipment, creates good opportunities for a quality-checked product.

The repeating effect accelerates the production like the assembly band tenet.

The customer generates profitability and their wishes navigate the production, although alternatives for variation are limited because of the repeating effect.

Logistical thinking that permeates the whole production chain, pursuant to JIT, ease to attain wanted efficiency.

Usage of ICT makes the project-specific information easily accessible for all actors involved and creates a channel where regulations and updates easily can be transmitted.

The outcome of completed projects is analyzed for gathering experience in order to develop upcoming project.

The conclusion is that planning is an important part encouraging efficiency by receiving an overview of the whole process (Christopher, 2005). By being prepared, unexpected occurrences could be fended which spare resource waste. An overview presenting the project’s processes and goal could be used as a tool for motivating employees. The customer’s focus is also a difficulty since the whole idea of the concept collapses if every production is customized. Developing a flexible platform-system where customization is operated in the final stage creates a compromised solution. According to Lean, striving after creating a platform that enables the repeating effect, increases efficiency and creates value for customer and company. Since industrialized building is about creating efficient processes by continuous improvements, are non-value adding activities reduced. By executing controls and evaluations, faults could be illuminated and avoided. Figure 8 illustrates the reasoning of studied literature that led to highlighted parts, which, according to the authors summarize the concept industrialized building.