Characterization of mechanical properties of Vasa oak and their application in a full-scale numerical model for support assessment

R. Afshar (1*), A. Ahlgren (2) and E.K. Gamstedt (1)

1. Division of Applied Mechanics, Department of Engineering Sciences, Uppsala University, Uppsala, Sweden;

2. Swedish National Maritime Museums, The Vasa Museum, Stockholm, Sweden *reza.afshar@angstrom.uu.se

Abstract

The 17th century Vasa shipwreck is a well-known object of cultural heritage. According to geodetic measurements inside and outside of the ship as well as on the support structure, the ship is sinking onto its cradle. The analysis of measurements showed the ship undergoes continued deformation with increasing strain. Previous research projects on the Vasa ship have largely been focused on the chemical degradation of the Vasa oak, which concerns the waterlogged polyethylene glycol (PEG) impregnated oak wood. The main goal was to provide understanding of the degradation mechanisms and possible remedies to mitigate the chemical decay. In this paper, a review is presented of previous research in term of characterization of mechanical properties, and effects of PEG and moisture on the mechanical behaviour of the Vasa oak. In addition, a full-scale finite-element model of the Vasa ship has been developed to assess its current and future structural behaviour, as well as a tool to design an improved support structure. The mechanical properties, defined in the model in terms of orthotropic elastic engineering constants, have been determined in previous work. Moreover, creep properties of the archaeological wood material have been and are being characterized, so that the model can be extended by extrapolation to predict future deformation. Geodetic measurements have been used for validation of the static model. The approach undertaken in this project could hopefully be useful in design strategies of improved support for other aging and deforming wood structures in cultural heritage.

Keywords: cultural heritage, wood, Vasa oak, numerical model, geodetic measurements.

1. Introduction

The Vasa ship is relatively speaking a monumental structure. It is equivalent of a seven-story building with weight of approximately 900 tonnes. The length of the hull is 69 m (including bowsprit), its height at the stern is 19.4 m and its width is 11m [1]. Currently, it suffers from increasing deformation over time, caused mainly by creep in the wood members, time-dependent deformation of joints and damage accumulation due to chemical degradation and softening effect from polyethylene glycol (PEG) impregnation [2]. Therefore, an objective set by the Vasa museum is to use the mechanical and chemical data of the Vasa oak and create a full-scale three-dimensional (3D) finite element (FE) model of the entire ship as an analytical tool to be used in the design an improved support structure.

dried material and material softening. This is because PEG acts as a plasticiser [3]. The effects of PEG impregnation are crucial for the preservation of sensitive objects of cultural heritage. Some examples are the Vasa in Stockholm, the Bremer Cog in Bremerhaven and the Mary Rose in Portsmouth [4–6], which underwent centuries buried under water and rests on supporting structures after salvage.

The creep properties of the PEG-impregnated archaeological wood material have not been much investigated despite their importance to long-term dimensional stability. Hoffmann [7] performed creep and relaxation bending experiments on wooden planks from PEG-impregnated oak wood from the Bremer Cog ship and compared with sound seasoned oak wood. The effects of moisture content, temperature and PEG on creep behaviour of Vasa oak are investigated in [8]. It is shown that the variable ambient conditions have a higher impact on mass, and therefore on moisture content, of wood with high PEG content. For the Vasa oak loaded in the T and R directions, the creep behaviour is dominated by the effect of annual fluctuations in moisture and temperature. The creep phenomena in the L direction of Vasa oak samples have scattered response for the stresses between 15% and 30% of its compression yield strength.

3. Development of finite element model of the ship

A wireframe model, consisting of only lines, points and curves to describe the geometry of the ship, has been provided by the Vasa museum. It has been developed based on geodetic measurements using a total station. From this wireframe model, a 3D model comprising solid bodies for solid-like parts (i.e. hull and keel), surfaces for the shell-like components (deck planks) and lines for beam-like constituents (deck beams) has been developed in PTC Creo Parametric 3.0 M060.

The geometric model, developed in Creo parametric, was imported in finite-element software Ansys, for further development of the stiffeners (knees, riders, columns, masts, etc.), adjustment of the correct location of deck beams and finally structural analyses of the entire ship.

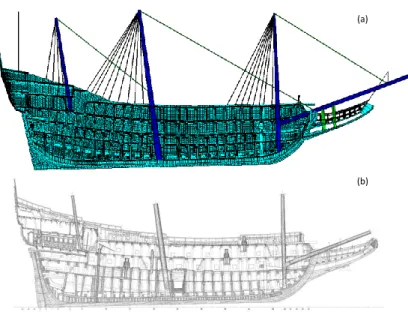

The purpose of the FE model of the entire ship is to capture the response of the ship to the current and potential future support solutions. The model allows to estimate the loading conditions at the global level (i.e. in the sections of the entire ship such hull, decks, keel, columns, etc), as well as interactions of different sections of the ship, and the reaction forces in contact areas of the supports. The three main reasons why a detailed geometrical model of the ship was needed for the FE model are: First, the main load on the ship is the self-weight of the components, which depend on the volume and density of ship components. Second, the ship is markedly asymmetric comparing the port and starboard side, which means that load distribution of the components must be addressed accurately. This is particularly important in the aft region, where the maximum movement of the ship has been observed. Third, the thickness of hull varies in all the cross sections along the length of the ship. Therefore, any useful information about the ship, including wireframe model, on board measurements, drawings, books, etc. was used to develop the model as accurate as possible. A longitudinal cross section of the ship, comparing the FE model with the drawings provided by Vasa museum is shown in Figure 1.

Figure 1. A longitudinal cross section of the ship, comparing (a) the FE model with (b) the drawings provided by Vasa museum (b).

3.1 Material properties

The elastic properties of the wood material are a necessary input in the FE model. The stiffness characterisation of timber is challenging due to inherent anisotropy, time dependent response and variation between and within samples [9]. In addition, the Vasa oak has a unique nature due to factors such as aging, chemical degradation, and PEG (polyethylene glycol) content. The waterlogged Vasa oak has been impregnated with PEG to prevent cracking and deformation during drying. Both the aging [10] and the PEG impregnation [11,12] have affected the mechanical properties [9]. Since the material is scarce and valuable, only small specimens could be spared for destructive mechanical testing.

Timber can be regarded as a cylindrical orthotropic material on the macroscale due to the circumferential orientation of the annual rings. The orthotropic material properties of the Vasa oak were taken from Vorobyev et al. [13] as it is given in Table 1. Mechanical testing on members in the ship was not an option, due to the risk of damaging the structure. The material samples were extracted from drill holes for ventilation shafts at the bottom of ship, since mechanical characterization of samples is destructive. There is a significant natural variation in wood stiffness, mainly dependent on density and fibre orientation [14] but also the local variation in PEG content, which effectively acts as a softening plasticizer [15]. Implicitly, the local moisture content and temperature influence the elastic properties, but since the museum has a well-controlled stable climate, these effects are not accounted for here. Nor is the local variation of the wood stiffness accounted for. The elastic properties chosen for the FE simulations are considered to be representative average values for the entire assembly of Vasa wood.

(a)

Table 1. Orthotropic material properties of Vasa oak [13].

EL [GPa] ET [GPa] ER [GPa] GLT [GPa] GTR [GPa] GLR [GPa]

6.75 0.35 0.60 0.33 0.14 0.62

υLT υTR υLR

0.69 0.30 0.37

3.2 Geodetic measurements used for validation of the model

A total station has been used as monitoring set-up for the Vasa ship. The monitoring set-up consists of a Leica TDA5005 total station and a large set of reflective targets. There are in total 66 measurement locations, 301 reflective targets (tapes) on the hull, 69 prisms on board the ship, 6 prisms on support structure and 23 reference prisms on the walls of the building [16].

The data acquisition is a time-consuming process and is done only twice a year. The measurements started in the year 2000 and should be interpreted as the relative motion since then. This data, as well as earlier data, shows progressive downward displacements of the entire ship. This may indicate a significant amount of increasing deformation under a relatively constant load, i.e. creep [2].

Since the geodetic measurements show time dependent displacements of the ship, for comparison, the corresponding time dependent analysis (creep) is required. At the moment, the creep material tests are ongoing and as such the geodetic measurements are used for qualitative comparison with centre of mass (CM) distribution along the ship, as shown in Figure 2.

Figure 2. (a) Top view showing 8 different zones used for CM calculation, and (b) a corresponding displacement of CM from 2000 to 2012. (c) Ship hull positions from geodetic measurements starting in 2000 (dashed mesh) and ending in 2012 (solid line), where the relative displacements magnified × 200.

As it can be seen from Figure 2 (c) (solid lines) geodetic measurements (from 2000-2012) show more relative displacements of the ship towards port side, especially at the aft side. The CM distribution from FE model, Figure 2 (b), confirms this trend quite well by more inclination of CM towards the port side (more asymmetric) at the aft side. The similar agreement in term of asymmetry of the ship and CM inclination towards port side is observed at the very front of the ship i.e. bow side. The asymmetry of the ship (especially at the aft side and Gallion) is also evident according to the CAD drawings of the ship.

4. Conclusions

The following conclusions can be highlighted:

The effects of PEG, moisture content and temperature are crucial on the mechanical behaviour of the archeological wooden material like Vasa oak.

In order to assess current and future structural behaviour of large wooden cultural heritage x port (b) (c) x y (a) starboard bow aft

Acknowledgements

Financial support from the Vasa Museum, Sweden is gratefully acknowledged.

References

[1] Hocker E. Maintaining a stable environment: Vasa’s New climate-control system. APT BULLETIN: Journal of Preservation Technology 2010;41.

[2] van Dijk NP, Gamstedt EK, Bjurhager I. Monitoring archaeological wooden structures: Non-contact measurement systems and interpretation as average strain fields. Journal of Cultural Heritage 2016;17:102–13. doi:10.1016/j.culher.2015.03.011.

[3] Hoffman P. Conservation of Archaeological Ships and Boats. London: Archetype Publications Ltd; 2013.

[4] Hoffmann P. On the Stabilization of Waterlogged Oakwood with Polyethylene Glycol (PEG) III. Testing the Oligomers. Holzforschung - International Journal of the Biology, Chemistry, Physics and Technology of Wood 2009;42:289–294. doi:10.1515/hfsg.1988.42.5.289.

[5] Jones A, Rule M, Jones E. Conservation of the timbers of the tudor ship Mary rose. In: Biodeterioration 6. Washington, DC: CAB International; 1986.

[6] Cederlund CO, Hocker FM. Vasa I: The Archaeology of a Swedish Warship of 1628. International Journal of Nautical Archaeology 2007;36:426–9. doi:10.1111/j.1095-9270.2007.163_1.x.

[7] Hoffmann P. On the long-term visco-elastic behaviour of polyethylene glycol (PEG)

impregnated archaeological oak wood. Holzforschung 2010;64:725–728.

doi:10.1515/hf.2010.082.

[8] Vorobyev A, van Dijk NP, Kristofer Gamstedt E. Orthotropic creep in polyethylene glycol impregnated archaeological oak from the Vasa ship. Mech Time-Depend Mater 2018. doi:10.1007/s11043-018-9382-3.

[9] Vorobyev A, Arnould O, Laux D, Longo R, van DNP, Gamstedt EK. Characterisation of cubic oak specimens from the Vasa ship and recent wood by means of quasi-static loading and resonance ultrasound spectroscopy (RUS). Holzforschung 2015;70:457–465. doi:10.1515/hf-2015-0073.

[10] Bjurhager I, Halonen H, Lindfors E-L, Iversen T, Almkvist G, Gamstedt EK, et al. State of degradation in archeological oak from the 17th century Vasa ship: substantial strength loss correlates with reduction in (holo)cellulose molecular weight. Biomacromolecules 2012;13:2521–7. doi:10.1021/bm3007456.

[11] Bjurhager I, Ljungdahl J, Wallström L, Gamstedt EK, Berglund LA. Towards improved understanding of PEG-impregnated waterlogged archaeological wood: A model study on recent oak. Holzforschung 2010;64. doi:10.1515/hf.2010.024.

[12] Ljungdahl J, Berglund LA. Transverse mechanical behaviour and moisture absorption of waterlogged archaeological wood from the Vasa ship. Holzforschung 2007;61:279–284. doi:10.1515/HF.2007.048.

[13] Vorobyev A. Static and time-dependent mechanical behaviour of preserved archaeological wood : Case studies of the seventeenth century warship Vasa. DIVA 2017.

[14] Bodig J, Jayne BA. Mechanics of Wood and Wood Composites. Krieger Publishing Company; 1993.

[15] Vorobyev A, Almkvist G, van DNP, Gamstedt EK. Relations of density, polyethylene glycol treatment and moisture content with stiffness properties of Vasa oak samples. Holzforschung 2017;71:327–335. doi:10.1515/hf-2016-0202.

![Table 1. Orthotropic material properties of Vasa oak [13].](https://thumb-eu.123doks.com/thumbv2/5dokorg/4630213.119704/4.892.169.719.118.321/table-orthotropic-material-properties-vasa-oak.webp)