PAPER WITHIN Production Development & Management AUTHOR: Anders Broman & Clark-Kent Helmersson JÖNKÖPING June 2021

A conceptual model

for VSM in a

produc-tion system with

paral-lel material flow

- a case study of a SME in the wood

industry

This exam work has been carried out at the School of Engineering in Jönköping in the subject area of Production system with a specialisation in production development and management. The work is a part of the Master of Science program. The authors take full responsibility for the opinions, conclusions, and findings presented.

Examiner: Gary Linnéusson

Supervisor: Malin Löfving & Julia Trolle

Scope: 30 credits (second cycle)

Abstract

i

Abstract

There is a rapid change in the current market that requires more customisation and higher quality for a lower price. For SMEs, it is a challenge to compete and develop the production system in this increasingly competitive environment. One way to increase the competitive advantages is to investigate the possibilities to involve Lean tools such as VSM. The purpose of the VSM design is to get a quick holistic view of the production system to find value-added and non-value-added activities and improve the production system. A VSM is, however, not widely explored in a production system with high flexibility and a high number of variants in a functional layout. It has been discovered that there is a research gap in the literature, and some researchers proclaim that there is none or a negative correlation between VSM and flexible production. Therefore, there is a need to further explore these concepts together at a case company with these pa-rameters.

The methodological approach is a single case study at a case company. The research focuses on investigating how the VSM can be applicable in a production system with high flexibility on a functional layout facility. The study will focus on hard aspects such as the VSM itself and soft aspects such as Lean concepts, Change Management, and employee’s behaviour and reactions. The reason is that enterprises need to investigate parameters and employee behaviour since a production system with high flexibility on a functional layout often perceives as a complex system. Therefore a conceptual model has been developed to facilitate the adoption of this kind of production system. The created conceptual model is based on the findings from the case company and theories from the literature studies. The methods that supported the data collection in the case are interviews with the production personnel and personnel from the management de-partment, observations, VSM and a literature review.

Keywords

VSM, Change Management, Soft and Hard aspects, functional layout, flexibility, SME, wood industry

Contents ii

Contents

1

Introduction ... 1

BACKGROUND ... 1 PROBLEM DESCRIPTION ... 2PURPOSE AND RESEARCH QUESTIONS ... 3

DELIMITATIONS ... 4 OUTLINE ... 4

2

Theoretical background ... 5

PRODUCTION DEVELOPMENT ... 5 2.1.1 Performance objectives ... 5 2.1.2 Production layout ... 6 2.1.3 Lean production ... 7SMES DEFINITION AND CHARACTERISTICS ... 10

2.2.1 SMEs in the wood industry ... 11

2.2.2 SME in a Lean production view ... 12

CHANGE MANAGEMENT ... 13

2.3.1 Change Management in SMEs ... 13

3

Method and implementation ... 15

RESEARCH DESIGN ... 15

PRIMARY AND SECONDARY DATA COLLECTION ... 16

3.2.1 Interviews ... 16

3.2.2 Observation ... 18

3.2.3 Gemba ... 19

3.2.4 Literature review ... 20

FLOW MAPPING OF THE CURRENT PRODUCTION SYSTEM ... 22

3.3.2 Time-related key indicators ... 23

SKETCHING OF LAYOUT ... 24

Contents

iii

ETHICS AND MORALE ... 25

4

Findings ... 26

CASE COMPANY ... 26

INTERVIEWS ... 27

4.2.1 Unstructured interviews ... 27

4.2.2 Semi-structured interviews ... 28

SKETCHING OF LAYOUT AND MATERIAL FLOW ... 29

VALUE STREAM ANALYSIS ... 30

4.4.1 Flowchart ... 30

4.4.2 VSM findings ... 33

FINDINGS OF SOFT AND HARD ISSUES AT THE CASE COMPANY ... 37

5

Analysis ... 38

INVESTIGATION OF THE VSM CHARACTERISTICS IN A PARALLEL MATERIAL FLOW 38 DESIGN OF A CONCEPTUAL MODEL BASED ON MODIFIED VSM ... 42

CONCEPTUAL MODEL RELATIONS TO LONG-TERM EFFECTS ... 47

6

Discussion and Conclusions ... 50

DISCUSSION OF METHOD ... 50

DISCUSSION OF FINDINGS ... 51

6.2.1 Hard and Soft aspects for VSM in a production system with a functional layout 51 6.2.2 The conceptual model for SMEs in the wood industry ... 53

6.2.3 Suggestions for improvements at the case company ... 55

CONCLUSIONS ... 56

IMPLICATIONS AND FUTURE RESEARCH ... 56

7

References ... 58

8

Appendices ... 64

Contents

iv

APPENDIX 2INTERVIEW QUESTIONS TO SALESMAN AND CONSTRUCTOR ... 65 APPENDIX 3INTERVIEW QUESTIONS TO THE TECHNICAL MANAGER ... 66 APPENDIX 4FUTURE STATE VSM AT THE CASE COMPANY ... 67 APPENDIX 5SUGGESTIONS FOR IMPROVEMENTS IN THE LAYOUT AT THE CASE COMPANY ... 68

Introduction

1

1

Introduction

The introduction chapter introduces the topics of SMEs in wood industries and the con-cepts of VSM and Change Management. The chapter begins with a background and follow by the Problem Description of the study, Purpose and Research Questions and then finalised with delimitations and the outline of the study.

Background

The business environment has changed in the last decades for manufacturing compa-nies. With shifting customer expectations, visions for globalisation, and social struc-tures, companies may have difficulty keeping up with new demands or expanding their business (ElMaraghy, 2005). As customers are changing or expanding their demands, markets are fluctuating more rapidly. More customised products, short life cycles, and shorter time-to-market are expected from customers to satisfy their needs (Andersen, Brunoe, Nielsen & Rösiö 2017). The majority of all the manufacturing companies are small or medium-sized and play a crucial role in the country's economic growth. There-fore, small and medium-sized enterprises (SMEs) require special attention for develop-ment on both production and organisational levels (Cull, Davis, Lamoreaux & Rosen-thal 2006). According to Gunasekaran, Rai and Griffin (2011), SMEs have a more vig-orous competition when competing with other SMEs, thus has led to SMEs being more innovative and flexible. Despite the prevalence of SMEs, SMEs are more exposed to external influences than larger companies. It often results in SMEs being subcontractors for larger companies due to a lack of market power and competition on a domestic market (Gunasekaran et al., 2011; Man et al., 2002). Hence, it can put SMEs in a chal-lenging position to remain competitive or to survive in the highly competitive business environment. Therefore, SMEs must utilise and take advantage of their capabilities to satisfy shifting market requirements in a long-term perspective (Hudson Smith & Smith, 2007).

The lean approach gives SMEs a competitive advantage locally and globally by imple-menting continuous improvements strategies in both short-term and long-term perspec-tive (Green, Lee & Kozman 2010). Implementing different continuous improvements strategies, such as Value stream mapping (VSM), process flow mapping, can support and facilitate SMEs' vision of better quality of a product and improved performance on production systems (Sraun & Singh, 2017). With continuous improvement strategies, the SMEs can update or reform their production system to improve their competitive factors, such as flexibility, cost, quality, speed, and dependability, to tackle the shifting market (Moeuf, Pellerin, Lamouri, Tamayo-Giraldo & Barbaray 2018). With the suc-cessful implementation of improvements, it is essential to sustain these without risking implications and returning to previous settings.

Change management support companies to maintain changes, thus increase the proba-bility of success. The concept of Change Management is how the managers can develop and involve the employees and creating a shared purpose within the organisation to increase the probability of success to changes (Baharudin, Abdullah, Mohd Salleh &

Introduction

2

Shariffudin 2020). As has been noticed in earlier research, a technology gap and un-derutilisation of capacity are very common in SMEs (Khanduja, Wani & Singh 2009). Therefore, for SMEs, improving capacity can be a key decision when creating stronger competition. According to Olhager & Johansson (2012), there are two definitions for capacity in manufacturing. The first definition of capacity measures the maximum available output in a production system in a specific period or machine hours if the output is not homogeneous. The second definition of capacity defines it as connecting to time and work, which then compare to the total capacity in the production system and can express in either volume or numbers.

SMEs can improve their production system to increase competitive power and be resil-ient to sudden changes in the market. Developing a production system for reusing ena-bles the production system to introduce new products, change volumes, or variants, thus increasing capacity (Bellgran & Säfsten, 2010; Rösiö & Bruch, 2018). The production system is a “transformation system”, which transforms resources and creates goods or services with a combination of labour, capital, and material (Bellgran & Säfsten, 2010). Companies in the wood industries have historically been slow in developing and im-proving the existing production system. The impact is that the industries have been underperforming compared to the average level in other sectors such as metal or plastic industries (Johansson et al., 2016; Malerba & Orsenigo, 1997). It is more common for SMEs in wood industries to produce products with high variations and low volumes due to unique customer order, thus requires higher flexibility and changeability in the production system (Sandberg, Vasiri, Trischler & Öhman 2014). Improving machine technology, adding more variance of material type, increasing customisation, and the design of the product can be competitive factors for SMEs (Sandberg et al., 2014). Therefore, if SMEs in the wood industries can utilise a sound design lean approach method combining with how to sustain improvements changes, the capacity can be in-creased and thus be more competitive on the market and resilient towards external threats (Dextre-del-Castillo, Urruchi-Ortega, Peñafiel-Carrera, Raymundo-Ibañez & Dominguez 2020).

Problem description

Conducting a VSM may not be enough or have trouble gathering necessary data from a production system with high variations and high flexibility (Belekoukias et al., 2014; Lugert et al., 2018). It can become even more complex to conduct a VSM when manu-facturing multiple components from several different material flows, then unifies into a single flow, and assembles into a final product. The reason is that VSM is for a single line production with low variation (Rother, Shook & Helling 2001). This setting will be named “Parallel material flow” and be the concept this case will use when testing the VSM and referring to the production system. The lean approach fails the majority of the time due to culture and resistance to changes (Bhasin, 2012).

The limitation for a VSM is mainly based on the method for collecting information on physical aspects such as the material, product or management information system con-nected to the production system. According to Lenka, Damodar and Pratap (2010),

Introduction

3

these physical aspects are called hard aspects and will be used in the report to facilitate the reader. The VSM is a critical factor for SMEs but requires substantial commitment and budget to succeed and be profitable in the long term (Lucherini & Rapaccini, 2017). Without adequate resources and commitment from both employees and managers, it can be difficult to achieve and sustain improvement changes, which is common in SMEs (Dextre-del-Castillo et al., 2020). Change management increases the probability of success in implementing and maintaining these changes but often fails due to a lack of instructions and commitment from both manager and employees (Baharudin et al., 2020). Soft aspects and change management can affect the performance and outcome of the production system and thus the communication and synchronisation between each flow. Soft aspects could be leadership and communication between the employees, work climate, commitment, and satisfaction (Bailly & Léné, 2013; Lenka et al., 2010). There is no clear distinction between successful implementation of changes and sus-tainability. The reason is because there are no model or guideline to include these ele-ments in the improvement program (Poksinska & Swartling, 2018).

Thus, a VSM may not be enough alone, and a new conceptual model for VSM inte-grated with change management, hard-, and soft aspects may be necessary, so other SMEs with wood industry settings can apply it to their production. With a proper guide-line and conceptual model, SMEs will increase the probability of success in implement-ing and sustainimplement-ing improvements, thus increasimplement-ing profitability and creatimplement-ing a long-term effect (Tangen, 2005).

Purpose and research questions

The purpose is to gain insight on how VSM can be used in a production system with parallel material flow and create a new perspective on challenges to lean approaches, hard-, and soft aspects in SME wood industry settings. The aim is to contribute unique insight and perspectives to increase capacity at case Company A to aid them in future improvements. Therefore, three research questions will support achieving the purpose of the case.

To understand the requirements for bridging the knowledge gap, investigating and test-ing the VSM on the current production system will be necessary. The authors will pre-sent advantages and disadvantages to facilitate for the reader how the VSM behave in a production with parallel material flow combined with high variations and high flexi-bility. Therefore, the first research question is as following:

[1] What are the advantages and disadvantages when using VSM as a tool for analysing the current state in a production system with a parallel material flow?

There is a research gap and no clear guidelines on including employees’ behaviour and reactions to changes when conducting a VSM on a production system. Therefore, there is a need to investigate how hard and soft aspects can combine with change manage-ment in this environmanage-ment.

[2] How can a conceptual model be created and visualised by combining VSM with hard-, soft aspects and change management practices in a production system?

Introduction

4

By combining VSM with soft-, hard aspects and change management, a visualisation can facilitate the understanding of how the conceptual model will affect the organisa-tion in a long-term perspective, which leads to the third quesorganisa-tion.

[3] How can the conceptual model be further visualised to provide a long-term effect on an organisational level in a production system?

Delimitations

The study is limited to one case at a single company. Several flows are explored using the practical Lean method VSM combined with soft aspects such as leadership and Change Management. The study will not cover the painting, packing, and outbound department due to the project's timeframe and that the study with VSM in focus does not require these departments. However, the findings are focused on five flows and a single information flow to get as much informative and realistic data as possible to apply the upcoming data to other similar conditions. Change management, hard and soft aspects will be combined in the analysis chapter to simplify a solution for identical production systems, e.g. a guideline for future implementation of VSM. The majority of the chosen methods will be performed on each material flow and continuing until reaching the painting department. External factors and economic factors will not in-clude in this study.

Outline

In the first chapter, the introduction, the reader will view the background, problem de-scription, purpose, research question, and delimitation sub-chapter. Here the reader can understand what the thesis is about and what fundamental perspectives the authors have about the specific topic.

The second chapter introduces theoretical foundations for the case to give the reader a perspective on how a flexible production in an SME can be combined with the VSM approach and other concepts and achieve improvements through change management. The methodologies describe the data-collecting in chapter three. The methods are to explore the academic topics and describe how to conduct the methods and analyse the data. Ethical and moral and the validity and reliability of the project reside in the meth-odology.

The fourth chapter, findings, where the results from the execution of methods are col-lected and structured. Chapter five: analysis, analyses the findings and theories com-bined to guide the authors into answering the research questions and the purpose. A discussion and conclusions will be at the end of the report to discuss the authors' results. The methods, findings and conclusions can be drawn and finalised with future research. The report will end with a reference list and appendices.

Theoretical background

5

2

Theoretical background

The chapter theoretical background provides an overview on several aspects such as the layout of the production, SMEs, VSM, Lean perspective and Change Management. The theoretical background provides both definitions of the concept and how the con-nection towards each other works.

Production Development

The chapter begins by describing the production development concept and its charac-teristics. The theoretical concept performance objectives will cover the different com-petitive factors connected to production development. Production layout will describe other layout models and their connection to performance objectives. Lean production will cover main areas and support the improvement of a production system to increase competitive factors.

Production development is a concept based on creating an effective and efficient pro-duction system from a long-term perspective. Processes transform a combination of capital, work, and material into a custom-based product or services. Production devel-opment enables the develdevel-opment of the production systems capability when introducing new products in the future (Bellgran & Säfsten, 2010). Using the production develop-ment concept enables production systems to be improved or create new production sys-tems for competing and succeeding globally. Improving a production system gives an advantage in the competition since the production system can be developed for reusing when introducing new products, changing volumes, or variants (Rösiö & Bruch, 2018). Production development put forward the question of to whether improve or develop a current or a new production system. The reason for triggering a production development decision can vary, these are introducing a new product or a product family. This can either increase the capacity or improve the working environment. The existing produc-tion system can give alternatives, ideas and suggesproduc-tions on improvements when devel-oping a new production system (Bellgran & Säfsten, 2010).

According to Okoshi, Pinheiro de Lima and Gouvea Da Costa (2019), competitive fac-tors correlate with manufacturing decisions that influence the development of the pro-duction system. The ideal goal for developing a propro-duction system is to create a system that can be reused several times and only need to adjust by using the least effort to meet new demands or new products. Skinner (1969) supports that developing the production is essential, and the manufacturing must function to reach the overall company objec-tives. Skinner (1969) further argues that manufacturing decisions influence business strategies and connect them to competitive factors. The competitive factors are wider explained in 2.1.1 as performance objectives.

2.1.1 Performance objectives

Investigating performance objectives for improvements in a production system is a strategy to compete and gain an advantage over competitors in the global market. Ac-cording to Tangen (2005), there are five key indicators that define performance

Theoretical background

6

objectives; flexibility, speed, dependability, quality, and cost. These indicators depend on the facility's type of production system and the type of customer. The competitive factors are how the customer sees the performance objectives, e.g., low price is the desire from the customer from the cost. The list below presents the definition of the different performance objectives (Tangen, 2005).

• Flexibility – The availability of the production system to change quickly for new demands and without disturbances to switch between different tasks while not wasting time or capacity.

• Speed – how fast WIP products travel in the production system between the different processes and the responsiveness of the administrative department. • Dependability – deliver the product in time and what the customer had ordered. • Quality – not wasting time on overproduction or delivering flawed products that

may be remanufactured or discarded.

• Cost – operations with low cost allows for selling products for a competitive price and a higher profit.

Capacity falls under flexibility which connects it directly to performance objectives, but capacity can also influence speed, dependability, quality, and cost (Okoshi et al., 2019). Tangen (2005) states that flexibility describes three parameters; frequently new products in the production system, wide product range, and delivery depending on the customer demands. Lucherini & Rapaccini (2017) define Manufacturing Flexibility as the production system´s capacity to handle the variability within the production and operating conditions. Researchers or organisations can further investigate the concept of manufacturing flexibility combined with a lean approach to developing a framework for a production system with high variability and flexibility (Lucherini & Rapaccini, 2017).

2.1.2 Production layout

According to Bellgran & Säfsten (2010), planning the layout is an essential part of the development of a production system in production development. Knowing the layout types and suitable performance objectives for each layout saves both time and financial resources when planning the layout. Ballestín, Pérez and Quintanilla (2020) state that restructuring a production system could be an essential part of development when in-creasing the capacity since the whole process chain are affected by what occurs in the system. According to De Carlo, Arleo, Borgia and Tucci (2013), an improved layout can increase flexibility, work environment, support in reducing the lead times, and less WIP in the production system. There are four major layout models in the literature, which has different purposes for different products, e.g., volume or variants. The layout models are (Bellgran & Säfsten, 2010):

• Fixed layout: all value-adding activities are performed at only one specific area or station.

• Functional layout: process-oriented layout is when the same type of equipment is co-located (can also be mentioned as process layout).

Theoretical background

7

• Cellular layouts: A layout in which different equipment and processes reside in the same area.

• Line-based flow: the equipment is product-oriented with a sequential order line. Improving the layout enables the company to achieve a competitive advantage to reach and sustain customers in a long-term perspective. According to Peron, Fragapane, Sgarbossa and Kay (2020), performance objectives decides the arrangement of different resources in the facility. The different layout models in Table 1 focus on their perfor-mance objectives and properties (Bellgran & Säfsten, 2010). In Figure 1, the different layout properties present their relations to volume and variety and pick accordingly to the target production system (De Carlo et al., 2013).

Table 1. Different types of layout (Bellgran & Säfsten, 2010).

Figure 1. Layout models and their variety and quantity (De Carlo et al., 2013). 2.1.3 Lean production

Lean production was first developed in Japan within the Toyota group and aimed to reduce or remove the waste within the production compared to Ford’s philoso-phy where mass production is in focus (Seth & Gupta, 2005). Lean production de-scribes as a part of the production system. Lean production is a production tool that can increase productivity and improve an organisation's different tasks and

• Fixed layout • considers low volume, high flexibility, high WIP, high speed, high quality • Functional layout • considers low volume, high flexibility, high WIP, high speed, high quality

• Cellular layout

• is between the Functional and Line layout de-pending on the equipment and product availabil-ity

Theoretical background

8

processes. Green et al. (2010) state that it is a competitive advantage in the market both locally and globally when using the Lean approach. Its purpose is to reduce waste in production and be an assistance tool in both a short term and long-term perspective. The lean approach is increasing the organisation’s capacity and performance objectives, such as flexibility. However, it also improves synchronisation, safety and ergonom-ics, and increases the quality level and is more cost-efficient in the market (Chen, Li & Shady 2010).

Organisations can achieve competitive advantage through cross-sectional training for the employees within an organisation (Chen et al., 2010; Liker et al., 2009). Bottlenecks are a typical concept when working with Lean implementation in production. The lit-erature has many different definitions of bottlenecks, but there is no consensus and clear description on precisely what a bottleneck is and can vary from person to person. How-ever, bottlenecks can define as the capacity of the resources is less than the customer demand or a process that limits the material throughput of the production system (Wang, Zhao & Zheng 2005). The paragraphs below: Value Stream Mapping, the 14 principles of Lean, eight wastes of Lean (Muda) and ECRS, will describe the four Lean concepts.

Value Stream Mapping

VSM is a method that investigates the value-adding and non-value-adding activities in an organisation to satisfy the customer demands (McDonald et al., 2002; Wee & Wu, 2009). According to Chen et al. (2010), a VSM consists of both the material flow and information flow and could be sequential or parallel. A significant advantage of using a VSM approach is that unnecessary non-value adding, i.e. waste, can be found in the organisation and further be reduced or even be eliminated, which increases the value propositions in the output of the production (Pasqualini & Zawislak, 2005; Ramesh, Prasad & Srinivas 2008). As a result, the approach can be an indirect advantage for the organisation to reach the customers against their competitors. The operations within the organisation will be smoother and more effective after the reduction of the waste and, in the long term perspective, find and remove more non-value adding activities, accord-ing to Wee & Wu (2009). The analysaccord-ing tool VSM starts with decidaccord-ing the scope where the system starts and ends to investigate the organisation's current state (Seth & Gupta, 2005).

Lucherini & Rapaccini (2017) proclaims that it is critical for SMEs to make investments in Lean tools such as VSM since it requires effort and budgets to develop and sustain the production system. VSM can assist managers in making easier decisions and focus more on the activities within the production instead of directly increasing value to the products to eliminate wastes in the activities. Belekoukias et al. (2014) state that a VSM approach has almost no correlation with flexibility and can even have a negative effect on flexibility when applying this Lean concept. The result is from investigating 140 manufacturing organisations worldwide and the correlation between different Lean methods and operational performance measures (Belekoukias et al., 2014). Lugert et al.

Theoretical background

9

(2018) also state that the Lean method VSM itself has difficulties in systems with flex-ible production, but the combination of more Lean methods can be beneficial.

The 14 principles of Lean

Lean production is not only a method or a tool, and it can be as a philosophy, Liker et al. (2009) stated 14 principles that can be followed for an organisation to be or strive to become Lean:

1. Base your management decisions on a long-term philosophy, even at the expense of short-term financial goals.

2. Create a continuous process flow to bring problems to the surface. 3. Use “pull” systems to avoid overproduction.

4. Level out the workload (work like the tortoise, not the hare).

5. Build a culture of stopping to fix problems, to get quality right the first time.

6. Standardised tasks and processes are the foundation for continuous improvement and employee empowerment.

7. Use visual control, so no problems are hidden.

8. Use only reliable, thoroughly tested technology that serves your people and process. 9. Grow leaders who thoroughly understand the work, live the philosophy, and teach it to others.

10. Develop exceptional people and teams who follow your company’s philosophy. 11. Respect your extended network of partners and suppliers by challenging them and helping them improve.

12. Go and see for yourself to thoroughly understand the situation.

13. Make decisions slowly by consensus, thoroughly considering all options; imple-ment decisions rapidly.

14. Become a learning organisation through relentless reflection and continuous im-provement.

Eight wastes of Lean (Muda)

In the Lean and Toyota Production System approach, the elimination of waste is in focus. It can be as everything within an organisation that does not create any value for the customers. Since it is a customer-oriented approach, it is easier to observe the pro-duction in value-adding (VA) and non-value-adding (NVA) activities. It can be in sev-eral services and within the information perspective (Liker et al., 2009). A term called Muda in Japanese describes the eight wastes within an organisation according to Liker et al. (2009), and these eight wastes are:

1. Overproduction: is often seen as the most impactful waste since it adds much extra effort, i.e., the production of additional components that no one has or-dered creates inventory that requires personnel and added costs due to stock, transport, and time.

Theoretical background

10

2. Inventory: unnecessary amounts of goods, WIP, damaged goods, unnecessary transport and buffer costs and delays. Overstock often hides other problems such as long lead times, late deliveries from the supplier and bad production planning.

3. Overprocessing: to do unnecessary actions on the products that the customer is not paying for (i.e., products with higher quality than what is required). It could be insufficient tools that create unnecessary work procedures and de-fects.

4. Waiting: operators waiting for the next working step; it could be waiting for a machine, tools, or nothing to do due to lack of material or bottlenecks.

5. Transport: to move WIP in long distances creates inefficient transports be-tween the warehouses and the processes.

6. Motion: all the movements that do not create value that employees do, e.g., search, walk, reach for objects.

7. Defects: production of defective components, which results in adjustments, re-pairing, reprocessing, scrap, and control of defects. It costs time, money, and energy to adjust the defects within the production.

8. Unused Employee Creativity: the managers that do not listen or care about their employees’ opinions loses opportunities to utilise ideas, competence, im-provements, and time.

ECRS (Eliminate, Combine, Rearrange, Simplify)

ECRS is a management technique that can be useful in Lean production when improv-ing production processes and lines. Kasemset (2014) describes ECRS as followimprov-ing:

• E= Eliminate unnecessary work • C= Combine operations

• R= Rearrange sequence of operations • S= Simplify the necessary operations

This technique effectively reduces lead times, cycle times and waste since some parts of the production system can be optimised and more effective (Kasemset, 2014). It can also reduce the internal transport distances and reduce the number of “unnecessary” operators and then put them on another work task that creates more value.

SMEs definition and characteristics

The chapter begins with the definition of SMEs characteristics and performance on the market and then introduces how SMEs work in the wood industry. Subchapter 2.2.2 explains the barrier and challenges with lean production and connection to SMEs. According to European Commission (2012), SMEs represents 99% of all businesses in Europe. European Union has several support programs that are targeted at SMEs to assist the organisations. Table 2 presents the definition or the determining factors if an organisation is an SME; data is from the European Commission website (2012). The factors are the staff headcount and turnover or balance sheet total.

Theoretical background

11

Table 2. The European Commission’s definition of small and medium-sized enterprises (Euro-pean Commission 2012).

Company category Staff headcount Turnover Balance sheet total

Medium-sized < 250 ≤ € 50 m ≤ € 43 m

Small < 50 ≤ € 10 m ≤ € 10 m

Micro < 10 ≤ € 2 m ≤ € 2 m

According to Gunasekaran et al. (2011), SMEs strength is to be responsive and resilient when competing on the global market and meet new demands from customers. The new market demands can challenge responsiveness to switch the production system, keep a high-quality standard, and be innovative. Moeuf et al. (2018) stated that performance objectives could be a triggering factor for improving the production system with new technologies and reformed organisation level to be competitive on the market. Capacity is a vital factor for SMEs when responding to customers or being competitive in the market. A data-sharing system between different processes aids the improvement of the capacity (Moeuf et al., 2018). Typical characteristics of SMEs are centralised decision making, flexible structure and information flow, informal communication, simple plan-ning & control system and a smaller customer base with closer contact to the customer (Elkhairi, Fedouaki & Alami 2019).

2.2.1 SMEs in the wood industry

Wood industries, especially those practising furniture manufacturing, orient their busi-ness around customisation, flexibility, and responsivebusi-ness to the market. SMEs in wood industries rely on innovation and can negatively or positively impact the performance objectives (Otero-Neira et al., 2009). Sweden is a dense forest country, and according to Holmström (2020), SMEs consists of 99.9% of all enterprises in Sweden. The num-ber of SMEs in the wood industries is higher in dense forest countries and contributes to wood and furniture exports. Furniture created in wood is valued much higher than sawn timber due to handcraft and surface treatment.

According to Sandberg et al. (2014), the product mix, capacity, and material wood type can affect and influence the production system. A product made of wood and manufac-tured in wood industries tends to be very expensive, very customised and has long sup-ply delivery for the material. Every type of wood material is different depending on the weather as well the location in the world. Furniture industries depend on sawn timber timing when excavating the forest at the time of the season. Wood materials need to dry before processing, and the percentage of dryness differs from products to products. Wood materials can be difficult or near impossible to purchase for shorter forecasts; therefore, it prevents fast day deliveries and must be checked regularly for availability and then stocked up and stored for a more extended period within a controlled environ-ment in a warehouse (Sandberg et al., 2014).

Theoretical background

12 2.2.2 SME in a Lean production view

According to the literature, several SMEs struggle to implement or develop the Lean production approach in a production system. Elkhairi et al. (2019) state that only a lim-ited number of SMEs have implemented a successful Lean approach and maintained the changes. The reasons could be several different barriers, such as lack of knowledge about different Lean tools, the commitment to the norm and resources and expertise. These are more limited for an SME compared to a larger organisation. Another signif-icant barrier is the resistance to change within the organisation. Elkhairi et al. (2019) clearly state that managing the barriers enables the organisation to implement Lean op-erations in the production system. Elkhairi et al. (2019) further proclaim that solid lead-ership is required for a possible cultural change within the organisation. Other important factors are competence and communication within the organisation while committing to the Lean approach and further educating the personnel in a lean perspective to sustain the change (Sahoo, 2021). Sahoo (2021) further explains that the involvement of em-ployees increases the probability of success for lean implementation and creating a con-tinuous improvements culture.

Gazoli de Oliveira & Ribeiro da Rocha Junior (2019) states that SMEs often miss the holistic vision of waste reduction, which is seen more during economic fluctuations and other financial losses. The authors are proclaiming that investments are necessary to follow the development of the market. To implement Lean Manufacturing, the SMEs must examine the current system, plan for the implementation, and then execute the implementation with continuous improvement to maintain the changes (Gazoli de Oliveira & Ribeiro da Rocha Junior, 2019). The authors lift that the SMEs should state the philosophies (e.g., VSM and Kanban) of Lean and proclaim listening to the person-nel who are the experts of the different processes.

Lean manufacturing is a socio-technical approach consisting of four categories accord-ing to Alefari, Almanei and Salonitis (2020): technical, human, external environment, and work organisation. The management of SMEs can see the Lean approach as a new management philosophy and not just a tool to optimise production. Alefari et al. (2020) state that teamwork and holistic system thinking are the keys to successful implemen-tation and sustaining the organisation's Lean philosophy. Leadership is a non-value add-ing; however, it is a fundamental bridge between the Lean implementation and the em-ployees who will maintain and improve working. Gemba and celebrating success are other factors that are important for a leader to make the organisation strive for the same goal. The employees are motivated about the pay and self-satisfaction, and association and the leader can increase these concepts by working closely and developing the em-ployees (Alefari et al., 2020). Belhadi, Sha´ri, Touriki and El Fezazi (2018) state that in the literature, it is missing frameworks for SMEs to follow when implementing a Lean approach, which makes it difficult to conduct a plan for the organisation; this results in neglecting the philosophy or hiring a consultancy to develop the production system.

Theoretical background

13 Change Management

The chapter starts with the definition of Change Management and the concepts within change management. The Change Management approach within SMEs describes the change management, hard-, and soft aspects in subchapter 2.3.1.

Change management defines as a tool or a process for assisting an organisation and preparing employees for change (van der Voet & Vermeeren, 2017). Communication and leadership can help an organisation to achieve the desired objective, which leads to that change management depend on human factors for success and their collaboration with projects (Baharudin et al., 2020). Successful change management begins with un-derstanding why a change is necessary and how a personal transition can enable en-gagement and utilisation of the difference (Hayes, 2018).

2.3.1 Change Management in SMEs

For SMEs, change management can be perceived as a delicate business decision that can affect the production personnel, positively and negatively. Change management can be a great tool and process to increase their competitiveness and the possibility to re-spond to external threats and improve adaptability (Dextre-del-Castillo et al., 2020; Ferenc Tolner et al., 2021). Even though, initiate a change on SMEs can be a challenge due to how centralised or decentralised the organisation level is. SMEs organisations are typical centralised and often lacks management to initiate change management, and are more affected by human factors (Tolner et al., 2021). As Forza & Salvador (2001) state, organisations benefit when having a decentralised decision-making approach at the production floor since it creates a minor error in communication, quicker channels for communication, and facilitates knowledge and experience sharing at the production floor level.

An organisational culture and a framework that support the strategies are crucial for change management success. According to Sahoo (2021), managers are part of success with change management since they are the key to involving the employees with con-tinuous improvement strategies. Managers with a mentorship of good quality, contrib-ute to good communication flow, information sharing, and creates transparency be-tween employees and the organisation (Baharudin et al., 2020). Change management is a great contributor to successful lean production implementation. According to Moeuf, Tamayo, Lamouri, Pellerin and Lelievre (2016), managers with solid decision power are key for implementation and often found in the top management branch. Managers are usually formed from previous experience and expertise, facilitating their decision-making and increasing their decision power. The decision power can impact the moti-vation of the employees, time assignments, and if investments are necessary for the change.

Lean practices can affect the employees differently and create negative effects, they can be damaging, such as increased stress, sickness, and uncomfortable work conditions. It has proven by Hasle (2014) that when implementing lean practices, involving employ-ees in the project is important for reducing the negative effects, thus leads that change management is an important factor for success. Lean implementation is to favour the

Theoretical background

14

organisation, but it is important to include employees to be in their favour in the long term, and change management can support this. According to Lugert et al. (2018), man-agement of human and organisational elements support the implementation of VSM and thus can eliminate weaknesses of the VSM and improving responsiveness to exter-nal and interexter-nal influence. It states that management is important for VSM to reduce fluctuations and irregular production patterns.

According to Gunasekaran et al. (2011), SMEs have a more robust competition when competing with other SMEs, thus has led to SMEs being more innovative and flexible. Flexibility has been a significant factor for SMEs to increase their competitiveness, improving the capabilities and responsiveness to various customer expectations (Matejun, 2014). With high flexibility, SMEs increase their ability to react to sudden external threats and rapid changes in external conditions. The article by Matejun (2014) heavily implies that SMEs should concentrate on improving the flexibility of the pro-duction system to increase the competitiveness level.

When enterprises speak in terms of flexible production, it enables them to transform the productions technological level and capacity to meet sudden changes in the market (Stanev et al., 2008; Ulukan, 2020). Due to customer demands, more innovative prod-ucts, faster response, and a higher level of creativity, being proactive can resolve a crisis that can damage the company. Luburić (2019) further explains that change management can help prevent a crisis by involving the employees and establishing continuous im-provement strategies. It can help develop the organisation to be more sustainable and prepare the top management for an emergency, resist external influence, and increase their competitiveness in the market.

Ferreira, Araujo and Echeveste (2020) argue that ten factors exist that affect the imple-mentation of continuous improvement strategies, it cites as follows:

learning and qualification of people; upper and middle management support and commitment; engagement of all workers; autonomy of em-ployees; communication process; health and well-being of the work-ers; development of vision and strategies to change and establish a sense of urgency; developing lean leadership and definition of an agent for change; development of an organisational culture; and change Planning.(Ferreira et al., 2020)

Hard and soft aspects affect the performance of operators in the production system, according to Lenka et al. (2010). Soft aspects define as management of employees, working and service climate, inspirational leadership, employees’ commitment and job satisfaction. The hard aspects are the physical evidence factors such as infor-mation management system and materials and machines. These two aspects are essen-tial to consider in a production system when working with improvements changes and to sustain them due to the human interactions that occur during the process (Lenka et al., 2010).

Method and implementation

15

3

Method and implementation

This chapter will introduce methods for investigating the production system by per-forming a VSM and investigating the perspective regarding change management. The methods to collect data will be Interviews, Observations, Literature review, and flow mapping of the current production system. The study´s approach will be in Research Design and the chosen literature search in the literature review. Primary and second-ary data will describe how the different data gathering were used, with explanations. At last, arguments for the validity and reliability, and implications of ethical and morals aspects.

Research Design

The research of the study consists of a qualitative approach. The choice of collection technique depends on how the information and data are collected, processed, and ana-lysed in the research. Qualitative data describes researchers focusing on collecting “soft” data, which often consist of qualitative interviews and verbal analyses. In con-trast, quantitative data consists of more measuring data collection and statistical analyt-ical methods (Saunders, Lewis & Thornhill 2016).

From the research perspective, three approaches relate to the methods and theories. These are induction, deduction, and abduction, and Patel & Davidson (2011a) describe them in their research book. Induction is an explorative path where the researcher ob-serves the object without testing the research on an existing theory and by the observa-tion formulating a generalisable theory. An inductive approach is often based on a spe-cific situation, making the formulated theory not applicable to other cases. The deduc-tion can perceive as the opposite; the researcher uses generalised and existing theories and makes conclusions due to specific circumstances. The deduction is the most used approach in research, according to Patel & Davidson (2011a). Abduction is a hybrid between induction and deduction, where the approach often starts with induction from a case into formulating a theory (theory 1). Then it goes over to a deductive approach where the hypothesis created is tested on one or several cases. Later on, the theory can be further developed and generalised for several specific cases into theory 2 (Patel & Davidson, 2011a).

This study has an abductive approach because it relates between the research and theo-ries that consist of both an inductive and deductive approach. An initial stage is an inductive approach where the first step is discovering information from the case com-pany. The researcher tests a theory on the case company and then further developed it into a more generalised theory for enterprises with the same production system to make the production system more effective and more Lean. The research is mainly qualita-tive, but some factors of quantitative elements are combined. Qualitative interviews were for finding essential data to aid in the pursuit to achieve the purpose and aim. However, the study has been using numbers and measures in some parts, but only to make the data more straightforward with the context and strengthen the reliability and validity.

Method and implementation

16

Primary and secondary data collection

To answer the RQs, it was necessary to collect and analyse the enterprise's data. The missing data that the authors collect is called primary data. At the same time, secondary data is the data that already exists or are managed by a second party (Patel & Davidson, 2011b). When collecting primary data, it is the most important aspect to be as objective as possible to sustain high trustworthiness results. Most of the data is of primary state during the project since the enterprise does not have that much information, and they do not want the authors to be affected by the enterprise’s information. Still, comparisons between the primary and secondary data keep a high validity and reliability. The pri-mary data has come from both unstructured and semi-structured interviews and direct observations.

3.2.1 Interviews

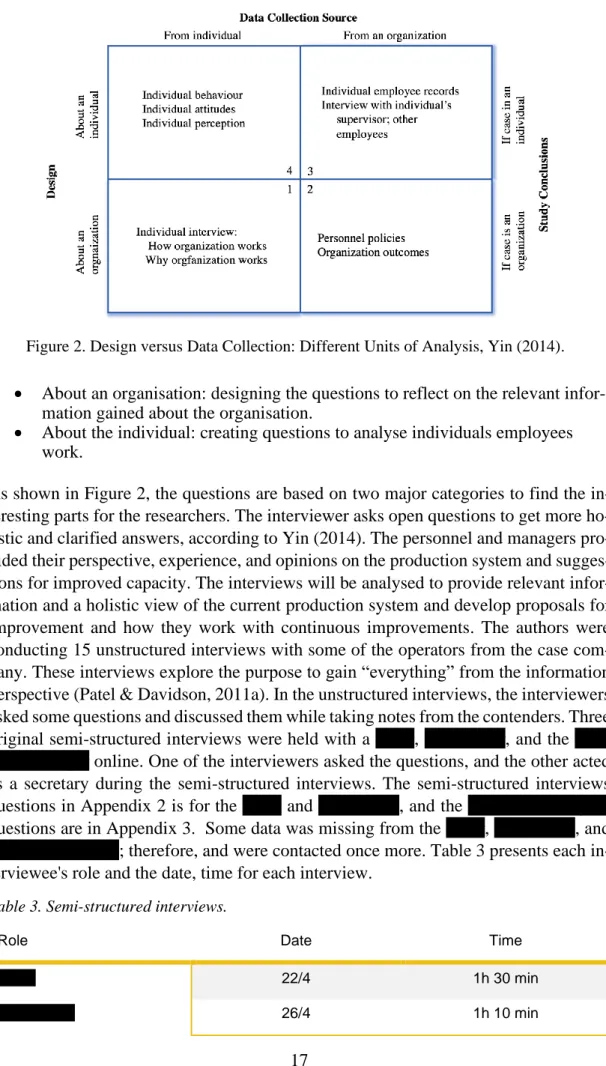

In a case study, interviews were one of the most helpful and common data collection method. Interviews are useful to gain more explanatory information from the case and the circumstances (Yin, 2018). The interview forms were semi-structured and unstruc-tured interviews. Semi-strucunstruc-tured interviews are when the researcher lists specific themes or questions, but the interviewee can freely answer the questions (Patel & Davidson, 2011b). It can often perceive as an ordinary conversation, but about a spe-cific topic and the interviewer can come up with supplementary questions during the conversation. The interviewer will gain a more in-depth understanding and knowledge (Patel & Davidson, 2011a). Unstructured interviews are when interviewees can express how their aspects are regarding a specific topic. The format of the interview has no restrictions more than the topic itself. The interviewer will gain reliable information about the case (Saunders et al., 2016). In the project, conducting several interviews were to secure and conclude data for the findings. The technique was inspired by the “Data Collection Source” from the literature “Case Study Research Design and Methods” by Yin (2018) to form the interviews questions, Appendix 2 & 3.

Method and implementation

17

• About an organisation: designing the questions to reflect on the relevant infor-mation gained about the organisation.

• About the individual: creating questions to analyse individuals employees work.

As shown in Figure 2, the questions are based on two major categories to find the in-teresting parts for the researchers. The interviewer asks open questions to get more ho-listic and clarified answers, according to Yin (2014). The personnel and managers pro-vided their perspective, experience, and opinions on the production system and sugges-tions for improved capacity. The interviews will be analysed to provide relevant infor-mation and a holistic view of the current production system and develop proposals for improvement and how they work with continuous improvements. The authors were conducting 15 unstructured interviews with some of the operators from the case com-pany. These interviews explore the purpose to gain “everything” from the information perspective (Patel & Davidson, 2011a). In the unstructured interviews, the interviewers asked some questions and discussed them while taking notes from the contenders. Three original semi-structured interviews were held with a seller, constructor, and the tech-nical manager online. One of the interviewers asked the questions, and the other acted as a secretary during the semi-structured interviews. The semi-structured interviews questions in Appendix 2 is for the seller and constructor, and the technical manager's questions are in Appendix 3. Some data was missing from the seller, constructor, and technical manager; therefore, and were contacted once more. Table 3 presents each in-terviewee's role and the date, time for each interview.

Table 3. Semi-structured interviews.

Role Date Time

Seller 22/4 1h 30 min

Constructor 26/4 1h 10 min

Method and implementation

18

Technical Manager 27/4 1h 30 min

Seller 28/4 30 min

Constructor 28/4 30 min

Technical Manager 29/4 40 min

Comparing and analysing the semi-structured interviews to the unstructured interviews' data decreased the risk of missing valuable data. Both authors would exchange infor-mation between them to secure and verify the data. Typical questions that the authors asked the operators during the unstructured interviews were “How often do you produce the objects?”, “What are the reasons for time differences for each product?” and “Is this a normal day in your process station?”.

3.2.2 Observation

Observations are the most familiar concept to gain primary data by observing the whole process flow. Each observation was planned systematic, and the information was reg-istered systematically to achieve a more profound validity and reliability. Observations often explore the circumstances and often compare or base on other information gaining techniques (Patel & Davidson, 2011a).

Before each visit, observations were planned the day before by investigating these ques-tions to conduct the observaques-tions to gain data for answering the purpose and the RQs. The questions beneath were answered before each planned visit to be better prepared for the observations, and the last question is due to COVID-19 restrictions and to be as safe as possible for the researchers and the personnel:

• What should we observe?

• How can we note these observations? • How should we, as observers, act?

The observations are to collect information for the VSM by measuring the real-time actions in the different processes and the employee’s behaviour, and how they com-municate and work. Since the facility has several flows (several processes within them), it was required to collect data from all processes. Since the production system has many different parameters and a wide product range, some of the processes were more chal-lenging to collect data to establish a balanced VSM (further observations in the execu-tion of VSM is in chapter 3.3). However, with unstructured interviews with the opera-tors, the data became more reliable since it gave an unbiased view. The authors have visited the plant 16 times; these visits have included discussions, meetings, unstructured interviews, and sidewalk during production and closed production. For the case, the observations were made from door to door in the entire material flow. Observations have been a vital part of understanding the processes and the flows within the facility fully. The observation was beneficial since it played an important role in the collected qualitative data and provided ideas on complementary approaches. The observation gave insight and knowledge on the production system, employee movement behaviour while performing work tasks, and real-time actions. The data was to provide ideas for

Method and implementation

19

new possible literature scope (Yin, 2014). Table 4 presents the dates, times and context of the visits/observations.

Table 4. Observations and visits at case Company A.

Date Time

(hour)

Context

25/1-21 3 Pre-study, short interview and observation of closed production

9/2-21 3 Measure and CAD the layout of the facilities (closed production)

11/2-21 6 Guiding and observation around the production flow 4/3-21 4 Finalise the CAD of the layout (closed production) 9/3-21 4 Count the raw material buffers for VSM (closed

pro-duction)

11/3-21 4 Count buffers/WIP between the processes (closed production)

12/3-21 6 Count buffers/WIP between the processes (closed production)

16/3-21 9 Observed Stringer flow and took cycle times

17/3-21 9 Observed post flow and took cycle times

18/3-21 12 Observed other flows and took cycle times, counted buffer once more

23/3-21 4 Observed other flows and took cycle times

25/3-21 5 Observed the painting, packing, and assembly areas 1/4-21 5 Measured the rest of the cycle times for the VSM 15/4-21 4 Observation and interview with painting manager 22/4-21 5 Observations of the whole production system on

what can be improved 3.2.3 Gemba

Gemba is originally a Japanese concept and describes as the place where the action is often used in a production approach and is a part of Lean production, according to Ellis (2016). The authors Investigated the facility, employees, and process as a part of un-derstanding the production system fully. Gemba is often used to solve problems directly on the shop floor where the knowledge and information exists, but usually, managers try to solve the issues in a conference room. Gemba can provide different reasonable solutions in many different circumstances, which can support and improve the organi-sation (Ellis, 2016).

Method and implementation

20

In the study, the authors used the concept Gemba to be where the actual problem is to gain knowledge about the production system to conduct the VSM and develop new ideas and recommendations for both the case company and the literature. The Gemba approach was made by observing what happens on the shop floor and try to gain insight to come up with possible solutions for the future as a result of the purpose. By collecting data directly from the production floor and understand some of the root problems in the production system from their perspective, the study found a solution or a guideline for improvement.

3.2.4 Literature review

The literature review will help to extend and expand our knowledge about SMEs (in wood industries), Production Development, Change Management, Lean Production (VSM) and flexibility and changeability in a production system. By reviewing the lit-erature, we can find solutions and methods to achieve the purpose of the case, according to Saunders et al. (2016). Furthermore, newly acquired theories were to validate the created solutions for the case company to increase the capacity.

The first part of the literature review was by stating the theoretical topics of this project to gain basic knowledge about the case. The holistic overview of which literature is crucial since it benefits the further process of the comprehensive literature review (Patel & Davidson, 2011a). The theoretical topics in the first literature review assisted in de-fining the purpose and research questions of the case. There is a lot of existing research on each academic topic presented in Table 4. However, when combining each topic, there is not much information available in the literature, e.g., flexibility combined with VSM, which is the central core of this study. In addition, combining flexibility and VSM with SMEs in the wood industry and Change Management, there is no literature found. The literature review, therefore, supports this research taken the abductive ap-proach.

The literature review consists of books and scientific papers with basic knowledge and more profound knowledge. The basic knowledge provided a fundamental perspective on the research to strengthen the theoretical background. The information from the lit-erature provides the author with a possibility to summarise the information gained for the chosen field (Patel & Davidson, 2011a). The primary databases were Scopus since the authors are familiar with Scopus, and it is easy to read the abstract and combine search combinations. Figure 3 depicts that reviewing the literature is an iterative process and is inspired by the Stage of the hermeneutic circle model from Boell & Cecez-Kecmanovic (2010). This approach for the project is suited to give the readers and prac-titioners a holistic view of the theoretical topics. The list below presents the steps of the literature review process:

• Searching: Used the keywords and filters in the database Scopus. • Sorting: Observed the relevance of the case and the date.

• Selecting: Mainly selected due to the title and abstract and promising papers. • Acquiring: Used the “Inter-Library Loan” to gain the peer-reviewed papers. • Reading: A more profound understanding

Method and implementation

21

• Identifying: The central terms and sentences to use.

• Refining: Make citations in our report. Then start from the beginning if more is required.

In the project, the handbook by Rother et al. (2001) has been helpful since it provides information and examples on how to conduct the VSM. Since some theoretical topics combined are missing in the literature review, snowball sampling was applied. A non-randomised sampling technique provides referrals for more literature within the same subject (Dobrovolskyi & Keberle, 2019). It made it easier for the authors to find new sources and information for the case.

Table 5 shows the structured literature review and the papers' search results, which pro-vided more profound knowledge and theoretical background for the case. Transforming the academic topics to literature reviews keywords supported the search for relevant articles and theories. The review consisted of three selections after the first number of hits.

1. Reading the topic and abstract of the article.

2. Get an overview and reading the conclusion of the article and later a thorough reading.

3. Final selection of the articles to use for our theoretical framework. Figure 3. Stage of the hermeneutic circle, Boell & Cezec-Kecmanovic (2010).

Method and implementation

22 Table 5. Literature Review of the theoretical topics.

Flow mapping of the current production system

To depict the logical connection between the activities, from supplier to customer, cre-ating a VSM was needed within the production system. The chosen product to be stud-ied and observed was a wood-based stair with high variations but manufactured in low volumes and made to order. The VSM was established and finished by investigating the information- and material- flow in the production flow. The inspecting process started from the inbound of the facility and continued upwards until the painting pro-cess. The last process decided the pace for the rest of the production system and its processes (Rother et al., 2001).

By investigating the entire production system, the authors acquired information about how the processes are implemented on the different components and fully understand how to execute the primary method efficiently. Collecting information was mainly by observation and unstructured interviews without disturbing the personnel and the pro-duction system. It was required to clock the cycle times, which is from one point of a process until the operator starts the next component at the same point. A stopwatch was for measuring set-up times and different time measurement. Other factors estimated to strengthen the VSM were the distances between the workstations and the scrap rate from every process. The lead time was by calculating the value of counting all the buff-ers before and between the stations. The buffbuff-ers contain several components and trans-form into a time value measured in days. When calculating the material and buffers, it was advantageous to do it in closed production since there were no goods movements at those times. The authors started to count the buffers before the different material flow for each stair component in the evenings. Cycle times are value-adding activities, and lead times are non-value-adding activities. By dividing cycles times with lead times, a quota value represents the percentage of how much time value is added to the product. The lower quota, the more non-value adding activities exists; this means material flow

120

"Value Stream Mapping" AND Flexib* 3 45 15 4 2 16

Language: English Document type: Article Subject Area: Engineering

"Lean Production" AND SME

Language: English Document type: Article Subject Area: Engineering

19 10 5 3

63 31 10

7 2

50 10

Language: English Document type: Article Subject Area:

Engineering & Business Management and Accounting

SME "SME" AND wood industr*

Language: English Document type: Article Subject Area:

Engineering "Change Management" AND SME Change Management "Change Management" AND Flexib*

Language: English Document type: Article Subject Area:

Engineering & Business Management and Accounting

1st selection (topic/abstract) 2nd selection (overview) Papers used Number of hits

Filters used Keywords used

Theoretical Topic

"Lean Production" AND Value Stream Mapping

Language: English Document type: Article Subject Area: Engineering Lean Production: Flexibility/Changeab ility, VSM and Change Management 20 7 4 134 52 3 28 13 7 2 "Change Management" AND "Lean Production"

Language: English Document type: Article Subject Area:

Engineering & Business Management and Accounting

Method and implementation

23

or a specific process can be further improved. This can either be improving the pro-cesses or removing bottlenecks of the production system. Figure 4 illustrate the symbols for the material- and information flow.

Figure 4. Symbols for material- and information mapping flow (Rother et al., 2001).

A value flows analysis analysed the value-adding, necessary, and nonvalue-adding time in the current production system. The authors used the value flow analysis to identify the current bottleneck and why wastes emerge, clarify processes, show connections be-tween material- and information flow within the production system, bridge communi-cations, expertise, and competence between operators. Combined will be the foundation for suggestions of improvements and how to modify the VSM accordingly to the current production system (Rother et al., 2001). The goal is to create a future state which is to increase capacity in the production system.

3.3.2 Time-related key indicators

Time parameters for this study are presented and described in Figure 5; these are lead time, process time, value-added time, and cycle time stated by Rother et al. (2001). These were considered to complete the VSM and give a holistic view of how the pro-duction system worked. Takt time is the time it takes to produce one unit due to the customer demand.

𝑇𝑎𝑘𝑡 𝑡𝑖𝑚𝑒 = 𝑎𝑣𝑎𝑖𝑙𝑎𝑏𝑙𝑒 𝑡𝑖𝑚𝑒 𝑑𝑎𝑖𝑙𝑦 𝑐𝑢𝑠𝑡𝑜𝑚𝑒𝑟 𝑑𝑒𝑚𝑎𝑛𝑑

𝐶𝑦𝑐𝑙𝑒 𝑡𝑖𝑚𝑒 = 𝑝𝑟𝑜𝑐𝑒𝑠𝑠 𝑡𝑖𝑚𝑒 𝑛𝑢𝑚𝑏𝑒𝑟 𝑜𝑓 𝑝𝑟𝑜𝑑𝑢𝑐𝑡𝑠

Method and implementation

24 𝐿𝑒𝑎𝑑𝑡𝑖𝑚𝑒 = 𝑡𝑜𝑡𝑎𝑙 𝑞𝑢𝑎𝑛𝑡𝑖𝑡𝑦 𝑜𝑓 𝑝𝑟𝑜𝑑𝑢𝑐𝑡𝑠

𝑑𝑎𝑖𝑙𝑦 𝑐𝑢𝑠𝑡𝑜𝑚𝑒𝑟 𝑑𝑒𝑚𝑎𝑛𝑑

Figure 5. Time-related key indicators (Rother et al., 2001).

Sketching of layout

To fully understand the arrangement of the processes and material flow visually, sketch-ing the complete layout of the production system was necessary. The reason was to analyse and map the material flow and visually show the layout's complexity and its effects on the VSM. It was done by first measuring the outer walls of the building and further mark out every pillar in the building. This was to have a more accessible refer-ence when sketching out the positions of the machines and processes. The layout meas-urement data was then imported into a CAD program named AutoCAD, and the sketch was in 2D and only required for this case. AutoCAD was to sketch on a 1:1 scale to gain a holistic and complete perspective of the production system and its layout with every process, material placeholder, and other equipment.

Reliability & Validity

The authors in this project have used several methods to increase reliability. Patel & Davidson (2011b) states that reliability is about how well a method has resistance to random influences. The selected methods to answer the research questions are inter-views, observations, literature review, and using these methods, a VSM of the produc-tion flow. The cycle time is from when an operator grabs the first item until he takes the other, it is possible to argue that the outcome would be the same for whoever collects