Solid solution strengthening effect on creep

strength of austenitic stainless steel

Sara Abouzari

Department of Material Science and Engineering

Royal Institute of Technology

Stockholm

2012-03-14

Master of Science Thesis

Supervisor:

Rolf Sanström

1

Abstract

Sanicro 25 is a newly developed austenitic stainless steel, designed for the next generation of Ultrasupercritical coal-fired boilers in electrical power plants. This material is applicable in

reheater and superheater tubes, where the material temperature is up to 700°C.

One of the main strengthening mechanisms in high temperature materials is solid solution strengthening. A combination of this mechanism and precipitation hardening, promotes creep strength of heat resistance materials. The aim of this work was to characterize the effects of solid solution strengthening on creep strength of Sanicro 25.Previous works has been done for effects of phosphorous in copper and also for influence of laves phase on the creep properties of CrMo alloys. The results of these two works are used and the model is adapted to austenitic stainless steel. First a Zero starting state was defined which was Alloy 316H and then the calculation was made for Sanicro 25. Thermodynamic calculations were made using DICTRA and Thermo-Calc. Elastic misfit parameter was determined using ab initio calculations. The results from the simulation in this work indicate that solutes with larger size misfit compare to the parent atoms have better solid solution strengthening effect. A decrease in the creep strength by increasing temperature has been observed which could be attributed to growth of laves phase.

2

ACKNOWLEDGEMENT

I would like to show my gratitude to Professor Rolf Sandström as my supervisor for providing an opportunity for me to do this work. This project bears on imprint of many peoples.I sincerely thank to Pavel Korzhavyi, Johan Zander and Johan Pilhagen, staff members of “Department of Material Science and Engineering, Royal Institute of Technology” and my dear friends who rendered their help during the period of this project. At last but not the least I would like to thank my dear parents for all their encouragements and supports, and I would like to dedicate this work to them.

3 Table of Content Abstract ... 1 ACKNOWLEDGEMENT ... 2 Table of Content ... 3 1. Introduction ... 4 1.1 Background... 4 1.2 Purpose ... 4 2. Literature study ... 5

2.1 Ultrasupercritical (USC) coal-fired boilers ... 5

2.2 Stainless steel ... 6

2.2.1 Austenitic stainless steel ... 7

2.3 Strengthening mechanisms ... 8

2.3.1 Work Hardening ... 8

2.3.2 Precipitation Hardening ... 9

2.3.3 Grain Boundary Strengthening ... 9

2.3.4 Solid Solution Strengthening ... 9

2.4 Creep ... 13

2.4.1 Dislocation Creep ... 14

2.4.2 Diffusion Creep ... 15

2.4.3 Grain boundary sliding ... 15

2.5 Solid solution strengthening and creep ... 16

2.6 Effects of solid solution strengthening on creep properties of austenitic stainless steel ... 18

2.6.1 High nitrogen strengthening ... 18

2.6.2 Solid solution strengthening by W and Mo ... 19

3. Matrials ... 22 3.1 Steel 316H ... 22 3.2 Sandvik Sanicro® 25... 22 4. Methods... 24 4.1 Matlab Software ... 24 4.2 DICTRA ... 24 4.3 Thermo Calc ... 25

4.4 Lattice misfit parameter calculations ... 26

5. Results ... 28

5.1 Thermo Calc calculations ... 28

5.2 DICTRA calculations ... 29

5.3 Lattice misfit parameter calculations ... 31

5.4 Matlab calculations ... 32

6. Discussions ... 43

7. Conclusions ... 44

4

1. Introduction

1.1 Background

One of the main sources of carbon dioxide emission is the world’s electrical power

generations which produce approximately 10 billion tones CO2 per year. This estimated CO2

emission may contribute to climate changes like greenhouse effect and global warming. One way to reduce these environmental impacts of electricity generation is to increase the efficiency of power plant, which leads to less fuel consumption and consequently less CO2 emission compared with the today’s power plants. The efficiency of conventional coal fired power plants strongly depends on the steam temperature and pressure. This leads to development of high temperature materials with improved creep rupture strength and steam-oxidation resistance.

One of the recent developed materials for power plants application is Sanicro 25 with high creep strength and good oxidation and corrosion resistance. The temperature in the new boilers is about 700°C and this material has been design to be able to operate at this condition.

1.2 Purpose

The purpose of this thesis was to present a model for the effects of solute atoms on creep strength of austenitic stainless steel for application in Ultra supercritical boilers. The study materials were including Sanicro 25 and Alloy 316H. In Sanicro 25, the modeling has been done for W-, Nb- and Cr-solutes. In case of Alloy 316H, the effects of Mo- and Cr-solutes were investigated.

5

2. Literature study

2.1 Ultrasupercritical (USC) coal-fired boilers

The global energy demand in one hand and the emission of Carbon dioxide CO2 in the atmosphere, in the other hand, leads to improve the efficiency of coal-fired power plants. The world’s electrical coal-fired power generation is one of the main sources of carbon dioxide emission which produce approximately 10 billion tonnes CO2 per year. This estimated CO2 emission may contribute to climate changes like greenhouse effect and global warming. Coal has a vital role in electricity generation worldwide. Today, coal consumption plants fuel 41% of global electricity while in some countries it fuels a higher percentage of electricity (about 90% in Poland and South Africa, 79% in China, 69% in India).It has been estimated that in 2030 coal will fuel around 44% of global electricity. The estimated emission of CO2 from 1990 to 2030 is from about 35 % to 45 %. These trend leads to increase the efficiency of coal-fired power plants in order to reduce the consumption coal and consequently reduce CO2 emission compared with the today’s power plants. Increasing the efficiency of the conventional coal-fired power plants by one percent, results in a 2-3% reduction in CO2 emissions [1].

The efficiency in coal-fired power plants has been increased from 42% in 1990 to 48% today, by replacing supercritical steam condition with ultrasupercritical ones. Temperature and pressure in supercritical coal-fired boilers was 540 ºC and 20 MPa respectively which this value raised to 600°C and 30.5 MPa in ultrasupercritical coal-fired boilers. Boiler is a part of the power plants which burns the coal to boil the water to superheated steam. Later, the superheated steam is sent to the steam turbines to generate electricity. The boiler has been made from different parts: superheater and reheater tubes, furnace panels, thick sections and steam lines. Potential superheater and reheaters in the boiler are exposed to temperature about

700 ºC. The only materials which could withstand this condition are austenitic steels such as

Super 304H and Nickel-based alloys due to their good creep rupture strength and high temperature corrosion resistance. However, for the hottest part of the superheater and reheater tubes, austenitic stainless steel do not have the required properties and Ni/based alloys are applied. Moreover, for application in thick parts of the boiler, austenitic stainless steel is excluded due to its low thermal conductivity and high thermal expansion which cause fatigue

6

damage during service. Candidate materials for these applications are Ferrites and Ni/based grades. The properties required for the component in furnace panels, where the temperature reaches to 700 ºC, are high creep strength and corrosion resistance and good manufacturing properties. The candidate materials are ferritic/martensitic 9-12% Cr steels and Ni-based alloys like alloy 617. When selecting the material economic aspects should be considered as well, while Ni-based alloys are more expensive than stainless steel [2].

The efficiency of conventional coal fired power plants strongly depends on the steam temperature and pressure in the boiler. The increase in temperature and pressure of the steam leads to need for a developed material as a component in the boiler, with high creep rupture strength and oxidation resistance at elevated temperatures. Ultrasupercritical coal-fired power

plants have been developed recently to operate at 700 ºC and 32 MPa.

Recent attempts have been made to improve mechanical properties of Austenitic stainless steels for operation of about 700 ºC and 32 Mpa. Improving creep properties of austenitic stainless steel for operation at the elevated temperature and pressure in the new developed ultrasupercritical boilers is crucial.

One of the candidate material for the new generation of USC coal fired boilers, is a developed austenitic stainless steel with creep strength up to 100 MPa at 700 ºC and 100000 h. This material should also have high temperature oxidation resistance and good manufacturing properties. The austenitic stainless steel used today will not fully meet these requirements at 700 ºC.

2.2 Stainless steel

Stainless steel is a class of alloys with at least 11 wt% chromium content with specific superiorities over other types of steels including: resistance against stain, rust and corrosion. Stainless steels are mostly used for their corrosion resistance and also for their high temperature properties. Therefore, it is a recommended material where high temperature oxidation and strength is necessary.

In stainless steel Fe-Cr is the base system which accompanied with other alloying elements whose presence enhances specific properties. For instance, if an austenitic stainless steel is desirable Ni is added. Mn also acts as an austenite stabilizer, while having lower price than Ni. Carbon can be added if higher hardness is desirable. Mo is another element which could

7

improve its resistance against corrosion. The amount of the added elements to stainless steel should always be kept below the iron content for the sake of having steel as a resulting alloy. There are different types of microstructure in stainless steels: austenitic stainless steel, ferritic stainless steel, martensitic stainless steel, duplex stainless steel, precipitation hardening stainless steel and Mn-N substituted stainless steel [3]. Among all types of stainless steel, austenitic stainless steel has the greatest acceptance because of desirable combination of properties like, corrosion resistance, good weld ability, excellent toughness and creep strength.

2.2.1 Austenitic stainless steel

Austenitic stainless steel with a Fe-Cr-Ni base system plays an important role in high temperature structural applications. The addition of Ni is to stabilize austenite which could also highly increase the resistance against corrosion. High chromium content is very beneficial for applications where high temperature corrosion resistance, strength and scaling are necessary. However, Cr is a ferrite stabilizer. Thereby, it should be in a balance amount with nickel. For further improvement in corrosion resistance, the weight percentage of Cr and Ni could be raised up to about 25% and 20% respectively. 310 is an example. However, it does not have good creep rupture strength at high temperature.

AISI 300 series are the most familiar group of austenitic alloys, which among them 304 steel with 18% chromium and 8 % nickel is the most common one.

Dispersion of secondary phases like carbides and nitrides increases high temperature strength of austenitic stainless steel by precipitation hardening. Therefore, addition of carbide and nitride stabilizer elements like Nb and Ti, to the austenitic stainless steel is very common. Carbides and nitrides act as a barrier to dislocation movement and increase the strength of the steel. In the other hand, formation of carbide can lead to intergranular corrosion by depleting the surrounding of elements like Cr and Mo that contribute to corrosion resistance. Addition of Nb and Ti could prevent this event by binding the carbon and preventing formation of carbides.

Solid solution hardening in austenitic stainless steel is normally occur before service and during service precipitation hardening by fine intermetallic phases or carbonitrides is the dominant mechanism at high temperatures. The creep strength of austenitic stainless steel for application in coal-fired boilers has been improved from 18Cr-8Ni steels to 20Cr-25Ni steels

8

with presence of W in solid solution, which can withstand 98Mpa stress at 700C for 100,000 hours. creep rupture strength of some newly developed heat resistance steels has shown in table 2.1. A combination of solid solution strengthening and precipitation hardening of fine carbides, carbonitrides and some intermetallic phases is basically the dominant strengthening mechanism in these steels.

The diffusivity of iron in an austenitic matrix is smaller than in a ferritic matrix. Therefore, austenitic steels have better creep strength at elevated temperatures compared to the ferritic steels [4]. One of the most common hardening mechanisms for austenitic stainless steels is precipitation hardening by carbides. However, when the material is exposed to an elevated temperature for a long term, due to the higher recovery speed, this method loses its efficiency.

2.3 Strengthening mechanisms

Plastic deformation occurs due to dislocation movements which lead to macroscopic deformation. In other words, the ability of a material to plastically deform depends on the ability of dislocation to move within the crystal lattice. Prohibiting the movement of dislocations will result in the hardening of the material by improving its mechanical properties like yield and tensile strength. There are different mechanisms to impede the mobility of dislocations, including:

Work hardening

Precipitation hardening

Grain boundary strengthening

Solid solution strengthening (alloying)

2.3.1 Work Hardening

Work hardening (also called strain hardening) is a strengthening mechanism which occurs by interaction between dislocations. When a material is plastically deformed the dislocation movement will generate new dislocations. Enhancing the dislocation density will lessen their movement by increasing the yield stress which leads to higher required shear stress to move the dislocations; therefore they become tangled and pinned. Consequently, by reducing the dislocation motions the strength of the material will increase. This process should be

9

performing at temperatures low enough to prevent the atoms to rearrange themselves (cold-working). At higher temperatures (hot working) the dislocation can rearrange and the same strength cannot be achieved. However, this method of strengthening will result in a reduction in ductility.

2.3.2 Precipitation Hardening

Precipitation hardening is one of the most widely used heat treatment techniques for the strengthening of metal alloys including stainless steels. It is based on the fine dispersion of particles of a phase which leads to strengthening of a material by pinning the dislocation and resisting against their movements in a crystal lattice. However, precipitation of some phases such as Laves phase, Sigma and chi has a detrimental effect on hardening of a material and encourages the brittleness. These intermetallic particles are a favorable place for stress concentration and therefore, initiation and propagation of cracks which may lead to fracture of the material. Moreover, presence of these undesirable precipitates could deplete the solute atoms that are contributing in solid solution hardening and therefore reducing the creep strength. This depletion could also result in lower corrosion resistance.

2.3.3 Grain Boundary Strengthening

Grain boundaries act as a barrier to dislocation motion. The size of the grains has an influence on the strength of the material. The smaller the grain size are the larger the grain boundary area will be and consequently more barrier to dislocation movements. The mechanism of grain boundary strengthening is due to the difference in crystallographic orientation within the grains and this means outside each grain boundary there is a different orientation. When a dislocation meet the grain boundary, its direction of motion should change due to the lattice mismatch.

2.3.4 Solid Solution Strengthening

Solid solution strengthening involves addition of other metallic elements to the lattice which results high distortion due to the size difference of the base metal and the solute atoms which reduce the movement of dislocations and cause increase in yield stress of the material. The stress fields around the solute atoms could interact with those of dislocations. The added

10

atoms could occupy two different positions in the crystal structure: Interstitials and Substitution.

Interstitials: interstitial impurities are atoms with smaller size than parent atoms which can occupy the open spaces it the matrix.

Substitution: when the atom of a different type substitute the original atoms in the crystal lattice.

The addition of the alloying element has a limit and beyond that limit the second phase might be created. Therefore, it is important to consider the phase diagram for the desired material and the alloy.

Since the solute atoms (impurities) have different sizes with the matrix atoms, they introduce tensile or compressive lattice strains. They cause disturbance in the regular order of the atoms and make the sliding of the layers more difficult. This leads to higher strength and at the same time less ductility of the alloy than pure metal.

According to Nabarro and Mott approach in 1948 [5], presence of foreign atoms with smaller or larger size than the parent atoms results in a stress field around them which cause an interaction between the foreign atoms and dislocations. This stress field, assumed to vary

from a zero mean value with amplitude τi and wavelength λ which considered to be equal to

the mean space between solute atoms in the volume of the crystal λ= bc-1/3.

Further assumptions made for this model involve closely packed solute atoms that the dislocation cannot move under the internal stress. Due to line tension in dislocations, they are not flexible enough to move corrugated with the wavelength of stress filed. Therefore, the dislocation segments move separately through the stress field (Fig. 2.1).

11

Fig.2.1 Corrugated dislocation in Mott and Nabarro model. The arrows show the direction of internal force on

the dislocation segments in the slip plan [5].

Solid solution hardening depends on different factors including the concentration, shear modulus, size and valence of solute atoms (for ionic materials), and the symmetry of the solute stress field. Experimental observations by Fleischer indicates that the strengthening effect of the solute atoms with significant difference in valence with the parent atoms is more than those with less valency difference [6]. However, he pointed out that in comparison with

modulus mismatch

ε

G = (1/G)(dG/dc) the effect of valency could be negligible.In case of non-symmetric stress fields, solutes can interact with both edge and screw dislocations that results in higher hardening magnitude compare to symmetric stress fields which cause only volume change and not shape change, thus it can only interact with edge dislocations. Dislocation segments with length L >>λ could move independently of their neighboring segments. The randomly exerted force by internal stress on each segment is equal to τibλ .This random force on the length L of the dislocation has a magnitude of τibλ(L/λ)1/2. The dislocation movement will occur when the applied stress is balanced with the random stress as following equation:

Eq. 2.1

12

dislocation could move easily under the mean internal stress:

Eq. 2.2

where E is line energy per unit length of dislocation with a magnitude of Gb2/2, where G is the shear modulus. Presence of solute atoms leads to increase in the strain field which can be introduced by the misfit parameters εb and εG [7]:

Eq. 2.3

Eq. 2.4

In 1970, Labusch [8] noted that the assumption of a uniform dispersion of solute atom could not be correct and apart from dispersion of some single obstacles, groups of closely packed

atoms, clusters, also exist. Thus, the density of the obstacles in the crystal would be fluctuating. In addition to the cluster concept, Labusch has found the interaction force between the solute atoms and dislocations:

Eq. 2.5

In this equation εL is a single misfit parameter which is a Linear combination of size and modulus misfit factors:

εL =[(ε׳G)2+(αεb)2]1/2 Eq. 2.6

where ε׳G = εG / [1+(0.5) |εG| ] and α is equal to ±16 for edge dislocation. The edge dislocations identify the positive or negative sign of α.

13

solution hardening which could be considered as a developed Labusch’s approach [8]:

Eq. 2.7

By using the Labusch-Nabarro theory the following equation for the increase in yield strength due to solid solution strengthening has been obtained [10]:

ΔRp 0.2 = KLN . ε4/3b . c2/3 Eq. 2.8 where KLN is a constant with the value of

Eq. 2.9

m is the Taylor factor for Austenite m=3.06, α set to the value of 16 for edge dislocation. The magnitude of w (interaction distance between solute and dislocation) is set to 5b [11].

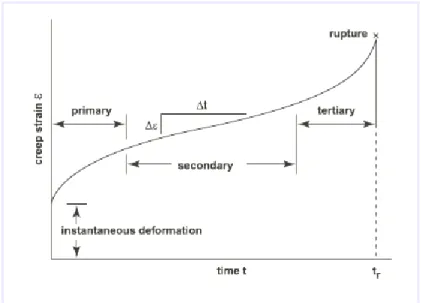

2.4 Creep

Creep is a tendency of a material to deform plastically after long term exposure to high level of stresses even below its yield stress. Creep occurs more often in materials which are used for high temperature applications. However, depending on the material it could happen in lower temperatures as well, but mostly it is negligible. Boilers, gas turbine engines, and furnaces components are examples of systems which may experience creep. There are three different mechanisms which contribute to creep in metals, including:

I. Dislocation creep

II. Diffusion creep

III. Grain boundary sliding

The creep rate is a function of applied stress, temperature time and material properties. By increasing the applied stress and temperature the creep rate will increase.

14

Creep strain vs. time diagram is shown in fig. 2.2. Stage I represent the primary creep where the deformation takes place. Due to the work hardening, the resistance against creep increase and thus, the creep rate decrease in this stage. This trend reaches to a minimum which is the start of stage II (secondary creep). As can be seen in the fig. 2.2 in secondary stage, the creep rate is roughly constant which is a reslt of a balance between work hardening and thermal softening (annealing). In other words, the density of dislocation has reached a point where a constant dislocation density due to work hardening reached to the same level as recovery and annihilation of dislocations. This stage also referred to steady state creep. Secondary creep is the most understood and the longest stage in the creep process.

Fig. 2.2Creep strain as a function of time

The third stage, so called tertiary creep, occurs when the strain rate increase exponentially with stress and happens due to the necking which causes reduction in cross sectional area or due to void formation resulting in effective reduction in area. After this stage the rupture will occur.

2.4.1 Dislocation Creep

At relatively low temperature and under high level of stresses, the dominant creep mechanism is dislocation creep which occurs due to dislocation movements. Dislocations are line defects

15

which can move by gliding in a slip plan in the crystal lattice. In order to reduce the creep rate caused by dislocation creep, there should be some barriers against dislocation motions. These barriers could be solute atoms, precipitates, grain boundaries or other dislocations. Therefore by introducing these obstacles for the dislocations, the creep strength of the metal could be increased. These strengthening mechanisms are including solid solution strengthening, precipitation hardening and grain boundary strengthening.

2.4.2 Diffusion Creep

Diffusion creep occurs due to migration of crystalline defects like vacancies through the lattice which leads to the grain deformations. Diffusion is a temperature dependent phenomenon. By increasing the temperature the diffusivity of a material increases and results in deformation in the material. There are two different types of diffusion creep, first type, so called Nabarro-Herring mechanism, happens when the vacancies migrate through the grains. If the diffusion of vacancies occurs along the grain boundaries, the mechanism is called Coble creep. Diffusion creep is more common in the crystals with small grain size, under low stresses at high temperatures. Since the elongation of the grains under the loading direction occurs on the scale of individual grains, in fine-grained materials, the diffusion distance is less and therefore, the tendency of the material to creep is more prominent. Diffusion creep at low temperatures could be neglected, and thus not participating in the creep process.

2.4.3 Grain boundary sliding

Grain boundary sliding happens under the action of shear stress on the grain boundaries. When the grain boundaries are sliding against each other, the stresses in the boundaries will increase and leads to the formation and growth of the voids. In order to prevent grain boundary sliding the total area of the grain boundaries should be decreased, which means larger grain size or no grains. Moreover, the temperature, shape and orientation of the grains could affect the gliding rate. At higher temperature the gliding rate will increase.

16

2.5 Solid solution strengthening and creep

The alloying elements that are not contributed in precipitation hardening, take part in solid solution strengthening and by lowering the dislocation movements can increase the creep strength. However, the effect of solid solution strengthening on creep is still controversial.

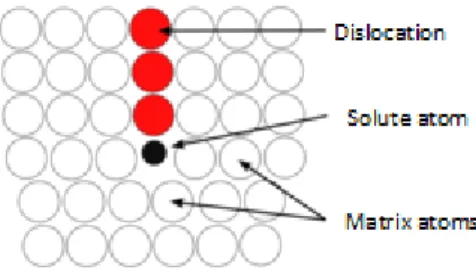

Fig. 2.3 Distortion in a lattice caused by presence of dislocation and solute atom

The stress field around dislocations, is a favorable place for solute atoms. The size differences between solute atoms and the matrix cause a slight distortion in the crystal lattice which creates a stress field around the solutes. When a solute atom diffuses toward a dislocation, it could relax the stress field around the dislocation by creating a Cottrell atmosphere. When the dislocation starts to move, the solute atom gets dragged as well and thus it pins the dislocation by solid solution strengthening mechanism.

When the dislocations start to move, the solute atmosphere attracts to the dislocation and gets dragged due to the formation of Cottrell atmosphere. The interaction energy between a solute atom at position (x,y) and an edge dislocation is given by [12] :

Eq. 2.10

x and y show the position of solute in the glide and climb directions respectively. b is burger’s vector and E is the elastic approximation of the interaction energy between the solute and dislocation and can be expressed as

17

is the atomic volume, is the lattice misfit parameter which is different for each alloying

elements and is Poisson’s number equal to 0.3.When the dislocations are climbing during

creep, their velocity can be expressed as

νclimb= Mclimbbσapp Eq. 2.12

where σapp represents the applied stress and Mclimb the climb mobility and is given by

Eq. 2.13

where is self-diffusion coefficient, T is the absolute temperature and k is the Boltzman

constant (k=1.3806503×10-23 m2kgs-2K-1). When a dislocation is not moving, the

concentration of solute atoms around it can be expressed as

Eq. 2.14

where Ci0 is the concentration of element i in solid solution. According to Hirth and Lothe, the concentration of solute around a moving dislocation with a Cottrell atmosphere can be given by

Eq. 2.15

where Cidyn is the concentration of alloying element i and Di is diffusion coefficient of element i. The solute atoms around a dislocation create a drag force which causes solid solution hardening and can be expressed by the following equation

18

2.6 Effects of solid solution strengthening on creep properties of austenitic

stainless steel

The elements which can contribute in solid solution strengthening of austenitic stainless steel include: tungsten, molybdenum and nitrogen. According to Simmons (1996) [13], by replacing carbon with Nitrogen, high strength austenitic stainless steel can be produced. Nitrogen is a strong austenite stabilizer, therefore the amount of applied nickel for stabilization reduced and consequently the cost of the material will reduce. Moreover, it could reduce the tendency of ferrite and martensite formation. It could also improve corrosion resistance of the steel. Nitrogen can participate in hardening of austenitic stainless steel by occupying interstitial position in the crystal lattice and has greater solid-solubility than carbon and unlike carbon, it reduces the tendency for precipitation. Beside solid solution strengthening, Nitrogen also has positive effect on grain size (Hall-Petch) strengthening.

2.6.1 High nitrogen strengthening

Nitrogen has a beneficial effect on creep strength of austenitic stainless steels in terms of interstitial solute atoms along with precipitation of fine nitrides. Austenitic material are considered high nitrogen when their nitrogen content is about 0.4 wt.% while for ferritic steels this limit is about 0.08 wt.%. High nitrogen alloys have higher tensile strength than the conventional AISI 200 and 300 series. Chromium and Manganese presence in the steel increases the nitrogen solubility while nickel is reducing it. Therefore, for high nitrogen alloying the amount of nickel should be decreased. Ti, Zr, V and Nb also have a positive effect in solubility of nitrogen with a strong tendency to nitride formation.

According to available data, solid solution strengthening by nitrogen has a positive effect on

the creep strength of austenitic stainless steel at temperatures up to 1000ºC.Nitrogen in solid

solution is more effective than carbon at high temperatures. Matsuo et al. [14] studied the effect of solid solution hardening by nitrogen on creep strength of Fe-25Cr-20Ni steels with

different carbon contents (0.008, 0.03 and 0.07wt. %) at 700-1000ºC. They observed that in

the steel with lowest carbon level, increasing nitrogen content in solution results in decreasing the steady state creep rate.

19

Fig. 2.3Ratio of minimum creep rates of alloys with nitrogen to alloys without nitrogen concentration in

Fe-25Cr-28Ni alloys [14].

In the steels with 0.03 and 0.07 carbon concentrations, where the M23C6 precipitates form, the minimum creep rate decreased with increasing nitrogen content. Matsua et al. concluded that at high temperatures up to 1000ºC solid solution strengthening due to nitrogen has a beneficial effect on high temperature creep strength and this strengthening factor is not dependent on carbon content.

The presence of nitrogen as a solute in high nitrogen steels leads to formation of subgrains which results in higher density of uniform distribution of dislocations. High nitrogen steels compared to high carbon steels showed lower minimum creep rates, longer duration of steady state creep and higher rupture strength.

Presence of carbon and nitrogen in the crystal structure results in the lattice distortions which interact elastically with both edge and screw dislocations, and according to most models these interactions are the primary mechanism of strengthening.

2.6.2 Solid solution strengthening by W and Mo

Molybdenum and Tungsten, with high atomic sizes, are two favorable solute atoms for substitutional solid solution strengthening of creep resistance austenitic stainless steels. This

20

effect combined with other hardening mechanisms like precipitation hardening has a beneficial effect on general creep strength of heat resistance steels. In high temperature applications, the amount of W and Mo solute atoms should be limited in order to avoid the formation of Laves phase and increase in precipitation of fine M23C6 carbides.

According to available data in austenitic 23Cr-43Ni (5-7)W, 23Cr-43Ni-(3-5)Mo steels, solid solution strengthening by substitution of tungsten and molybdenum atoms raises the creep strength of these materials. In Mo steel the precipitates are including M23C6 carbides, sigma phase at the grain boundaries and Laves phase inside the grains. In W steel, there is a no precipitation of sigma phase but precipitation of fine M23C6 carbides, Laves phase and MX, which have an important role against dislocation movement [15].

Narita et al. showed that Tungsten could improve the high temperature strength of 9CrODS ferritic steel by solid solution hardening [16]. However, an excess amount of W will cause precipitation of Laves phase which reduces the ductility. They indicated that by increasing Tungsten concentration up to 2% the solid solution strengthening increases as well without Laves phase formation.

Semba et. al showed the effect of W in solid solution in HR6W steel for application in USC boilers in comparison with Alloy 617. They indicated that the tungsten addition combined with laves phase precipitation enhance the creep strength of HR6W steel while keeps stability of austenitic matrix. They have reached to this conclusion by carrying out creep rupture

experiments at different temperatures up to 800°C for hours. They have estimated a

creep rupture strength of 88 MPa at 700°C and 64 MPa at 750 °C for 100,000 hours [17]. Presence of W in a material, eliminates formation of sigma phase which leads to rather stable long-term creep strength and promotes fine dispersion of laves phase which can enhance creep strength by one order of magnitude.

Mimura and Ishitsuka has investigated the effect of Mo in solid solution in NF709 which is a 20Cr-25Ni-1.5Mo-Nb-N austenitic stainless steel. They observed presence of one percent Mo in the alloy after long-term exposure of the material at 615°C which had a beneficial effect on creep strength [18]. A combination of Mo solid solution strengthening and fine dispersion of NbCr nitrides and Nb carbonitrides is the strengthening mechanism in this material. Creep strength of some materials is shown in table 2.1.

21

Table 2.1 105 Creep rupture strength [19],[20].

Material Composition 600 ºC 650 ºC 700ºC

TP316H 16Cr-12NiMo 120 43-78 20-50

Sanicro® 25 22Cr-25NiWCuNbN 285 178 97 NF709 20Cr-25Ni-1.5MoNbTi 170 130 85

22

3. Matrials

In this section the applied materials in the present work are briefly described. This includes

Alloy 316H and Sandvik Sanicro® 25.

3.1 Steel 316H

Type 316H is a high carbon austenitic stainless steel. The increased carbon content in this type compare to type 316, makes this steel suitable for high temperature applications and increases the tensile and yield strength and also the short and long term creep strength. Thus when high temperature strength is required, this steel is recommended. Chemical composition of this steel is shown in table 3.1.

This material has an additional amount of Molybdenum which delivers good corrosion resistance to this steel and slightly improves creep strength of the steel and the austenitic structure promotes the toughness. Presence of 0.8 carbon gives a slight increase to the creep strength. In addition, it has a good weldability and workability characteristic. Solution treatment is one common way for hardening grad 316 austenitic steels [21].

Table 3.1 Chemical composition of steel 316H

C Cr Mn N Ni Si Mo

0.08 17 1.6 0.03 12 0.6 2.5

3.2 Sandvik Sanicro

®25

Sanicro® 25 is an austenitic 22Cr25NiWCoCu stainless steel designed for the next generation

of coal-fired power plants. Its most useful application is in the reheater and superheater tubes, where the material temperatures are up to 700ºC (1290ºF). Application of this material in the power plant, leads to higher efficiency of the boiler and consequently less CO2 emissions. The high temperature resistance of this material results in significant creep strength and corrosion resistance, which are crucial properties for application in the boilers. High structural stability and good fabricability are other characteristics of Sanicro® 25.

23

mechanism in this alloy is achieved by precipitation of fine Nb(C,N), NbCrN, M23C6 and Cu-rich precipitates. Tungsten in solid solution is also added to improve the high temperature resistance. High chromium and low molybdenum content result in excellent corrosion resistance. However, the high chromium and tungsten content promote the formation of sigma-phase, which has negative effects on the mechanical properties. Increasing Ni and N content could modify the detrimental effects of sigma-phase formation [22]. The chemical composition of the steel is shown in table 3.2. Table 2.1 shows the creep strength of these two materials at three different temperatures during 100,000 hours which has been hardened by combination of different strengthening mechanisms.

Table 3.2 Chemical composition of Sanicro® 25 (wt%)

C Cr Ni Si Mn N W Co Cu Nb

24

4. Methods

In the last decade, various simulating software have made a revolution in material science and engineering. In this chapter, the methods used in the present work, are briefly described. This thesis accomplished by using three different simulation software, engineering computations and analysis. The main computational method here was Matlab R2010 (the language of technical computing). In order to run this program there are some parameters in the study equations which are needed to be extracted using other programming software, handbooks and calculations. For thermodynamic calculations, Thermo-calc and DICTRA have been used.

4.1 Matlab Software

MATLAB (a contraction of "Matrix Laboratory") is a high-level language, developed by MathWorks, for numerical computation, plotting of functions, problem solving and data and algorithm development. MATLAB software, solves technical computing problems, faster than other programming environments like Java, Fortran, C and C++. Moreover, it interfaces with programs written in these languages. Using MATLAB, powerful operations can be solved by a simple program containing just one or two commands. For a particular application, one can build desirable set of functions.

The first version of MATLAB was written by Cleve Moler in 1970s. It has since improved into a popular and applicable software [23]. MATLAB is widely used by engineers, scientists and economists. In MATLAB, a one dimensional (n×1 or 1×n)matrix represents a vector, which in the other programming languages an array represents a vector. Fundamental engineering problems based on vector and matrix operation can be solves using MATLAB. MATLAB operate based on highly respected algorithms and generates reliable results. It also provides quality graphic features which can be inserted into word documents or LATEX. In this work, MATLAB was the key software for the main computations.

4.2 DICTRA

DICTRA is a leading software for accurate simulations of diffusion controlled transformations in multicomponent alloy systems. The DICTRA software is functioning based

25

on a mathematical solution of the multicomponent diffusion equations. DICTRA gives the possibility of defining flexible boundary conditions to the user. This software is also capable of solving problems with moving boundary. Using DICTRA, the user could define the boundary conditions.

For thermodynamic calculation, DICTRA requires Thermo-Calc software. Using DICTRA many practical and scientific problems can be simulated including: Homogenization of alloys, Nitriding of steel, nitrocarburization of steel, carburization and decarburization of steel, growth of pearlite in alloyed steels, austenite to ferrit transformations in steel, growth or dissolution of precipitates, coarsening of precipitates, microsegregation during solidification and carburization of high-temperature alloys. The DICTRA software solves the following multicomponent diffusion by use of a diffusivity matrix that is dependent on temperature and concentration:

Eq. 4.1

where is the diffusivity matrix and can be calculated from Thermo-Calc database and the

stored parameter in the mobility database. DICTRA also uses some experimental data that are collected and selected from available literatures. An optimum value for the mobility parameter is evaluated that has the closest value to the experimental data. These optimized values are then saved in the mobility database. Self, intrinsic, tracer and interdiffusion coefficient could be calculated by use of the mobility databases.

4.3 Thermo Calc

Thermo-Calc software uses a combination of thermodynamic and kinetic to predict structure, composition and properties of materials. The classic Thermo-Calc software was developed in 1984 at Royal institute of technology in Sweden. Thermo-Calc has a windows version which provides a user friendly environment for material scientists for operating advanced thermodynamic calculations. Using the Thermo-Calc for windows, multicomponent phase diagrams can be calculated fast and easy.

Thermo-Calc uses highly reliable experimental data available in different references which are accessible during calculation steps. In this work Thermo-Calc for windows version 5 has been used to calculate the mass fraction of alloying elements in solid solution at three

26

different temperatures in the selected austenitic stainless steels. The chosen database was TCFE7 for Fe-alloys. The applied temperatures are the service temperature 700, 800 and 900°C. Some materials like steel 316H has already been defined in the software, but for the rest of the materials, the composition was inserted manually through the periodic table. Choosing the TCFE7 database, the periodic table will only show the elements within this database.

After choosing the compositions, the equilibrium conditions may be inserted in the next window. Weight fraction of the elements, temperature, pressure and total number of moles are some other conditions that need to be added to reach a zero degree of freedom to perform the calculation.

4.4 Lattice misfit parameter calculations

Lattice mismatch is a common phenomenon in stainless steels and it normally happens between the solute atoms or precipitates and the matrix and it is one of the parameters which influence the creep strength of these materials. It also has a considerable effect on their other mechanical properties.

There are several techniques to measure lattice misfit parameter such as X-ray diffraction (XRD), Convergent beam Electron Diffraction (CBED) and also Neutron diffraction (ND).Unfortunately, there are not enough experimental data for the change of lattice parameter with concentration for austenitic stainless steel. Therefore, the value of lattice

misfit parameter is not available as well. For stainless steel, can be calculated using ab

initio calculations.

In section (2.5) an equation for the interaction energy between a solute atom at position (x,y) and an edge dislocation was given (Eq. 2.10). In the equation for the elastic approximation of the interaction energy (Eq. 2.11), εb was introduced. As mentioned earlier, εb is the lattice

misfit parameter. For linear expansion ɛb can be obtained using the following equation:

27

It is also common to characterize concentration expansion using the volume expansion parameter Ω:

Eq 4.3

where Ω is volume expansion parameter, a is lattice parameter of element j (matrix) and c is concentration of element i (alloying element).

For cubic material is three times larger than ɛb

28

5. Results

5.1 Thermo Calc calculations

One of the parameter needed in the MATLAB program was mass fraction of solute atoms in the austenitic matrix, which was calculated by help of Thermo-Calc. In this thesis, the windows version of Thermo-Calc and the database TCFE6 for Fe-alloys was used. Table 5.1

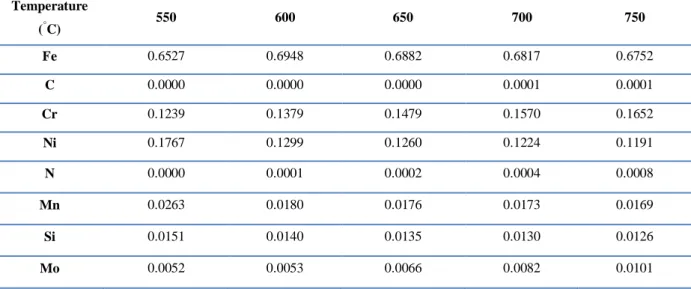

and 5.2 shows the result of this computation for Alloy 316H and Sanicro25.

Table 5.1Mass fraction of solute atoms in Alloy 316H at different temperatures calculated with Thermo-Calc

TCFE6 Temperature (°C) 550 600 650 700 750 Fe 0.6527 0.6948 0.6882 0.6817 0.6752 C 0.0000 0.0000 0.0000 0.0001 0.0001 Cr 0.1239 0.1379 0.1479 0.1570 0.1652 Ni 0.1767 0.1299 0.1260 0.1224 0.1191 N 0.0000 0.0001 0.0002 0.0004 0.0008 Mn 0.0263 0.0180 0.0176 0.0173 0.0169 Si 0.0151 0.0140 0.0135 0.0130 0.0126 Mo 0.0052 0.0053 0.0066 0.0082 0.0101

29

Table 5.2 Mass fraction of solute atoms in at Sandvik Sanicro®25different temperatures calculated with Thermo-Calc TCFE6 Temperature (°C) 550 600 650 700 750 Fe 0.513942 0.507863 0.501656 0.496636 0.492224 Ni 0.311328 0.301545 0.291802 0.282066 0.272884 Cr 0.135096 0.147615 0.159828 0.173910 0.188393 Cu 0.025488 0.028757 0.032344 0.032761 0.031388 W 0.001880 0.002266 0.002728 0.003273 0.003969 Mn 0.006746 0.006550 0.006339 0.006116 0.005898 Si 0.005414 0.005241 0.005060 0.004878 0.004698 Nb 0.000024 0.000032 0.000042 0.000054 0.000068 N 0.000003 0.000009 0.000022 0.000058 0.000143 C 0.000001 0.000003 0.000008 0.000019 0.000043

5.2 DICTRA calculations

In order to compute equations for climb mobility and the concentration of solute around a

moving dislocation , the self-diffusion coefficient and diffusion coefficient of solute

atoms in the matrix need to be calculated. For this purpose, DICTRA software version 26

has been used.

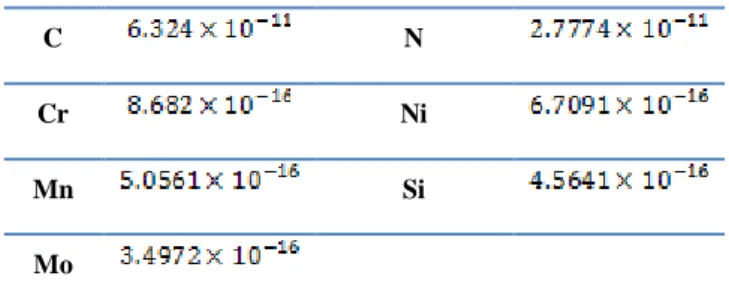

The chemical composition and temperature are the only required parameters for this computation. Table 5.3 shows the result of this calculation for 700°C.

Table 5.3 Diffusion coefficient (m2/S) of alloying elements in steel 316H at 700°C.

C N

Cr Ni

Mn Si

30

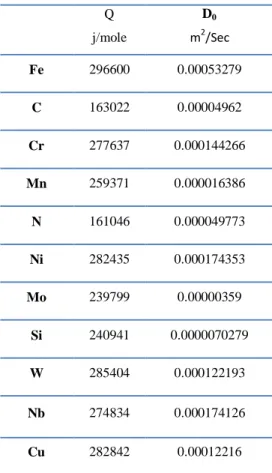

Diffusion coefficient can be best described by following equation:

Eq 5.1

where D0 is a frequency factor and Q is the activation energy. These values were calculated for both 316H and Sanicro 25 (Table 5.4 and 5.5).

Table 5.4 Diffusion coefficient and activation energy for 316H

Q j/mole D0 m2/Sec Fe 293305 C 164690 Cr 278960 Mn 259558 N 161979 Ni 286512 Mo 239799 Si 242999 W 279981

31

Table 5.5 Diffusion coefficient and activation energy for 316H

Q j/mole D0 m2/Sec Fe 296600 0.00053279 C 163022 0.00004962 Cr 277637 0.000144266 Mn 259371 0.000016386 N 161046 0.000049773 Ni 282435 0.000174353 Mo 239799 0.00000359 Si 240941 0.0000070279 W 285404 0.000122193 Nb 274834 0.000174126 Cu 282842 0.00012216

5.3 Lattice misfit parameter calculations

The value of ɛb for some materials can be found in Pearson’s handbook. In this thesis the

value for the ɛb and then have been calculated for steel 316H as the base alloy and is shown in table 5.6 (by Pavel Korzhavyi). The chemical composition of the alloy and temperature are two required parameters for this calculation. The calculation has been made at 1000°K (727°C), including electronic and magnetic thermal excitations.

In order to calculate the values for lattice misfit parameters, the volume expansion parameter Ω was used. To obtain this parameter, the Gibs free energy as a function of lattice volume expansion for FeCrNi alloy was sketched. The minimum point of the curve shows the value

32

individual element was calculated. Then the value for has been obtained using equation

4.3. The relation between for cubic materials was given by equation 4.4.

Table 5.6 Lattice misfit parameter for Alloy 316H

Cr Ni Mo Cu Mn Nb P Si W

-0.0029 0.0118 0.1848 0.0638 0.0134 0.2514 -0.0116 0.0152 0.2117 -0.0089 0.0355 0.5546 0.0638 0.0402 0.7543 -0.0349 0.0458 0.6351

5.4 Matlab calculations

In order to adapt the model in the previous work [12] to stainless steel, Equations 2.14, 2.15 and 2.16 has been simulated using MATLAB program. The simulation was done for two materials: Alloy 316H and Sanicro 25 at five different temperatures: 550, 600, 650, 700 and

750ºC. Chemical compositions of the materials (tables 3.1 and 3.2), mass fraction of fcc phase

(tables 5.1 and 5.2) , diffusion coefficient and interaction energy (tables 5.4 and 5.5) and also lattice misfit parameter (table 5.6) are the inputs of the program. The simulation has been done for both climbing and gliding dislocations in y and x direction respectively. For Alloy 316H, the effects of Cr and Mo and for Sanicro 25, the effects of W, Nb and Cr have been investigated.

Figures 5.1 and 5.2 present the interaction energy between a dislocation and solutes in Sanicro 25 as a function of y-coordinate for a climbing dislocation and x-coordinate for a gliding dislocation. These illustrations have been made according to equation 2.10. The length unit is in Burgers vector. The simulation was done at five different temperatures. However, interaction energy is not strongly dependent on the temperature. According to equation 2.10 interaction energy is only dependent on temperature trough shear modulus. Figure 5.1 shows the result at 750°. For Sanicro 25, Cr, Nb and W were the selected elements which participate in the solid solution strengthening. W and Nb were selected due to their large misfit parameter and Cr was chosen due to its high concentration in the material. In case of Alloy 316H, Mo and Cr were selected. Mo also have a large size misfit.

33

dislocations (y>0) with a positive interaction energy and blew the dislocation (y<0) with a negative interaction energy (fig 5.1a). For a gliding dislocation the interaction energy is negative. W and Nb atoms, with larger atomic size than the matrix atoms, are first repelled below the edge dislocation (x<0) and then they are attracted to the dislocation at x>0 (fig. 5.1b).

a b

Fig. 5.1 Interaction energy between a dislocation and solute atoms as a function of distance between them at

750°C inSanicro 25: (a) climb and (b) glide.

Close to the dislocation core, interaction energy would approach to infinity. To avoid this

situation, a core radius equals to 2/3 is chosen to approach a reasonable value for interaction

energy which has an agreement with the binding energy.The difference between interaction energy for different elements is due to variation in their lattice misfit parameter (table 5.6). Cr, with a negative misfit parameter, shows an inverse result for both climbing and gliding dislocations (Fig 5.2).

34

a b

Fig. 5.2 Interaction energy between a dislocation and a Cr-atom as a function of distance between them at 750°C

in Sanicro 25: (a) climb and (b) glide

In Alloy 316H, Mo with different size misfit shows the same trend as W and Nb in Sanicro 25 but different values for interaction energy in both climb and glide (Fig 5.3). Cr with a negative misfit parameter again presents an inverse trend (Fig 5.4).

a b

Fig. 5.3 Interaction energy between a dislocation and a Mo-atom in Alloy 316H as a function of distance between them at 750°C In Alloy 316H: (a) Climb (b) glide.

35

a b

Fig. 5.4 Interaction energy between a dislocation and a Cr-atom in Alloy 316H as a function of distance between them at 750°C: (a) Climb (b) glide.

Figure 5.5 shows the predicted concentration profiles for a climbing dislocation at 550 and 750°C. These figures are illustrated according to equations 2.14 and 2.15 for static and dynamic dislocations respectively. Applied stress of 100 MPa, interaction energy and climb velocity are needed for this computation. The dislocation climb velocities used in this simulation are shown in table 5.7. According to this table, the dislocation climb velocity is increasing by elevating the temperature.

Table 5.7 the velocity (m/s) of climbing and gliding dislocation

Temperature (°C) 550 600 650 700 750

Vclimb Vglide

As can be seen in these figures, concentration of solutes in front of dislocation is trough with a peak behind it. Here again, the difference in the graphs for different elements is due to the difference in size misfit parameter. In case of Cr, lattice misfit parameter has a negative value, therefore it shows an inverse trend compare to W and Nb. The difference between the static and the dynamic curves is that in dynamic case, the peak and trough are more pronounced. As can be seen, by increasing the temperature, the height of the peak is decreasing. The peak around the dislocation is higher in the dynamic case than in the static one for y>0 and it is opposite for y<0.

36

Fig. 5.5 Concentration c/c0 of solute atoms in sanicro® 25 relative to the equilibrium value as a function of

37

For a gliding dislocation equation 2.15 is again used but the integration was taken along the x-coordinate and the interaction energy is different. Predicted concentration profile for gliding dislocation is presented in figure 5.6 at 750°C. As can be seen for the glide case, the solute atoms are concentrated on the dilatation side of the dislocation and at distances (y) away from

the dislocation, the solute concentration approaches to equilibrium values. The highest

concentration belongs to Nb, followed by W and Cr. By getting away from dislocat ion, the concentration is getting close to the equilibrium values. Compare to climbing dislocation, the

concentration of solutes around a gliding dislocation is more pronounced. The computed

dislocation glide velocity was the same at both temperatures (table 5.7).

a b

C

Fig. 5.6 Concentration c/c0 of solute atoms in sanicro® 25 relative to the equilibrium value as a function of

38

Figure 5.7 shows the results of simulated concentration profile for Alloy 316H for both Mo and W at 550 and 750ºC.

a b

Fig. 5.7 Concentration c/c0 of solute atoms in Alloy 316H relative to the equilibrium value as a function of

39

a b

Fig 5.8 Concentration c/c0 of solute atoms Alloy 316H relative to the equilibrium value as a function of distance

between solutes and a gliding dislocation in x-direction at 750°C. (a)Cr and (b) Mo.

As mentioned earlier, the solute atoms around a dislocation form a Cottrell atmosphere which creates a drag force that impede the dislocation and increase the strength (Eq. 2.16). Therefore, the value of the drag force can determine the ability of solutes in strengthening. The higher the drag stress is, the more effective the solute would be in solution hardening. Figures 5.9 and 5.10 show the drag stresses created by the elements in solid solution at different temperatures for Sanicro 25 and Alloy 316 for both climbing and gliding dislocations. The computed drag stresses are shown in tables 5.8 - 5.11. The values of the drag force are dependent on the diffusion rate and the size misfit of the elements. Higher diffusion rate causes lower drag force and larger misfit parameter leads to higher drag stress. Since the diffusion rate increases by increasing temperature, a decrease in the drag stress at elevated temperatures can be predicted.

In Sanicro 25, Cr seems to have the lowest value of drag stress due to its rapid diffusion rate while W shows the highest value among all. The negative sign in Cr data is again due to the negative size misfit. For a gliding dislocation these values are even smaller than climbing case (table 5.9).

40

a b

Fig. 5.9 Drag stress of solutes in Sanicro® 25as a function of temperature: (a) climb and (b) glide

The effect of temperature on the drag stress is more remarkable. W has a decreasing trend by increasing temperature. At higher temperatures, diffusion rate is increasing which leads to

lower drag stress in W and would lead to decrease in W strengthening effect. The other two

elements do not show any significant changes by temperature which might be due to their high diffusion rate at all these operating temperatures.

Table 5.8 Drag stress (MPa) values assessed from profile in fig. 5.9(a)

Temperature (°C ) W Nb Cr 550 2.0199 0.0052703 -0.00092675 600 1.6097 0.0050936 -0.0010978 650 1.3435 0.0050419 -0.0012722 700 1.1633 0.0050577 -0.0014631 750 1.0531 0.0051111 -0.0016646

41

Table 5.9 Drag stress (MPa) values assessed from profile in fig. 5.9(b)

Temperature (°C ) W Nb Cr

650 1.0332 0.018658 -0.00063959 700 0.14662 0.0023813 -0.00014486 750 0.02258 0.00036438 -0.000012

In Alloy 316H, for both gliding and climbing dislocation the same decreasing trend as Sanicro

25 is observed (Fig5.10). Tables 5.10 and 5.11 present the computed values for the drag stress for Alloy 316H.

a b

Fig. 5.10 Drag stress of solutes in Alloy 316Has a function of temperature: (a) climb and (b) glide

Table 5.10 Drag stress (MPa) values assessed from profile in fig. 5.10(a)

Temperature (°C ) Mo Cr 550 3.16195 -0.0013764 600 2.04991 -0.00157953 650 1.71511 -0.00173563 700 1.49967 -0.00187976 750 1.35089 -0.00200997

42

Table 5.11 Drag stress (MPa) values assessed from profile in fig. 5.10(b)

Temperature (°C ) Mo Cr

650 1.90971 0.00020371 700 0.266181 0.000033911 750 0.041144 0.0000071457

According to given data in Alloy 316H, Mo shows higher drag stress than Cr, which indicates higher solid solution strengthening effect.

43

6. Discussions

In order to investigate the effects of solid solution strengthening on creep properties of austenitic stainless steel, the results of previous work [12],[24] have been used. The effects of phosphorus on creep in copper and the influence of Laves phase on the creep properties in 9% Cr steels were modeled in the prior work. The attempts have been made to adapt these models to austenitic stainless steel. The selected austenitic steels were including: Sanicro 25 and Alloy 316H.

The presence of a dislocation causes a distortion in the crystal lattice which creates a stress field around it. This stress field is a favorable place for the solutes that can relax the stress with their size differences. This accumulation of solutes creates a so-called Cottrell atmosphere. Consequently, the edge dislocation would become more resistance to move even in the original glide plan which raises the strength as the accumulated solutes get dragged. This phenomenon was simulated using diffusion equations. The simulation results show a high concentration of solute atoms close to the dislocation due to the formation of Cottrell atmosphere. Interaction energy between solute atoms and dislocation as a function of the distance between them has different forms in glide and climb position and it shows a higher concentration of solutes around the dislocation in glide direction compared to climb.

In case of Sanicro 25, W and Nb make the largest misfit. The mobility of W is less than Nb while it has more concentration. Thus, it has the most contribution in solid solution strengthening. Concentration of Cr is the highest compare to W and Nb but it has a very small misfit parameter and weakly contributes to the creep strength. In Alloy 316H, the addition of Mo and Cr was observed. Mo, with higher interaction energy and larger size misfit shows higher contribution in creep strength than Cr.

By increasing temperature the drag stress has decreased for all elements in both steels which could be attributed to the growth of Laves phase that leads to depletion of solute atoms in the matrix and reduces the effect of solid solution hardening.

44

7. Conclusions

The effect of solute atoms on creep strength of Sanicro 25 and Alloy 316H was analyzed. The interaction energy between solutes and dislocation as a function of distance between them for both climbing and gliding dislocation was simulated. Phase fraction and diffusion coefficient was predicted by thermodynamic modeling. Lattice misfit parameter was computed using ab-initio calculations. The concentration of solutes (W, Nb and Cr for Sanicro 25 and Mo and Cr for Alloy 316H) around an edge dislocation has been modeled for both non–moving and moving dislocations. The drag stress created by solutes has been predicted.

The accumulation of solutes around the strain field of the dislocation forms a Cottrell atmosphere that decreases the climb mobility and takes part in strengthening. The solute atmosphere is larger for the glide than the climb case. The size difference of the solutes and the parent atoms give rise to the strain field which increases the strength. This has been proved by the values of the drag stress. Higher drag force of the solutes as a function of

temperature, indicates the highest contribution in strengthening. InSanicro 25, W with largest

misfit parameter shows the highest deviation from equilibrium concentration and has the largest values for the drag stress. In terms of Alloy 316H, Mo, with higher drag stress than Cr, presents better contribution in creep strength. The decrease in drag stress by temperature can be related to the growth of laves phase.

45

References

1. Ultra super critical boilers, Burmeister and Wain, 2010

2. R. Viswanathan-EPRI, Effect of Creep in Advanced Materials for Use In Ultrasupercritical Coal Power Plants, 2009

3. R.A. Lula, Stainless Steel, American Society for Metals, 1986.

4. Distribution of solute atoms around a moving dislocation, F.R.N. Nabarro, 2005, University of Witwatersrand

5. N.F. Mott and F.R.N. Nabarro, Report of a conference on the strength of solids, 1948, p.1. R.L.

6. Fleischer, Acta metal. 11 (1963) 203.

7. M.Z. Butt, P.Feltham, J. Mater, Sci. 28 (1993) 2557-2576 8. Idem, Acta Metal. 20 (1972) 917.

9. F.R.N. Nabarro, Phill. Mag. 35 (1977) 613.

10. H. Sieurin, J. Zander, R. Sandström, Mater. Sci. Eng. A 415 (2006) 11. M.L.G. Byrnes

12. floRSandström, Henrik C.M. Andersson, The effect of phosphorous on creep in copper, Royal Institute of Technology, Sweden, 2008

13. J.W. Simmons, A207 (1996) 159-169.

14. T. Matsuo, N. Morioka, S. Kaise, M. Kikuchi and R. Tanaka,Effect of nitrogen on creep deformation of 25Cr-28Ni austeniticsteels - solid solution strengthening due to nitrogen, in J. Foctand A. Hendry (eds.), HNS 88, Lille, France, May 1988, TheInstitute of Metals, London, 1989, p. 213.

15. F. ABE, Strengthening mechanisms in steels for creep and creep rupture, National Institute for Material Science (NIMS), Japan

16. T. Narita, S. Ukai, Effect of tungsten addition on microstructure and high temperature strength of 9CrODS ferritic steel, Hokkaido University, Japan, 2011

17. Hiroyuki Semba, HirokazuOkada,Semba, H., Okada, H., 2008, Creep properties and strengthening mechanisms in HR6W alloy and Ni-base superalloys for 700°C , A-USC boilers advances in material technology for fossil power plant – Proceeding from 6th International Conference

46

18. Mimura, H., Ishitsuka, T., 2008, Properties of 20Cr-25Ni-Mo-Nb-N steel tubes exposed in sddystone unit no.1 boiler for 75,000 hours. 8th international Conference on Creep and Fatigue at Elevated Temperatures

19. Landolt-Bornstein, creep properties of heat resistance steels and superalloys, Group VIII, Vol. 2, Subvolume B, 2004

20. J Hogberg, G. Chai, P Kjellstrom, M Bostrom, U Forsberg, R Sandström, Creep behavior of the newly developed advanced heat resistant austenitic stainless steel Grade UNS S31035,ASM 2010 Pressure Vessel & Piping Conference, 2010

21. ASM handbook, Vol. 1. Material design

22. R. Rautio, Tillverkning av Sanicro 25 via CLU, No. 050535TE.doc

23. David F. Griths, An Introduction to Matlab Version 2.3 , Department of Mathematics, The University Dundee DD1 4HN With additional material by Ulf Carlsson, Department of Vehicle Engineering KTH, Stockholm, Sweden

24. Hans Magnusson, Rolf Sandström, Modelling of the influence of laves phase on the creep properties in 9% Cr steels.

![Fig. 2.3Ratio of minimum creep rates of alloys with nitrogen to alloys without nitrogen concentration in Fe- Fe-25Cr-28Ni alloys [14]](https://thumb-eu.123doks.com/thumbv2/5dokorg/4279972.95203/20.892.265.609.148.514/ratio-minimum-alloys-nitrogen-alloys-nitrogen-concentration-alloys.webp)

![Table 2.1 10 5 Creep rupture strength [19],[20].](https://thumb-eu.123doks.com/thumbv2/5dokorg/4279972.95203/22.892.219.677.179.381/table-creep-rupture-strength.webp)