i

PAPER WITHIN Production Systems AUTHOR: Daniel A. de los Rios Pérez JÖNKÖPING June 2021

A system dynamic

approach for

manufacturing

reshoring

decisions

ii

subject area of Production systems with a specialization in production development and management. The work is a part of the Master of Science program. The author takes full responsibility for opinions, conclusions, and findings presented.

Examiner: Kerstin Johansen

Supervisor: MovinSequeira

Scope: 30 credits (second cycle)

iii

Acknowledgment

Pursuing a master's degree has been a longed-for step in my professional career. Many steps got in the way before even start it and many are waiting to continue a career that I love.

Many people have been part of this result.

First, I am very grateful to Movin Frank Sequeira for being my supervisor and foremost for becoming my friend. Movin, your support and guidance during the master's, and especially in this thesis have been a big part of this result. Your knowledge in research methodology and supervision proves that you are an excellent researcher and professional.

Thanks to Gary Linnéusson for his knowledge, advice, and enjoyable talks about system dynamics and VENSIM modeling. I also would like to thank Amir for his valuable time and inputs shared.

Thanks to my classmates that participated in thistwo-yearjourney with me, and to our teachers that shared their knowledge with us.

Finally, the most important thanks go to my family. To my parents for being my example to follow of effort, perseverance, and success. A mi abuela, por su cariño constante. To Yinef, thanks for your love, for being my support and companion in many adventures like this one. To Allan, because your smile boosted my energy and lighted up my work nights.

iv

All decisions are based on models (...) and all models are wrong.

v

Abstract

During the last two decades, many companies have reshored their manufacturing operations to the home country, reversing previous offshoring decisions. Reshoring is a strategic decision for manufacturing companies because it is costly, complex, dynamic; thus, it is an important topic for research. Nevertheless, there is a research gap in how reshoring decision-making process is modeled. Therefore, the overall purpose of this research is to increase the understanding of reshoring decision-making process. The purpose is fulfilled through two research questions: (1) what is the state-of-the-art of reshoring making process? and (2) how the reshoring decision-making process can be explored using a system dynamics model? The research design includes a literature review, modeling, and an expert interview.

The findings indicate that the state-of-the-art of reshoring decision-making process comprises the drivers, barriers, and other factors are variables that motivate or hinder reshoring decision-making. However, their behavior varies over time and context. Environment and sustainability topics are not completely neglected in the decision-making process. Nevertheless, they are not a priority in reshoring decisions. The developed system dynamics model identifies relationships between the variables of reshoring decisions and how one variable can have a cause-and-effect relationship with another. During modeling of the reshoring decision-making, the complexity considerably increases as more variables are considered in the model. The developed system dynamics model provides a holistic view of the variables, their relationships, dynamics, and the overall complexity of the reshoring decision-making process. The research has implications for researchers because it increases the understanding of reshoring decision-making concerning the variables involved and relationships among them. Furthermore, this research contributes to the overall topic of reshoring by addressing modeling aspects. The research has implications for practitioners because it contributes to increasing the practitioners’ visualization of the decision-making, which can be used to communicate with various stakeholders. In order to advance this highly relevant field, it is recommended to quantify relationships among the variables that the developed system dynamic model can be simulated.

Keywords

Reshoring, modeling, system dynamics, manufacturing, decision-making, location decisions

vi

Contents

1

Introduction ... 1

1.1. BACKGROUND ... 1

1.2. PROBLEM DESCRIPTION ... 2

1.3. PURPOSE AND RESEARCH QUESTIONS ... 2

1.4. DELIMITATIONS ... 3

1.5. OUTLINE ... 3

2

Theoretical background ... 4

2.1. RESHORING CONCEPTS AND TERMINOLOGY ... 4

2.2. DRIVERS AND BARRIERS OF RESHORING ... 5

2.3. SYSTEM DYNAMICS ... 6

3

Research Methods ... 8

3.1. RESEARCH DESIGN ... 8 3.2. LITERATURE REVIEW ... 8 3.2.1. Data collection ... 10 3.2.2. Data analysis ... 13 3.3. MODELING ... 15 3.4. EXPERT INTERVIEW ... 17 3.4.1. Data collection ... 17 3.4.2. Data analysis ... 17 3.5. RESEARCH QUALITY ... 183.6. ETHICS AND MORALE ... 19

4

State-of-the-art of reshoring decision-making process ... 20

4.1. DATA AND INFORMATION COLLECTION ... 20

4.1.1. Drivers of reshoring decision-making process ... 20

4.1.2. Barriers of reshoring decision-making process ... 21

vii

4.2. BUILDING UP THE CONCEPTUAL MODEL ... 21

4.2.1. Variables for building up the model ... 22

4.2.2. Heuristics for building up the model ... 23

5

Exploring reshoring decision-making process ... 26

5.1. MODELING METHOD AND SIMULATION TOOL ... 26

5.2. SYSTEM DYNAMICS MODELING USING CAUSAL LOOP DIAGRAMING ... 26

5.2.1. Reinforcing feedback loops ... 28

5.2.2. Balancing feedback loops ... 29

5.2.3. Open loops and conflicting variables ... 29

5.3. MODEL VERIFICATION ... 30

5.3.1. Expert and company description ... 30

5.3.2. Variables considered in reshoring decision-making process ... 31

5.3.3. Heuristics considered in reshoring the decision-making process ... 32

6

Discussion ... 34

6.1. DISCUSSION OF THE RESEARCH DESIGN AND METHODS ... 34

6.1.1. Literature review ... 34

6.1.2. Modeling ... 34

6.1.3. Interview ... 35

6.1.4. Research process and design ... 35

6.2. DISCUSSION OF FINDINGS ... 36

6.2.1. Reshoring decision-making process ... 36

6.2.2. Variables involved in the model ... 37

6.2.3. Heuristics involved in the model ... 38

6.2.4. Complexity in the modeling ... 40

6.2.5. Variables that lack attention ... 41

7

Conclusions ... 44

7.1. WHAT IS THE STATE-OF-THE-ART OF RESHORING DECISION-MAKING PROCESS? 44 7.2. HOW RESHORING DECISION-MAKING PROCESS CAN BE EXPLORED USING CAN A SYSTEM DYNAMICS MODEL? ... 44

viii

7.3. IMPLICATIONS AND FUTURE RESEARCH ... 45

8

References ... 46

9.

Appendices ... 52

APPENDIX 1:SEARCH TERMS COMBINED WITH BOOLEANLOGIC ... 52

APPENDIX 2:ARTICLES IN THE FINAL SAMPLE AND ITS JOURNALS'IF ... 55

APPENDIX 3:INDUSTRY EXPERT INTERVIEW QUESTIONS ... 56

1

1 Introduction

This chapter introduces the research. First, it provides a background of the research. Next, it describes the problem, followed by purpose and research questions. Next, it provides the delimitations and finally presents an outline of the remainder of the report.

1.1. Background

In the past four decades, globalization has led to geographically dispersed markets and suppliers (Brennan et al., 2015), transforming the manufacturing industry. As a result, manufacturing companies, irrespective of size and sector, have moved their manufacturing operations from high-cost countries to low-cost countries. This phenomenon is termed offshoring, and it is mainly a location decision (Eriksson et al., 2018; Gray et al., 2017; Zhai et al., 2016). As a result, many studies related to offshoring location decisions have been carried out by researchers (Grossman & Rossi-Hansberg, 2008; Hätönen & Eriksson, 2009; Kedia & Mukherjee, 2009). Furthermore, tools, for instance, the center-of-gravity factor-rating method, the locational break-even analysis, the geographic information system, and regression models have been explored to support these decisions (Barry et al., 2005).

However, during the last two decades, a reversal of these offshoring decisions has been carried out by companies within the manufacturing industry. Furthermore, different situations, for example, the Covid-19 pandemic, have shown how supply chains can be vulnerable, leading to an interest in locating in the home country (Strange, 2020). The phenomenon of returning the operations to the country of originis termed reshoring (Gray et al., 2017). To put this quantitatively, between 16-25% of offshoring decisions were reversed within 4-5 years. Furthermore, another 15% reversed offshoring decisions after five years in a sample of 1663 companies (Kinkel & Maloca, 2009). Reshoring is observed in high-cost countries like Germany and Sweden, where most activities come from formerly low-cost countries like China and the new EU-member states (Johansson & Olhager, 2018b; Kinkel & Maloca, 2009). In Sweden, 75% of reshoring activities have come from Europe (Johansson & Olhager, 2018b). Meanwhile, in Germany, 55% of reshoring activities have come from the new EU members (Kinkel & Maloca, 2009). Therefore, the reshoring topic is highly relevant for high-cost countries.

The reshoring topic is relevant for practitioners, irrespective of the size of the industry or country of origin. This is because it is a costly, complex, and strategic decision (Barbieri et al., 2018; Grappi et al., 2020; Wiesmann et al., 2017). It involves investments in production resources (Lampón & González-Benito, 2020). This demands a long-term perspective and a thorough analysis. Next, the reshoring topic is relevant for researchers because it is shaping the global manufacturing footprint (Johansson & Olhager, 2018b). However, acknowledging the novelty of the topic, there is a need to develop theories to explain reshoring in high-cost countries.

2

1.2. Problem description

The main focus for researchers has been in addressing the reasons for reshoring, specifically the drivers/barriers perspective (Barbieri et al., 2018; Foerstl et al., 2016; Wiesmann et al., 2017). Furthermore, researchers have also covered the expected and achieved outcomes of reshoring (Vestin & Sequeira Frank, 2017). However, the issue that is largely unexplored in research is the reshoring decision-making process (Barbieri et al., 2018). A probable reason for this is the novelty of the topic and that the reshoring research has not matured concerning the decision-making process. Therefore, there is a need to study the reshoring decision-making process.

Moreover, it is important to highlight that majority of the research methods devoted to reshoring decision-making are related to conceptualization, theoretical frameworks, case studies, and literature reviews. There are limited models that have been developed within academia (Wiesmann et al., 2017). For instance, until 2017, only seven studies implemented mathematical modeling as a research method (Barbieri et al., 2018). Therefore, there is a research gap in the modeling of the reshoring phenomena. Modeling refers to representing the real world to understand how "something" works (Bertrand & Fransoo, 2002). Thus, in order to understand the reshoring decision-making process, more modeling methods need to be explored.

The reshoring decision-making process is complex (Barbieri et al., 2018; Grappi et al., 2020; Wiesmann et al., 2017). There is recent evidence that the decision-makers do not follow a systematic process, but rather it is based on the preferences of the decision-makers (Gray et al., 2017). Therefore, a behavioral style of making decisions (or heuristics) also needs to be accounted for in the modeling process. One way to understand this heuristic style of making decisions is to employ system dynamics (Boffelli et al., 2020). System dynamics models were developed for solving dynamic and complex problems in the real world (Pruyt, 2013; Sterman, 2002), for example, environmental issues, military issues (Forrester, 2007), health care issues (Dangerfield, 1999), maintenance performance (Linnéusson, 2018), value stream mapping and lean thinking (Noto & Cosenz, 2020). Therefore, a system dynamics model is considered appropriate to understand the reshoring decision-making process.

1.3. Purpose and research questions

Three relevant issues are described in the background and problem description. First, manufacturing companies are often faced with the challenge to make a complex reshoring decision. Second, there is a limited understanding of the reshoring decision-making process. Thirdly, limited modeling studies have been conducted that give insights into the decision-making process. Based on the three issues, the purpose of this research is:

"To increase the understanding of reshoring decision-making process."

To fulfill the purpose, two research questions (RQ) are specified. The first research question will investigate the current state of knowledge of how managers make reshoring decisions. Therefore, RQ 1 is:

3

RQ 1: What is the state-of-the-art of reshoring decision-making process?

Next, the second research question strives to fulfill the purpose by exploring a specific modeling method that incorporates the heuristic style of the reshoring decision-making process. Despite decision-making being supported by various models, reshoring decisions are not always based on the best available models. Furthermore, the complexity and dynamics in reshoring decision-making process contribute to a narrow view of the issue. Therefore, the second research question serves to use system dynamics to understand the reshoring decision-making process. The RQ 2 is:

RQ 2: How the reshoring decision-making process can be explored using a system dynamics model?

To answer RQ 1 and RQ 2, and thus fulfill the purpose of the study, a literature review, modeling, and an interview were conducted. The literature review is used to identify the variables for the model, while the developed model is verified by an expert interview.

1.4. Delimitations

The research will focus on reshoring of manufacturing activities, and all the other non-manufacturing activities such as R&D, IT, and administrative services will be excluded. Furthermore, the research is not limited to the size and type of manufacturing company concerned with reshoring, due to the novelty of the topic. Within decision-making literature, system dynamics modeling will be the focus of this research. Given the time and data limitations to carry out this study, the modeling method will only include the development of a system dynamics model. The simulation of the model is excluded due to the limitation of obtaining quantitative data. The verification of the model is done by interviewing an industry expert. However, validation of the model with multiple companies or decision-makers will not be included.

1.5. Outline

The report is organized as follows. Chapter 2 provides the background on the topic used as the foundation for conducting the research. Chapter 3 describes the research method that comprises the literature review, modeling, and interview. Moreover, it presents the research quality, ethics, and morale that was ensured during the research. Chapter 4 presents the main findings of the state-of-the-art of reshoring the decision-making process. It includes the variables and heuristics for modeling based on evidence found in the literature. Next, Chapter 5 shows how the reshoring decision-making process was explored using system dynamics modeling. It includes the development of a system dynamics model for reshoring. Further, Chapter 6 discusses the method and the main findings of this research. Finally, in Chapter 7, conclusions of this research are presented together with implications and future research.

4

2 Theoretical background

This chapter provides a background of the concepts used in this research. It starts with unfolding some concepts and main terminology related to reshoring. Then it provides a background of drivers and barriers together with existing methods of decision-making. The chapter ends by introducing system dynamics, its practical applications, and the main parts of a system dynamics model.

2.1. Reshoring concepts and terminology

International location decisions for manufacturing activities were enabled mainly due to increased international trade and globalization (Schmidt et al., 2017). The change of location of firm manufacturing activities from their home country to a foreign country is termed as an offshoring location decision (Baraldi et al., 2018). If an international location decision results in the destination country differing from a previous offshoring decision, then this decision is termed as a second-degree relocation (Barbieri et al., 2019). Within second-degree relocations, if the choice is to move the manufacturing activities to a second host country, then this decision is a further-offshoring or third-degree relocation, as defined by Barbieri et al. (2019). On the other hand, if the relocation is to the home country (Barbieri et al., 2019), and the result of the relocation is reversing earlier offshoring decision (Gray et al., 2017) to return the operations to the country where its parent company is located (Ellram, 2013; Tate et al., 2014), then this process is termed as reshoring.

Several terms were used to describe reshoring. For instance, back-shoring, back reshoring, back-sourcing, and repatriation (Barbieri et al., 2018). Furthermore, Fratocchi et al. (2016) add the terms on-shoring, in-shoring, and nearshoring as keywords in their research related to reshoring, considering the various governance modes (either in-sourcing or out-sourcing). Even general terms such as manufacturing relocation have been used (Hartman et al., 2017). The terms that describe reshoring and its sources are summarized in Table 1. Nevertheless, the terminology is becoming clearer and uniform (Barbieri et al., 2018), as reshoring and backshoring became the two most dominant terms in this field of research (Dachs et al., 2019). The terms are described in Table 1. Among all the different terms, the term used in this thesis is 'reshoring’.

5

Table 1: Terms used to describe reshoring

Terms Description Source

Reshoring “reversing earlier offshoring decisions and reshoring from low-cost countries back to high-cost countries”.

“moving manufacturing back to the country of its parent company”.

“a company decision to bring production or sourcing back to their home country”.

Gray et al. (2017), p. 46

Ellram (2013), p. 3 Fratocchi et al. (2016), p. 99

Backshoring “indicates a relocation back to the firm's home country of origin”.

“the company decision to relocate activities back to the home country regardless of the ownership of the activities relocated”.

Johansson and Olhager (2018b), p. 37 Stentoft et al. (2016), p. 54

Back-reshoring "it is the reverse decision with respect to a previous off-shoring process (...) it is essentially a decision to relocate, irrespective of the ownership mode (in-sourced and out-sourced) in the offshore country."

Fratocchi et al. (2014), p. 56

Onshoring "making its high-fashion clothes [products] in Spain [country of origin] itself"

Jung (2020), p. 751

Inshoring "refers to intermediates sourced from the country of interest by other countries (...), involves the export of intermediates to other countries."

Foster-McGregor and Pöschl (2015), p. 147

2.2. Drivers and barriers of reshoring

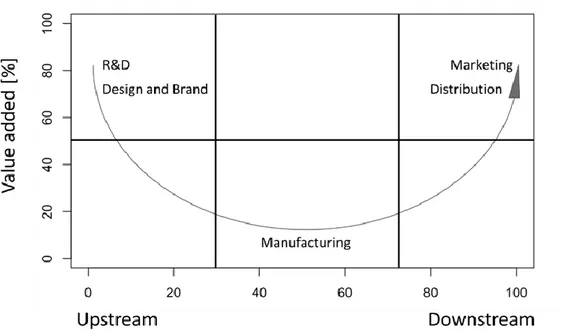

Even though reshoring has not received major attention as a field from the scientific community, several theoretical studies and systematic reviews have been made. Most of the literature in reshoring evaluates the "why" and "why not" of reshoring (Wiesmann et al., 2017). The "why" is associated with drivers and the "why not" with barriers. The interpretation of barriers and drivers depends on the standpoint or geographical location (i.e., host or home country), as a driver in one location can be a barrier in another location. Of these, the home country's perspective is relevant (Wan et al., 2019). Furthermore, the smiling curve concept proposed by Shih (1992) suggests how activities during the production process are spread in geographical locations. Hence, the home country context might be the most relevant for reshoring decision-making. Activities like R&D, design and brand, marketing, and distribution add high value to the final product, and they are often carried out in-house (Meng et al., 2020). These activities are located upstream and downstream of the supply chain. Moreover, they add more value to the product than the manufacturing activities, located in the middle of the stream (Ito & Vézina, 2016) (see Figure 1).

6

Figure 1: Shih's Smile Curve concept. Adapted from Shih (1992)

The existing methods for decision-making related to offshoring and reshoring, like total landed costs (TLC), the total cost of ownership (TCO), and total value contribution (TVC) consider multiple factors. Furthermore, many of those factors are interconnected, creating multidimensional and complex decision-making. Thus, those approaches are difficult and time-consuming to implement, which is a disadvantage (Gray et al., 2020). Gray et al. (2020) related several mathematical methods, including simulations, multi-method models, mathematical programming, among others, to reshoring and offshoring decision-making. Heuristics is another approach for reshoring decision-making. Heuristic techniques seek to provide good, approximate solutions within a reasonable amount of time (Melo et al., 2012). Rational heuristics, or simple rules, are part of what organizations learn from experience (Bingham & Eisenhardt, 2011).

2.3. System dynamics

The beginnings of system dynamics in academic programs were at the end of the '50s. Prior to this, their focus was on issues outside of academia (Forrester, 2007). Forrester is considered the father of the field of system dynamics. System dynamics is based on nonlinear dynamics theories and has a strong mathematical foundation. However, system dynamics is considered a tool for solving important problems in the real world (Sterman, 2002). System dynamics were developed to manage the dynamically complex reality and/or systems. Furthermore, system dynamics are associated with the modeling and simulation of those systems (Pruyt, 2013).

System dynamics have been mainly applied in academic programs related to management (Forrester, 2007). The most well-known application of system dynamics among students and practitioners is the Beer Game, developed in the early 1960s as part

7

of Jay Forrester (Sterman, 1992). The game simulates system dynamics problems in the supply chain and introduces the need for system thinking. Furthermore, it recreates the implications of Just-In-Time inventory management (Sterman, 1992) and the Bullwhip Effect. Nevertheless, system dynamics has had many applications in environmental questions, military (Forrester, 2007), health care issues (Dangerfield, 1999), behaviors of maintenance performance (Linnéusson, 2018), Value Stream Mapping, and Lean Thinking (Noto & Cosenz, 2020).

Different diagrams are used in system dynamics, the more popular ones are the causal loop diagrams (see Figure 2) and stock-flow diagrams (Pruyt, 2013). According to Sterman (2002), the foundation elements of system dynamics and modeling are feedback, stocks and flows, and time delays. Also, it is formed by equations and other variables (auxiliaries, parameters, and constants). Stocks and flows are the only two kinds of variables; and all variables must be defined (Forrester, 2009). The connection between two variables is termed causal links, and they can have a positive (+) or a negative (-) polarity. According to Pruyt (2013), the equations can be integral or differential, being both underlying the system dynamic models. Furthermore, they must be unambiguous. The feedback, also known as the feedback loop, can either be an open or a closed-loop, with the latter being the more realistic perception of a system (Forrester, 2009). A feedback loop is formed by two or more causal links between the elements or variables. In a closed-feedback loop, a change in one variable directly causes a change in the next variable (s) in the loop, and eventually, because of the causality and closed-loop, the change returns to the first variable. A closed-feedback loop could be either positive/reinforcing or negative/balancing (see in Figure 2 B-a and R-a) (Pruyt, 2013).

8

3 Research Methods

This chapter will present the methodological approach adopted in the research. Firstly, it will illustrate the research design. Next, the literature review procedure will be described in detail. Next, the chapter continues with a description of the steps followed by the modeling method. The chapter ends with presenting the research quality and ethics and morale, where the considerations regarding these topics will be outlined.

3.1. Research design

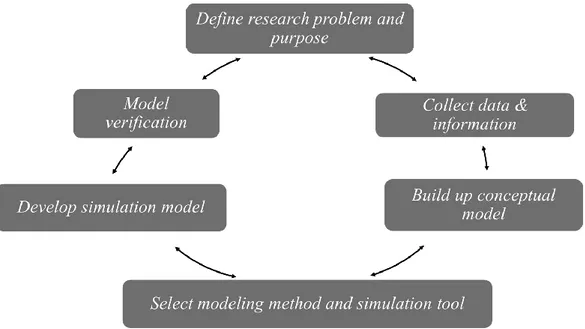

To fulfill the purpose and answer the research questions, this research explores modeling methods for the reshoring decision-making process. The chosen research design includes three major parts. First a literature review, second modeling, and third an interview (see Figure 3). One strength of using this research design is that it presents multi-strategy research, combining qualitative and quantitative techniques (Wilson, 2014). System dynamics is a method that mixes qualitative and quantitative approaches (Pruyt, 2013). Moreover, the literature review and interview are qualitative methods. Furthermore, the research design pursues a deductive approach using a literature review to identify the theory for the modeling.

Figure 3: Research design for exploring manufacturing reshoring decision-making

3.2. Literature review

The literature review is a research method and the cornerstone of most academic research. There are several procedures to guide a literature review process. The methodological guide selected in the literature review is the content analysis presented by Seuring and Gold (2012). This research followed some of the guidelines, milestones, and critical considerations presented by the authors. A formal procedure allowed organizing the search and data analysis. Besides, it enables replicability, systematicity, transparency, and traceability of the research and its results (Seuring & Gold, 2012). Similar guidelines were applied in previous research on manufacturing reshoring (Barbieri et al., 2018).

9

According to Seuring and Gold (2012), to conduct a literature review, four main milestones were presented, this research followed three of them. The first milestone was to collect the articles for the review that follows pre-defined criteria. To do so, definitions and delimitations were specified at the time of the search. The second milestone was to conduct a descriptive analysis, and published years and journals were mainly considered. The third, and last milestone followed, was to evaluate the articles found using coding to categorize their title and main ideas in the abstract.

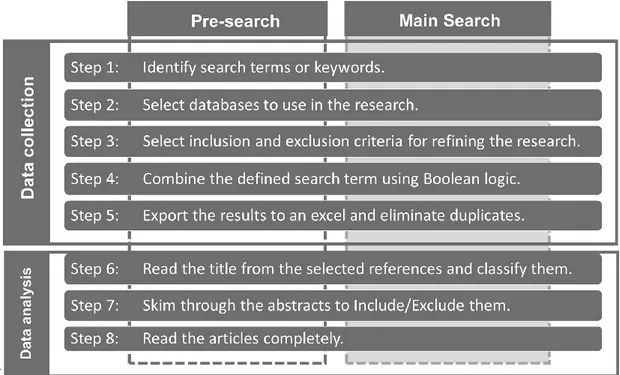

The motivation for using a literature review as a research method was to gain theoretical knowledge about the topic in order to build the system dynamics model. A literature review might be the most suitable initial method because of the limited knowledge about the reshoring decision-making process (Barbieri et al., 2018). Then, the literature review allowed to identify the state-of-the-art modeling methods used in reshoring decision-making. Also, the literature review provided the research with case study evidence to build a conceptual model. The literature review and its procedure had two main parts, data collection, and data analysis. The data collection included five iterative steps. The data analysis comprised the next three steps. The entire literature review had two iterations, pre-search, and main search. The first five steps were repeated in both phases (see Figure 4). Data collection and data analysis were intertwined resulting in an iterative process. Furthermore, an Excel file was created to complement these steps, as a record of search strategy, number of results, sample to review, among other applications.

`

10 3.2.1. Data collection

The data collection was carried out through a systematic search. It corresponds to the first two milestones and their corresponding critical considerations (Seuring & Gold, 2012) mentioned in the theoretical background. The first step was to identify search terms or keywords. For this research, relevant terms were reshoring, modeling, system dynamics, decision making, and heuristics (see Table 2). This decision was based on the purpose, research questions, and terms associated with reshoring. For example, backshoring, back-sourcing, and relocation are synonymous with the main term reshoring. Furthermore, Boolean and truncation operators were used with the lexeme “reshor” and morpheme “shoring” aiming to cover the variety of terms related to reshoring. The search term “reshor*” AND “*shoring” covered, for example, back shoring, back reshoring, back-sourcing, onshoring, inshoring, in-sourcing, near shoring, and reshoring.

Table 2: Main terms used in the literature search Main terms Search terms

reshoring

“reshoring” OR “backshoring” OR “back-shoring” OR “back-sourcing” OR “relocation”

"reshor*" OR "*shoring"

modeling "modeling" OR "modelling" OR "modell*" OR "model*" system dynamics "system dynamics"

decision making "decision making" heuristics "heuristics"

The second search term included the combinations of the term "modeling". Besides, the Boolean and truncation operators were used with the word's lexeme "model" in the form "model*" AND "modell*". Then, variations like model, models, modelation, modeled were covered. During the pre-search, some search was conducted to understand how a hyphen affects the number of results. In all search terms, the use of the hyphen does not make any difference in search engines and databases. Nevertheless, the number of results was not the same if back-shoring or back shoring were compared to the term backshoring. The latter term had 64 results in Scopus whilst back-shoring or back shoring had 19, as was mentioned before. Therefore, both search terms were included in the search combinations.

The second step was to select the databases. The selected databases were Scopus and Web of Science (WOS) Core Collection. These databases cover most journals in production management domains, which is the core of this research. The duplicates were eliminated after exporting to Excel using articles' DOI. This approach makes the search process more robust.

The third step introduced inclusion and exclusion criteria for refining the research. The first delimitation was time. According to Barbieri et al. (2018), the first study of reshoring appeared in 2009. So, the search was delimited from 2009 until the present, 2021. The other two delimitations were document and source type. The latter was

11

limited to journals and the former only included articles because journals articles are the highest quality of knowledge communication. Next, the language was limited to English and Spanish, based on the language preferences of the author. This would provide wider results than past reviews. The last delimitations were subject area, category, or research area. The approach was to exclude categories or subject areas that are not related to the topic rather than refine only the most related ones. Even though business, management, engineering, decision science, mathematics seem to be the most relevant subject areas in Scopus, some were excluded from the beginning, such as pharmacology, nursing, biochemistry, among others. In WOS, the search excluded categories like construction building technology, biology, related to medicine, and health, among others.

During the pre-search phase, each term was searched individually to explore how big the literature is for the term. The search terms like "reshoring" OR "backshoring" OR "back-shoring" OR "back-sourcing" OR "relocation" resulted in 9,450 and 694 hits in Scopus and WOS, respectively. The number of results for the search terms like "decision making" and "heuristics" was even higher in both Scopus and WOS. The latter search term had 102,163 results on Scopus, and the former had 264,279 results on Scopus and 10,978 in WOS1.

The fourth step was to combine the terms using Boolean logic. Scopus and WOS allow several Boolean and truncation operators. The operator NOT was avoided in the main search since “NOT offshoring” resulted in the exclusion of relevant articles. For example, Martínez-Mora and Merino (2014). Nevertheless, a drawback was that the number of results increased considerably in some cases. For example, “reshor*” OR “*shoring” AND NOT “offshoring” resulted in 88 hits in Scopus, which otherwise would result in 2,502 hits. This issue was compensated further by adding and combining more research terms like “relocation”, “system dynamics”, “modeling” and “heuristics”.

Moreover, in step four, 31 search combinations were tested, including those in the pre-search phase (see Appendix 1). A unique ID number was added to each pre-search string to facilitate the traceability of the search string and its combinations. The ID also helped to follow up the number of results of each search string and organize the data in the associated Excel file. The main term of the search was “reshoring” with its two search terms, and the other search terms were added or combined for refining the search. However, on some occasions, reshoring was excluded from the search combination to expand the search’s scope and to identify how modeling, system dynamics, decision making, and heuristics are combined and used in the literature on other topics. For instance, the search string (“modeling” OR “modelling" OR "modell*" OR "model*") AND ("system dynamics") AND ("decision making") AND ("heuristics") has 18 results. This search string was selected to follow up in step 5.

12

Regarding the term reshoring, the best results were obtained by the string ("reshor*" OR "*shoring" OR "relocation") and complemented with ("modeling" OR "modelling" OR "modell*" OR "model*"), (“heuristics"), and/or ("system dynamics"). Furthermore, the complete search string provided for each database was saved to replicate the searches and obtain similar results in the future. Also, the search string included the filter and delimitations selected.

Seven of the search combinations resulted in only one result, that is, Gray et al. (2017). Thus, these combinations were not followed up in the next step. Two criteria were used to follow up the search combination in the next step. First, the search combination’s results were 100 or less in either of the databases, to get a manageable sample size. Second, the search combinations should not provide unique results obtained from other search combinations. Table 3 depicts the eight search combinations fulfilling the criteria.

Table 3: Search strings selected to follow up, duplicates, and final samples

ID Search string SCOPUS WOS Duplicates Final

6 ("reshoring" OR "backshoring" OR "back-shoring" OR "back-sourcing") AND ("modeling" OR "modelling" OR "modell*" OR "model*")

25 29 17 37

9 ("reshoring" OR "backshoring" OR "back-shoring" OR "back-sourcing") AND ("modeling" OR "modelling" OR "modell*" OR "model*") AND ("decision making")

2 5 2 5

20 (” modeling” OR “modelling” OR “modell*” OR “model*”) AND (” system dynamics”) AND (”decision making”) AND (”heuristics”)

12 8 5 15

22 (" reshor*" OR "*shoring") AND ("heuristics")

2 3 1 4

28 (" reshor*" OR "*shoring" OR "relocation") AND ("heuristics")

132 64 41 155

29 (" reshor*" OR "*shoring" OR "relocation") AND (" system dynamics")

9 11 5 15

30 (" reshor*" OR "*shoring" OR "relocation") AND (" modeling" OR "modelling" OR "modell*" OR "model*") AND ("heuristics")

74 37 38 73

32 (" reshor*" OR "*shoring" OR "relocation") AND (" modeling" OR "modelling" OR "modell*" OR "model*") AND ("system dynamics")

13

In the fifth step, the results from each search string were exported in a separate excel for each database. This resulted in 16 excel files. The files were unified and the duplicates between the databases were eliminated. As the files exported from Scopus and WOS had their own formats, all the excel files were converted to a common format, eliminating the unnecessary fields, and reorganizing the columns to the same order. The field select as relevant for this search were: author (s), Title, Year, Volume, Issue, Cited by, DOI, Abstract, Keywords, Language, Document Type, Source title, and Source. Source title and Source are referred to the Journal name and database, respectively. This was an iterative process and to simplify this, three Excel macros were created. Two of the macros were used for formatting from Scopus and WOS, respectively, to the format used in this research. The third macro was used to eliminate the duplicates and to double-check no duplicates remained. The macros were verified by comparing the results with that of a manual process. This process made the search more robust and scalable because it facilitates expanding this search process to other disciplines. Another reason was to enable replication by other authors. Once the three macros were executed, the results were formatted and unified automatically. As a result, duplicates per string search were instantly identified (see Table 3).

In total, 114 duplicated references were eliminated. Reducing the sample of articles to review from 346 to 232 references. However, the same reference appeared in more than one search string, and it happened with several references. For example, Gray et al. (2017) appeared in six search strings. Thus, the results from the eight search strings were unified and using one of the previous Excel macros. The results from each search string were kept for further analysis. From this refining process, 25 duplicates were identified, and the last article sample comprised 207 references.

3.2.2. Data analysis

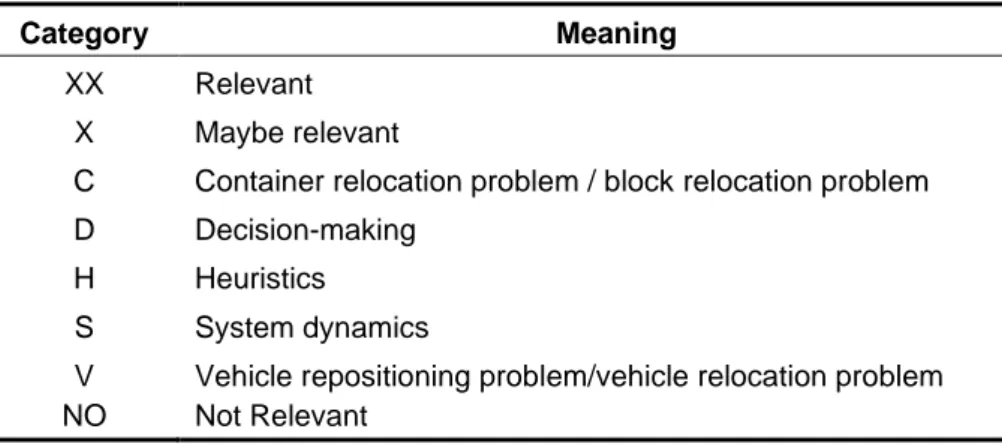

The data analysis was carried out following the fourth milestone presented by Seuring and Gold (2012). The analysis comprises reading the article and categorizing it through codes. The sixth step in the literature review procedure was to read the title from the 207 references and classify them as relevant (XX), no relevant (NO), and intermediate categories (C, D, H, S, V, x) the letters respond to the meanings presented in Table 4.

Table 4: Classification categories according to articles' titles

Category Meaning

XX Relevant X Maybe relevant

C Container relocation problem / block relocation problem D Decision-making

H Heuristics

S System dynamics

V Vehicle repositioning problem/vehicle relocation problem NO Not Relevant

14

The intermediate categories were created to evaluate the relevance of the article after a more detailed reading of the abstract article. The references classified as "Not Relevant" were eliminated directly from the sample because neither the title nor the abstract denote any relation to reshoring and relevant areas for the research.

The articles related to vehicle and container relocation problems were not eliminated straightaway from the sample because these articles required a further investigation of their relevance to reshoring. In the beginning, the decision was to read these topics and decide if the quantitative or modeling approaches from those topics could be relevant for this research. Subsequently, the articles classified as C and V were moved to the category "Not Relevant".

In total, 42 articles were classified as "Relevant" at this point in the search, and these passed directly to the next step for a full reading. The articles classify in the intermediate categories were leaving it to pause momentarily.

In step seven, the 42 abstracts were read to decide whether to "Include" or "Exclude" them from the sample. From the sample, 13 articles were excluded but they were subjected to further consideration. However, within the 29 included articles, three of them did not have DOI and hence these were also excluded, resulting in 26 articles in the sample.

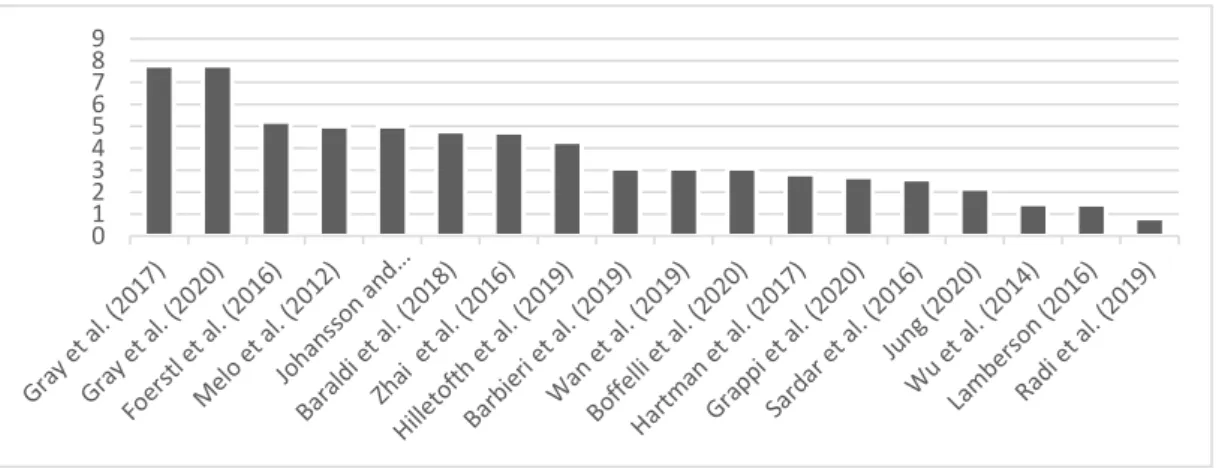

The journal impact factor (IF) was identified for these 26 articles. This decision aimed to optimize the time and prioritizing reading the more relevant articles first. The IFs were determined using Clarivate Master Journal List. The IFs went from 7.78 of the Journal of Operations Management (Gray et al., 2017; Gray et al., 2020) to 0.814 from Macroeconomic Dynamics (Radi et al., 2019). Nevertheless, some journals did not exist in Clarivate's tool, and some journals appeared but the IF was not displayed. Hence, these were also eliminated, resulting in 18 articles. Then, 18 articles resulted from this research process were sorted based on their IF (see Figure 5).

Figure 5: Impact factor of the journal in which the article was published

In the eighth step, the 18 articles were entirely read (see Appendix 2). The reading process started based on the prioritization made in the previous step. It is highly important that the 18 articles were the most relevant according to the procedure

0 1 2 3 4 5 6 7 8 9

15

followed because they fulfilled all the refining criteria. Nevertheless, after a second iteration and studying the abstracts, two articles (Cassia, 2020; Schmidt et al., 2017) were considered relevant. Furthermore, some articles (Ancarani et al., 2015; Fratocchi et al., 2014; Hasan, 2018; Shao et al., 2020; Sirilertsuwan et al., 2019) were added manually through a snowballing technique because they contained relevant ideas. They were cited in some articles retrieved during the literature search. The technique of snowballing was used by Fratocchi et al. (2016) in a similar context.

In the data analysis, relevant literature with theory, models, approaches, and case study papers for in-data that support the research was summarized. Key ideas, case study quotes, or theories were identified that supported answering the first research question. Furthermore, heuristics or simple rules for reshoring decisions were identified and extracted.

3.3. Modeling

The second part of this research design is modeling, using system dynamics. As mentioned earlier, reshoring is a complex, dynamic, and non-linear decision. With this research method, a descriptive model of the reshoring decision-making process is developed. Modeling was chosen as one of the research methods because it provides a better understanding of the problem identified (Dresch et al., 2015). Furthermore, Yin and McKay (2018) consider modeling as another scientific research methodology, together with deductive and inductive approaches.

There are also several methods and techniques related to modeling. For instance, agent-based simulations (Yin & McKay, 2018), discrete-event simulations, multi-objective optimization, and system dynamics (Linnéusson, 2018; Pruyt, 2013; Sterman, 2002). The modeling was carried out using the system dynamics because of two major reasons. First, reshoring cannot be explained by a single variable (Wiesmann et al., 2017) and many of the variables are interconnected (Gray et al., 2020). Second, complex business decisions with real-world characteristics can be represented by system dynamics models (Sterman et al., 2015). So, the system dynamics model is suitable for dealing with reshoring decision-making processes.

The procedure followed has six main steps (see Figure 6). This procedure was selected because it describes the several steps inherent in this process. The procedure is based on Yin and McKay (2018) and Pruyt (2013).

16

Figure 6: Modeling procedure. Adapted from Yin and McKay (2018) and Pruyt (2013)

The procedure has six steps that summarize systems dynamics modeling process: 1. Define research problem and purpose: Reshoring decision-making depends on

multiple variables; thus, it is a complex, dynamic, and non-linear decision, which is a challenge in decision-making. The purpose is to increase the understanding of reshoring decision-making process.

2. Collect data and information: Data and information required to create the conceptual models were retrieved during the literature review. Those comprised drivers and barriers, practices, and case study examples for reshoring.

3. Build up conceptual model: The conceptual model was built up based on input information in the literature review. Variables and relationships pertaining to the model were defined. Next, heuristics that describe the decisions were extracted.

4. Select modeling method and simulation tool: Albeit simulation was not included in the scope of this research, the model can be simulated using system dynamics. Vensim PLE 8.2.0 was the software tool selected to represent the model. 5. Develop simulation model: A computer-based system dynamics simulation

model for reshoring decision-making was developed using the software Vensim PLE 8.2.0 and the conceptual model created with a heuristics approach. 6. Model verification: An expert from the industry was interviewed to carry out

the verification of the model, including the variables and heuristics. The verification was made through a semi-structured interview.

The research does not include simulation activities as these require additional quantitative information to create mathematical equations. The research focuses on model development and the model was verified through an expert interview.

17

3.4. Expert Interview

The third part of this research design was a semi-structured interview. This method accomplished the step of model verification. The interview was carried out with an expert from the industry. An industry expert is defined as top executives, consultants with long work experience, or individuals holding a contextualized expertise (Melander, 1997).

3.4.1. Data collection

An interview guide was developed to support the interview process (see Appendix 3). Before the interview, the expert was contacted through mail. A short guide about the interview was sent together with the questions. Moreover, details about the confidentiality agreement and anonymity of the interview and its results were agreed upon. Therefore, no names from the expert and the company are shared in this report. In this report, the company will be referred to as "Company A" and the expert as "Expert A".

The interview had three parts. The first part comprises seven questions, to know more about the company, context and to characterize the expert (e.g., years of experience, professional background, previous experiences in reshoring decisions). The second part comprises 16 questions, which aimed to identify the variables, heuristics, and relationships that the expert and the company consider for reshoring decision-making. The third part of the interview comprises nine questions, which provided the opportunity for an in-depth discussion of the model. In this part of the interview, the eight variables and their corresponding heuristics were presented to the expert. The expert evaluated them either as relevant or not, based on personal experience gained working in reshoring projects. Next, the variables were prioritized. The priority order followed the convention where "1" represented the most important variable, "2" for the second most important, and so on until "n" for the least important variable. Furthermore, the system dynamics model was presented to the expert for evaluating causal links, feedback loops, and the types of causal loops defined (reinforcing or balancing loops). 3.4.2. Data analysis

The interview was audio-recorded and transcribed. Later, both were analyzed, summarized, and compared with the literature and the results from the modeling. The use of an IT tool like Live Transcribe™ during the interview considerably reduced the time required for the interview analysis, as transcribing audio-recorded interviews can be very time-consuming (Saunders et al., 2007). After the transcription, it was compared with notes taken during the interview. Thereafter, the main findings and conclusion were summarized.

18

3.5. Research quality

The evaluation of research quality is one cornerstone of any research with scientific rigor. In order to evaluate the research quality, the trustworthiness criteria described by Lincoln and Guba (1985) were used. The trustworthiness criteria provide additional constructs that allow the reader to judge the quality of the research.

Table 5 describes the four trustworthiness criteria: credibility, transferability, dependability, and confirmability. Next, it is described how these criteria were presented and applied within this research.

Table 5: Research quality evaluation based on trustworthiness criteria Trustworthiness criterion Implementation

Activities examples

Credibility The research was based mostly on peer-reviewed journal articles. The three main research methods (e.g., literature review, modeling, and interview) followed formal procedures.

Furthermore, the process for obtaining the results has been explained through the report. Moreover, every step and decision were motivated either with theory, procedures, or direct quotes from the support of the literature.

The research triangulates methods and their results. For example, the results obtained in the literature review and modeling methods were compared with the finding in the interview with the industry expert.

Transferability The procedures followed in the research were presented step by step and described in detail. Therefore, other researchers can replicate the study or consider using the procedures in a different context.

The research provided an Excel file and two Excel macros that can be used by other researchers as a tool during the literature search.

Dependability The research process and its report were reviewed in-depth several times by the research supervisor and experienced researcher in the field.

The procedures, results, and conclusions from this research were peer-reviewed by peers, evaluated by a researcher, presented, and discussed in the Final Project work seminar. Moreover, the developed model was verified by an industry expert.

19

Confirmability The results from every step in the literature review procedure were documented in an Excel file and the report, including the initial search terms, to the final sample of articles.

The exact search string used in each database and its results were presented in the report and archived in the Excel file as raw data.

Theoretical findings from the literature review, empirical data from the expert interview, and the results of the modeling process were compared.

3.6. Ethics and morale

Ethics and morals were considered in different steps of the research. As this research has only one author, consideration of the order of authorship was unnecessary. However, the acknowledgment of the supervisor for his contribution was made. Furthermore, the authors kept the objectivity and impartiality as a researcher. For example, during the data analysis, the data all the findings were reported. All the statements, ideas, data were referenced, and the bibliographies were managed using the reference management software package Endnote and the referencing style APA 7th. In general, the research did not store any sensitive data, apart from the interview with the industry expert. In that case, details about the confidentiality agreement and the anonymity of the interviewee were agreed upon. Therefore, no names from the expert nor the company were shared in this report.

20

4 State-of-the-art of reshoring decision-making process

This chapter presents the state-of-the-art of modeling in reshoring decision-making process. Therefore, it presents the main findings from the literature review concerning the variables used in the system dynamics modeling. The chapter analyzes the barriers, drivers, and other factors related to the state-of-the-art of reshoring decision-making process.

4.1. Data and Information collection

The data and information required to create the conceptual models are retrieved during the literature review. The focus is to collect variables to build up the system dynamics model, but also rules, examples, and heuristics are considered. This step in the procedure answers RQ 1, studying the state-of-the-art of reshoring decision-making.

In comparison with offshoring, reshoring decisions incorporate a broad spectrum of factors, and many are not quantifiable (Gray et al., 2017). Thus, managers and companies base their reshoring decision-making on many variables. After the literature review, many drivers and barriers were found in reshoring decision-making. Furthermore, the literature presents drivers and barriers in a wide range of categories or areas, e.g., company-specific or internal, global competitive dynamics or external, strategic decisions, managerial mistakes, supply chain (Barbieri et al., 2018; Wiesmann et al., 2017).

Two large systematic reviews in reshoring are identified among other relevant articles. The systematic reviews summarize the drivers and barriers to reshoring decision-making. Barbieri et al. (2018) found 57 drivers in 57 thoroughly selected books and journal articles indexed on Scopus during the past 10 years, which is an increase from 31 drivers and 16 barriers previously identified in 22 peer-reviewed journal papers (Wiesmann et al., 2017). 4.1.1. Drivers of reshoring decision-making process

Poor quality of products manufactured offshore is another driver highly cited in the

literature; it was found in 33 sources, according to Barbieri et al. (2018). In consonance, Foerstl et al. (2016) state that quality issue is the main driver for reshoring in manufacturing companies from the USA. Zhai et al. (2016) point out that quality, and not increasing labor cost, is the leading single driver for reshoring decisions in the USA. In their study, 51 companies prioritized quality.

Costs as a group were the most cited and included the major number of drivers (Barbieri

et al., 2018). Similarly, Zhai et al. (2016) consider costs as the most influential driver for reshoring. Most of the costs mentioned by Barbieri et al. (2018) could be grouped as operational costs. However, within cost, several authors (Foerstl et al., 2016; Fratocchi et al., 2014; Radi et al., 2019; Zhai et al., 2016) specify labor cost as a driver for reshoring.

Access to skills and knowledge is one driver of reshoring (Barbieri et al., 2018;

Johansson & Olhager, 2018a). Barbieri et al. (2018) found 25 references who cited drivers within this category. Some drivers included are the availability of production capacity and skilled workers in the home country. Other drivers classified in different categories by

21

Barbieri et al. (2018) are technology clusters and home labor market flexibility. Furthermore, production technology availability (e.g., production automation) and disruptive technological advances (e.g., 3D printing) could be considered as a driver for reshoring (Foerstl et al., 2016). All the previous drivers could be grouped as the development of competencies in the home country.

4.1.2. Barriers of reshoring decision-making process

Moreover, some barriers for reshoring are stricter environmental legislation, lack or shortage of raw materials and components, large economic differences, success with offshoring, lack of proper decision support/data, among several other (Wiesmann et al., 2017).

4.1.3. Variables lacking attention in reshoring decision-making process

From the analysis of the literature review, it is important to highlight that environment and sustainability are not widely addressed in the literature as factors leading to reshoring decision-making. Research that mentions environment and sustainability as factors for reshoring are limited. Two extensive literature reviews, Wiesmann et al. (2017) and Barbieri et al. (2018) identified only four and seven articles, respectively. More recently, Hilletofth et al. (2019) consider the concept of sustainability in reshoring decision-making. The number of factors (i.e., barriers and drivers) related to the environment or sustainability is also small. The factors identified were only four; increased awareness of the environmental impact, stricter environmental legislation, increased focus on sustainability (Wiesmann et al., 2017), firm's aims in terms of environmental and social sustainability (Barbieri et al., 2018). According to Gray et al. (2017), environment or sustainability are not considered during reshoring decision-making. The authors found companies were indifferent to environmental aspects for reshoring decisions, even though they are aware of the environmental problems and new regulations. Similar results were got by (Hilletofth et al., 2019; Sequeira et al., 2021) This author presents industry experts' opinions regarding six criteria for manufacturing reshoring decision-making, e.g., sustainability, time, cost, quality, flexibility, and innovation. According to experts' opinion, sustainability was the criterion that received the least weight, thus less priority for the industry.

4.2. Building up the conceptual model

Some categories can be used to group some drivers and barriers found in the literature. Then, similar drivers and barriers are grouped as was pinpointed in previous paragraphs. A similar procedure is performed by other authors found in the literature (Barbieri et al., 2018; Wiesmann et al., 2017).

Some drivers and barriers might stand alone because they cannot be grouped. Furthermore, another finding related to the drivers and barriers was that they can be seen, at the same time, as motivators or deterrents for reshoring decisions. The inflection point is from which perspective or standpoint (i.e., home or host country) the driver or barrier is analyzed. This finding is supported by Baraldi et al. (2018) who show that the context

22

in the home country affects positively or negatively reshoring decision; i.e., the context in the home country might act as a driver or a barrier for reshoring decisions. Furthermore, Wiesmann et al. (2017) also mention some examples of drivers and barriers with dual roles depending on the context. For instance, on the one hand, a decrease in the labor costs in the host country acts as a barrier to reshoring decisions. On the other hand, a decrease in the labor cost in the home country portrays as a driver for reshoring decisions. If the labor cost increases in either the home or host country, will either become a barrier in the former or a driver in the latter. The home or host country perspective creates two combinations with the variable labor cost. This can be observed in most of the drivers and barriers identified in the literature depending on the standpoint (i.e., home or host country) and the variation (increase or decrease). To avoid confusions in modeling, hereafter, the drivers and barriers are considered and termed as “variables”.

4.2.1. Variables for building up the model

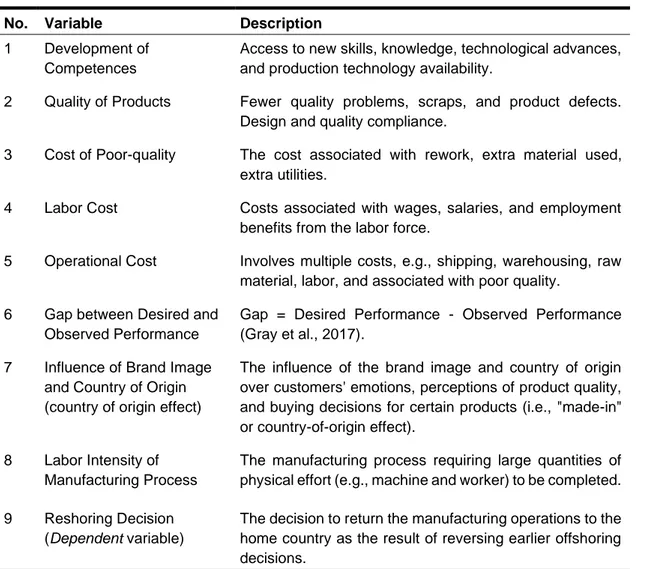

The variables previously described and analyzed could be used to model reshoring decision-making. Therefore, the research proceeds to model reshoring decision-making using eight independent variables and one dependent variable (e.g., Reshoring Decision). Table 6 includes the variables and a brief description of each one.

Table 6: Main variables for modeling reshoring decision-making

No. Variable Description

1 Development of Competences

Access to new skills, knowledge, technological advances, and production technology availability.

2 Quality of Products Fewer quality problems, scraps, and product defects. Design and quality compliance.

3 Cost of Poor-quality The cost associated with rework, extra material used, extra utilities.

4 Labor Cost Costs associated with wages, salaries, and employment benefits from the labor force.

5 Operational Cost Involves multiple costs, e.g., shipping, warehousing, raw material, labor, and associated with poor quality.

6 Gap between Desired and Observed Performance

Gap = Desired Performance - Observed Performance (Gray et al., 2017).

7 Influence of Brand Image and Country of Origin (country of origin effect)

The influence of the brand image and country of origin over customers' emotions, perceptions of product quality, and buying decisions for certain products (i.e., "made-in" or country-of-origin effect).

8 Labor Intensity of Manufacturing Process

The manufacturing process requiring large quantities of physical effort (e.g., machine and worker) to be completed. 9 Reshoring Decision

(Dependent variable)

The decision to return the manufacturing operations to the home country as the result of reversing earlier offshoring decisions.

23

Following the convention presented by Gray et al. (2017), variables’ names in the model are capitalized and italicized throughout the text. Together with the eight variables, the evidence found during the literature review is used to create heuristics for modeling reshoring decision-making. The only effect of the change in the variable is an increase or decrease in the reshoring tendency.

After all the previous considerations, the structure to follow to create the heuristics is: If the Variable increases/decreases in the home country, then increase/decrease the Reshoring Decision tendency.

4.2.2. Heuristics for building up the model

For each variable, one heuristic or "simple rule" was created.

Table 7 shows the eight main heuristics for modeling the reshoring decision-making process. The heuristics created for building up the model represent the cause-effect relationship between the independent variables and the dependent variable. The support for these heuristics is based on the evidence found during the literature review. Therefore, supporting quotes and their sources are summarized in Table 7.

Table 7: Heuristics for modeling reshoring decision-making

No. Rule Supporting quotes Source

1 If the Development of

Competences increases

in the home country, then increases the

Reshoring Decision

tendency.

... development competences, including access to skills and knowledge, are the key incentive for backshoring."

Johansson and Olhager (2018a), p. 43 " [Reshoring's driver]: Access to skills and

knowledge"

Stentoft et al. (2016), p. 57 "[Drivers of reshoring]: Production

technology availability in locations (production automation). Disruptive technological advances (e.g., 3D printing)"

Foerstl et al. (2016), p. 504

2 If the Quality of Products increases in the home country, then increases the Reshoring Decision tendency.

"... the quality issue is the primary single factor for reshoring of American manufacturing companies"

Zhai et al. (2016), p. 69

"A number of benefits are also associated with backshoring, including higher quality"

Johansson and Olhager (2018a), p. 39 "This decision was made because of the

dramatic decline in sales resulting from unforeseen product quality problems"

Foerstl et al. (2016), p. 499

24

3

If the Cost of

Poor-Quality decreases in the

home country, then increases the Reshoring

Decision tendency.

"At SME D, reshoring decisions followed repeated deliveries of poor-quality products from its Chinese steel item (D-2) supplier"

Gray et al. (2017), p. 39

4 If the Labor Cost decreases in the home country, then increases the Reshoring Decision tendency.

"Wages increase at the Chinese factory slash China's labor cost advantage over states in the US, which makes the companies relocate their business operations back home."

Zhai et al. (2016), p. 66

"the efficiency seeking offshoring by utilizing the lower labor cost is more likely to reshore."

Zhai et al. (2016), p. 64 "... the firm initially nearshored to Mexico to

benefit from government incentives and comparatively low-labor costs, it decided to backshore production"

Foerstl et al. (2016), p. 500

General Electric's reshoring decision due to: "the faster than expected increase in Chinese labor costs."

Foerstl et al. (2016), p. 499

"The investigation underlines that increasing labor costs in the technological-laggard country reduces its attractiveness and may spark a reshoring process."

Radi et al. (2019), p. 4

5 If the Operational Cost decreases in the home country, then increases the Reshoring Decision tendency.

"... the cost as a group factor is still the most important motivation for reshoring."

Zhai et al. (2016), p. 63 "The location decisions of Multinational

Enterprises are updated at discrete-time periods and are based on comparative production-cost advantages in the two countries that depend on (...) extra operational costs."

Radi et al. (2019), p. 3

"... cost was the most relevant [reshoring driver category] in terms of both number of drivers and total citations."

Barbieri et al. (2018), p. 92

6 If the Gap between

Desired and Observed Performance decreases

in the home country, then increases the

Reshoring Decision

tendency.

"Given the assumption that reshored production results in better responsiveness and fewer unanticipated problems than offshore production, the realization of a Gap between Desired and Observed Performance would encourage reshoring (i.e., a decrease in Offshoring)."

Gray et al. (2017), p. 41

25

7 If the Influence of Brand

Image and Country of

Origin increases in the home country, then increases the Reshoring

Decision tendency.

"...resources/strategic assets considerations (...), brand image, (...) have been called to explain firms' decisions to relocate closer to their headquarters."

Ancarani et al. (2015), p. 141

"... problems with brand image in the offshore location are suffered especially by large firms."

Ancarani et al. (2015), p. 149

"... consumers feel emotions toward specific elements connected with a product (as the country of origin) "

Grappi et al. (2020), p. 89

"Traditionally, the country of origin has strongly influenced consumers' buying decisions for certain products."

Ancarani et al. (2015), p. 152

"Recently, many firms have reshored manufacturing activities back to their home countries to increase customer perceptions of product quality."

Cassia (2020), p. 1099

"... the "made-in effect" (...) is the fourth most important motivation of reshoring decisions in our sample."

Fratocchi et al. (2016), p. 115

8 If the Labor Intensity of

Manufacturing Process

increases in the home country, then decreases the Reshoring Decision tendency.

"... the labor-intensive manufacturing processes of apparel have made reshoring financially infeasible."

Hasan (2018), p. 1 "Labour-intensive products are sometimes manufactured in neighbouring lower-cost countries in a practice known as nearshoring."

Sirilertsuwan et al. (2019), p. 552

Based on these heuristics, a system dynamics model for exploring reshoring decision-making will be developed in the next chapter, answering the second research question.