RHEOLOGICAL EVALUATION OF ASPHALT MODIFIED WITH

AUTOMOBILE WASTE ENGINE OIL

Touqeer Shoukat

Korea Institute of Construction Technology, South Korea

Gyeonggi-do, Goyang-si, Ilsanseo-gu, 1565 Chungang-ro, Daehwa-dong, South Korea Phone: + 82 1020071601 E-mail: touqeer@ust.ac.kr

Co-authors(s); Pyeong Jun Yoo, Korea Institute of Construction Technology, South Korea

1.

AIM OF STUDY

Asphalt is a temperature sensitive material [1] and generally used in pavement industry as an essential ingredient for asphalt concrete. Viscosity of asphalt is an important factor to characterize its workability which in turn is employed for mixing and compaction of asphalt concrete. Viscosity can be manipulated by modifying asphalt binder with compatible polymeric materials. Thermally induced cracking of flexible pavements is a big problem which is more prominent in cold regions. As the pavement structure tends to shrink under low temperature conditions, asphalt modification is needed to handle this shrinkage without losing cohesion with aggregates. Asphalt modified with used lubricating oil improved the low temperature PG grade but the results were not good for high temperature grade [2]. Modification of aged asphalt with 4% waste cooking oil decreased the viscosity to its un-aged condition [3]. The waste engine oil modification of asphalt decrease the stiffness of binder at low temperatures [4]. Glass transition temperature can be decreased and relaxation capability of asphalt binder can be enhanced using 5% refined waste oil [5]. X-Ray fluorescence spectroscopy of asphalt modified with waste engine oil shows loss of strain tolerance and physical hardening of asphalt binder [6].

There are very few researches that focused on oil modification of asphalt binder and with different types of oil. With the increased production of waste engine oil by vehicle use, it is very essential to use the waste oil as a modifier which will also reduce the cost of modification. Considering these factors, this study is based on evaluating viscosity and rheological properties of asphalt binder modified with 2.5% 5W30 viscosity grade waste engine oil. The study is still undergoing for proper characterization of modified binder and expected to be completed this year.

2.

METHOD

2.1. Materials

Waste engine oil employed in this study was taken from a local automotive repair shop. Due to wear and tear of engine while vehicle performance, engine oil is contaminated with metal traces and repeated heating and oxidation actions [7]. Availability of viscosity grade engine oils, waste engine oil obtained from different vehicles might have different viscosity. Considering this fact, waste SAE 5W30 viscosity grade oil was selected for this study (Table 1). Waste oil was filtered using Whatman 1002-150 grade filter papers.

A PG64-22 (AP5) asphalt binder was used as the base binder for samples preparation and laboratory experimentation. Samples were also prepared after short term aging using Rolling Thin Film Oven (RTFO) of base asphalt binder. Physical characteristics of virgin asphalt is given in Table 2.

Table 1. Physical properties of Fresh Engine Oil (SAE 5W30) [9]

Property Fresh Oil (SAE 5W30)

Density at 15C [g/cm3] 0.861

Viscosity at 40C, centistokes 71 Viscosity at 100C, centistokes 11.75

Table 2: Physical properties of virgin asphalt binder (PG64-22)

Property Unaged Condition

Specific Gravity 1.037

Absolute Viscosity at 60C, poise 1588 Kinematic Viscosity at 135C, centistokes 362

2.2. Experimentation

2.2.1. Mixing Process

To study the effect of waste engine oil on asphalt performance and make the waste oil components blend well with asphalt, high mixing speed at 2000 rpm, the maximum possibility without material spillage, was used. The blending time and temperature were controlled at 30 min and 150 ± 5 0C, respectively.

2.2.2. Sample Preparation

Samples were prepared by mixing 2.5% by weight of waste oil into asphalt binder in two different conditions i.e. unfiltered and filtered oil. At least two samples for each condition and for each test were prepared to check the repeatability and results were shown as an average. Virgin asphalt binder samples were also prepare for comparison.

2.2.3. Rotational Viscometer Test

Viscosity test for all the samples were conducted using Brookfield DV-III Ultra Viscometer. Rotational viscosity at a range from 1350C to 1750C was measured according to AASHTO T 316 and ASTM D

4402 testing standards. Ideal mixing and compaction temperature for virgin and modified binder were calculated by using viscosity data.

2.2.4. Fourier Transform Infrared Spectroscopy

FTIR spectroscopy was employed to characterize change in functional groups and chemical alteration of base asphalt due to waste oil modification. This test was performed using JASCO 4200 spectrometer with Attenuated Total Reflection (ATR) accessory in the range of 4000 to 650 cm-1 wavenumbers. For each spectrum obtained, a total of 32 consecutive scans at a resolution of 4 cm-1 were used as an average.

2.2.5. Dynamic Mechanical Analysis

A Discovery Hybrid Rheometer (DHR-2) with Environmental Temperature Control (ETC) system was used for determination of viscoelastic behavior of base and modified binder. Frequency sweep test was performed on a temperature range of 450C to 750C in stress controlled mode. Frequencies of 0.1, 0.72

conditions [8]. The results for intermediate temperature still have to be obtained and also MSCR test will also be conducted for binder elastic recovery evaluation. A master curve will also be developed after rheological analysis at intermediate temperatures.

3.

RESUTLS & DISCUSSIONS

3.1. Rotational Viscometer Test

The RV test is to be conducted at various temperatures, but since manufacturing and construction temperatures are fairly similar regardless of the environment, the test for Superpave PG asphalt binder specification is usually conducted at 135°C and 165°C. The results for viscosity test are tabulated in Table 3. It can be clearly seen that modifying asphalt with un-filtered waste oil has decreased its viscosity while the filtered oil modification has increase the asphalt viscosity. The reason behind is due to the metal traces as a result of engine wear hinders the waste oil molecules to attach with asphalt structure.

Table 3: Dynamic Viscosity of Asphalt Binder

Temperature (0C)

Viscosity (m.Pa.s) Unmodified Modified with 2.5% Un-filtered

Waste Engine Oil

Modified with 2.5% Filtered Waste Engine Oil

135 452.5 422.5 465

165 125 120 125

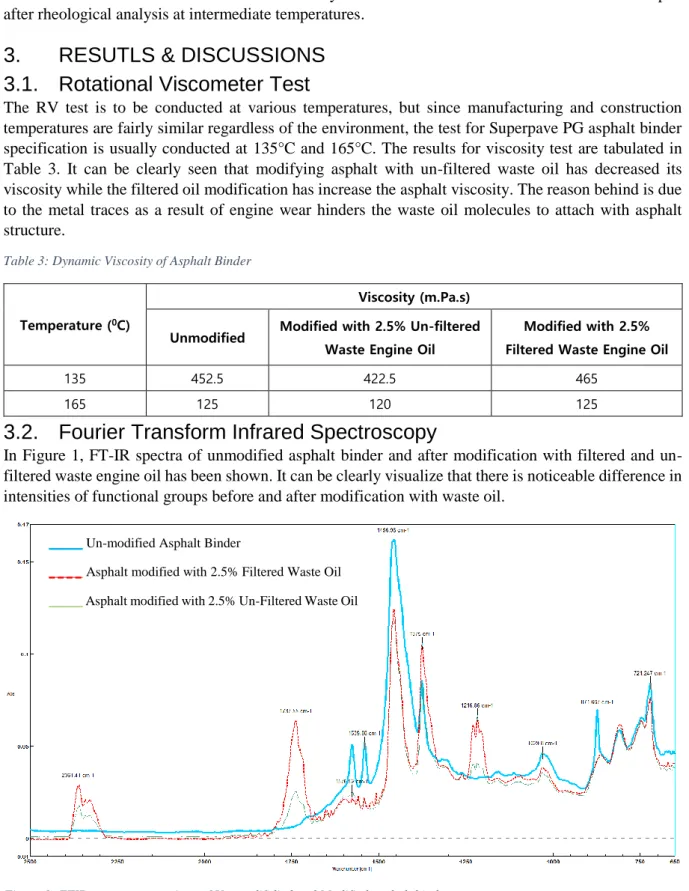

3.2. Fourier Transform Infrared Spectroscopy

In Figure 1, FT-IR spectra of unmodified asphalt binder and after modification with filtered and un-filtered waste engine oil has been shown. It can be clearly visualize that there is noticeable difference in intensities of functional groups before and after modification with waste oil.

Figure 1: FTIR spectra comparison of Un-modifidied and Modified asphalt binder

_____Un-modified Asphalt Binder

_____Asphalt modified with 2.5% Filtered Waste Oil

Some additional bands appear due to modification at ν ≈ 2361 cm-1, 1738 cm-1 and 1216 cm-1. The band at ν ≈ 2361 cm-1 indicate appearance of C≡C, ν ≈ 1738 cm-1 indicates increase concentration of carbonyl group C=O while ν ≈ 1216 cm-1 represents C-O bond due to ester molecules in the lubricant oils. The decrease in intensity at 1029 cm-1 proves the formation of unsaturated bonds in polymer chains of modified asphalt.

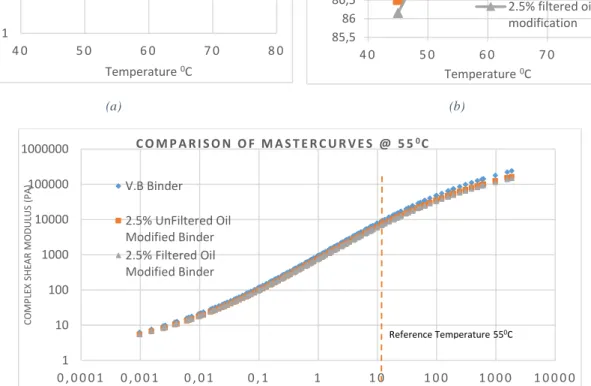

3.3. Dynamic Mechanical Analysis

Figure 2(a) shows the log-reduced complex shear modulus G* of unmodified and modified asphalt binder versus temperature at 0.1 Hz to evaluate the asphalt behavior under low traffic speeds. The modification results in decreased stiffness of binder which in turn expected to perform well in resisting thermal cracking at low temperatures. Moreover, actual low temperature tests results will confirm this expected outcome.

Phase angle, ratio of permanent deformation to elastic deformation, increases with increasing temperature till 700C, after which it tend to decrease (Figure 2(b)). With modification, phase angle

exhibit a decrease which signifies that asphalt can recover more on removal of shear stresses.

(a) (b)

(c)

Figure 2: Complex Shear Modulus(a), Phase Angle(b) & Mastercurves(c) of unmodifiend and modified asphalt binder

85,5 86 86,5 87 87,5 88 88,5 89 89,5 90 4 0 5 0 6 0 7 0 8 0 Phas e A n gl e 0 Temperature 0C Unmodified Binder 2.5% Unfiltered oil modification 2.5% filtered oil modification 1 10 100 1000 10000 100000 1000000 0 , 0 0 0 1 0 , 0 0 1 0 , 0 1 0 , 1 1 1 0 1 0 0 1 0 0 0 1 0 0 0 0 CO M PL EX SHE A R M O D U LU S (PA )

REDUCED FREQUENCY (RAD/SEC) C O M P A R I S O N O F M A S T E R C U R V E S @ 5 50C V.B Binder 2.5% UnFiltered Oil Modified Binder 2.5% Filtered Oil Modified Binder Reference Temperature 550C 1 10 100 1000 10000 4 0 5 0 6 0 7 0 8 0 Co mp le x Sh ear Mo d u lu s (P a ) Temperature 0C Unmodified Binder 2.5% Unfiltered oil modification

4.

CONCLUSIONS

Based on the currently available results presented here, following conclusions can be drawn;

a. Increased viscosity of asphalt modified with 2.5% filtered waste engine oil results in increased cohesion of asphalt molecule chains.

b. FTIR data signifies increased carbonyl groups which in turn might be helpful in minimizing the stiffing effect due to aging of asphalt binder.

c. Waste engine oil addition has decreased the stiffness of asphalt binder and lowered δ which is more pronounced in asphalt binder containing filtered waste engine oil.

d. Comparison of mastercurves shows that binder modified with waste engine oil can better perform at low temperatures to resist fatigue cracking.

e. This study might be helpful to construct safer roads prone to low temperature cracking. f. Different percentages of waste engine oil can be employed to find the optimum modification

percentage of waste engine oil with asphalt binder.

g. This study is still undergoing, evaluation at intermediate and low temperatures is needed.

REFERENCES

[1] Bailey H. K., & Philips, P. (2010). Asphalt Rejuvenation. US Patent 0034586 A1.

[2] Villanueva A., Ho S. and Zanzotto L. (2008). Asphalt modification with used lubricating oil. Canadian Journal of Civil Engineering. 35: 148-157

[3] Asli H., Ahmadinia E., Zargar M. & Karim M.R. (2012). Investigation on physical properties of waste cooking oil – Rejuvenated bitumen binder. Construction and Building Materials, 37, 398–405. [4] Xiaoyang J., Baoshan H., Bowers B.F. and Sheng Z. (2013). Infrared spectra and rheological properties of asphalt cement containing waste engine oil residues. Construction and Building Materials. 50, 683-691,

[5] Zhang L., Bahia H. and Yi-qiu T. (2015). Effect of bio-based and refined waste oil modifiers on low temperature performance of asphalt binders. Construction and Building Materials. 86: 95-100.

[6] Hesp Simon A.M. and Shurvell H.F. (2010). X-ray fluorescence detection of waste engine oil residue in asphalt and its effect on cracking in service. International Journal of Pavement Engineering. 11(6): 541-53.

[7] Dominguez-Rosado E, Pichtel J. Chemical Characterization of fresh, used and weathered motor oil via GC/MS, NMR and FIRT techniques. Proc Indiana Acad Sci. 112(2):109-16

[8] Ahmedzade P., Gunay T., Altun S. and Kultayev B. (2003). Usage of Ion-Irradiated Recycled Polypropylene as Modifier in Bituminous Binder. National Academy of Sciences of Ukraine.

[9] Vicente M., Bernardo T., Santiago R. and Guillermo M. (2016). Low viscosity engine oils: Study of wear effects and oil key parameters in a heavy duty engine fleet test. Tribology International. 94: 240-248

![Table 1. Physical properties of Fresh Engine Oil (SAE 5W30) [9]](https://thumb-eu.123doks.com/thumbv2/5dokorg/4940124.135977/2.892.102.709.200.560/table-physical-properties-fresh-engine-oil-sae-w.webp)