FUTURE DEVELOPMENT OF

BIOENERGY IN SOUTH AFRICA

A study of increased use of available biomass for the future development of

renewable energy in South Africa

ALEXANDER LUNDQVIST

School of Business, Society and Engineering

Course: Degree Project in Industrial Engineering

and Management with Specialization in Energy Engineering

Course code: ERA 402

Supervisor: UP Ryan Merckel Supervisor: MDH Jan Skavril Examinor: MDH Monica Odlare Date: 2020-06-04

ABSTRACT

The development of renewable energy has become increasingly important as countries strive to become less dependent on fossil-derived energy. Biomass accounts for a large part of energy derived from renewable energy sources in Africa. However, the biomass is used in primitive ways like cooking and heating, which is not at all effective at taking advantage of the biomass's true energy potential and contributes to premature death due to pollution. Scarce water supply and infrastructure built around an energy production from coal have hindered the development of bioenergy in South Africa. The Stated Policy scenario has

developed energy targets for South Africa to reached by 2040 to streamline South Africa's use of available biomass. To find out if these goals can be achieved, data regarding biomass quantities for different biomass types have been collected to see how much biomass is available for energy production. Various types of technologies for converting biomass have been investigated to compare the efficiency of each technology and production costs to be able to analyze which technology is considered best for application in South Africa. Various scenarios have been developed where previous research and insights from interviews have been involved and influenced the type of technology used to convert the biomass and which end product is considered to have the highest potential. The different scenarios were modeled in Excel and then simulated in to optimize total production costs and energy production. The bioenergy produced has then been compared with the current energy production from fossil fuels to see how much can be replaced. The technologies that were considered to be

applicable were combined heat and power together with hydroprocessing. These technologies contributed to efficient energy production and low production costs as well as lower

transport costs. Due to drought and lack of water supply, the most optimal places for the implementation of this type of technology were in the northeastern parts of South Africa. These areas have better access to water and, therefore produces more biomass. Considering the current infrastructure in South Africa, transport by trucks was considered to be the most flexible choice of transport mode for transporting the biomass. With the available biomass and the selected technologies, bioenergy can replace up to 15% of the energy produced from coal in South Africa, and prices are competitive with today's electricity and fuel prices in South Africa. For this to happen, political support, public confidence, and investment are required. Increased bioenergy in South Africa would reduce dependence on energy from fossil fuels and also streamline the use of available renewable energy that would contribute to increased and safer energy supply. A more efficient use of bioenergy would also contribute with less premature deaths caused by primitive use of biomass, less emissions and a healthier environment.

Keywords: Available biomass, Biomass, Bioenergy, Conversion technologies, South Africa

SUMMARY

Background: The interest in the development of bioenergy production has increased

worldwide, and countries have increased their energy production from renewable resources. In Africa, biomass-based sources produce more than 90 % of the total primary energy supply from renewable energy sources. However, Africa has the lowest production of electricity and liquid fuels from biomass, since the biomass is used mainly for cooking and heating. Water scarcity and infrastructure depending on coal-derived energy, have hindered the

development of efficient use of bioenergy in South Africa. The Stated Policy Scenario has set energy targets for energy production from biomass in South Africa until 2040 to force the implementation and adaption of more efficient technologies to utilize the available resources to produce renewable energy. Purpose: The purpose of this thesis work is to find the

quantities and location of biomass available to decide the optimal location of bioenergy technologies. The aim is to investigate further which conversion technologies are efficient and economically favored and what mode of transport could be paired with to minimize transportation costs. Further investigation will be applied regarding the impact of future increased bioenergy effect on South Africa's energy supply and could bioenergy potentially replace the energy derived from coal. Research question: The purpose was filtered down into the following research questions:

• RQ1 - What are the current biomass quantities and distributions within South Africa? • RQ2 - What conversion techniques are efficient and economically favorable to replace

the energy from fossil fuels in South Africa?

• RQ3 - What is the future potential for cultivating biomass in South Africa?

Method: Data regarding quantities and location of available biomass for energy applications

was collected with information regarding efficiencies and production cost of various conversion technologies. This information, together with different inputs from interviews, built the foundation for constructing different scenarios of producing bioenergy. Models were constructed according to the different scenarios and simulated to produce the amount of energy required with the lowest production cost as an outcome. These simulations made it possible to compare the different technologies' effects on the production cost. Data from previous research regarding the cost of transporting the biomass was collected to compare the impact of different technologies on transportation costs. The energy produced from the different scenarios was then compared with the total energy supply and demand in different sectors to see how much could be replaced by bioenergy. Discussion: It became clear that the technologies that were already mature and commercial were more efficient and had lower production costs than the other technologies. Nevertheless, efficient conversion contributed to more energy but also lower transport costs since less biomass was required to produce the same amount of energy. Since the available biomass used in the simulations mostly contained lignocellulose, which is inedible to humans, it does not compete with food production. It is clear that the potential exists for developed bioenergy, but the fear is that increased

development of bioenergy will lead to unemployment. Conclusions: Presently, bioenergy accounts for 8.3% of total energy production in South Africa. There are currently 61 million tons of available biomass. The majority is located in the northeastern parts of the country, which makes these parts optimal for the extraction and implementation of bioenergy applications. Given the current infrastructure, trucks are considered to be the most feasible transport mode. The techniques most suitable for establishment are combined heat and power with hydroprocessing. Combining these technologies will provide the lowest

production costs but also the most significant energy production possible. The development of renewable energy lacks confidence in South Africa, and significant investments would be required to accelerate the development of bioenergy and renewable energy as a whole. The use of the available biomass could meet the energy demand in different sectors of South Africa and increase the total supply of energy up to 9 % or replace the energy supply derived from coal by 15%. Increased production from bioenergy would make the country less

dependent on coal-derived energy, which would lead to fewer emissions and significant environmental benefits.

SAMMANFATTNING

Bakgrund: Intresset för utveckling av förnyelsebar energi har ökat världen över vilket har

lett till ökad energiproduktion från biomassa har ökat. I Afrika produceras 90% av all förnyelsebar energi från biomassabaserade källor. Dock har Afrika den lägsta produktionen av elektricitet och bränslen från biomassa, eftersom biomassan främst används till

matlagning och uppvärmning. Vattenbrist och en nuvarande infrastruktur uppbyggd runt kol som huvudsaklig energikälla, har hindrat utvecklingen av effektiv användning och

produktion av bioenergi i Sydafrika. Stated Policy Scenario har satt energimål för

energiproduktionen från biomassa i Sydafrika fram till 2040 för att tvinga implementering och anpassning av effektivare tekniker för att utnyttja de tillgängliga resurserna för att producera förnybar energi. Syfte: Syftet med detta examensarbete är att hitta mängderna och placering av biomassa som är tillgänglig för att fastställa vilken plats som är mest optimal för appliceringen av bioenergiteknologier. Målet är att undersöka ytterligare vilka

konverterings tekniker som är mest effektiva och har samtidigt låga produktionskostnader som samtidigt kan bidra med låga transportkostnader. Ytterligare så kommer det undersökas hur ökad bioenergiproduktion påverkar Sydafrikas energiförsörjning och om bioenergi potentiellt kan ersätta den energi som produceras från kol. Frågeställningar: Syftet smalnades av till dessa frågeställningar:

• F1 - Vilka är de nuvarande biomassakvantiteterna och distributionerna i Sydafrika? • F2 - Vilka omvandlingstekniker är effektiva och ekonomiskt fördelaktiga för att

ersätta energin från fossila bränslen i Sydafrika?

• F3 - Vad är den framtida potentialen för odling av biomassa i Sydafrika?

Metod: Uppgifter och data gällande kvantiteter och plats för tillgänglig biomassa som är

tillgänglig för energi och bränsleproduktion samlades in tillsammans med information gällande effektivitet och produktionskostnader för olika konverteringstekniker. Denna

information tillsammans med åsikter från intervjuer, byggde grunden för att konstruera olika scenarier för att producera bioenergi. De olika scenarierna simulerades för att producera den mängd energi som krävdes med lägsta produktionskostnad som ett resultat. Dessa

simuleringar gjorde det möjligt att jämföra de olika teknikernas påverkan på produktionskostnaden. Ekvationer från tidigare forskning för att räkna ut

transportkostnaderna för biomassa samlades in för att jämföra hur de olika teknikers påverkade transportkostnaderna. Energin som producerades från de olika scenarierna jämfördes sedan med den totala energiförsörjningen och efterfrågan i olika sektorer för att se hur mycket som kan ersättas med bioenergi. Resultat och Diskussion: Det blev tydligt att teknologierna som redan var mogna och kommersiella var mer effektiva och hade lägre produktionskostnader än de resterande teknologierna. Effektiv konvertering lede inte bara till mer energi men också lägre transportkostnader eftersom mindre biomassa krävdes för att producera samma mängd energi. Eftersom den tillgängliga biomassan som användes i

simuleringarna innehöll lignocellulosa, vilket är oätlig för människor, och därför inte konkurrerar med matproduktionen. Det är tydligt att potentialen finns för utvecklingen av bioenergi, men rädslan är stor att utveckling av bioenergi kommer medföra hög arbetslöshet.

Slutsatser: För närvarande står bioenergi för 8,3% av den totala energiproduktionen i

Sydafrika. Det finns för närvarande 61 miljoner tonbiomassa. Majoriteten ligger i de

nordöstra delarna av landet på grund av bättre vattentillgång och kortare regnperioder. Detta gör dessa delar optimala för utvinning av biomassa och implementering av

bioenergiapplikationer. Med tanke på den nuvarande infrastrukturen anses lastbilar vara det mest framgångsrika transportypen. De tekniker som är mest lämpade för etablering är

kombinerad värme och kraft tillsammans med vätgasbearbetning av bio olja. En kombination av dessa teknologier resulterar i lägst produktionskostnaderna och samtidigt störst

energiproduktion. Utvecklingen av förnybar energi saknar förtroende för Sydafrika, och betydande investeringar skulle krävas för att påskynda utvecklingen av bioenergi och förnybar energi som helhet. Användningen av den tillgängliga biomassan kan möta

eller ersätta energiförsörjningen från kol upptill 15%. Ökad produktion från bioenergi skulle göra landet mindre beroende av kol som energikälla, vilket skulle leda till färre utsläpp och betydande miljöfördelar.

PREFACE

This thesis was conducted in the spring of 2020 at Mälardalens University in Västerås. This thesis work was directed towards the field of energy technology within the Industrial Engineering and Management program and focusing on the development of bioenergy in South Africa.

With this preface, I want to take this opportunity and thank the people who contributed to the completion of this thesis work.

I want to give huge thanks to Ryan Merckel, who was my supervisor in South Africa. His help and cooperation contributed to the most unforgettable journey of my life. His broad

knowledge and understanding within the area of bioenergy were inspiring and instrumental for me, carrying through this thesis work.

I want to thank Jan Skavril, who was my supervisor back at home in Sweden. Even during unprecedented conditions brought by the COVID-19 pandemic, he was always there to support and inspire me during this journey.

Mälardalens University 2020

CONTENT

1 INTRODUCTION ... 1

1.1 Background ... 1

1.2 Problem definition ... 2

1.2.1 Identifying the knowledge gap ... 3

1.3 Purpose ... 3

1.4 Research questions ... 3

1.5 Scope and delimitation ... 4

2 METHOD ... 4 2.1 Data collection... 5 2.2 Interviews ... 6 2.3 Scenarios ... 6 3 LITERATURE STUDY ... 7 3.1 Types of Biomass ... 7 3.1.1 Biomass... 7 3.1.2 Lignocellulosic Biomass ... 8

3.1.3 Crops and Vegetables ... 9

3.1.4 Waste Biomass ... 9 3.2 Conversion techniques ... 9 3.2.1 Direct combustion ... 9 3.2.2 CHP ... 9 3.2.3 Pyrolysis ... 10 3.2.3.1. PYROLYSIS PROCESSES ... 10 3.2.3.2. SLOW PYROLYSIS... 10 3.2.3.3. FAST PYROLYSIS ... 10 3.2.3.4. FLASH PYROLYSIS ... 11 3.2.3.5. PYROLYSIS YIELD ... 11 3.2.4 Gasification ... 11 3.2.5 Hydroprocessing ... 12 3.2.6 Catalyst upgrading ... 13

3.2.6.1. IN- AND EX SITU UPGRADING ... 13

3.3 Transportation ... 13

3.4 Maturity and commercialization of bioenergy ... 14

3.4.1 Direct Combustion ... 15

3.4.2 CHP ... 15

3.4.4 Pyrolysis ... 16 3.4.4.1. HYDROPROCESSING ... 16 3.4.4.2. CATALYTIC UPGRADE ... 16 4 CURRENT STUDY ... 17 4.1 Location of biomass ... 17 4.2 Available biomass ... 20

4.3 Energy production in South Africa ... 22

4.4 Conversion of biomass via pyrolysis ... 24

4.5 Hydroprocessing ... 24 4.6 Catalytic upgrade ... 25 4.7 Gasification ... 26 4.8 Direct combustion ... 26 4.9 CHP ... 27 4.10Transportation ... 27

4.11Current energy prices... 28

4.12Obstacles for future development of bioenergy ... 29

5 SCENARIOS ... 30

5.1 Simulating the scenarios ... 31

5.2 Scenario 1 ... 31

5.3 Scenario 2 ... 32

5.4 Scenario 3 ... 33

6 RESULT AND DISCUSSION ... 34

6.1 Summary of discussion ... 39

7 CONCLUSIONS ... 41

8 SUGGESTIONS FOR FURTHER WORK ... 41

REFERENCES ... 42 APPENDIX 1: WHEAT RESIDUES AND SOLID WASTE

APPENDIX 2: SORGHUM GRAIN AND SORGHUM SUBSISTENCE

APPENDIX 3: SUNFLOWER SUBSISTENCE AND SOYBEANS SUBSISTENCE APPENDIX 4: GROUNDNUTS SUBSISTENCE AND DAYS/YEAR WITH MILD SOIL WATER STRESS

APPENDIX 5: ENERGY DEMAND IN DIFFERENT SECTORS IN SOUTH AFRICA APPENDIX 6: TRANSPORTATION COST

APPENDIX 7: INTERVIEW QUESTIONS APPENDIX 8: INTERVIEW QUESTIONS

LIST OF FIGURES

Figure 1 Method ... 5

Figure 2 CHO – Plot - Retrieved from (Ryan Merckel, 2019) ... 8

Figure 3 Domestic supply of different biomass fuels globally inspired by (Global Bioenergy Statistics 2019) ...14

Figure 4 Trend in biomass as renewable energy publications during the period 2000-2018 inspired by (Perea-Moreno et al., 2019) ... 15

Figure 5 The technology trend in bio-pyrolysis technology (adaptive by author) ...16

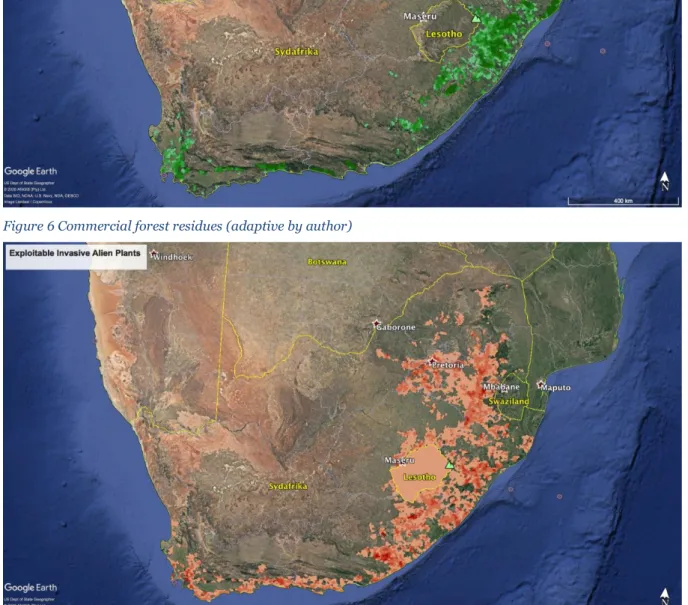

Figure 6 Commercial forest residues (adaptive by author) ... 18

Figure 7 Exploitable invasive alien plants (adaptive by author) ... 18

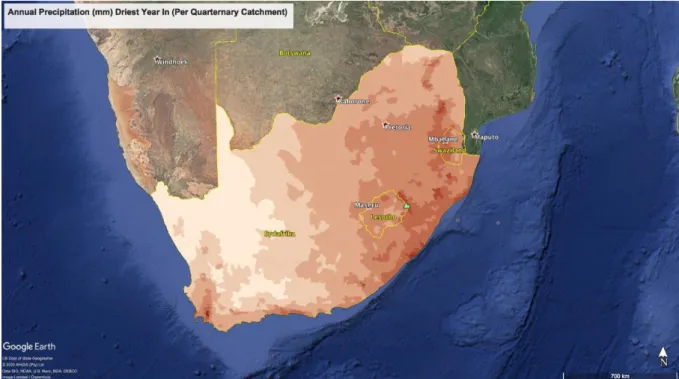

Figure 8 Annual precipitation(mm) driest year in (per quaternary catchment) (adaptive by author) ...19

Figure 9 Highest annual stormflows(mm) in 10 years (adaptive by author) ...19

Figure 10 Total primary energy supply in South Africa (Pelkmans & Bali, 2018) ... 22

Figure 11 Supply of renewable energy sources in South Africa (Pelkmans & Bali, 2018) ... 23

LIST OF TABLES

Table 1 Pyrolysis yield (Basu, 2018) ... 11Table 2 Yield from pyrolysis oil through hydrotreating (Wright et al. 2010) ... 12

Table 3 Cost per liter from hydrotreating – Retrieved from (Wright et al. 2010) ... 12

Table 4 Yield from catalytic upgrade – Retrieved from (Dutta et al. 2015) ... 13

Table 5 MFSP In Situ/Ex situ - Retrieved from (Dutta et al. 2015) ... 13

Table 6 Utilized biomass (adaptive by author) ... 20

Table 7 Available biomass for energy applications (adaptive by author) ... 20

Table 8 Biomass resource utility ... 21

Table 9 Stated Policy Scenario energy demand ... 22

Table 10 Total primary energy supply (adaptive by author) ... 23

Table 11 Cost of hydroprocessing ... 25

Table 12 Average cost per liter of catalytic upgrade ... 25

Table 13 Average cost liter of catalytic upgrade ... 25

Table 14 Hydrogen from gasification ... 26

Table 15 Current energy prices... 28

Table 16 Cost of different conversion technologies... 28

Table 18 Scenario 2 ... 32

Table 19 Scenario 3 ... 33

Table 20 Scenario 1,2,3 – 293 PJ ... 34

Table 21 Scenario 1,2,3 – 293 PJ – Production and transportation costs ... 34

Table 22 Scenario 1,2,3 – 418 PJ ... 35

Table 23 Scenario 1,2,3 – 418 PJ – Production and transportation costs ... 35

Table 24 Scenario 1,2,3 – 544 PJ ... 36

Table 25 Scenario 1,2,3 – 544 PJ – Production and transportation costs ... 36

Table 26 Scenario 1,2,3 – Max production ... 37

Table 27 Scenario 1,2,3 – Max production – Production and transportation costs ... 37

NOMENCLATURE

Symbol Description Unit

°C Celsius Degrees

$ Dollar Currency

EJ Exajoule Joule

kWh Kilo watt hour Joule

L Liter Volume

LHV Lower Heating Value MJ/kg

MJ Mega joule Joule

MPa Mega Pascal Pascal

P Power Watt

PJ Peta Joule Joule

PJ/a Peta joule/annual Joule

PJ/Tg Peta joule/Tera gram Joule

Tg/a Tera gram/annual Gram

ABBREVIATIONS

Abbreviation DescriptionCHO Carbon, Hydrogen and Oxygen

CHP Combined heat and power

MFSP Minimum fuel selling price

Mtoe Million tons of oil equivalent

Wt% Weight percent

DEFINITIONS

Definition Description

Ex Situ Catalytic upgrading of the steam takes place outside of the boiler

In Situ Catalytic upgrading of the steam takes place inside the boiler

1

INTRODUCTION

The effects of today’s climate change combined with the continued volatility in fuel prices, the recent food crisis, and the global economic turbulence have triggered a sense of urgency among policymakers, industries, and development practitioners to find sustainable solutions in the field of biofuels. (Amigun et al., 2011)

In Africa the lack of access to electricity, clean cooking and unreliable electricity supply needs to be addressed. Almost half of all Africans do not have access to electricity in 2018, and several countries in Africa are often affected by electricity disruptions that lead to economic losses. Population lack access to clean cooking and the resulting household's air pollution from traditional biomass use causes 500,000 premature deaths per year. (Cozzi et al., 2019) A more efficient use and implementation of biomass derived technology would not only increase energy security but also reduce the number of deaths caused by traditional biomass use.

When it comes to the development of bioenergy in South Africa, water supply is a major problem. It is imperative that bioenergy strategies that are developed for a country like South Africa to consider water resource effects along with all other relevant social, economic, and environmental considerations associated with the industry's development (Amezaga et al., 2010). It is essential that resources being used as biomass to further produce bioenergy or biofuels do not affect food production or minimize existing water resources.

This thesis work will investigate different types of conversion methods for refining biomass and how the effect differs between the different technologies and what final fuels can be produced from different feedstocks. In 2017, the amount of electricity produced from

renewable energy sources and bioenergy came third after wind and water as the third-largest contributor. Bioenergy is the most used renewable energy source for derived heating and is considered one of the best options for replacing fossil oil (Global Bioenergy Statistics, 2019). The different modes of transport will be compared to find the most optimal transportation mode for the biomass. The transportation of the biomass contributes to the production price and emission of producing bioenergy (Searcy et al., 2007). This is important to consider for appropriate choice of technology.

In this thesis work, the biomass will be located and the biomass available for energy use will be examined and how the produced energy from biomass will affect the demand and supply from fossil fuel and in which sectors the energy could be of use. In order to find which type of technology is best suited for biomass processing, they are further investigated to see which technology is most efficient and also has the lowest production cost. The technologies will also be examined regarding maturity and the readiness for commercialization.

1.1 Background

Bioenergy is a renewable energy recourse, and because of its short life cycle, biofuels have the potential to replace fossil fuels. As biomass grows, it absorbs carbon from the atmosphere, which is released into the environment when it is incinerated. This makes biomass a carbon-neutral fuel, and the development of this fuel will be significant if dependence on fossil fuels is to decrease in the future. By reducing the use of fossil fuels, greenhouse gas emissions will reduce, which in turn reduces global warming and climate change. (Chen et al., 2019) The

interest in the development of bioenergy production has increased, and more than 30 countries have announced that they will increase their production of renewable resources from biological materials and convert them into products such as food, animal feed, and bioenergy (Bosch et al., 2015).

There is a wide selection of different raw materials that can be used to produce biomass for potential end-use applications, which will play a significant role in avoiding or reducing the effects of land use and related potential competition between food- and fuel production (Parajuli et al., 2015). In Africa, renewable energy accounts for about 50 % of energy supply from renewable energy sources, and biomass-based sources produce more than 90 % of total primary energy supply from renewable energy sources. However, Africa has the lowest production of electricity and liquid fuels from biomass, since the biomass is used for cooking and heating. (WBA, 2018)

Biomass is a vital source of energy in Africa that can be used to lower their dependence on fossil fuels. However, in South Africa, increased use of biomass could lead to rapidly

declining crop production, leaving millions exposed to starvation, with the rural population being most affected (Amigun et al., 2011). Water scarcity is a significant problem in South Africa, which has hindered the development of biomass production to some extent. The importance of implementing the right technology and growing the right raw material is, therefore, crucial. To maintain the balance between biomass and food cultivation is critical for bioenergy development. Technologies implemented have to be able to use a variety of resources thus reduce their dependencies of resources used for food cultivation. (Amezaga et al., 2010)

The focus needs to be to use biomass feedstocks that can be grown and cultivated on land that will not directly compete with existing agricultural resources, limiting the impact of increased use of biomass for bioenergy applications (Blanchard et al., 2015). If appropriately implemented, bioenergy offers an opportunity for the production of renewable energy and the displacement of fossil fuels as energy sources. The production and use of biomass would lead to a more developed and integrated sustainable agricultural system and improved natural resource management. (Stafford et al., 2019)

The Stated Policy Scenario has set energy targets for how large the future energy production from bioenergy should look in South Africa until 2040. To force the implementation and adaption of more efficient technologies that utilize the available resources to produce renewable energy. (Cozzi et al., 2019)

1.2 Problem definition

Energy supply in South Africa relies heavily on fossil fuels due to the productive coalfields present in the region. The local grid is managed almost solely by the parasternal company, Eskom, which generates most of South Africa's energy. (Muller, 2017) The South African climate is conducive to ensuring high specific growth rates of biomass due to high solar irradiance, albeit being a water-scarce area. Unfortunately, Eskom has not been able to meet the increasing demand for energy, which has led to regular power cuts, which in turn has led to significant growth in the renewable energy sector (Avila & Kammen, 2018). Among renewable energy resources, biomass is the one most used. Through the literature study, there were many papers and articles on the available biomass (Hugo, 2016), the

transportation of biomass (Searcy et al., 2007), conversion technology (Basu, 2018), the maturity of bioenergy (Dehghani Madvar et al., 2019), energy demand in various sectors (Ratshomo & Nembahe, 2019) and production cost (Wright et al., 2010). Nevertheless, there

final decision of what bioenergy technology should be implemented to develop the usage of bioenergy in South Africa.

1.2.1 Identifying the knowledge gap

The purpose of exploring existing literature is to discover what has already been studied and what the research should be focused on. What concepts and relevant theories are relevant, what research methods and research strategies have been used, and are there any

inconsistencies in findings relating to this area. (Bryman,2012) There was no literature comparing the production of bioenergy from different types of biomass through different bioenergy techniques in South Africa and comparing production costs to decide which one is more commercially ready and cost competitive for establishment. There is no information on how the choice of conversion technology affected transport costs in South Africa and the choice of fuel produced. From the information gathered from previous research, it became clear that there was a knowledge gap considering all the different aspects that contribute to the development of biomass energy. Once the gap was identified, the purpose and research questions for this thesis work were constructed. By going through the literature, it will become clear if the problem formulation has been answered before and if it is relevant to this study. Reading past research and articles gives a better knowledge of which technologies are best suited for extracting different types of biofuels. Sources investigated displays how much biomass is currently available and how much of that biomass actually can be used to produce bioenergy. Costs have been generated to see how much it costs to refine biomass into energy or fuel and if it has an impact on choosing different techniques. Information that has been used is from research articles and previous research. The information collected is from different databases such as NREL, USDA, Science direct, Primo, Google scholar and UP library. Furthermore, a method was developed to answer the research questions with the help of the literature study.

1.3 Purpose

The purpose of this thesis work is to find the what kind of biomass feedstocks that are available for energy production. Gather information regarding the quantities and location of the biomass available to decide the optimal location of bioenergy technologies. The aim is to investigate further which conversion technologies are efficient and economically favored and what mode of transport could be paired with to minimize transportation costs. Further investigation will be applied regarding the impact of future increased bioenergy effect on South Africa's energy supply and could bioenergy potentially replace the energy derived from coal.

1.4 Research questions

• RQ1 - What are the current biomass quantities and distributions within South Africa? • RQ2 - What conversion technology is efficient and economically favorable to replace

the energy from fossil fuels in South Africa?

1.5 Scope and delimitation

The vast biomass resources will be considered in connection with their proximity to significant infrastructure in the South African. Of these, the most significant biomass resources are selected for further analysis. Costs for each commodity will not be considered as the price varies widely for each commodity from location to location.

Typical biomass technologies will be analyzed based on available information provided in the literature and the types of biomass resources selected. Significant comparisons are mainly based on economic feasibility in view of the energy change. Since there are many ways to convert biomass to fuel, hydrogen through gasification, direct combustion, combined heat and power, pyrolysis and upgrading of the pyrolysis oil via hydroprocessing and catalytic upgrading has chosen to be investigated in more depth. This thesis will compare production costs against the efficiency of the various conversion technologies to produce the final fuel. This report does not consider the political situation or any laws that prevent the use of biomass, as it would require an in-depth analysis to cover the political situation in South Africa. Therefore, any capital costs and investments will be excluded as this would require support from both politicians, investors, and companies.

2

METHOD

The following sections describe how the method of this thesis was conducted. This chapter describes the procedure for information and data collection as well as interviews and how it was used for the construction of various scenarios that were then used as a basis for

designing a model that is simulated and optimized to achieve the desired results. At first, a literature study was conducted, from which the problem was identified. The purpose and research questions for this report were then formulated. The study areas and data collection contributed to the formation of the various scenarios that, through simulation, produced a result that could be analyzed. The analysis could then be discussed to come to the conclusions of this report. An overall picture of the method is shown in Figure 1, and this section deals with each method step in further depth. The picture also describes how the method was divided into three parts and the following paragraphs go into more detail how the method conducted.

Figure 1 Method

2.1 Data collection

By classifying data and categorizing sources in different fields of science, one can draw the assumption of whether the information is useful or not. Information and sources that the author himself has produced are seen as primary sources. Secondary sources are information that does not fall within the scope of his or her research area and, for example, be researchers who have written about a particular area. (Blomkvist & Hallin, 2017)

The primary information in this report will consist of data collected from government-owned sites that promote the development of renewable energy sources in South Africa. The other part is information given from the interviews. In the first interviews conducted, the questions were semi-constructed to give a better insight into what material needed to add to answer the survey questions. After that, more detailed interview questions were constructed where the interviewee must value what is most important for the development of bioenergy to move forward. Secondary data consisted of literature and data collected on the various areas chosen to analyze.

Keywords such as "biomass availability in South Africa" were used to find information about where in South Africa biomass is available. Through the literature research, the page Bio energy atlas was found. Data files collected from the Bio Energy Atlas in the form of zip files that contained the location of different biomass sources and the amount in different parts of South Africa. The zip files contained data, and by uploading these files on google earth, made it possible to create own maps that could illustrate where in the country, biomass is available. By finding out where the biomass was available, it was possible to determine how much biomass was available and what different types of biomass were available. To better understand why biomass is available in these areas, zip files were also loaded that could illustrate weather conditions and how much drought or rain it was in some areas in South Africa. By comparing the availability with the weather change, conclusions could be drawn as to why these areas were more suitable for growing biomass than others.

The division between what is a primary source and a secondary source depends on their function in the study. Primary sources are the empirical material that is very close to the purpose of the study. (Blomkvist & Hallin, 2017) Data on the different biomass types and quantities was obtained from the Department of Science and Technology, which is a government-owned institution promoting the development of renewable energy in South Africa. The information regarding different conversion technologies that was obtained from

Literature study Problem definition Purpose Research questions Methodology Result/Discussion Conclusions

• Data collection

• Interviews

• Design of scenarios

the literature study. These sources are therefore classified as a primary source as the

information regarding the quantities of biomass in South Africa and the different conversion technologies is close to the purpose of this study.

To help evaluate the reliability of different empirical sources, whether they are primary or secondary sources you should always critically analyze whether the sources are scientifically useful for your purpose. (Blomkvist & Hallin, 2017) By being critical of the information, and the data collected by comparing it with previous studies, conclusion could be drawn whether the information was reliable or not. By using the function peer-reviewed the academic and scientific research used in this report have been reviewed by experts which brings credibility to the research.

2.2 Interviews

Correspondents who have been selected to be interviewed are people with knowledge of the various processing techniques used to process biomass into final fuel. They also had a sense of how the current development of bioenergy looked like in South Africa. The first round of interviews was held to provide a better overall view of the areas that have been selected to be investigated. The conduction of the interviews was contributing to the report as the answers provided knowledge and insights about what might be needed to be added or supplemented. In the second round of interview questions, factors, and limitations that were considered to have a significant impact was collected, giving an understanding of whether there is potential for future bioenergy development in South Africa. The interview products contributed to the construction of the various scenarios when they were involved and contributed with opinions regarding which techniques should be used and which end product should have the best potential in South Africa. The responses also influenced the choice of transport mode regarding the transportation of the biomass, as the correspondents possessed a better knowledge of the current infrastructure. The interview questions are attached in appendix 7 and 8.

2.3 Scenarios

The Stated Policy scenario has set out goals for South Africa to reach regarding energy produced from bioenergy. This is to make use of available renewable energy sources more efficiently and thus increase the development of renewable energy. (Cozzi et al., 2019) Three scenarios have been designed in this report to achieve these goals. This is to see which technologies best to use when producing the final energy required cost-effectively and what type of energy is being produced to keep the production cost as low as possible. As

transportation cost also has its effect on the final cost, they were also calculated.

• The first scenario was designed to use specific raw materials to produce specific end products. This was constructed in this way because it was considered to be the best option, according to Hugo (2016).

• Since the different biomass raw materials have the potential to be used in several different processes to produce different types of energy, a scenario was built to utilize this to see if it could mean increased energy production and lower production and transport costs.

• The third and final scenario was constructed based on what the interviewed persons considered to be the type of energy or fuel that should be produced from the biomass. The answers from interviews also influenced the choice of conversion technology in this scenario.

Each scenario served as a template for building a model for each scenario in excel that could be simulated. Through the simulation of the different models, optimization of costs and energy production could be performed. Restrictions were put into excel so that only the selected technologies according to the respective scenario can be used to produce the final fuel from the respective raw material. Data regarding the quantities of biomass, production costs, and efficiency for each technology as well as transport costs, were transferred into an Excel sheet. Then a function called problem solver was used to find the technology that produces the requested energy as cheaply as possible by dividing the biomass between the different technologies to reach the requested level of energy with as low production cost as possible. The biomass used in the simulations was also used to calculate transport costs. The result illustrated the different production cost, transportation cost, and the final amount of energy produced. The final costs made it possible to see how different technologies affected these different areas and which type of technology or fuel is better to decrease total cost or increase efficiency. The technologies used to a large extent to produce energy were compared with previous literature regarding the degree of maturity and commercial readiness to see if there were any connections regarding the energy production and production costs.

3

LITERATURE STUDY

To develop further knowledge in the area regarding different types of biomass and the different energy products to which the biomass can be converted into, a literature study was conducted. The literature study also covers the various techniques available to convert the biomass into bioenergy in form of electricity, biofuel, heat and hydrogen that laid the

foundation for designing the various scenarios and procedures for calculating production and transportation costs.

3.1 Types of Biomass

There are different forms of biomass, and they all require water to be produced. This

becomes a problem because water is required to produce food for the population. Since South Africa is an already water-scarce country, the biomass used to produce energy must not compete with food production. This chapter presents different types of biomass and why some do not compete with food production, which makes it possible to use it for bioenergy production instead.

3.1.1 Biomass

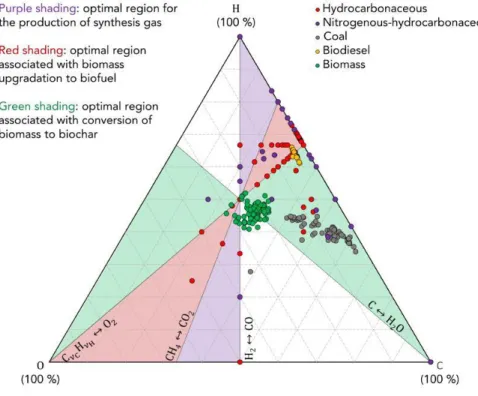

Biomass feedstocks are generated from agricultural crops and residues, herbaceous and woody materials, and organic wastes. These materials can be either directly combusted for energy production or processed into energy products such as bioethanol, biodiesel, and biogas, which are used as transportation fuels or for electricity and heat production. (Cheng, 2018) The triangle in Figure 2 is a CHO plot where the corner with C stands for carbon, H for hydrogen, and O for oxygen. The CHO-triangle provides a good overview of how the process of converting biomass into different fuels works (Merckel, 2019).

Biomass is located in the middle of the triangle, which means that it is an excellent raw material for producing different fuels and is very flexible as a feedstock. If the goal is to create a synthesis gas, then carbon monoxide is extracted which is within the purple area. If the goal

is instead to produce biochar, then water is extracted which is illustrated within the green area.

A ternary diagram can depict thermochemical transformation processes on the diagram. For example, slow pyrolysis moves the product toward carbon by forming solid carbon; fast pyrolysis moves it towards hydrogen and away from oxygen, which means higher liquid product. Oxygen gasification moves the gas product toward the oxygen corner, while steam gasification takes the process away from the carbon corner. The hydration process increases hydrogen and thus moves the product towards hydrogen. (Basu, 2018)

Figure 2 CHO – Plot - Retrieved from (Ryan Merckel, 2019)

3.1.2 Lignocellulosic Biomass

A significant part of biomass is lignocellulose and consist of cellulose, hemicellulose, and lignin (Basu, 2018). According to Kuila & Sharma (2017) hardwood, softwood, grass, and agricultural residues all consist of lignocellulosic material, which is the most superior raw material. They also mention that lignocellulosic biomass has very high energy density and is compatible with combustion processes for energy conversion and biofuel production without contributing to emissions that affect the environment or climate. Lignocellulosic biomass is not a part of the human food chain, and therefore its use for biogas or bio-oil does not threaten the world’s food supply (Basu, 2018). In the agricultural sector, vast quantities of residues are produced. Worldwide, billions of tons are produced annually, but the majority of these remains are discarded or burned (Hassan et al., 2018).

There are numerous techniques to convert lignocellulose biomass into energy. In a study by Cao et al. (2014) biomass can be transformed into biofuels either via combustion, pyrolysis, hydrothermal conversion, or hydrolysis. The method that has revealed to be most successful is pyrolysis due to technological development when it comes to thermal conversion (Cao et al., 2014).

3.1.3 Crops and Vegetables

While the body of a plant or tree is lignocellulosic, the fruit is a source of carbohydrate, starch, and sugar. The use of crops or vegetables for the production of chemicals and energy must be weighed carefully as it might affect food supplies. Compared to lignocellulosic compounds, carbohydrates are more comfortable to dissolve, so it is relatively easy to derive liquid fuels from them through fermentation or other processes. For this reason, most commercial ethanol plants use crops as feedstock. Animal waste like also provides fat that can be transformed into bio-oil. (Basu, 2018)

The economic turmoil in using crop residues as bioenergy is that increased use may affect or reduce the use of residues in more traditional approaches as farmers use the leftover animal crop as manure on the farms. If the biomass is used to produce energy, then the amount of fertilizer available for agriculture will decrease.

(Dahiya et al., 2014)

It becomes clear that the crops or vegetable used to produce bioenergy do not compete with the production of food in agriculture.3.1.4 Waste Biomass

Waste biomasses are secondary biomass, as they are derived from primary biomass like trees, vegetables and meat during the different stages of their production or use. The sewage sludge that contains human excreta, fat, grease, and food wastes is a vital biomass source. Another waste is produced in sawmills during the production of lumber from wood. (Basu, 2018) Biomass waste is also consisting of solid waste from agricultural residues, agricultural-industrial waste, and liquid food waste, and related agricultural-industrial wastewater is abundant with raw materials to produce biofuels and bioenergy. (Chen et al., 2018; Liu & Wu, 2016)

3.2 Conversion techniques

There are many different processes for converting biomass from raw material to final product. According to Batidzirai et al. (2016) these processes have different degrees of efficiency, production prices and types of final product. The comparison of production cost between the different technologies is important as the costs of producing bioenergy need to be competitive against the production costs of energy from fossil fuels in order to make it economically attractive to invest in such technologies (Batidzirai et al., 2016).

3.2.1 Direct combustion

By burning the biomass, the heat is used to heat water to produce steam, which in turn drives a turbine that produces electricity. This technique is one of the most basic techniques and has been used for a long time. Both Bertrand et al. (2014) and Peterson & Haase (2009) explains that the technology has a very low efficiency because it does not take advantage of excess heat from the combustion process and therefore has an efficiency of about 25 %.

According to U.S Department of energy (2016) the cost for producing electricity from

biomass through direct combustion varies between 3 000-5 000 $ per kW and levelized cost of energy for this system is around $0.08 to $0.15 per kWh depending on fuel cost.

3.2.2 CHP

In a combined heat and power (CHP) system, the process produces both heat and energy from various feedstocks (Thorin et al., 2015). Thorin et al., 2015 mention that the CHP process is highly efficient in utilizing the heat produced for different heat demands, for

example, in a district heating network, an individual building, or industrial processes. According to several authors, the efficiency of such a process is quite high and is,

consequently, around 90 %, and by implementing this kind of technology would contribute to lower CO2 emissions (Skouloudi et al., 2019; Thorin et al., 2015).

Lako et al. (2015) investigated the possibility of either developing a plant that only runs on biomass, or to redesign an already existing coal power plant so that it can additionally produce energy from biomass. The investment cost for a biomass-based CHP plant is

between 70 $ to 290 $/MWh, and retro-fitting already existing coal-fired power plant is only 40 to 130 $/MWh (Lako et al., 2015).

3.2.3 Pyrolysis

Pyrolysis is a process where biomass is fed into a boiler and is exposed to rapid heating, and absence of air and oxygen at different temperatures and produces end products in form of bio-oil, biochar and gas (Basu, 2018). According to Goyal,Seal & Saxena (2008) the interest in the pyrolysis method as a thermochemical process has increased considerably as the quality of the final product is better, compared to any other process.

Since the product in the form of bio-oil, bio-char, and gas is different depending on the temperature and heating rates, there are different names for the different pyrolysis processes. In the study by Dickerson & Soria (2013) slow pyrolysis produces more char, while fast and flash pyrolysis tends to produce more oil and gas. Pyrolysis is considered to be the most promising technology when it comes to converting cheap and local resources such as

lignocellulosic biomass such as trees and grass into useful fuel compatible to replace existing petroleum products (Dickerson & Soria, 2013).

3.2.3.1.Pyrolysis processes

In pyrolysis, larger molecules are broken down into smaller molecules, which in turn produces final products in the form of liquid oil, solid char, and gas. The quantities of these products depend, as previously stated, on three factors, the heating rate, time, and the final temperature of the material. (Basu, 2018) The following paragraphs briefly describe the difference between the different pyrolysis methods and what they are called.

3.2.3.2.Slow pyrolysis

Under oxygen-free conditions, slow pyrolysis is the oldest approach to treating biomass. The raw material can come from many different resources, but the most common are traditional wood, shells, and palm. The time the biomass spends in the boiler during slow pyrolysis can take anywhere from days to weeks. The heating takes place over a longer period of time, which means that coal production is increased as it slowly dries the material. An example of the use of slow pyrolysis is to produce charcoal used for barbeque. Slow pyrolysis is flexible as it can produce several different end products in the form of gas, oil and coal. (Hornung, 2014)

3.2.3.3.Fast Pyrolysis

In fast pyrolysis, during typical operating conditions, the temperature is usually around (450-600°C). The residence time inside the reactor is usually less than 2 seconds. This process produces mostly gas and bio-oil. Compared to other biofuel technologies, biomass fast pyrolysis allows a cost-effective route to liquid fuels. (Sharifzadeh et al., 2019)

3.2.3.4.Flash Pyrolysis

For flash pyrolysis, the heating rate is swift and goes up to 1000 °C/s. Furthermore, the temperature in the pan is between 800 – 1300°C. (Pandey et al., 2019) Because of the different heating rates and temperature differences, there are different yields of bio-oil, biochar, and gases from each process, which is illustrated in Table 1.

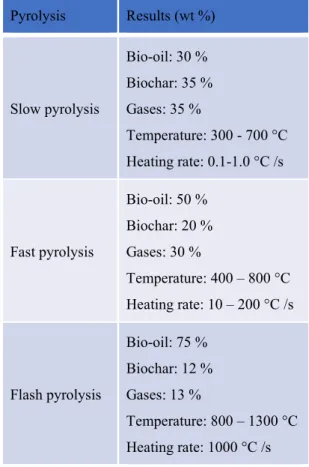

3.2.3.5.Pyrolysis yield

As mentioned earlier, there are different types of pyrolysis methods. Depending on which pyrolysis method is used, different types of biofuel are extracted. The most extensive types extracted are biocarbon, gas, and bio-oil. The size of these products extracted depends on the time and temperature parameters. According to Pandey et al (2019) the biggest yield of biooil that can be extracted from biomass is via flash pyrolysis. In Table 1 it shows the different yields in bio-oil, biochar and gases extracted from biomass at different temperatures and residence time (Basu, 2018).

Table 1 Pyrolysis yield (Basu, 2018) Pyrolysis Results (wt %) Slow pyrolysis Bio-oil: 30 % Biochar: 35 % Gases: 35 % Temperature: 300 - 700 °C Heating rate: 0.1-1.0 °C /s Fast pyrolysis Bio-oil: 50 % Biochar: 20 % Gases: 30 % Temperature: 400 – 800 °C Heating rate: 10 – 200 °C /s Flash pyrolysis Bio-oil: 75 % Biochar: 12 % Gases: 13 % Temperature: 800 – 1300 °C Heating rate: 1000 °C /s 3.2.4 Gasification

A typical gasification step involves chemical reactions among the hydrocarbons in fuel, steam, carbon dioxide, oxygen, and hydrogen in the reactor, as well as chemical reactions among the evolved gases. Of these, char gasification is the most important, and since this process is slower than devolatilization process, it takes up bulk of the time of the whole thermochemical process. (Basu, 2018) According to several studies, gasification has been shown to be the process that produces the most hydrogen per kg of biomass feedstock and production cost of hydrogen can vary between 2.1 $/kg to 6.1 $/kg. (Parks et al., 2011; Sara et

al., 2016; Valente et al., 2019). For every kg biomass, 4 grams is converted into hydrogen (Jaganathan et al., 2019).

3.2.5 Hydroprocessing

According to Wright et al. (2010) hydroprocessing or also called hydrotreating is an exothermic process used to remove contaminants that may affect downstream equipment selectively. Hydrocracking then breaks down the molecules into diesel and gasoline fuels that have competitive product value (Wright et al., 2010).

Hydro-processing rejects oxygen as water by a reaction with hydrogen. This is normally considered as a separate and distinct process to fast pyrolysis that can, therefore, be carried out remotely. The process is typically high pressure (up to 200 bar) and average temperature (up to 400°C) and requires a hydrogen supply of source. Full hydrotreating gives a naphtha-like product that requires orthodox refining to derive conventional transport fuels. (Brown & Stevens, 2011)

Table 2 explains how much of the bio oil is actually upgraded to gasoline and diesel fuel (Wright et al., 2010). This information can then be used to determine how much of the pyrolysis oil can be converted into petrol fuel. The petroleum fuel as mentioned earlier can later be utilized as transportation fuel or used as fuel in the industry to produce heat and electricity.

Table 2 Yield from pyrolysis oil through hydrotreating (Wright et al. 2010)

Feed Wt % Pyrolysis Oil 100 Hydrogen 3-4.5 Products Light Ends 15 Gasoline 30 Diesel 8

Water, Carbon Dioxide 51-52

There are different costs for upgrading bio-oil via hydro upgrade. The first way is to use some of the hydrogen extracted from the process. The second way is to import hydrogen from a separate source, which is then used to enhance the bio-oil to petrol fuel. The selling price for producing the final fuel through these different pathways is according to Wright et al. (2010), illustrated in Table 3, which shows that it is cheaper to buy hydrogen to upgrade the bio-oil than to produce hydrogen on-site. In the hydrogen purchase scenario, hydrogen that is not produced from non-renewable energy sources is preferred. This is to ensure that hydrogen production has as minimal greenhouse gas emissions as possible (Wright et al., 2010). According to Xiu & Shahbazi (2012), the real advantage of hydrotreating is that it is cheaper than catalytic upgrading but that the final fuel is of inferior quality.

Table 3 Cost per liter from hydrotreating – Retrieved from (Wright et al. 2010) Petrol/diesel fuel via hydroprocessing $/l

Hydrogen producing plant 0.82 $/l

Hydrogen purchase plant 0.56 $/l

The production price of biofuels from hydroprocessing with purchased hydrogen is low compared to the production price with onsite hydrogen production. However, this is because the purchase of hydrogen from fossil hydrogen production is cheaper than the production of hydrogen from renewable energy. Therefore, it is very important that the hydrogen gas used

to produce biofuels via hydroprocessing comes from renewable energy sources so that it does not contribute to additional greenhouse gases.

3.2.6 Catalyst upgrading

3.2.6.1.In- and Ex Situ upgrading

There are two different ways when it comes to catalytical upgrading. The first one is In Situ upgrading and the second one is Ex Situ upgrading. According to Dutta et al. (2015) In situ is when catalytic vapor upgrading occurs within the fast pyrolysis reactor, and Ex situ

upgrading of catalytic vapor takes place in a separate reactor after the fast pyrolysis reactor. An In Situ system includes catalytic upgrading in the fluidized bed rapid pyrolysis reactor system (Dutta et al., 2015).

In Table 4, the final fuel blend stock is illustrated. In situ cost more than Ex Situ because it requires a more advanced reactor to upgrade the biofuel with the catalytic vapor inside the reactor rather than outside. The minimum fuel selling price for in situ/ex-situ is showed in. (Dutta et al., 2015)

Table 4 Yield from catalytic upgrade – Retrieved from (Dutta et al. 2015) Final Fuel Blend stock

Catalyst method In Situ Ex Situ

Yield% 24% 25%

Table 5 MFSP In Situ/Ex situ - Retrieved from (Dutta et al. 2015) MFSP $/Gallon Fuel

In Situ

3.37 Gasoline blend stock 3.85 Diesel blend stock 3.46 Gasoline equivalent Ex Situ

3.26 Gasoline blend stock 3.68 Diesel blend stock 3.31 Gasoline equivalent

3.3 Transportation

This chapter examines whether the transport of the biomass affects the final price of producing bioenergy or biofuel and what type of transport is the most common. Prices for transporting the biomass have been collected to understand better how it varies in terms of weight, distance, and type of transport to deliver the biomass from area to location where the bioenergy or biofuel can be produced.

According to a study by to the power plant Searcy et al. (2007), transportation costs of the biomass from extracted location affects the final price of the fuel and energy produced from the feedstock. The study also mentions that the biomass can be transported via trucks, trains, ships, and pipelines, and by analyzing the distance and weights of the biomass being

transported, a comparison can be made regarding the transport costs between the different types of transport modes.

In order to transport the biomass toward the larger cities in South Africa, where the biomass later can be transformed from biomass to biofuel, a type of transportation has to be selected. According to Mahmudi & Flynn (2006), the two most traditional ways when transporting biomass is either by using trucks or trains. Transportation of biomass by train is the most economical alternative. Nevertheless, the design of railroads makes it challenging to install biorefineries or biopower plants as they must be incorporated into the railroad design (Mahmudi & Flynn, 2006).

In a study by Searcy et al. (2007), they have made it possible to calculate the cost of

extracting and transporting the biomass from location to the power plants or biorefinery by generating the average value for each type of transport. The result was that despite the high transportation costs of moving biomass with the help of trucks, this mode is preferred simply because of its high flexibility. The table in appendix 6 illustrates the different modes of transporting the biomass and its fixed and variable costs that can be used to calculate the total transportation costs.

3.4 Maturity and commercialization of bioenergy

This chapter examines the development of bioenergy and how mature the various conversion technologies are in order to understand whether any technology is considered more mature or commercially ready for implementation compared to the other technologies.

Its discussed whether bioenergy is the best direction to go and how far we have got into the development of various alteration processes. To comprehend what classification of

technology must be implemented, one needs to discover if the technology is sufficiently mature enough for a commercial establishment. If the technology is going toward a

commercial-stage, then this will gain trust, and corporations will be more enthusiastic about investing in such technology (Kampman et al., 2010).

Presently, bioenergy is the largest renewable energy source and accounts for more than half of all energy coming from renewable energy sources. Customarily, the biomass sources classify into six different types, municipal and industrial waste, primarily solid biofuel, biogas, and liquid biofuels. The data assembled is illustrated in Figure 3 displays the expansion and development of the numerous classes of biomass fuel. (Global Bioenergy Statistics, 2019)

Figure 3 Domestic supply of different biomass fuels globally inspired by (Global Bioenergy Statistics 2019) In the early 2000s, there were not many publications regarding biomass energy. All of this changed when the oil price increased to $ 136 per barrel, which was due to the economic downturn in 2008. Scientific production in the area has never been as high but is starting to

0 10 20 30 40 50 60 Biomass Municipal Waste Industrial Waste Primary Solid Biofuels Biogases Liquid Biofuels EJ 2000 2005 2010 2015 2016 2017

Figure 4 Trend in biomass as renewable energy publications during the period 2000-2018 inspired by (Perea-Moreno et al., 2019)

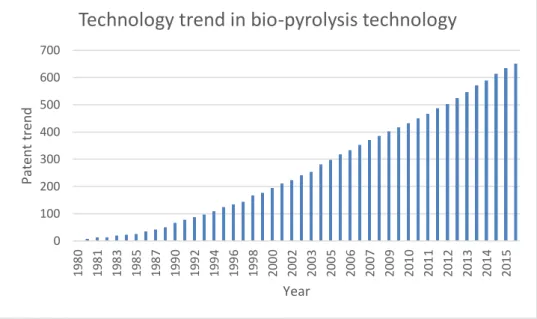

The research and development regarding lignocellulosic biofuel technologies have increased enormously worldwide. Patent studies in the biofuel field have increased significantly since the beginning of the 2000s and have sparked a commercial interest in biofuel production technologies (Toivanen & Novotny, 2017).

Biofuels technology has reached a high degree of commercial maturity as the technology has developed, which has led to an increasing number of countries starting to look at biomass as an alternative energy source. (McMillian & Saddler, 2019)

3.4.1 Direct Combustion

Combustion is one of the simplest methods for producing electricity from biomass. As this technology is very primitive, it also means that this technology is the one most used and applied. Therefore, combustion of biomass is already at a commercial-stage when it comes to electricity and heat production (Malico et al., 2019; Stephen & Periyasamy, 2018). The production of electricity from direct combustion of biomass is considered to be a technology that is developed and entirely commercial. (Brown & Le Feuvre, 2017)

3.4.2 CHP

Combined heat and power plants are today already considered to be the most widely used and mature technology when it comes to biomass production for electricity and the technology is already at a commercial stage. (Malico et al., 2019) One of the barriers right now in bio-cogeneration and biogas turbine technologies is the high installation costs (Dehghani Madvar et al., 2019).

3.4.3 Gasification

The potential for producing hydrogen from biomass is excellent, but the technology is not at that stage to be sufficiently mature to increase the mass production of hydrogen. The main obstacles are that production costs are too high, and the technology is not the same trust as other technologies. Therefore, this technology in early market development on a small scale. (Brown & Le Feuvre, 2017) This is confirmed by Taibi et al., (2018) who states that the technology is not yet mature and is in the stage between prototype and demonstration.

0 200 400 600 800 1000 1200 1400 1600 1800 2000 P u b lic ati o n s Year

3.4.4 Pyrolysis

Jacobson (2013) states that biomass and waste biomass has great potential for conversion into transportation fuels through fast pyrolysis and subsequent upgrading processes. Bio-oils are a promising renewable energy source that has gained wide recognition worldwide for its properties such as combustion fuels used in the boiler, engines or gas turbines and resources in the chemical industry. (Xiu & Shahbazi, 2012)

Bio-oil is one of the products produced by pyrolysis which can then be upgraded to petroleum fuel which in turn can be used as a fuel or to produce energy. The development of the

pyrolysis technology offers more durable products compared to other available technologies. (Uddin et al., 2018)

The development of pyrolysis as a technology shows excellent potential for producing bio-oil. In a study by Dehghani Madvar et al. (2019), the trend for Pyrolysis production as biomass technology is illustrated in Figure 5 and shows an increased interest in this technology and states that biofuels will play a vital role in the future of energy demand. Due to the costs, only a few commercial pyrolysis plants in Europe are currently operational (Malico et al., 2019).

Figure 5 The technology trend in bio-pyrolysis technology (adaptive by author)

3.4.4.1.Hydroprocessing

There have been significant advances regarding research on hydroprocessing of biomass during the last five years. Hydroprocessing produces higher yields of biofuels than catalytic upgrade and studies have shown that this technology is competitive with other biofuel processes. (Resende, 2016)

In several studies they mention that upgrading the bio-oil from pyrolysis through hydroprocessing is already considered a mature technology used on a commercial scale. (Amin, 2019; Baldino et al., 2019) This shows that hydroprocessing is ready for commercial establishment and should be prioritized over less commercial technologies when it comes to conversion of biomass into biofuels.

3.4.4.2.Catalytic upgrade

There are uncertainties regarding catalytic upgrading and its degree of maturity and

efficiency in previous literature. According to Brown & Stevens (2011), the production costs 0 100 200 300 400 500 600 700 1 9 8 0 1 9 8 1 1 9 8 3 1 9 8 5 1 9 8 7 1 9 9 0 1 9 9 2 1 9 9 4 1 9 9 6 1 9 9 8 2 0 0 0 2 0 0 2 2 0 0 3 2 0 0 5 2 0 0 6 2 0 0 7 2 0 0 9 2 0 1 0 2 0 1 1 2 0 1 2 2 0 1 3 2 0 1 4 2 0 1 5 P at e nt t re nd Year

also believe that the method has only been researched at the basic research level and needs further development.

Further research is needed before this process can be considered optimal. The catalytic upgrade of bio-oil is a process that arouses great interest at both research and development levels. There needs to be more research when it comes to choosing the right catalyst for this process. (Hu & Gholizadeh, 2019; Perkins et al., 2018)

4

CURRENT STUDY

In this chapter, the biomass has been located to see where in South Africa, the most

abundant quantities are situated, and which factors affect the availability of biomass in these areas. The amount of biomass available for energy and fuel production has also been

analyzed in this section, and what types of biomass are available as the energy content varies between the different types. Depending on the type of biomass available, they can be used to produce several different energy products in form biofuels, electricity and hydrogen. In this chapter, each commodity has been examined to determine which conversion technology can benefit from that commodity.

After that, the Stated Policy Scenario for South Africa is presented, and the current energy supply in South Africa. Energy already produced from bioenergy is presented in this chapter in order to be able to compare how further production of bioenergy can replace the energy in the different sectors. The different conversion techniques are discussed in this section to describe how biomass production for energy or fuel is calculated and how production costs and transport costs are calculated. Current fuel prices in South Africa have been collected to make a comparison between the fuel prices and production costs from the conversion technologies. Finally, barriers that have affected or affected the current development of bioenergy are presented.

4.1 Location of biomass

A study by Batidzirai (2016) confirms that there is potential to increase the energy potential of biomass, which could then replace energy production from fossil fuels in South Africa. By looking at how much biomass is available from different biomass feedstocks, conclusions can be made whether the energy produced from the available biomass can potentially replace energy production from different fossil fuels.

The mapping of the different biomass resources is of great importance in defining the power plants' type and location. Higher capacity needs a more significant amount of biomass feedstock to be supplied from the larger area, i.e., longer distances. Therefore, determining an optimal biomass power plant's optimal location plays a vital role in the efficient

organization of logistics operations, reducing total costs. (Bojić et al., 2013)

To create maps illustrating the different biomass feedstocks and different weather conditions data files was collected from The BioEnergy Atlas of South Africa in the form of zip files. By uploading the zip files on google earth it made it possible to create own maps that could illustrate where in the country, biomass is available.

Figure 6 and Figure 7 and pictures illustrated in appendix 1-4 show the potential for an increase in the production of the different types of biomass feedstocks in South Africa. Those parts that have darker color have a considerably higher potential for increased biomass availability, whereas there is no color, the potential is mostly non-existent. Figure 6

illustrates commercial forest residues and Figure 7 illustrates exploitable invasive alien plants residues and the maps in appendix 1-4 illustrates potential biomass feedstocks. These

feedstocks, with the exception of solid waste, contain lignocellulose that according to Hugo (2016) can make a significant contribution to electricity generation in regional powerplants.

Figure 6 Commercial forest residues (adaptive by author)

Figure 7 Exploitable invasive alien plants (adaptive by author)

It is clear the majority of the available biomass residues is located in the eastern parts of South Africa. To get a better understanding of why the potential for the different areas is better in these particular areas can be explained by looking at the figures below.

Figure 8 shows the rainfall for the driest year, where darker color indicates rainfall even during the driest periods. The areas that have the highest rainfall during the driest periods

Figure 8 Annual precipitation(mm) driest year in (per quaternary catchment) (adaptive by author)

Figure 9 shows the highest annual stormflows (mm) in 10 years. Stormflows are the drainage water from the country's surface water from rainfall. The darkest parts are the parts in South Africa with the most stormflows. It also shows here that the most humid parts are also in the eastern parts of South Africa.

Figure 9 Highest annual stormflows(mm) in 10 years (adaptive by author)

In Appendix 4, the picture shows the soil water stress in South Africa. The darker parts are the parts that have the least water stress, and the lighter parts have high water stress. This image is essential to observe, as it shows the areas where the water content is critical or not. By comparing Figure 6 and Figure 7 with Figure 8 and Figure 9, it gives a better

understanding of why the biomass is located the way it is and why it is challenging to

accumulate raw materials in certain parts of South Africa. In the western part of South Africa, there is not much rain, and therefore the soil is subjected to significant stress, which makes it