RUTTING POTENTIAL OF ELVALOY

®TERPOLYMER AND

POLYPHOSPHORIC ACID-MODIFIED ASPHALT BINDERS BASED

ON THE MSCR TEST AND THE BURGERS MODEL

Matheus David Inocente Domingos

Department of Transportation Engineering, São Carlos School of Engineering, University of São Paulo Avenida Trabalhador São-Carlense, 400, Parque Arnold Schimidt, São Carlos, SP, Brazil, 13566-590

Phone: +55 16 33739613 E-mail: matheusdavid@sc.usp.br

Co-authors(s); Adalberto Leandro Faxina, Department of Transportation Engineering, São Carlos School of Engineering, University of São Paulo.

ABSTRACT

Asphalt binders play a key role in the resistance of the asphalt mixture to failure by rutting, fatigue cracking and low-temperature cracking. With respect to rutting, the multiple stress creep and recovery (MSCR) test has been taken by researchers worldwide as an interesting alternative to estimate the susceptibility of the material to the accumulation of permanent strain (Jnr – nonrecoverable creep

compliance) and the level of its elastic response (R – percent recovery), as well as its stress sensitivity and degree of nonlinearity (Jnr, diff – percent difference in nonrecoverable compliances). In addition to

these parameters, the four-element Burgers model has been commonly used in the literature to fit the repeated creep data obtained in this test. The present study utilized the MSCR test to analyze the creep-recovery behavior of asphalt binders modified with polyphosphoric acid (AC+PPA, PG 76-xx) and Elvaloy® terpolymer combined with PPA (AC+Elvaloy+PPA, PG 76-xx) at high pavement temperatures

ranging from 52 to 76°C. A recent test protocol standardized by AASHTO (T350-14) was followed in the experiments, and rheological modeling of the data was made based on a seven-step procedure previously described elsewhere. Substantial increases in R and considerable decreases in Jnr are observed

in the binder after the addition of PPA or a combination of Elvaloy® terpolymer and PPA, which can be

translated into higher elastic responses (R values) and a much lower rutting potential in the field (Jnr

values). This is especially remarkable for the AC+Elvaloy+PPA, which showed the best outcomes in the MSCR test, a high level of elasticity at the aforementioned pavement temperatures and a fairly low stress sensitivity. On the other hand, the parameter GV (viscous component of the creep stiffness)

obtained from the Burgers model ranked the AC+PPA as the most rut resistant formulation at temperatures no greater than 58°C. Despite the fact that the results of the AC+PPA in the MSCR test are not as promising as the ones of the AC+Elvaloy+PPA, this formulation may be taken as an option to replace the base material on roads and highways with higher traffic levels and/or lower vehicle speeds, provided that the pavement temperatures are not higher than 64°C.

Keywords: Elvaloy® terpolymer, polyphosphoric acid, MSCR test, performance grade, asphalt

1.

INTRODUCTION

Permanent deformation (or rutting) is a very common distress mechanism found in flexible asphalt pavements. It is typically characterized by surface depressions in the wheelpath and, in some cases, pavement uplift (mixture shearing) may occur along the sides of these depressions. The appearance of rutting in the pavement can be explained by the accumulation of thousands of small permanent strains after the passage of each axle load and, after a period of time, these strains become particularly visible. Very high temperatures and slow vehicle speeds are the most relevant factors that accelerate the formation of rutting in the traffic lanes, provided that the pavement design criteria are adequate and were fully satisfied during construction. If these technical conditions are not observed (e. g., the asphalt mixture is not sufficiently compacted and/or the pavement structure is not appropriate for the estimated traffic loads and levels along the service life), then rutting may not be restricted to the surface layer and the maintenance program will demand more severe interventions. Pavements with high levels of rutting lead to hazardous driving conditions, since they can cause vehicle hydroplaning in the rainy days and pull the vehicle towards the depression path. In general, depressions lower than 0.33 in (≈ 0.84 cm) are not a matter of significant concern and can be left untreated (Pavement Interactive, 2008).

In a laboratory scale, rutting tests can be carried out either on mixture samples or binder samples. The mixture tests include dynamic modulus (Li et al., 2010; Witczak et al., 2002), flow number (Apeagyei, 2014; Onofre et al., 2013; Wasage et al., 2009), accelerated loading facilities (D’Angelo et al., 2007; Kim et al., 2009; Reinke, 2010; Wasage et al., 2011) and triaxial repeated creep tests (Borges, 2014; Xu et al., 2014), among other ones. The binder tests include dynamic oscillatory shear and repeated creep tests, most of which were standardized by the American agencies ASTM and AASHTO and added to the binder specifications in the United States (ASTM D6373 and AASHTO M320 standards). With the advent of the Superpave® specification and devices in the 90’s (Roberts et al., 1996) and its further

refinements, researchers have markedly changed their protocols and test methods for studying the rutting performance of asphalt binders, especially the modified ones. Several changes in these test protocols and binder rutting parameters have been proposed in the literature; however, many of them were not included in the specifications due to controversies over their applicability, fundamental concepts and lack of correlation with asphalt mixture data. An in-depth discussion on this topic can be found in another paper from the authors (Domingos and Faxina, 2015b).

The multiple stress creep and recovery (MSCR) test, pronounced as “massacre” by some researchers (Gierhart, 2013), is a quite recent innovation for characterizing the binder rutting behavior and quantifying its susceptibility to the accumulation of permanent strain under traffic loading. It was developed by the United States Federal Highway Administration (FHWA) as a result of many studies and refinements in the repeated creep and recovery test (RCRT) proposed by Bahia et al. (2001). In the original protocol, the MSCR test is comprised by ten creep-recovery cycles at each of the 11 stress levels ranging from 0.025 to 25.6 kPa. The stress level is doubled as soon as these creep-recovery cycles are applied on the sample, and there are no time lags between one stress level and the other neither between one loading-unloading cycle and the other (D’Angelo, 2009; D’Angelo et al., 2007). The standardizations of the MSCR test by ASTM (designation D7405) and AASHTO (designations TP70 and T350) took into account only two of these original stress levels, i. e., 0.1 and 3.2 kPa. It is questionable as to whether such stress levels represent the actual loading levels experienced by the binder in the pavement, since they have an arbitrary nature (Delgadillo et al., 2012) and many studies have indicated that the correlations between the outcomes of the MSCR test and the rutting measurements on asphalt mixtures are good when very high stress levels – 10 kPa or higher – are applied on the binder sample (D’Angelo et al., 2007; Golalipour, 2011; Wasage et al., 2011).

Basically, three parameters can be calculated from the accumulated strains measured by the dynamic shear rheometer (DSR) during the MSCR test. The first is the percent recovery R, which is an indication of the elastic response of the asphalt binder and the presence of polymer networks within the binder phase. Higher

R values are expected to correlate with formulations with extensive cross-linking and greatest extent of polymer structure, as previously observed by D’Angelo and Dongré (2009) in fluorescence micrographs. The second is the nonrecoverable creep compliance Jnr, which has been accepted as the new binder rutting

parameter in the Superpave® specification (AASHTO M320-09 and later versions) instead of the original

G*/sinδ (complex modulus G* divided by the sine of the phase angle δ) from the oscillatory shear test. Finally, the percent difference in nonrecoverable compliances (Jnr, diff) provides an estimate of the stress

sensitivity of the asphalt binder and its degree of nonlinear response at higher stress levels, since it represents the percentage of increase in Jnr when the stress level increases from 0.1 to 3.2 kPa. The

Superpave® specification establishes that the J

nr, diff value cannot be greater than 75% at the maximum

expected pavement temperature. This limitation was accepted in order to minimize the risk of accumulating large amounts of permanent strain under unpredicted loading and temperature conditions, as well as to control the degree of nonlinearity in the response of the binder.

In addition to calculating the parameters R, Jnr and Jnr, diff and correlating them with mixture data and the

extent of polymer network in the formulation, one can also study the creep-recovery response of the asphalt binder based on rheological models. Bahia et al. (2001) offered this alternative to develop a new rutting parameter in the binder scale – the viscous component of the creep stiffness (GV) – and, some years later,

Delgadillo et al. (2006) showed a draft version of the Superpave® specification based on G

V and minimum

values for this parameter as a function of the traffic level. The parameter GV is given by the ratio of the

isolated dashpot element of the Burgers model (parameter ηM in Figure 1) to the total loading time tF, see

Equation 1. This model was also used in many further studies (D’Angelo et al., 2007; Domingos and Faxina, 2015a; Golalipour, 2011; Hajikarimi et al., 2015) with varying purposes, e. g., to calculate the impact of different loading-unloading times on the repeated creep response of polyethylene-modified binders (Domingos and Faxina, 2015a) and to compare the rankings of rubber-modified materials based on GV with the ones based on G*/sinδ and the zero shear viscosity (Hajikarimi et al., 2015).

Figure 1: Schematic representation of the Burgers model.

ܩ ൌߟݐெ

ி (1)

Although it is known that the four-element Burgers model has some technical limitations – it is a linear viscoelastic model – and cannot account for all of the relaxation mechanisms of the binder due to the presence of only one relaxation time in the equations (Krishnan and Rajagopal, 2005), it makes it possible to easily identify the three major components of the total strain in the binder during a creep-recovery cycle.

These components can be summarized as follows: (i) the instantaneous elastic strain, which is recovered as soon as the load is removed; (ii) the viscous strain, which remains in the sample when the load is removed; and (iii) the delayed elastic strain, which is recovered with time. Equation 2 gives the accumulated strain ε(t) in the creep portion of the cycle, whereas Equation 3 provides the accumulated strain in the recovery portion of the cycle (Liu and You, 2009). In both equations, σ0 is the applied stress,

EM is the isolated spring element (instantaneous elastic strain), ηM is the isolated dashpot element (viscous

strain) and the spring and dashpot elements EK and ηK dictate the amount of delayed elastic strain. Together

with the presentation of the equations for each of the portions of the creep-recovery cycle, Liu and You (2009) also showed a seven-step procedure for determining the elements of the model. This simple and effective technique was employed by the authors in a previous paper (Domingos and Faxina, 2015a) and, due to the great degree of success, it will be adopted in the present study as well.

ߝሺݐሻ ൌܧߪ ெ+ ߪ× ݐ ߟெ + ߪ ܧ× ቆ1 − ݁ ିா಼×௧ ఎ಼ ቇ (2) ߝሺݐሻ ൌߪߟ× ݐ ெ + ߪ ܧ× ቆ1 − ݁ ିா಼×௧ಷ ఎ಼ ቇ × ݁ ିா಼×ሺ௧ି௧ಷሻ ఎ಼ (3)

1.1. Objectives

The piece of research described herein mainly aims at studying the creep-recovery response of asphalt binders modified with polyphosphoric acid (PPA, AC+PPA) and a combination of Elvaloy® terpolymer

with PPA (AC+Elvaloy+PPA) in the MSCR tests and, based on the results and the climatic conditions in Brazil (Leite and Tonial, 1994) and the United States (Asphalt Institute, 2010), to choose the best formulation for paving applications. The secondary objectives of the study include the following:

• to compare the rankings of binders from the most to the less resistant to rutting based on the numerical values of the parameters Jnr, G*/sinδ and GV and report the differences and similarities among them;

• to evaluate the level of elasticity of the formulations with reference to their Jnr values at 3.2 kPa (Asphalt

Institute, 2010; Gierhart, 2013) and high pavement temperatures typically found in Brazil (Leite and Tonial, 1994) and the United States (Asphalt Institute, 2010); and

• to report the advantages and disadvantages of binder modification with PPA and Elvaloy+PPA based on the numerical results and discussions in the scientific literature.

2.

EXPERIMENTAL PLAN

A 50/70 base asphalt binder supplied by the Lubnor-Petrobras refinery (Fortaleza, Ceará, Brazil) was used to prepare the formulations with PPA and Elvaloy+PPA. This base binder has a colloidal instability index (IC) of 0.72 and percentages of saturates, aromatics, resins and asphaltenes – SARA fractions –

equal to 15.57%, 31.78%, 26.29% and 26.37%, respectively (Pamplona, 2013). It is graded as PG 64S-xx in the revised version of the Superpave® specification, as given by the AASHTO M320-09 standard

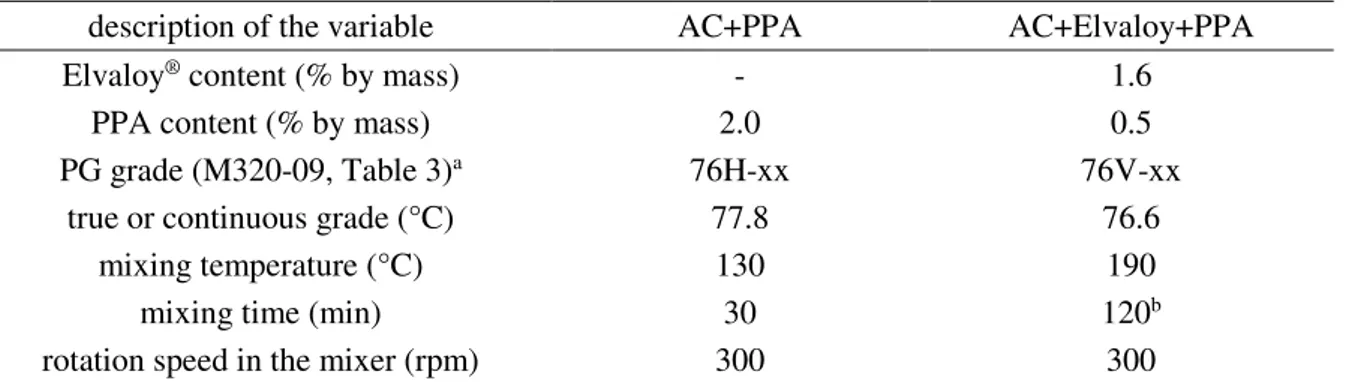

and its later versions. The true grade of the binder is equal to 66.3°C. Table 1 provides the modifier contents, the PG grades and the corresponding true grades of the AC+PPA and the AC+Elvaloy+PPA, as well as some processing variables. These contents were chosen such that the true grades fall between 76.0 and 78.0°C, and therefore the degrees of stiffness are approximately the same for both formulations. A Fisatom 722D low-shear mixer was used to mix the modifier (s) with the base material.

Some characteristics of the additives and the short-term aging process can be pointed out as follows. The 4170 ethylene butyl acrylate glycidylmethacrylate (Elvaloy®) terpolymer was supplied by DuPontTM and

Innovalt® E200 polyphosphoric acid was supplied by Innophos Inc. (Cranbury, NJ, United States). Finally,

the short-term aging procedure was carried out in the rolling thin-film oven (RTFO) by following the steps described in the ASTM D2872-04 standard. Approximately 35 ± 0.5 g of asphalt binder was poured into a cylindrical glass bottle and stored in a rolling oven at 163°C for 85 min. This procedure is expected to simulate aging of the asphalt binder during mixing with the aggregates in the plant and compaction in the field pavement.

Table 1: Modifier contents, processing variables and Performance Grades (PG) of the formulations.

description of the variable AC+PPA AC+Elvaloy+PPA

Elvaloy® content (% by mass) - 1.6

PPA content (% by mass) 2.0 0.5

PG grade (M320-09, Table 3)a 76H-xx 76V-xx

true or continuous grade (°C) 77.8 76.6

mixing temperature (°C) 130 190

mixing time (min) 30 120b

rotation speed in the mixer (rpm) 300 300

a The letters right after the high PG grades of the binders identify the acceptable traffic level at such temperatures, namely, standard (S), heavy (H), very heavy (V) and extremely heavy (E).

b The polyphosphoric acid (PPA) was added to the AC+Elvaloy after 60 min of mixing time.

2.1. Laboratory Tests and Rutting Parameters

The binder tests are comprised by the dynamic oscillatory shear and the MSCR tests at the temperatures of 52, 58, 64, 70 and 76°C. An AR-2000ex DSR supplied by TA Instruments was used in these experiments. The oscillatory shear protocol consists of applying sinusoidal loads in a 25-mm short-term aged binder sample at a fixed frequency of 10 rad/s (≈ 1.59 Hz). Five data points (G* and δ values) were collected at each temperature, and then the parameter G*/sinδ was calculated and the results were averaged for the two replicates. The MSCR tests were conducted in accordance with the most recent protocol in the AASHTO standards (AASHTO T350-14), i. e., 20 creep-recovery cycles at 0.1 kPa followed by 10 more cycles at 3.2 kPa were applied on the aged sample at each of the aforementioned temperatures. The last 10 cycles at 0.1 kPa and all the cycles at 3.2 kPa were used to calculate the parameters R (percent recovery),

Jnr (nonrecoverable compliance) and Jnr, diff (percent difference in nonrecoverable compliances). Equations

4-6 give details about the calculations of these parameters, in which σ0 is the applied stress, ε0 is the strain

at the beginning of the creep portion of the cycle, εC is the strain in the end of this creep portion, εR is the

strain in the end of the recovery portion, Jnr100 is the nonrecoverable compliance at 0.1 kPa and Jnr3200

is the nonrecoverable compliance at 3.2 kPa.

ܴሺ%ሻ ൌ 100 ×[ሺߝ− ߝߝሻ − ሺߝோ− ߝሻ] − ߝ (4) ܬൌߝோߪ− ߝ (5) ܬ,ௗሺ%ሻ ൌ 100 ×ܬ3200 − ܬܬ 100 100 (6)

The Burgers model was used to fit the creep-recovery data of all the samples – original and replicate ones – as provided by the MSCR tests and the formulae shown in Equations 2-3. The rutting parameter

GV (Equation 1) was determined at the two last cycles and the stress level of 0.1 kPa (i. e., 19th and 20th

cycles), which is not exactly the same protocol followed by Bahia et al. (2001). These last two cycles were selected in an attempt to be as close to the steady state condition of the binder as possible, whereas the value of 0.1 kPa is within the interval of stress levels suggested by Bahia et al. (2001) in the original RCRT protocol (from 30 to 300 Pa). The final GV value was taken as the average of the two replicates

tested for each formulation and pavement temperature.

In addition to the rutting parameters, the modified materials were also analyzed with respect to their level of elasticity (Asphalt Institute, 2010; Gierhart, 2013). The analysis of this level of elasticity makes it possible to have an idea about the extent and the distribution of polymer networks within the formulation. If the R value is higher than a minimum required value for the binder as a function of Jnr at

3.2 kPa and the high pavement temperature, then the binder will be classified as a “material with high elasticity”. Similarly, R values lower than this minimum value based on Jnr at 3.2 kPa will lead the binder

to be classified as “material with poor elasticity”. It may be important to note that this procedure can be applied only when the parameter Jnr is no greater than 2.0 kPa-1 in such test conditions.

3.

PRESENTATION OF RESULTS AND DISCUSSION

3.1. MSCR Tests and Levels of Elasticity

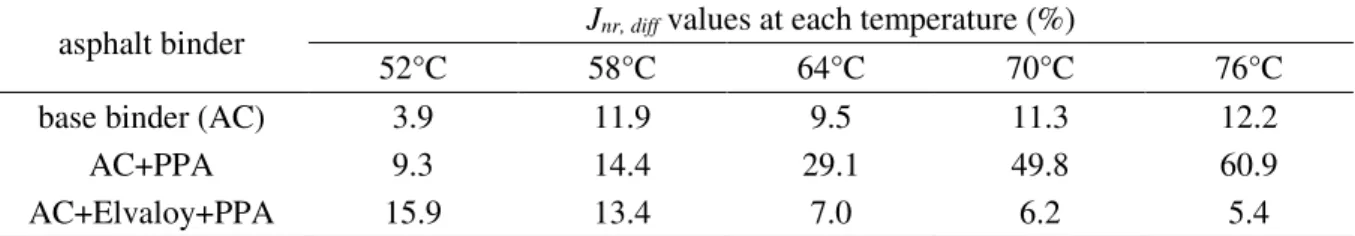

Figures 2-3 and Table 2 provide the outcomes of the MSCR tests for the base binder, the AC+PPA and the AC+Elvaloy+PPA at all temperatures, namely, percent recovery (Figure 2), nonrecoverable compliance (Figure 3) and percent difference in nonrecoverable compliances (Table 2). As it can be seen, binder modification with PPA and Elvaloy+PPA substantially increased the R values and markedly decreased the Jnr values within the whole temperature range and at both stress levels, especially for the

Elvaloy-modified material. With respect to the Jnr, diff values, it can be observed that the AC+PPA is

much more stress sensitive than the 50/70 base binder (results range from 9 to 61%), and also that the AC+Elvaloy+PPA shows a quite similar interval of Jnr, diff values when compared to the base material.

However, the pattern behavior of the Jnr, diff values is not the same for the unmodified binder and the

AC+Elvaloy+PPA: while these values typically increase with increasing test temperature for the former, they gradually decrease with increasing temperature for the latter. None of the formulations studied in this paper are overly stress sensitive according to the Superpave® binder criterion (parameter J

nr, diff no

greater than 75%) at any of the selected pavement temperatures, which makes it possible for them to be used for paving applications.

The promising results of the AC+Elvaloy+PPA are closely related to the characteristics of the Elvaloy®

terpolymer and its reaction with the base asphalt binder. Due to the chemical nature – a combination of ethylene, glycidylmethacrylate (GMA) and an ester group (in this case, butyl acrylate), in which ethylene is the main component – and the improved polarity of the polymer chain, the modifier is able to react with functional groups present in the binder (e. g., the carboxylic ones) and considerably change its rheological properties. It is suggested that this modification process takes place when the oxiranic ring of GMA reacts with the functional groups of the binder. The result is a polymer-linked-asphalt system with enhanced rheological properties, provided that the polymer content is not high enough to cause inter-chain reactions among the polymer macromolecules and lead to the formation of a useless asphalt gel (Polacco et al., 2006, 2015). With respect to PPA, it typically increases the high PG grade of the asphalt binder without affecting the low PG grade. Also, the use of PPA makes it possible to obtain modified asphalt binders with PG grades similar to those modified with polymer alone, but with lower polymer contents. This is the case of the present study, in which a very small amount of PPA was enough to decrease the Elvaloy® content and improve the workability of the formulation without changing the

PG grade of 76-xx. Some literature reviews point out that the effects of PPA on asphalt binders are somehow comparable to those of air-blowing (Polacco et al., 2015).

Figure 2: Percent recoveries of the asphalt binders at 0.1 kPa (R100) and 3.2 kPa (R3200).

Figure 3: Nonrecoverable compliances of the asphalt binders at 0.1 kPa (Jnr100) and 3.2 kPa (Jnr3200). Table 2: Percent differences in nonrecoverable compliances (Jnr, diff) of the asphalt binders.

asphalt binder Jnr, diff values at each temperature (%)

52°C 58°C 64°C 70°C 76°C

base binder (AC) 3.9 11.9 9.5 11.3 12.2

AC+PPA 9.3 14.4 29.1 49.8 60.9

AC+Elvaloy+PPA 15.9 13.4 7.0 6.2 5.4

The MSCR test data in Figures 2-3 indicate that either PPA or Elvaloy+PPA have a marked effect on the parameters R and Jnr at pavement temperatures up to 64°C. However, the AC+Elvaloy+PPA is the

only formulation that still depicts very high R values at the temperatures of 70 and 76°C. The values are

1 1 .7 6 .5 0 .0 0.0 0.0 9 .7 1 .0 0 .0 0.0 0.0 7 0 .0 6 1 .1 5 0 .2 3 8 .9 2 5 .4 6 6 .9 5 5 .2 3 7 .0 1 6 .6 2 .6 8 5 .5 8 4 .2 8 0 .8 7 4 .9 6 5 .6 8 3 .1 8 1 .8 7 8 .6 7 1 .2 5 9 .0 0 20 40 60 80 100 120 52 58 64 70 76 P er ce n t R ec o v er y R (%) Temperature (°C)

R100 - Base Binder (AC) R3200 - Base Binder (AC) R100 - AC+PPA

R3200 - AC+PPA R100 - AC+Elvaloy+PPA R3200 - AC+Elvaloy+PPA

0 .2 9 7 0 .8 1 7 2.1 9 7 5 .2 8 7 1 1 .7 6 3 0 .3 0 9 0 .9 1 3 2.4 0 6 5 .8 8 3 1 3 .1 9 2 0 .0 2 0 0 .0 5 7 0 .1 6 1 0 .4 3 2 1 .1 5 1 0 .0 2 2 0 .0 6 5 0 .2 0 8 0 .6 4 7 1.8 5 3 0 .0 1 9 0 .0 4 1 0 .0 9 6 0 .2 3 3 0 .5 7 5 0 .0 2 2 0 .0 4 6 0 .1 0 3 0 .2 4 7 0 .6 0 5 0 2 4 6 8 10 12 14 16 52 58 64 70 76 C o m p li a n ce Jn r (k P a -1) Temperature (°C)

Jnr100 - Base Binder (AC) Jnr3200 - Base Binder (AC) Jnr100 - AC+PPA Jnr3200 - AC+PPA Jnr100 - AC+Elvaloy+PPA Jnr3200 - AC+Elvaloy+PPA

no lower than 59% for this formulation, whereas they do not achieve 20% for the AC+PPA at 3.2 kPa and temperatures higher than 64°C. These broad differences between the modified binders are also clearly observed for the parameter Jnr at the highest MSCR test temperatures (64, 70 and 76°C), in which

the results of the AC+PPA are about two times higher than the ones of the AC+Elvaloy+PPA for the same stress level. In other words, an increase in the test temperature leads to a more clear distinction between the effects of the modifier (s) on the repeated creep responses of the formulations.

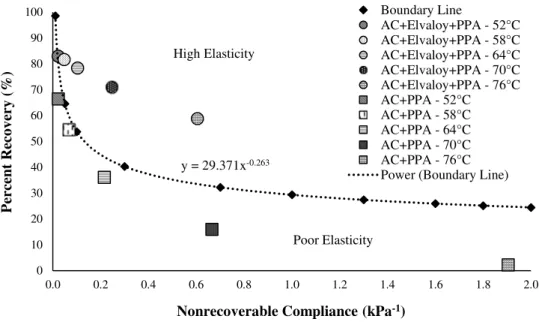

Figure 4 shows the levels of elasticity of the AC+PPA and the AC+Elvaloy+PPA. The temperatures of 64 and 70°C are typically found in many regions of Brazil (Leite and Tonial, 1994). The other temperatures are commonly observed in the United States except for the highest one (76°C), which is restricted to a few locations in the southwest portion of the country (Asphalt Institute, 2010). Even though the maximum expected pavement temperature is much lower than 76°C, a modified asphalt binder with a high PG grade of 76-xx may be required due to other reasons such as severe traffic conditions, i. e., high percentages of heavy vehicles and/or very low traffic speeds. As it can be inferred from the data points, the AC+Elvaloy+PPA shows a high level of elasticity at all pavement temperatures (results are above the boundary line) and the AC+PPA shows a poor level of elasticity (results below the boundary line). This is in agreement with the above-mentioned discussion on the formation of an asphalt-polymer system in the AC+Elvaloy+PPA and, although the fluorescent micrographs are not reported here, it is believed that polymeric networks will be observed in the material, just like the ones observed by D’Angelo and Dongré (2009).

Figure 4: Levels of elasticity of the AC+PPA and the AC+Elvaloy+PPA based on their results at 3.2 kPa.

3.2. Rutting Parameters G*/sinδ and G

Vand Rankings of Binders

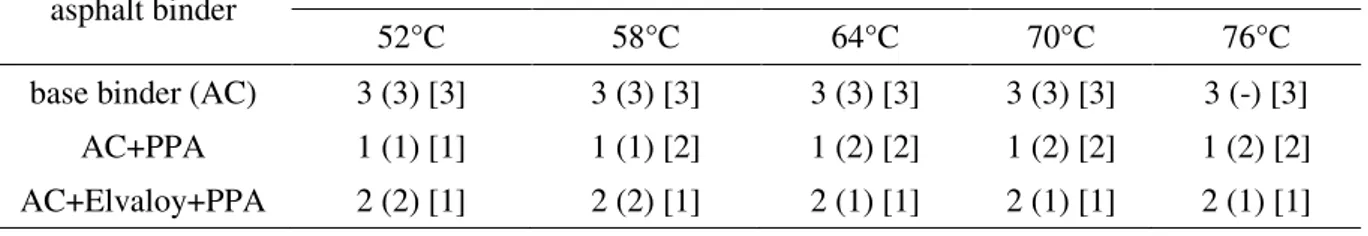

Table 3 reports the numerical values of the parameters G*/sinδ and GV at each pavement temperature

for the AC+PPA and the AC+Elvaloy+PPA. The results of the 50/70 base binder are also shown for comparison purposes. The rankings of the binders from the less to the most susceptible to rutting are given in Table 4, including the ones based on the nonrecoverable compliance at 3.2 kPa (Jnr3200, Figure

3). It can be seen that these positions are not exactly the same for all the studied parameters, e. g., the parameter G*/sinδ ranks the AC+PPA as more rut resistant than the AC+Elvaloy+PPA within the whole temperature interval and the opposite is observed for Jnr3200. Also, the ranking based on GV precisely

matches the one based on Jnr3200 at the temperatures of 64, 70 and 76°C: the AC+Elvaloy+PPA is the

y = 29.371x-0.263 0 10 20 30 40 50 60 70 80 90 100 0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6 1.8 2.0 P er ce n t R ec o v er y ( %)

Nonrecoverable Compliance (kPa-1)

Boundary Line AC+Elvaloy+PPA - 52°C AC+Elvaloy+PPA - 58°C AC+Elvaloy+PPA - 64°C AC+Elvaloy+PPA - 70°C AC+Elvaloy+PPA - 76°C AC+PPA - 52°C AC+PPA - 58°C AC+PPA - 64°C AC+PPA - 70°C AC+PPA - 76°C Power (Boundary Line) High Elasticity

most rut resistant material (1) followed by the AC+PPA (2) and the unmodified binder (3). This means that the suggestion of GV as a new binder parameter was an essential step towards a better understanding

of the contribution of the binder to the resistance of the asphalt mixture to rutting. The use of G*/sinδ as a binder rutting parameter has been seriously questioned by many researchers worldwide not only because of the lack of correlation with mixture data, but also the scientific concepts involved in the oscillatory shear test (Domingos and Faxina, 2015b).

Table 3: Parameters G*/sinδ (complex modulus over sine of the phase angle) and GV (viscous component of the creep stiffness)

for the unmodified and modified binders.

asphalt binder parameters G*/sinδ and GV (both in kPa) at each temperature

a

52°C 58°C 64°C 70°C 76°C

base binder (AC) 17.69 (3.26) 7.07 (1.21) 2.98 (0.46) 1.33 (0.19) 0.62 (-) AC+PPA 65.76 (32.49) 29.51 (12.99) 13.55 (5.05) 6.42 (2.02) 3.13 (0.79) AC+Elvaloy+PPA 25.55 (21.69) 12.50 (10.37) 6.47 (5.10) 3.53 (2.48) 2.01 (1.18)

a The results are reported in the following order: parameter G*/sinδ (parameter G

V).

Table 4: Rankings of the binders from the less (1) to the most susceptible to rutting (3) based on the parameters G*/sinδ

(complex modulus over sine of the phase angle), GV (viscous component of the creep stiffness) and Jnr3200

(nonrecoverable compliance at 3.2 kPa).

asphalt binder rankings of the binders based on G*/sinδ, GV and Jnr3200

a

52°C 58°C 64°C 70°C 76°C

base binder (AC) 3 (3) [3] 3 (3) [3] 3 (3) [3] 3 (3) [3] 3 (-) [3] AC+PPA 1 (1) [1] 1 (1) [2] 1 (2) [2] 1 (2) [2] 1 (2) [2] AC+Elvaloy+PPA 2 (2) [1] 2 (2) [1] 2 (1) [1] 2 (1) [1] 2 (1) [1]

a Position based on G*/sinδ (position based on G

V) [position based on Jnr3200].

The results suggest that G*/sinδ is not a very reliable parameter to predict the rutting resistance of modified asphalt binders. The fact that the AC+Elvaloy+PPA is more rut resistant than the AC+PPA has also been observed by the authors in another study with these same modifiers and a different crude source (Replan-Petrobras refinery), but with similar high PG grades (Inocente Domingos and Faxina, 2015). Mixture rutting tests carried out by Onofre et al. (2013) have indicated that the AC+PPA from the Replan-Petrobras refinery is less susceptible to the accumulation of permanent strain than the base material, but its rutting performance is much poorer than the one of the AC+Elvaloy+PPA. In summary, Jnr3200 was the parameter

that underlined the superiority of the AC+Elvaloy+PPA over the AC+PPA at all temperatures with respect to the resistance to rutting. The same can be said for GV, but only at temperatures higher than 58 °C.

4.

MAJOR CONCLUSIONS

Based on the results and analysis of data reported in this paper, the following conclusions can be reached: • asphalt binder modification with PPA and Elvaloy+PPA had a marked effect on the percent recoveries (R) and the nonrecoverable compliances (Jnr) of the 50/70 base asphalt binder, i. e., substantial

increases in the elastic response and marked decreases in the susceptibility to rutting could be observed at typical high pavement temperatures (from 52 to 76°C) after the addition of PPA and a combination of Elvaloy® terpolymer and PPA, especially for the AC+Elvaloy+PPA;

• the stress sensitivity of the AC+Elvaloy+PPA (range of Jnr, diff values) was very close to the one of the

50/70 base binder, whereas the AC+PPA showed much higher percentages of increase in Jnr after the

increase in the stress level from 0.1 to 3.2 kPa; however, none of the selected materials overcame the upper limit of 75% set by the Superpave® specification;

• the AC+Elvaloy+PPA showed a high level of elasticity within the whole temperature interval, whereas the AC+PPA showed a poor level of elasticity at these same temperatures;

• the rankings of the asphalt binders from the less to the most susceptible to rutting based on the parameter G*/sinδ (complex modulus G* divided by the sine of the phase angle δ) and the ones based on GV (viscous component of the creep stiffness) and Jnr at 3.2 kPa (Jnr3200) reflected substantial

differences between them: while the parameter G*/sinδ ranked the AC+PPA as more rut resistant than the AC+Elvaloy+PPA, an opposite trend was observed when GV and Jnr3200 were used (the

AC+Elvaloy+PPA is less susceptible to rutting than the AC+PPA);

• the correlations between the results presented in this study and the ones published elsewhere (Inocente Domingos and Faxina, 2015; Onofre et al., 2013) indicated that the AC+Elvaloy+PPA is less prone to rutting than the AC+PPA, which is in agreement with the rankings based on GV

(temperatures higher than 58°C) and Jnr3200; and

• the AC+PPA may be taken as an alternative to increase the rutting resistance of the asphalt binder in the pavement, but its use is recommended only at some pavement temperatures (no greater than 64°C); on the other hand, the AC+Elvaloy+PPA can be used at any pavement temperature studied in this paper due to the very promising results of the parameters R (very high elastic responses), Jnr

(much lower susceptibility to rutting) and Jnr, diff (stress sensitivity is comparable to the one of the

base asphalt binder).

ACKNOWLEDGEMENTS

The first author publicly acknowledges the Research Agency of the São Paulo State (FAPESP) for providing funds in the format of a doctorate scholarship (FAPESP Process Number 2013/20483-6). The second author acknowledges FAPESP for providing financial funds to a research project (FAPESP Process Number 2006/55835-6).

REFERENCES

Apeagyei, A. K. (2014). Flow number predictive models from volumetric and binder properties. Constr. Build. Mater., Vol. 64, pp. 240-245. doi: 10.1016/j.conbuildmat.2014.04.069.

Asphalt Institute. (2010). Guidance on the use of the MSCR test with the AASHTO M320 specification. Retrieved from http://amap.ctcandassociates.com/wp/wp-content/uploads/Guidance-on-Using-MSCR-with-AASHTO-M320_Final.pdf. Accessed 25 Nov. 2015.

Bahia, H. U., Hanson, D. I., Zeng, M., Zhai, H., Khatri, M. A., and Anderson, R. M. (2001). Characterization of modified asphalt binders in Superpave mix design. NCHRP Report 459. Transportation Research Board, Washington, D.C.

Borges, R. L. (2014). Deformação permanente em misturas asfálticas a partir do shift model viscoplástico e ensaios triaxiais de carga repetida [Permanent deformation on asphalt mixtures based on the viscoplastic shift model and triaxial repeated creep tests]. Dissertação (Mestrado em Engenharia de Transportes) – Departamento de Engenharia de Transportes, Universidade Federal do Ceará, Fortaleza.

D’Angelo, J., and Dongré, R. (2009). Practical use of multiple stress creep and recovery test: characterization of styrene-butadiene-styrene dispersion and other additives in polymer-modified asphalt binders. Transp. Res. Rec., No. 2126, pp. 73-82. doi: 10.3141/2126-09.

D’Angelo, J., Kluttz, R., Dongré, R., Stephens, K., and Zanzotto, L. (2007). Revision of the Superpave high temperature binder specification: the multiple stress creep recovery test. J. Assoc. Asph. Paving Technol., Vol. 76, pp. 123-162.

D’Angelo, J. A. (2009). The relationship of the MSCR test to rutting. Road Mater. Pavement Des., Vol. 10, Supl. 1, pp. 61-80. doi: 10.1080/14680629.2009.9690236.

Delgadillo, R., Bahia, H. U., and Lakes, R. (2012). A nonlinear constitutive relationship for asphalt binders. Mater. Struct., Vol. 45, No. 3, pp. 457-473. doi: 10.1617/s11527-011-9777-y.

Delgadillo, R., Nam, K., and Bahia, H. (2006). Why do we need to change G*/sinδ and how? Road Mater. Pavement Des., Vol. 7, No. 1, pp. 7-27. doi: 10.1080/14680629.2006.9690024.

Domingos, M. D. I., and Faxina, A. L. (2015a). Rheological behaviour of bitumens modified with PE and PPA at different MSCR creep-recovery times. Int. J. Pavement Eng., Vol. 16, No. 9, pp. 771-783. doi: 10.1080/10298436.2014.953503.

Domingos, M. D. I., and Faxina, A. L. (2015b). Susceptibility of asphalt binders to rutting: literature review. J. Mater. Civ. Eng., 04015134, in press. doi: 10.1061/(ASCE)MT.1943-5533.0001364.

Gierhart, D. (2013). Multiple stress creep recovery (MSCR): why it should be implemented. Louisiana Transportation Conference, Baton Rouge, LA.

Golalipour, A. (2011). Modification of multiple stress creep and recovery test procedure and usage in specification. Thesis (Master of Science) – Department of Civil and Environmental Engineering, University of Wisconsin-Madison, Madison.

Hajikarimi, P., Rahi, M., and Nejad, F. M. (2015). Comparing different rutting specification parameters using high temperature characteristics of rubber-modified asphalt binders. Road Mater. Pavement Des., Vol. 16, No. 4, pp. 751-766. doi: 10.1080/14680629.2015.1063533.

Inocente Domingos, M. D., and Faxina, A. L. (2015). Rheological analysis of asphalt binders modified with Elvaloy® terpolymer and polyphosphoric acid on the multiple stress creep and recovery test. Mater.

Struct., Vol. 48, No. 5, pp. 1405-1416. doi: 10.1617/s11527-013-0242-y.

Kim, S., Sholar, G. A., Byron, T., and Kim, J. (2009). Performance of polymer-modified asphalt mixture with reclaimed asphalt pavement. Transp. Res. Rec., No. 2126, pp. 109-114. doi: 10.3141/2126-13. Krishnan, J. M., and Rajagopal, K. R. (2005). On the mechanical behavior of asphalt. Mech. Mater., Vol. 37, No. 11, pp. 1085-1100. doi: 10.1016/j.mechmat.2004.09.005.

Leite, L. F. M., and Tonial, I. A. (1994). Qualidade dos cimentos asfálticos brasileiros segundo as especificações SHRP [Grading of the Brazilian asphalt cements according to the SHRP specifications]. Anais do 12° Encontro de Asfalto. Rio de Janeiro: Instituto Brasileiro de Petróleo, Gás e Biocombustíveis, pp. 94-119.

Li, X., Clyne, T., Reinke, G., Johnson, E. N., Gibson, N., and Kutay, M. E. (2011). Laboratory evaluation of asphalt binders and mixtures containing polyphosphoric acid. Transp. Res. Rec., No. 2210, pp. 47-56. doi: 10.3141/2210-06.

Liu, Y., and You, Z. (2009). Determining Burger’s model parameters of asphalt materials using creep-recovery testing data. In: You, Z., Abbas, A. R., and Wang, L. (Eds.) Pavements and Materials: Modeling, Testing, and Performance. Reston: American Society of Civil Engineers, pp. 26-36. doi: 10.1061/41008(334)3.

Onofre, F. C., Castelo Branco, V. T. F., Soares, J. B., and Faxina, A. L. (2013). Avaliação do efeito de ligantes asfálticos modificados na resistência à deformação permanente de misturas asfálticas densas [Analysis of the effect of modified asphalt binders on the resistance of dense-graded asphalt mixtures to rutting]. Transportes, Vol. 21, No. 3, pp. 14-21. doi: 10.4237/transportes.v21i3.685.

Pamplona, T. F. (2013). Efeito da adição de ácido polifosfórico em ligantes asfálticos de diferentes fontes [Effect of polyphosphoric acid on asphalt binders from different crude sources]. Dissertação (Mestrado em Engenharia de Transportes) – Departamento de Engenharia de Transportes, Escola de Engenharia de São Carlos, Universidade de São Paulo, São Carlos.

Pavement Interactive. (2008). Rutting. Retrieved from

http://www.pavementinteractive.org/article/rutting/. Accessed 19 Nov. 2015.

Polacco, G., Filippi, S., Merusi, F., and Statsna, G. (2015). A review of the fundamentals of polymer-modified asphalts: asphalt/polymer interactions and principles of compatibility. Adv. Colloid Interface Sci., Vol. 224, pp. 72-112. doi: 10.1016/j.cis.2015.07.010.

Polacco, G., Stastna, J., Biondi, D., and Zanzotto, L. (2006). Relation between polymer architecture and nonlinear viscoelastic behavior of modified asphalts. Curr. Opin. Colloid Interface Sci., Vol. 11, No. 4, pp. 230-245. doi: 10.1016/j.cocis.2006.09.001.

Reinke, G. (2010). Use of Hamburg rut testing data to validate the use of Jnr as a performance parameter

for high-temperature permanent deformation. Transp. Res. Circ., No. E-C147, pp. 14-24.

Roberts, F. L., Kandhal, P. S., Brown, E. R., Lee, D.-Y., and Kennedy, T. W. (1996). Hot mix asphalt materials, mixture design, and construction. 2nd Ed. National Asphalt Pavement Association Research and Education Foundation, Lanham, MD.

Wasage, T. L. J., Kazatchkov, I. B., Stastna, J., and Zanzotto, L. (2009). Rutting evaluation of asphalt binders and mixes. In: Loizos, A., Partl, M., Scarpas, T., and Al-Qadi, I. L. (Eds.) Advanced Testing and Characterisation of Bituminous Materials. Leiden: CRC Press/Balkema, Vol. 2, Chapter 7, pp. 989-998. doi: 10.1201/9780203092989.ch95.

Wasage, T. L. J., Stastna, J., and Zanzotto, L. (2011). Rheological analysis of multi-stress creep recovery (MSCR) test. Int. J. Pavement Eng., Vol. 12, No. 6, pp. 561-568. doi: 10.1080/10298436.2011.573557. Witczak, M. W., Kaloush, K., Pellinen, T., El-Basyouny, M., and Von Quintus, H. (2002). Simple performance test for Superpave mix design. NCHRP Report 465, Transportation Research Board, Washington, DC.

Xu, T., Wang, H., Li, Z., and Zhao, Y. (2014). Evaluation of permanent deformation of asphalt mixtures using different laboratory performance tests. Constr. Build. Mater., Vol. 53, pp. 561-567. doi: 10.1016/j.conbuildmat.2013.12.015.