How to Fully Obtain the Potential Benefits of a Digital

Document Management System

A Guide to Successful Implementation

Axel Söderlund Carlborg

Lund University, Faculty of Engineering (LTH) December 2016

echnological advancements over the last decades have resulted in an increased degree of digitalisation within as well as in between companies around the world. As

a result, requirements on

companies in general are growing and global competition is steadily increasing. One area for which this is highly relevant, and for which there is still a lot of potential for improvement, is document management.

In many industries, it has today become more or less a mandatory requirement for companies to keep transparent and comprehensive in-depth documentation on specific company processes and operations. In order for companies to comply with these requirements, they need functioning document management systems (DMSs). A company’s DMS defines its ability to create, store and manage documentation, and if utilised properly the system also helps companies assure a certain level of quality in their operations.

The need for proper document management should not be overlooked, but in an environment in which competition and digitalisation is escalating quickly, optimisation is crucial. Consequently, in order to for companies to be able to optimise their financial and operational results, and thus increase their chances of survival, digitalisation of processes related to

document management (i.e. the implementation of a digital DMS solution) is inevitable.

Problem Description

This paper is based on a Master Thesis project that addresses mainly two problem areas. The first concerns the effects of document management in general, and the second concerns the process of implementing a digital DMS solution.

First of all, it can be concluded that a company’s DMS may have great affects on its financial and operational results. This is especially true for companies dealing with complex products, as their documentation needs are generally high. Establishing structures and routines for handling document management may lead to financial and operational improvements but in order to optimise results, digitisation of these activities is more or less necessary. However, in spite of the potential gains that effective and efficient DMSs may generate, many companies today are still turning a blind eye to this. Therefore the first problem area addressed by the Master Thesis is the general lack of knowledge regarding DMSs, their effects as well as why companies should strive for developing digital DMS solutions.

Secondly, the process of implementing a digital DMS ultimately affects the performance results of the system. In other words, if the implementation process is not performed properly,

there is a chance that the desired results will not be met. Today there does not exist any widespread digital solutions for document management, and for this reason, there does not either exist any general guidelines that facilitate the process of effectively and efficiently digitalising document management related activities. This is the second problem area addressed by the Master Thesis.

Purpose

The purpose of the Master Thesis project was to develop a generic framework supporting the implementation of a digital DMS solution. The aim of the framework is to provide guidelines that facilitate the process of effectively and efficiently implementing a digital DMS, and in turn enable companies to fully obtain the potential benefits related to such a system.

Methodology

The Master Thesis is based on an extensive literature review and a qualitative case study regarding the software system CodeIT eMRB at the Norwegian software company CodeIT AS (CodeIT). Empirical data was collected from the case study, which was based on a series of open and semi-structured interviews with the CEO and founder of CodeIT, Bjørnar Torsnes, as well as an archival data study of business documents from the company. The secondary data was collected from thorough review of literature on areas relevant to the subject.

Findings

The Master Thesis identified a number of issues related to non-digital DMSs. The main issues that were identified are presented in Table 1:

Table 1: Issues Related to Non-Digital Document Management Systems

Issues related to non-digital DMSs

Difficulties with generating and

processing large volumes of documents Difficulties regarding processes for checking and validating document content

Manual systems are prone to error Inability to create, find, access and deliver relevant information on time Complicated tracking and tracing of produced products

Complicated backward tracing of manufacturing equipment

The Master Thesis project also identified a number of incentives for developing an effective and efficient DMS. Some of these incentives are presented below:

1) Potential improvements of quality assurance and control activities

2) Quality Management System (QMS) improvements

3) Increased chances of obtaining certain forms of certification (e.g. ISO certification) as well as the benefits related to this. 4) Increased supply chain

transparency

Furthermore, the Master Thesis project concluded that digitisation of paper-based processes, within the area of document management, is necessary in order for companies to be able to compete and survive in the in the future. This is especially true for companies that are performing complex manufacturing or handling complex products. Hence, the Master Thesis identified a number of benefits related to the implementation of a digital DMS solution. These benefits included:

1) Elimination of time and resource consuming paper-based processes

Phase 1 - Pre-Installation • Identify and de1ine motives for implementation • De1ine implementation objectives and translate them into comprehensible metrics • Align motives and goals for implementation • Obtain suf1icient support from top level management • Identify the user facilities that will need access to the digital DMS • Identify the existing IT systems that need to be integrated with the digital DMS • Assure regulatory compliance Phase 2 - Installation • Enable personnel • Assure improved quality control • Enable collaboration within the supply chain • Create comprehensible and complete documentation • Create and facilitate procedures for retrieving documents • De1ine a clear and consistent document hierarchy • Enable system scalability Phase 3 - Post-Installation • Encourage proper utilisation of the QMS • Encourage Connected Manufacturing activities • Maintain system ef1iciency and effectiveness • Strive for continuous development • Perform on-site training in the use of the digital DMS Phase 4 - Evaluation and Corrective Action • Evaluate results of use of the digital DMS • Evaluate and handle of complaints regarding the digital DMS • Take corrective action 2) Improved track and traceability

3) Ability to automate processes 4) Improved communication and

collaboration with supply chain partners

5) Reduced need for ‘industrial tourism’ (i.e. the need for staff to be onsite to control,

document and evaluate production)

6) Ability to leverage more advanced technological capabilities

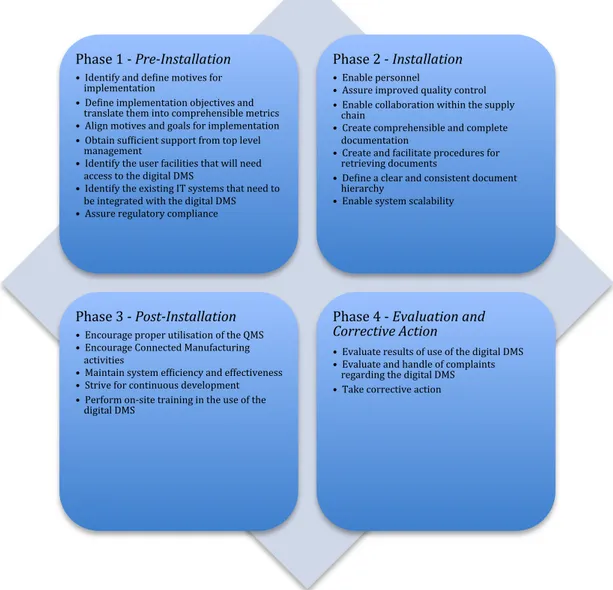

Ultimately, in order to serve the purpose of the Master Thesis project, a framework supporting the

implementation of a digital DMS (presented in Figure 1) was created. The framework consists of four phases (Pre-Installation, Installation, Post-Installation as well as Evaluation and Corrective Action). Each phase in the framework has its own challenges as well as opportunities and depending on how each phase is handled, they all have different effects on the implementation process and its results. Furthermore, each phase has also been broken down into critical steps or ‘guidelines’ that companies should follow in order to assure successful implementation results.

Figure 1: Framework for Implementation of a Digital DMS

References

International Organisation of Standardisation, ‘ISO 9000 Introduction and Support Package: Guidance on the Documentation Requirements of ISO 9001:2008’,

International Organisation of Standardisation, Document: ISO/TC 176/SC 2/N 525R2, 2008.

GE Intelligent Platforms, ‘Digitizing Complex Discrete Manufacturing Processes: Driving lowe costs, higher quality and faster production to stay competitive today and ensure success tomorrow’, GE Intelligent Platforms [Online white paper], Document: 11.12 GFT-851, 2012,

<http://www.geautomation.com/products/connected-manufacturing>, accessed 30 March 2016.

Patel, K.T. & Chotai, N.P., ‘Documentation and Records: Harmonized GMP Requirements’, Journal of Young Pharmacists, vol. 3, no. 2, 2011, pp. 138-150. Rusjan, B. & Alič, M., ‘Capitalising on ISO 9001 benefits for strategic results’,

International Journal of Quality & Reliability Management, vol. 27, no. 7, 2010, pp. 756–778.

Sampaio P., Saraiva P. & Rodrigues A.G., ‘ISO 9001 certification research: questions, answers and approaches’, International Journal of Quality & Reliability

Management, vol. 26, no. 1, 2009, pp. 38-58.

Strategy& PwC, ‘Digitization: The Digitization megatrend’, Strategy& PwC [Website], 2016,

<http://www.strategyand.pwc.com/global/home/what-wethink/digitization/megatrend>, accessed 18 Jan. 2016.

Westerman, G., Bonnet, D. & McAfee, A., Leading Digital: Turning technology into business transformation, Harvard Business Review Press, Boston Massachusetts, 2014.