at hs 84.e a 7.1 ifo a § cena o

~lr 214 A ' 1981

SSN 0347-6030

I14A

Statens vag- och trafikinstitut (VTI) - 581 01 linkoping

National Road & Traffic Research Institute - S-581 01 Linkoping - Sweden

Plastic Foam Insulation of Roads

Frost resistance capacity, partial insulation

and frost heaving, special transitions,

icing and economy

PREFACE

This report has been presented at the Fourth Canadian

Permafrost Conference in Calgary, Alberta, 2-6 March,

1981. The conference was sponsored by the Associate

Committee on Geotechnical Research of the National

Research Council of Canada, in association with the

Canadian Geotechnical Society.

CONTENTS SUMMARY

INTRODUCTION

FROST RESISTANCE CAPACITY

PARTIAL INSULATION AND FROST HEAVING SPECIAL TRANSITIONS

ICING INVESTIGATIONS ECONOMY

REFERENCES

Plastic Foam Insulation of Roads

Frost resistance capacity, partial insulation and

frost heaving, special transitions, icing and economy

by Rune Gandahl

National Swedish Road and Traffic Research Institute

581 01 LINKCPING

SUMMARY

There are three layers which contribute to the frost resistance capacity of a road base insulated with

plastic foam. The greatest contribution comes from the

plastic foam layer itself and only a smaller amount

from the overlaying bearing course. What sometimes is not considered is, however, the fact that the soil

layers of non frost susceptible material immediately

beneath the plastic foam layer contribute to a not

negligible degree.

When the road is not fully insulated there will be some

heaving when the frost penetrates the frost susceptible

subgrade. The magnitude of the heaving depends on the

insulation prOperties of the road base.

An increased risk of early autumn icing is said to be a disadvantage on heat insulated roads. A three year test at a test field at the Institute indicates that

this risk can be minimized by an appropiate design.

Transitions from a fully insulated to a non-insulated part of the road in order to even out the insulation effect can be created by tapering off the plastic foam layer by purposely arranging Openings between the

boards. In comparison to conventional road materials, plastic foam (polystyrene) is more expensive by cubic meter. Practical experience, on the other hand, indi

cates that a road, frost protected by polystyrene foam,

II

is often cheaper to construct than a road which is

conventionally protected.

INTRODUCTION

Plastic foam used as a heat insulation layer in the

road base protects the road from frost damage. For

some years now this insulation method has been

practi-sed in Scandinavia and in other countries with a cold

climate. The present report gives a concentrated de

scription of som of the insulation properties and

effects. The following aspects are dealt with: frost

resistance capacity of the road base, partial insula

tion and frost heaving, special transitions with pur

posely arranged openings between the foam boards,

icing problems and construction economy.

FROST RESISTANCE CAPACITY

The frost resistance capacity is defined as the frost quantity (freezing index) which is required for

freezing the road base totally. The frost resistance

capacity is calculated by the formula of Skaven Haug

/1/, which is described below.

The calculation is based upon the model

F = 29 + E, hOC

where F is the frost resistance capacity.

The resistance to freezing from latent heat for a

single soil layer is

q-s2

So

0

Q: +q-SZ(T),

o

where:

s

= thickness of soil layer (m)

g

= frost accumulating ability of material (kcal/m3)

A

2 heat conductivity (kcal/thC)

52 = resistance to heat flow of frozen layers (mZhOC/

Ao

kcal)

The freezing resistance due to heat flow in the earth to the frost line (stored heat in unfrozen soil) can be expressed s

E = kGTAZ(X9), hOC

o where: k = a constant (usually 0.7)D II

temperature gradient below frozen zone of Feb. 1st

(QC/m)

T = actual reference time (h) for stored heat

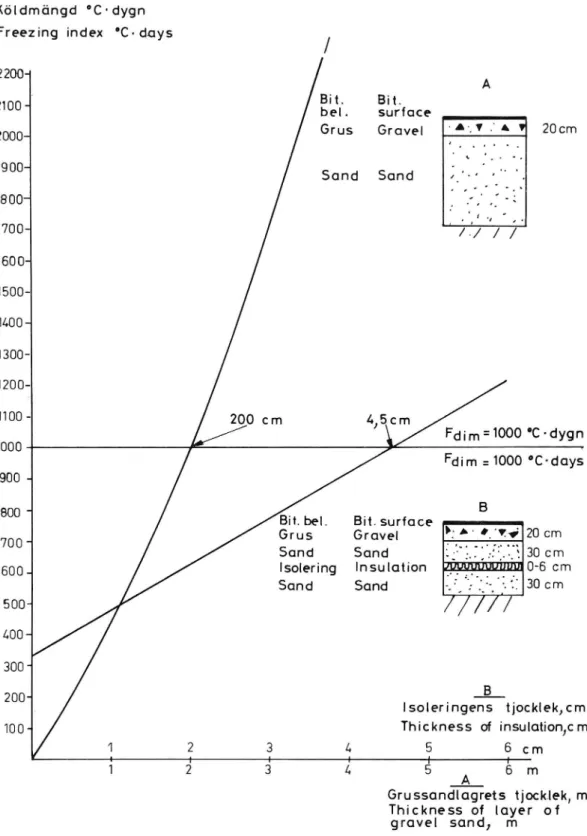

In fig 1 the frost resistance capacity of a road base

built up of layers of sand and gravel and of a road base insulated with polystyrene foam is plotted as a

function of the thickness of the gravel sand base and

of the thickness of the polystyrene foam layer. The design freezing index is assumed to be 1 000

degree-days for the actual part of the country. So, if during

one winter the freezing index will reach the value of

1 000 degree-days, the bases will just freeze but not

the subgrade. That means that you can choose either a 200<Hnthick road base of gravel and sand or a base

insulated with 4,5 cm of polystyrene foam with a total

base thickness of around 85 cm and during that winter

for either base get 100 % frost protection.

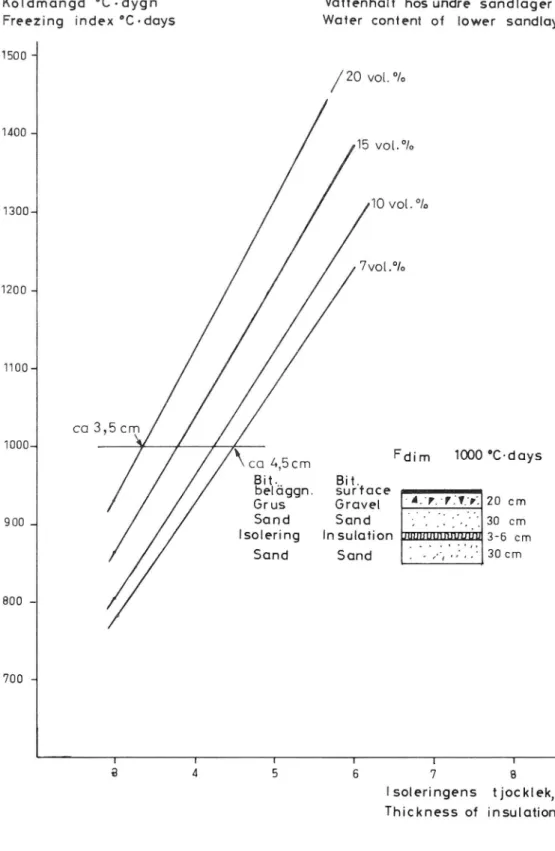

The frost resistance capacity of the polystyrene foam insulated base is dependent mostly on the insulation properties of the polystyrene foam (thermal conductivi

ty) and also of the water content of the layer of sand

below. Fig 2 is a diagram describing frost resistance

capacity related to the thickness of the polystyrene

foam for different thermal conductivity values of the

foam.

Next fig 3 shows you the importance of the water

con-tent of the layers beneath the plastic foam. That

layer acts as a freezing resistance layer and is

consequently more efficient the more water it contains.

As old road bases often are built up of fine grained

and moist material, it can be an advantage to insulate

them with plastic foam by merely placing the foam

boards directly upon the old road surface and

construc-ting a new base upon the plastic foam layer.

Koldm'angd °C - dygn Freezing index °C~days

zzm+ A ; mt. BH. 2 00 bel. surface

2000-

Grus

Gravel

"17

V 20cm

190% Sand Sand 1'. .1800

'

' I;

1700-

)f/ I/ /"

1600-1500 1400- 1300-1200-HOO

200 cm

4,5cm

Fdnn=1000'C-dygn 1mm 0Fdim = 1000 °C-days

mm-- B 800 Bilbel. Bit.surfaoe ' _ 700 Grus Gravel .3 3' Yv 20 cmSand

Sand

.

30 cm

500_ lsolering Insulation ._ u . . 0-6 cmSand

Sand

'

if 30 cm

500 400-3004 200-A lsoleringens tiocklek,cm. B . 100- Thickness of insulation,cm l 2 3 4 5 5 cmi

2'

j

i

6

_A_

is

m

Grussandlagrets tjocklek, m Thickness of layer of gravel sand, inFig 1. Example showing the calculated frost resistance

capacity of a sand-gravel road base and a base

frost protected with polystyrene foam. This

capacity values are not to be generally used. By

calculating the frost resistance capacity for

any single base the apprOpriate in put values

have to be

VTI RAPPORT 214 A

Ka'ldmangd °Codygn / Freezing index °C-days

1500 1400d 1300 '4 1200-Fdim = 1000 °C-dygn an . 0 Fdim -1000 C days 1100*

)x kcaL/m°Ch A032 »0,04 kcal/m °Ch

J

0knin en av isoleringens

1000 t

0,02

tjock ek

3*6cm increased thickness of insulation 900 a _ BH. 0,025 Bit.bel. surface . . Grus Gravel '(4 r. <? 20cmSand

Sand

30cm

800 lsolering Insulation _. 3-6cm0,030

Sand

Sand

30 3"

0,035

700-qmo

0,045

i l T l I | 3 A 5 6 7 8 Isoleringens tjocklek,cm Thickness of insulation,cmFig 2. The frost resistance capacity of a road base

with polystyrene foam for different values of

the thermal conductivity, as a function of the

thickness of the foam layer.

Koldm angd °Codygn

Freezing index °C-days Water content of lower sandlayerVatlenhalt hos undre sandlager

1500 -/20 vol.% 1400 -15 VOl.°/o 1300 10 VOl.°/o 7VOl.o/o 1200 -1100a ca 3,5 cm 1000 F ' 1000 °C \ca 4,5cm d'm 'days Bit. Bit. belaggn. surface O _ _, Grus Gravel 20 cm 900 _ Sand Sand "' ". 30 cm Isolering In sulation 3-6 cm Sand Sand I' 30 Cm 800 700 a l l l T l l 8 4 S 6 7 8 Isoleringens tjocklek,cm Thickness of insulation,cm

Fig 3. The frost resistance capacity of a road base

with polystyrene foam for different values of

the water content of the material in the layers

just beneath the foam layer,

as a function ofthe thickness of the foam layer.

PARTIAL INSULATION AND FROST HEAVING

If the road base of sand gravel or with polystyrene foam or other insulating materials is design for a choosen freezing index, which could be the mean free-zing index, no frost heaving will take place when the winters are not colder than this critical freezing

index.

The curves in fig 1 are based on the mean freezing

index, which statistically will happen one in two winters. Of interest is now the consequences of frost

heaving when the winters are colder than the assumed

winter. An attempt has been made by S Fredén at the

Institute to calculate the frost heaving when the assumed freezing index is exceeded.

Fig 4 describes the calculated relation between

free-zing index and frost heaving for three road bases with

the frost resistance capacity of 1 000, 500 and about

3000c - days.

The calculations were made under the assumption that the frost heaving is proportional to the net heat flow from the freezing zone (i.e. the total heat flow from the freezing zone minus the heat flow through the soil under the frost line). It has also been supposed that there is a steady flow of heat from the unfrozen soil to the freezing zone during the winter. The frost heaving caracteristics of the soil has been defined as the quotient between the heat energy used for

gro-wing ice lenses and the total energy used for freezing

the soil. In doing this calculation no concern has been given to the changing load on the freezing front or to the changing distance to the ground water table. The calculation has been done is short time steps,

where it has been supposed that every step can be

regarded as a stationary state (quasi stationary heat

transport). The introduced error during this type of

calculation has been computed and it does not exceed

10 % and are in most cases far less.

The upper curve in fig 4 describes the frost heaving

when the freezing index of the winter exceeds the assumed (designed) mean freezing index (1 000

degree-days) and the road base has been frozen through. The

curve is nearly a straight line and the quotient,

free-zing index (0C days)/frost heaving (cm), is 125. The

found quotient makes it possible to estimate the frost

heaving for any realistic freezing index. If fOr

example the freezing index for the 10 percent winter

is 1 500 degree-days, i.e. 500 degree-days above the

design freezing index the frost heaving will be 4 cm.

When designing for a lower freezing index than 1 000 degree days, which was assumed to be the mean freezing

index for a specific region, the resultant frost hea

ving after freezing of the base will be greater. The two lower curves in fig 4 exemplifies this. So will a sand-gravel base of 1,2 m thickness (frost resistance

capacity 500 degree days) give a frost heaving of

1 000/83 cm = 12 cm at a freezing index 1 500 degree

days, and a base of only 0,7 m of sand and gravel

(frost resistance around 300 degree-days) give a frost heaving of 1 200/44 cm = 27 cm.

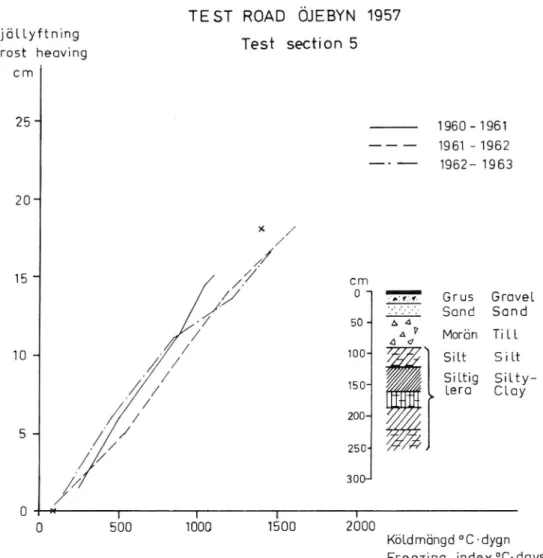

The curve in fig 4 is calculated. Field measurements give the same results. As an example study fig 5 which shows the relation between the measured frost heaving and the observed actual freezing index for a road base with morainic layer. The quotient freezing index in degree-days to cm frost heaving for this base and sub-grade is around 100, which caracterize the conditions to be of average degree of frost dangerousity.

_ Kéldmdn " Tjdllyftning

Q: Freezinq index (C,d0ys/Cm)

(C'dygn/cm)

Frost heaving

Kéldmc'ngd °C'dygn Freezing index C-dcys

1500 i 1000 " 500 "-l J I l r i 0 1 2 3 4 5 6 7 Tjéjllyftning, cm Fros-t heaving, cm

Fig 4. Calculated frost heaving in relation to freezing

index. According to S Fredén.

10

TEST ROAD 0JEBYN 1957

T'éle ftnin . J y .9 Test sectlon 5 Frost heovmg cm

250

1960 1961

--- 1961 1962 - 1962 1963 201 15 Cm 0 Grus Grovet Sond Sand 50~ A4AGV

Moron TiLL

10

100

W Silt

SiLt

SiLtig Silt

-150'

>Lero

cm;

200-5 1 250. gwe

0

"

I

I

I

I

0 500 1000 1500 2000 Kb'Ldméjngd °C°dygn Freezing index°C-doysFig 5. Frost heaving in relation to freezing index for

the Test Road bjebyn 1952 in the north of Sweden.

ll

SPECIAL TRANSITIONS

By insulationg a culvert witha plastic foam layer in frost susceptible subgrade there will arize a problem in flattening out the uneven frost heaving along the

road, from the culvert area to the point where the

plastic foam layer ends. The standard method is to

taper off the insulation layer by using thinner boards

towards the end of the insulation. There is also

an-other method now under testing, which take advantage

of the heat flow through purposely arranged openings

between the single boards. The curve in fig 6 shows the relation between the width of the openings and

the resulting frost heaving, when the full frost

resis-tance capacity of the road base for a desing freezing

index of 1 OOO degreewdays is 1 OOO degree-days and

for a particular winter when a freezing index of 1 435

degree-days occurs. As usually is here assumed a con-stant flow of heat up to the freezing zone. The curve

is calculated by S Fredén at the Institute. The calcu

lations have been made by means of a fast FEM-program in two dimensions. The program is constructed by the

Mathematical Institution of the Technical University

of Linkoping. The physical basis for this calculation

are the same as used for the simpler one-dimensional

frost heaving program, presented in this paper.

Fig 7 is a photo from a test road in North Sweden of

the polystyrene foam layer with increasing width of

the Openings between the boards towards the end of the

insulation. The Openings are filled with sand which

has a high thermal conductivity in compariosn to the

conductivity of the polystyrene foam. At this first

test road in 1975 the required width of the openings

were not fully known and the test construction did not

give the desired longitudinal frost heaving curve as

is illustrated in fig 8.

12

Tjallyftning utan isolering

, Frost heaving without insulation

TJallyftning,mm Frost heaving, mm

300

200

-Koldmangd 1435 °C'dygn Freezing index 1435 °Ctdygn 100- lsoleringens tjocklek, 6cm

Thickness of insulation, 6cm

0 t 4. 5 %

100 200

Springans bredd, mm

The with of the opening, mm

Fig 6. Frost heaving as a function of the with of plan

Oparallell openings between plastic foam boards.

The width of the boards is 60 cm and the

thick-ness 6 cm. Freezing index is l 435 OC - days.

l3

openings between the pl

the end of the transition.astic foam boards towards

VTI RAPPORT 214 A Tjal lyf tn in g, cm Fros t he avi ng , cm Tj ii llyf tn in gs kur va , ap ri l 19 76 Fr os t he ave cur ve , Ap ri l 19 76 Di me ns io ne rand e tj 'a ll yf tn in gs kurva De si gn ed fr os t he ave cur ve

it

15-/81

-02

-19

/

/ 81 -0 1-13w-_

~d

\

\

\

/

Ut spet sn in g, m Tr an si ti on . in / l 1 V l l I I r l-1

0

5

0

is

10

1'5

20

25

30

L

T

22

42

62

8

3o

32

34

36

38

4o

42

44

46

48

so

52

54

56

58

6O

62

Sp

ri

ng

br

ed

d,

cm

197

5/7

6

46

810

121

416

182

02

[

H

H

D

D

U

D

U

U

D

D

U

D

D

U

D

D

D

D

D

D

D

[1

D

D

D

D

D

D

D

D

Wi

dt

h

of

op

en

in

gs

,

cm

19

75

/7

6

Om byg gn ad aug 19 80 H Re co nstr uc ti on Aug 19 80 4 _ 4 1 1 1 1 1 1 2 l 2 22 3 34 A S S 6 7 8 9111 21 41 61 92 22 53 03 542 52 SA 56 58 6O 62 Sp ri ng br ed d, cr n1 980/ 81L

ti

li

i

i

ii

Li

ii

li

Il

Ul

iH

D

DU

DD

DD

DD

D[

3C

i[

3D

Width of op en in gs , cm 19 80 /8 1F

i

g

8.

F

r

o

s

t

h

e

a

vi

n

g

a

l

o

n

g

a

t

r

a

n

s

i

t

i

o

n

wi

t

h

s

uc

c

e

s

s

i

ve

l

y

wi

d

e

n

i

n

g

of

th

e

o

p

e

n

i

n

g

s

b

e

t

we

e

n

th

e

p

l

a

s

t

i

c

f

o

a

m

b

o

a

r

d

s

.

14

l5

The test road was reconstructed in 1980 according to

the new calculated curve (fig 6) and should

theoreti-cally give a better result. In January 13th and Feb

ruary 19th 1981 the longitudinal frost heaving curves

were measured and plotted in fig 8. It can be recogni-zed that these heaving curves are much more even and

rather well coincide with the theoretical curve. The

dashed lined parts of the curves represent stretches of the road, where the construction was incorrect. ICING INVESTIGATIONS

When inserting a heat insulating layer into the road base the heat flow from the subgrade is retarded

during winter. A possible consequence could be, that

in early autumn, when the weather is clear in the

nights and the net heat radiation from the road

sur-face is great, the sursur-face temperature will go down

below 00C and also below the dew point at insulated

sections causing hoar frost on the road surface, which

will not be the case at non insulated sections. This

problem has been thouroughly studied at a test field at the Institute (by K Gustafson). Fig 9 is an extract from the results of this investigations /2/.

Fig 9 describes some of the investigated types of bases and the times in hours during which the surface temperature at these bases during three winters was

measured to be lower than -20C. It is assumed that a

temperature of -20C and lower could be critical for

the formation of hoar frost on the road surface.

The sand gravel base is the standard base and the other bases are compared with this base. It can be recognized that the base which is "top" insulated (5) is most critical to surface icing with the length of time having a surface temperatur lower than 20C being 30 % longer than that for the standard base.

VTI RAPPORT 214 A

19 78 h 20 29 h 18 93 h 7, 2 %4,5

°/.

20 43 h 7,9°l o 2477 h

sa

yh

Bi t. Bi t. b e l d g g n . S U F f G C e i $ y 4 c m .-r. . Gr us Gr ave l f -. l r 16 II

16

o-Z?

(V

_ 4 c m 4 c m V .xi

Sa nd Sa nd ' _. 50 u f 30 n ' . . |. . ' . , 5 . -' \ . |. ' I . ' ; . 1 5"B;

1

.

4

T

El

se

?

ls

ol

er

in

g'

bo un d gr ave l515

,,

In

sum

lo

n

T'

Xéz'

.

16

~

1 . ~ .v

Be

rg

kr

os

s

.

Cr os se d . 45 .. y' st on e . -.. . . ' 2 0cm0

F i g 9. D ur a t i o n o f t i m e wi t h s ur f a c e t e m p e r a t ur e b e l o w -2 C f o r s o m e r o a d b a s e s , i n d ic a t i n g d i f f e r e n t d e g r e e o f r i s k f o r s ur f a c e i c i ng .l6

17

Two bases, with insulation at a depth of 35 cm (3) and a base with crushed stone (4), are critical to the same

degree. The crushed stone-base is a conventional base

in Sweden. According to the Swedish specification for

designing bases insulated with polystyrene foam the boards should be placed at least 50 cm below the road

surface (2). The period with lower temperature than

20C is 4,5 % longer than for a standard base, which

is accepted.

ECONOMY

Polystyrene foam is a comparatively expensive material per cubic meter. On the other hand only thin layers are needed for an efficient frost protection, which

will reduce the cost factors considerably. In fact,

for the same proteciton demand the base with

polysty-rene foam is cheaper to construct compared to the

equivalet base built up

by sand and gravel.

The construction costs have

been calculated for two

types of bases using the local costs figures for

materials and transportations in north Sweden (mean

freezing index 1 OOO degree-days). Compare the two

types of base in fig 1. The result of the calculations

is demonstrated in fig 10. The conditions is that the

full insulation must be tapered off along a stretch of

22,5 m at each side, and that the polystyrene foam,

(Styrofoam HI 50) of the high quality extruded type,

and sand gravel material is delivered at the site at a

fixed price. The transportation distance for the

sand-gravel material is 5 km. It is also assumed that the

road is to be repaired by excavating the poor material

in situ and refilling it with new sand-gravel material

and polystyrene foam.

From the fig 10 it can be seen that for all length of

repairing it is cheaper to frost protect with

VTI RAPPORT 214 A Kr lm 2 Ful li so le ri ng S w Cr/m 2 Ful l in sul at io n

\

35 0 l\;\

\

25 0'\

\

v

,

Ur

gr

ci

vn

in

g

oc

h

dt

er

-,. , _ . _ _ fyl lm ng m ed sa ndl\

oc

hg

rus

20 0 cm -'' -Exc ava ti ng and re fi ll in g with sa nd / / l1 20 0an

d

gr

ave

l

'2

50

cm

3 0 c m//

/,

27/

15 0 10 0 :\u\

"\ "\ . \/</ x

0

\ Ur gr avn in g oc h 8 0 x \ \ \ ce ll pl as ti so le ri ng \ 6 30 / \ \ \ t \ _ \ \ \ V Exc ava ti ng an d in sul at io n wi th \ N _ / p l a s t i c f o a m s I 70 ls ol er ings tj oc kl ek ,c mIn

sul

at

io

n

th

ic

kn

es

s,

cm

-\ \ -\ K \ \ -C h _ -} W'jh'. O DF

i

g

10

.

10 20 30 40 50 60 70 80 90 100 Ful li so leri ng en s ld ng d, m Leng th of ful l in sul atio n, mC

a

l

c

ul

a

t

e

d

c

o

n

s

t

r

uc

t

i

o

n

c

o

s

t

s

fo

r

r

e

p

a

i

r

i

n

g

r

o

a

d

s

in

th

e

n

o

r

t

h

of

S

we

d

e

n

wh

e

n

e

xc

a

va

t

i

n

g

th

e

p

o

o

r

m

a

t

e

r

i

a

l

in

s

i

t

u

a

n

d

r

e

f

i

l

l

i

n

g

it

b

y

p

ur

e

s

a

n

d

g

r

a

ve

l

m

a

t

e

r

i

a

l

a

n

d

p

o

l

ys

t

yr

e

n

e

f

o

a

m

.

(

S

t

yr

o

f

o

a

m

HI

50

)

l8

l9

styrene foam. For instance is the construction cost

for 100 m of insulation with polystyrene foam 75 SW.

Cr/m2 and for the sand-gravel alternative 125 SW. Cr/m2.

If the thickness of the sand gravel base is reduced to

120 cm the cost for this base will be 72 SW. Cr/m2,

but as is illustrated in fig 5 this reduction will give a frost heaving of 6 cm, when during the winter

20

REFERENCES

1. Skaven Haug, The Design of Frost Foundations, Frost-heat and SoilFrost-heat, Norwegian Geotechnical Institute. Publication Nr 90 Oslo 1971.

2. Gustafson, K. Road icing on different pavements. Investigation at Test Field VTI, 1976-1980. Statens