1972 GUIDE

TO MORE PROFITABLE

SUGAR BEET PRODUCTION

INDEX

Page

Introduction ... ... 1

Things to Remember... 2

Soil Management ... ... 3

Soil Fumigant Application Application rates and return ... ... 3

Calibration data ... ... 5

Nitrogen Fertilizer Usage .... ... ... .. 5

Farm For The Machine ... ... ... 7

Herbicides Principles of Chemical Weed Control ... ... 8

Preplant Doses, Weeds controlled ... 10

Postemergence Doses, Weeds controlled ... 11

Lay by Doses, Weeds controlled ... 13

Spray-Mixing Tables ... 13

Granular Tables ... 16

Sequence Applications ... 16

Equipment Calibration ... 17

Planting G. W. Hybrid Sugarbeet Seed ... 21

Plant Population ... 22

Seed Spacing ... 24

Planter Plates ... 27

Drill Check List ... 29

Insect Control Root Maggots ... 29

Pale-Striped Flea Beetle Larva ... 31

Webworms ... .. 31

Other Insect Pests and Toxicity ... ... .. 31

Irrigation ... 32

Mechanical Thinning ... 33

Notes (3 Pages) ... ... ... ... . .. 34 Telephone Directory ... Cover 3

INTRODUCTION

This booklet is designed to give helpful information to beet growers in Western areas served by The Great Western Sugar Company.

During the past few years the dramatic increase in the use of herbicides for weed control and selective electronic thinners for stand adjustment has brought complete mechanization of the sugar-beet crop extremely close.

During the 1971 crop year a small percentage of beet growers in G. W. territories actually did completely mechanize their beet crop and grow "Beets From The Tractor Seat" without hand labor being used for hoeing or thinning during the season.

The machinery to do this on a large scale is available now. Im-proved herbicides that hold great promise for giving season-long weed control are well along in the development stages.

Many acres in 1971 were grown with only one pass of labor, used after machine thinning, to clean up a few weed "escapes" that were left following a timely applied herbicide program.

"Beets From The Tractor Seat" should be the goal all Great West-ern growers work toward.

THINGS TO REMEMBER

.

I. PREPARE THE BEST POSSIBLE SEED BED for your conditions. Fall plowing and bedding will allow earlier planting. In areas subject to wind erosion in the spring, a minimum tillage program, leaving crop residue on the surface, may suit your purpose best. 2. FUMIGATE soils if nematodes are a problem.

3. FERTILIZE for maximum extractible sugar per acre. Determine ni-trate nitrogen inventories in the soil profile by use of deep (3-6 ft.) soil test.

4. HERBICIDE APPLICATION IS A MUST. Use pre-emergence herbi-cides on all but extreme sandy, problem soils. Be prepared to post spray weed "escapes" or fields not suited to pre-emergence herb-icides. Apply Lay-by herbicides to avoid late season weed problems. 5. PLANT EARLY with a seeding rate adapted to machine thinning.

Use the highest quality seed available.

6. CONTROL INSECTS with properly metered and applied insecticides. "FOLLOW LABEL PRECAUTIONS CAREFULLY".

7. IRRIGATE immediately if there is a shortage of natural moisture for germination. Moisture is a must to activate herbicides and produce maximum sugar per acre. Schedule irrigations during season for maximum production.

8. MACHINE THIN your beets to produce best possible stands and reduce hand labor.

9. CULTIVATE CLOSE to the row and timely. Set the field up for ma-chine thinning.

10. HARVEST CLEAN BEETS by using "grab-roll" screens on your har-vester and a top windrower for thorough topping and maximum top utilization.

11. CAREFULLY FOLLOW LABEL directions on all herbicide, fumigant, insecticide and fungicide materials.

12. CONTACT YOUR G. W. AGRICULTURIST if you have questions. A more detailed explanation of the above points is contained in the following pages.

EXPEND EVERY EFFORT TO MAKE YOUR INVESTMENT IN CHEMICAL CONTROL PAY OFF.

SOIL MANAGEMENT

Throughout the Great Western Sugar Company's sugarbeet grow

-ing district there are individual fields or whole areas (like eastern Colorado) that are extremely susceptible to spring blowing.

In these areas March 20 through May 10 is a very critical time in the life of a sugarbeet. It is at this time the mean wind velocity is at its highest and the sugarbeet plant, in the very vulnerable seedling stage, needs protection from the blowing soil.

Listed in Table 1 are eight techniques of soil management that can be used alone or in combination with one another to offer protec-tion to sugarbeet seedlings during the critical period.

Table 1. Techniques of soil management for use on soils susceptible to blowing.

Soil Management Technique Sidewinder mulch

+

strip plant Nebraska till-plant+

strip plant Sidewinder mulchNebraska till-plant Strip planting Plow plant Barriers Cover crop Sandy Soil excellent excellent good good fair poor fair fair Hard Lands excellent excellent good good good good use is ootional use is optional

SOIL FUMIGANT APPLICATION

Long term research with soil fumigants shows conclusively that soil fumigation for control of sugarbeet nematodes consistently in-creases yields and profits on infested land. Yield inin-creases of 7-9 Tons/ Acre are average and in many cases the increased yield is even greater.The following cost breakdown (based on an average 16% sugar,

$17 IT beet crop) shows how fumigation pays,

Beet yield without fumigation, 12T@$17.

Beet yield with fumigation, 19T@$17. Cost of fumigant Net

Fumigation net return 3 $204 $323

$

42 $281$

77From the growers point of view this means you need only to in-crease yield 2.44 T/A to completely offset the cost of the soil fumi-gant.

If you have nematode infested soil you can't afford not to fumigate.

Soil Fumigant Recommendations for Control of Nematodes in Sugarbeets (a)

Rate (Gal/ A) Plow down

Soil Type or broadcast In-bed Deep

Sandy-dry 15-20 12-15 12-15

Heavy-dry 20 15 15

Wet-Sandy or Heavy Do not fumigate

(a) Materials recommended for use are DOW TELONE, SHELL D-D, and DOW VIDDEN-D.

Flow Rate Chart for Use in Calibrating Gravity Flow Fumigant Applicators

OUNCES PER MINUTE PER OUTLET (a)

Miles/Hr. 3.0 3.5 4.0 4.5 Row Spacing 16"(b)22" 16"(b)22" 16"(b)22" 16"(b)22" Gal/ Acre 10 10.3 14.2 12.1 16.1 13.8 19.0 15.6 21.3 12 12.4 17.1 14.5 19.9 16.5 22.7 18.7 25.6 14 14.5 19.9 16.9 23.2 19.3 26.5 21.8 29.9 16 16.5 22.8 19.4 26.6 22.0 30.3 24.9 34.2 18 18.6 25.6 21.8 29.9 24.8 34.1 28.0 38.4 20 20.6 28.4 24.2 33.2 27.6 37.9 31.1 42.7 22 23.7 31.3 26.6 36.5 30.3 41.6 34.2 46.9

(a) Multiply by 29.6 to convert to Milliliters

(b) Multiply oz./Min by 1.12 for 18" shank or plow spacing 4

Flow Rate Chart for Use in Calibrating Fumigant Applicators with Constant Displacement Pumps

Oz (a)/Outlet/Distance Traveled Distance traveled (Ft.) 200 300 400 Spacing 11" 22" 11" 22" 11" 22" Rate Gal/A 10 5.36 10.72 8.04 16.08 10.72 21.44 12 6.43 12.86 7.65 19.30 12.86 25.72 14 7.50 15.00 l l.25 22.50 15.00 30.00 16 8.56 17.12 l~.84 25.68 17.12 34.24 18 9.65 19.30 14.48 28.96 19.30 38.60 20 10.72 21.44 16.08 32.16 21.44 42.88 22 11.79 23.58 17.69 35.38 23.58 47.16

(a) Multiply by 29.6 to convert to millileters.

Tractor Speed Calibration Chart Time in seconds required to travel a given distance

mph 100 Fl. 200 Ft. 300 Ft.

2.5 27 55 82

3.0 23 45 68

3.5 20 39 58

4.0 17 34 51

Miles per hour is equal to the number of 3 ft. paces traveled in

20 seconds, divided by 10.

Example:

40 (3 ft. paces in 20 seconds)= 4.0 miles per hour

10

NITROGEN FERTILIZER USAGE

Proper utilization of nitrogen fertilizer is a must if a profitable balance between high tonnage and high sugar content are to be

attained. (Continued)

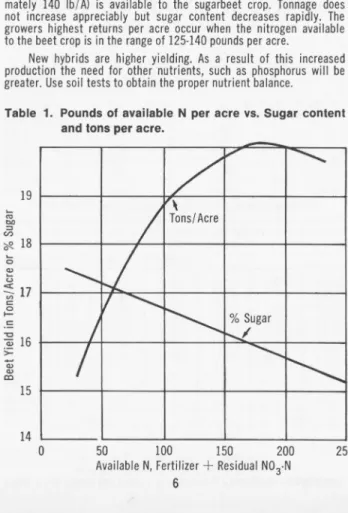

In the past few years it has been discovered that many sugar-beet fields have a high NO residual or reservoir in the lower 2-3 feet of the soil profile. In many cases this residual is equivalent to 100-150 pounds of available nitrogen which can be utilized by the sugar-beet crop. When the normal 100-150 pounds of nitrogen are added as fertilizer the results are very low sugar content beets. Table 1 clearly shows what happens when excessive nitrogen (above approxi-mately 140 lb/ Al is available to the sugarbeet crop. Tonnage does not increase appreciably but sugar content decreases rapidly. The growers highest returns per acre occur when the nitrogen available to the beet crop is in the range of 125-140 pounds per acre.

New hybrids are higher yielding. As a result of this increased production the need for other nutrients, such as phosphorus will be greater. Use soil tests to obtain the proper nutrient balance.

Table 1. Pounds of available N per acre vs. Sugar content and tons per acre.

19 ~ bD ::, ( / ) ~ 18 ~ 0 ~ <.>

~

17 C: 0 >-C: "C ~ 16 :;:-

Q) Q) ID 15 14 0 50 100 150 200Available N, Fertilizer+ Residual N03-N

6

FARM FOR THE MACHINE

Machines and chemicals form the new plan for labor saving sugarbeet production. We must think of the whole crop rotation if we are going to effectively control weeds in sugarbeets. Selection of the best row crop to precede sugarbeets, and the proper herbicides on all crops in the rotation have a significant affect on weed-free farming. Farm for the machine and not for labor. Desirable features in any weed-free farming system include:1. Place sugarbeets after a row crop in a field free of perennial weeds.

2. Prepare a seedbed ditched for "irrigating up" if necessary. Timely and adequate moisture has proved to be a "must" in herbicide effectiveness. Proper seedbed preparation facilitates uniform herbi-cide application and cultivation equipment operation.

3. Accurately meter the correct amount of weed chemical, either granular or liquid, and incorporate the herbicide in at a predeter-mined soil depth. When band-applied, confine the chemical to the band itself. Poor weed control and wasted money result from any device that "kicks" treated soil out or untreated soil into the band area. Use a separate tool bar to position each drill in the center of the treated band.

4. Use tractor guide marks to insure precise planting, cultivat-ing and selectronic thinncultivat-ing. Coulters and fins on the implement itself provide greater stability.

5. Provide a vigorously growing crop in a uniform stand that permits selectronic thinning and competition to late weeds.

6. Keep as clean as possible all places where weed seeds mature - ditches, fence rows, etc.

7. Accurate calibration of the herbicide applicator is absolutely essential for successful weed control. When changing chemicals in a liquid sprayer, the equipment must be flushed out completely with clean water-pump, tank, hoses and nozzles. Thorough cleaning is a must to make certain that th_e chemical in the second operation will not be adu Iterated.

8. Accurate incorporation of the herbicide to the proper depth is a "must." Experience indicates 1 ½ to 2 inches is desirable.

9. Even when the herbicide is used in the band, make certain that you are using the best cultivating tools possible as good, close

(Continued) 7

cultivation is important. We suggest for earlier cultivation that you use tools similar to the Bezzerides, Spyder or C & M whe'els as they have proved to give excellent small-weed control in the row without leaving a band to dry out, which may happen with disk cultivation. 10. Postplanting herbicides such as Eptam and Treflan (layby) and Pyramin, dalapon, Betanal, Herbicide 273 and Carbyne (post -emergencel are effective especially when used in sequence applica-tion after a preplanting herbicide and chemicals are combined with timely cultivating, thinning and irrigating. System management in weed control is farming for the machine.

11. We caution you in handling any chemical, whether it be herbicide, fungicide, insecticide, or any chemical of this type, that you bury or destroy all containers in order to avoid any reuse for any other purpose. See tables in this booklet for further details on chem-icals to use and dosage suggestions.

The USDA estimates that losses from weeds and costs of weed control on agricultural land equal about $3.8 billion each year. Expend every effort to make your investment in chemical and mechanical weed control pay off. Farm for the machine .

. · .

.

HERBICIDES

PRINCIPLES OF CHEMICAL WEED CONTROL Intensive research and practice over the years provides some basic principles of selective herbicide usage in sugarbeets which, if followed, can be expected to increase control efficiency:

1. Prepare a seedbed of fine tilth.

2. Use the correct preplanting herbicide at the proper rate and incorporation depth.

3. In the absence of precipitation, irrigate for germination within 7 days for activation of the herbicide.

4. Use a postemergence herbicide and/ or mechanical tools ahead of thinning to control weeds which may have escaped the effect of the preplanting chemical. It may be that only a postemergence treatment should be used on light, sandy or other types of problem soils.

5. At or after thinning, use in-the-row cultivation tools and layby chemical to control late germinating weeds. Layby chemical should be used early with the first cultivation or at thinning.

Herbicide Doses.

The following herbicide doses of active ingredient, for both prep/anting (Table ll and postplanting (Tables 2-3) are given for band application. Doses can be reduced up to 25 percent when ap-plied total coverage particularly before bedding on some soil types. Total coverage applications of Ro-Neet, Pre-Beta I and Pre-Beta II are effective when incorporated with a disk harrow, Tripple-K, Tread mulcher or other seedbed preparation machine.

It is difficult in a book of this kind to make recommendations or suggestions regarding the use of herbicides that may be applicable by any individual grower to his particular conditions.

The following tables summarize the information which will be used in 1972 by The Great Western Sugar Company as guidelines for its own agricultural and research staff in continuing their investiga-tions.

When using a chemical, read the label carefully, and then apply the chemical with precision.

Due to the variables of weather, soil condition, and application techniques The Great Western Sugar Company is not able to guaran-tee that chemicals and techniques suggested in this booklet will always perform to the manufacturers specifications. We have found by tests and observations of successful production operations that the chemicals and techniques suggested do perform with a high de-gree of success when label directions are precisely followed.

Table 1. Preplant .Doses for Various Chemicals and Soil Types. (a)

Dosage Active Ingredient Lb./ Acre Weeds Affected Med. Med.

u,ht Light Med. Heavy Heavy

Herbicide Soils Soils Soils Soils Soils Grassy Broad leaf Avadex 1.25 1.5 1.75 2 2 Wild Oat Variable

Foxtail control of Pigeon Pigweed Barnyard Lambsquarters

Nightshade

Ro-Ne et 2.5· 3 3.5 4 4 Foxtail Pigweed

2.25 Pigeon Nightshade

(Read Barnyard Shepherdspurse

Label) Sandbur Lambsquarters

Barley Purslane

Tillam 3- 3.5 4 4.5 5 Foxtail Pigweed

2.5 Pigeon Nightshade

(Read Barnyard Lambsquarter

Label) Pu rs lane

Pre- 2.5- 3 3.5 4 5 Wild Oat Pigweed

Beta I 2.25 Foxtail Nightshade

Pigeon Lambsquarters Barnyard Purslane

Pre- 3- 3.5 4 4.5 5 Wild Oat Pigweed

Beta II 2.5 Foxtail Nightshade

Pigeon Lambsquarters Barnyard Purslane Barley Herbicide 283 1.6 2 3 4 4.5 Foxtail Kochia Pigeon Wi Id Buckwheat Barnyard Smartweed Barley Pigweed

Shepherdspurse Purslane

Pyramin+ 2.4+ 3+ 3.25+ 3.75+ 4+ Foxtail Pigweed

Herbicide Pigeon Nightshade

283 1.6 2 2.25 2.5 3 Barnyard Lambsquarters

bTrial Wi Id Buckwheat

a sos Smartweed

only) Kochia

Mustards Purslane

Pyramin + 2.5+ 3+ 3.25+ 3.75+ 4+ Foxtail Pigweed Ro·Neet 1.5 2 2.25 2.5 3 Pigeon Nightshade

(Trial Barnyard Lambsquarters

basis Sandbur Shepherdspurse

only) Purslane

Ro-Nee!+ 2.25+ 2.5+ 3+ 3.5+ 4+ Foxtail Pigweed

Herbicide Pigeon Nightshade

283 1.6 2 2 2.5 3 Barnyard Kochia

(Trial Barley Shepherdspurse

basis Purslane

only) Lambsquarters

Pyramin+ 2.5+ 3+ 3.25+ 3.5+ 4+ Foxtail Pigweed

TCA 3 4 4.5 5 6 Pigeon Nightshade

(Trial Barnyard Lambsquarters

basis Wild Buckwheat

only) Smartweed

Mustards

Purslane (a) Use this table to determine dose tor your soil type, then consult Tables

4-6 for 7-inch band rates to use.

Pyramin is a wettable powder and requires careful mixing and agitation. Make a slurry before putting Pyramin into solution tank. Add the necessary Herbicide 283 as the entire solution is vigorously agitated. Continue agita-tion while Pyramin powder is in suspension. TCA doses given are acid

equiv-alent (94%).

Table 2. Postemergence Doses for Various Chemicals and Infestations. (b)

Dosage Maturity Stage

Active at Application weeds Affected Herbicide rniredient L /Acre Beets Weeds Grassy Broad leaf

Betanal 0.75-1 First Cotyledons Foxtail Wild Buckwheat

(after pre- trueleaf to 2-4 Pigeon Lambsquarters

planting) stage trueleaf Mustards

1-1.25 (½" and Kochia ~~maerdspurse

(post- longer) rosette

emerge 1" in dia. Purslane

only) or less Nightshade

Carbyne 0.75-1 Seedlings 2-leaf Wild Oat No control Dowpon or 2.25-3 and Up to 4- Seedlings Foxtail No control Basfapon 3-4.5 (at leaf stage, only Pigeon except

en-lay-by and (Dosage Barnyard hances control

only) directed depends when used with

lay-by afte1 on place- Pyramin 7-leaf ment,

stage timing, maturity,

and temp-erature)

Herbicide 0.75-1 First Cotyledons No control Wild Buckwheat 273 (after pre- true leaf to 2-4 Smartweed

planting) stage trueleaf 1-1.25 (¼" and (post- longer) emerge only) (Continued) 11

Dosage Maturity Stage

Active at Application Weeds Affected Herbicide Ingredient Lb/ Acre Beets Weeds Grassy Broad leaf

Pyramin 9-12 lbs. Same as tdr Plus material Pyramin +

(Pyramin + (after pre- Dowpon Dowpon planting) package 12 lbs. mix) material ( post-emerge only)

Pyramin + 2 + 1 · First true- Cotyledons Foxtail Pigweed Betana I 3 + 1 leaf stage to 2-4 Pigeon Wild Buckwheat

(trial basis (after pre- (½" and true leaf Lambsquarters

only) planting) longer) Kochia Mustards

3 + 1- rosette Shepherdspurse

3 + 1.25 l" in dia. Nightshade

(post- or less Kochia

emerge Purslane

only)

Pyramin + 3 + 2 - First true- Cotyledons Foxtail Pigweed Dowpon+ 4 + 2.25 leaf stage to 2-4 Pigeon Mustards Surfactant (after pre- (¼" and true leaf Barnyard Nightshade

(trial basis planting) longer) Wild Buckwheat

only) 4 + 2.25 Lambsquarters

( post-emerge only)

Pyramin + 3 + 2 + 1 Same as for Foxtail Pigweed Dowpon + (postemerge Pyramin + Pigeon Nightshade Herbicide only) Dowpon Barnyard Lambsquarters

273+ Wild Buckwheat

Surfactant Mustards

(trial basis Smartweed

only)

(b) Use this table to determine chemical and dose to use for species pres-ent, then consult Tables 4-6 for 7-,nch band rates to use. Consult foot-note, Table 1, for Pyramin mixing instructions. When refilling tank, place Betanal liquid in the tank first then add water. See Betanal label for other precautions. Use lower doses of herbicides after a preplanting herbicide when beets appear retarded at application time. Dowpon doses given are acid equivalent (74%). Surfactants suggested for use with py. ramin + Dowpon tank mix are Citowett (0.5-0.75% V /V) Agri-Oil Plus

(0.5% V/V) and Sun Oil-llE (1 gpa). Do not apply surfactant to any herbi-cide unless noted above and never with Betanal and Pyramin Plus. See Tables 4 and 6.

Table 3. Lay by Doses for Various Chemicals Soil Types. (c) Soil Class

I

Med.I I

Med.r;;-

Maturity stageLight Light Med. Heavy Heavy at application

soils soils soils soils soils

Herbicide Dosage Active Ingredient, Lb/ A Beets Weeds

Eptam 2 2 2.5 3 3 2-4 true- Pre

-leaf emergence

onward to weeds

before or and soil after incorpo-thinning. rated.

Treflan 0.5 0.5 0.5 0.75 0.75 4-6 true- Pre-leaf emergence onward to weeds before or and soi I after incorpo -thinning. rated. Keep

Treflan off beet crown. Eptam + 1.5 + 1.5 + 2+ 2+ 2.5+ Same as Treflan 0.5 0.5 0.5 0.5 0.5 above. (trial basis only)

(c) Lay by herbicides can be applied after a preplantir\g or postemergence herbicide. In addition, split-a~plications of lay by herbicides are effec-tive. For example, Eptam applied at 2 lb/A followed by Eptam at 1 lb/A in 4 to 5 weeks. Pyramin + Dowpon can be considered a lay by chemical also.

Table 4. Spray-Mixing Tables. (d)

Spray-mixing table for various preplanting and postplanting herbi-cides given in lb/ A active ingredient and rate of material per acre to apply in ounces. Add the ounce rate at the dose set forth to the

gallons-per-acre volume obtained by calibration of the sprayer (See Tables 1-3).

Rate of Material, Oz/A Dosage Total 7-ln. Band Herbicide Lb/A Active Coverage 2" Row 24" Row

(Pre planting) Avadex,4E 1 32 10 9 1.25 40 13 12 1.5 48 15 14 1.75 56 18 16 2 64 20 19 (Continued) 13

Rate of Material, Oz/ A

Dosage Total 7-ln. Band

Herbicide Lb/ A Active Coverage 22" Row 24" Row

Herbicide 283, 2S 2 - 41 37 3 - 61 56 4 - 82 75 4.5 - 92 84 Ro-Neet, GE or 2.25 48 15 14 Tillam, GE 2.5 53 17 16 3 64 20 19 3.5 75 24 22 3.75 80 26 23 4 85 27 25 4.5 96 31 28 5 107 34 31 Pre-Beta I, 5E 2.5 64 21 19 (Tillam+Avadex, 2:ll 3 77 25 22 3.5 90 29 26 4 102 33 30 4.5 115 37 34 5 128 41 37 Pre-Beta II, GE 3 64 20 19 mo-Neet+Avadex, 3:1) 3.5 75 24 22 4 85 27 25 4.5 96 31 28 5 107 34 31 Pyramin, 75.5W+ 2.4+ 1.6 - 16+33 15+30 Herbicide 283, 2S 3+2 - 20+41 19+37 3.25+2.25 - 22+46 20+42 3.75+2.5 - 25+51 23+47 4+3 - 27+61 25+56 Pyramin, 75.5W+ 2.5+ 1.5 - 16+10 15+10 Ro-Neet, GE 3+2 - 20+14 19+13 3.25+2.25 - 22+15 20+14 3.75+2.5 - 25+17 23+16 4+3 - 27+20 25+19 Ro-Neel, GE+ 2.25+1.6 - 15+33 14+30 Herbicide 283, 2S 2.5+2

-

17+41 16+37 3+2 - 20+41 19+37 3.5+2.5 - 24+51 22+47 4+3-

27+61 25+56 14Pyramin, 75.5W+ 2.5+3 - 16+16 15+15 TCA,94AE 3+4

-

20+22 19+20 3.25+4.5 - 22+24 20+22 3.5+5 - 24+27 22+25 4+6-

27+32 25+30 (Postemergence) Betanal, 1.3E 0.75-

23 22 1 - 31 29 1.25-

39 36 Carbyne, IE 0.75 96 31 28 1 128 41 37 Dowpon or 2 - 14 13 Basfapon, 7 4AE 2.25-

16 14 3 - 21 19 4.5 - 31 28 Herbicide 273, 3S 0.75 - 11 9 1 - 14 12 1.25 - 17 16 Pyramin Plus 9 lbs - 46 42 121bs - 61 56 Pyramin, 75.5W 2+1-

13+31 12+29 + Betanal, l.3E 3+1-

20+31 19+29 3+1.25 - 20+39 19+36 Pyramin, 75.5W 3+2 - 20+14 19+13 +Dowpon, 74AE 4+2.2? - 27+16 25+14 Pyramin, 75.5W 3+2+1-

20+14 19+13 +31 +29 +Dowpon, 74AE +Herbicide 273, 3S (Lay-by) Eptam, 6E 1 21 7 6 1.5 32 10 9 2 43 14 13 2.5 53 17 16 3 64 20 19 Treflan, 4E 0.5 16 5 4.7 0.75 24 7.6 7 Eptam, 6E+ 1.5+0.5 32+16 10+5 9.5+4.7 Treflan, 4E 2+0.5 43+16 14+5 13+4.7 2.5+0.5 53+16 17+5 16+4.7(d) Consult labels for instructions. For lay-by rates on 9-inch band increase

7-inch band rates given by 28.5%. Pyramin Plus dosage given is rate of material.

Table 5.

Spray-mixing table for surfactant applied in 7-inch bands at 22-and 24-inch row spacings. Add the ounce rate at the dose set forth for each herbicide to the gallons-per-acre volume obtained by calibration

of the sprayer. (See Tables 2 and 4). (e)

Adjuvant in % of Ounces to add to solution each band-acre for: total volume or gpa 1 gpa 10 gpa 15 gpa 20 gpa

Surfactant, 0.5%,

V

/

V

- 6.4 9.6 12.80.75%

V

/

V

- 9.6 14.4 19.2Non-phytotoxic

crop oil, 1 gpa 41 - -

-(e) Non-phytotoxic oil (Sun Oil-llE) for use only with Pyramin + Dalapon tank mix when broad1eaf weeds predominate. Use care if oil is used

especially after a preplanting herbicide and when temperature is above

85° F for excessive crop inJury may result.

Table 6. Granular Tables.

Granular table for various preplanting and layby herbicides given in lb/ A active ingredient and band-acre rates in 7 and 9-inch bands at

22-and 24-inch row spacings. (f)

Rate of Granular Weight in pounds per acre for:

10%

Dosage Material 7-inch band 9-inch band Lb/A Overall

Active Lbs/ A 22" Row 24" Row 22" Row 24" Row

2.5 25 7.96 7.29 10.23 9.38 3 30 9.55 8.75 12.27 11.25 3.5 35 11.14 10.21 14.32 13.13 4 40 12.73 11.67 16.36 15.00 4.5 45 14.32 13.13 18.41 16.88 5 50 15.91 14.59 20.46 18.75

(f) The above table can be used for any 10% granular material, including Eptam, Ro-Neet, Tillam, Avadex, Pre-Beta I and II. Double the above

gran-ular weight for Treflan 5% granular.

SEQUENCE APPLICATIONS

Several herbicide sequences are suggested for grower use in

1972. These are designed particularly for growers participating in the program of weed-free beets. Participants in chemical weeding should

expect crop suppression and in some instances some stand reduction depending on conditions. Proper and timely herbicide applications

can be expected to substantially reduce or eliminate labor costs. Growers should apply a preplanting herbicide in all sequences (except on problem soils), then follow with a postplanting herbicide either postemergence or layby or both. Examples follow:

Table 7. Some Herbicide Sequences for 1972. (g)

Herbicide and Sequence Ro-Neet-Eptam Ro-Neet- Betanal Ro-Neet-Pyramin + Dowpon Pre-Beta 11- Treflan Ro-Neet-Betanal-Eptam Dosage Range Lb/A 2.5 to 4-2 to 3 2.5 to 4-0.75 to 1 2.5 to 4-3 + 2 to 4 + 2.25 2.5 to 5-0.5 to 0.75 2.5 to 4-0.75 to 1-2 to 3 (g) Usage rates for each dose given are shown in Tables 4-6.

Spray Delivery For Best Results

For best preplanting and postemergence results, we suggest you use 15-20 gallons of solution per acre unless otherwise specified on the label. Even spray nozzles are preferable when

band-spraying pre-emergence or post-emergence herbicides.

Herbicide Applicator Calibrations: Total coverage formula:

The field procedure to use,

1. Select nozzles, spraying pressure and tractor speed. Test each nozzle tip for 2-minute flow output. Discard tips with greater than 5% ± error.

2. Fill spray tank completely with water.

3. Spray water over measured distance of 660 feet in a fitted field.

4. Measure and record the amount of water needed to refill the tank.

5. Then,

gallons sprayed in 660 ft. x 66

gpa

=

---spray pattern width in ft.

6. Add recommended amount of herbicide to enough water to

make the spray quantity (gpa) calculated. 7. Test for accuracy and spray output.

(Continued) 17

Band spraying formula: The field procedure to use:

1. Consult Table 10 for selected sprayer unit settings (30 psi, 3.0 mph, and 8002E nozzle tips).

2. Test each nozzle tip for 2-minute flow output at 30 psi with

8002E nozzzle tips. Discard tips with greater than 5% ± error.

3. Fill tank completely with water.

4. Then:

Fl. oz. per nozzle per min. x 46.4

gpa

=

mp x nozz e spacing h I . . in inc . h es5. Gallons per acre (gpa) for ?-inch bands at 22- and 24-inch row-spacings obtained from the results of item 4 above (see Table 8).

To compute refill quantities of herbicides, use the following for-mula: Quantity of herbicide to add

=

gallons of water added to spray tank + gpa x band-acre rate of material (Table 4).To calculate the quantity of liquid, wettable powder or granular herbicide to purchase, use the following formula:

Quantity of herbicides to purchase

=

band-acre rate in ounces per acre of material x acres + 16 or 128 (to obtain pounds or gallons). The band-acre rate=

the band-acre factor x total coverage dos-age. The band-acre factors for the ?-inch band width and 22- and 24-inch row spacings are: 7 / 22=

.32; 7 / 24=

.29.Table 8. Delivery Rates of Nozzle Tips at Various Pressures and Ground Speeds

Nozzle Gallons per acre (gpa) at:

Tip, Liquid Nozzle

Teejet Pressure k;apacity 2.5 mph 3.0 mph

or

Delavan psi fom 22" 24" 22" 24"

80015E 20 14.1 11.9 10.9 9.9 9.1 ES4-80 30 16.6 14.0 12.8 11.7 10.7 40 19.2 16.2 14.9 13.5 12.4 8002E 20 17.9 15.1 13.8 12.6 11.5 ES5-80 30 21.8 18.4 16.9 15.3 14.1 40 25.6 21.6 19.8 18.0 16.5 8003E 20 26.9 22.7 20.8 18.9 17.3 ES6-80 30 33.3 28.1 25.8 23.4 21.5 40 38.4 32.4 29.7 27.0 24.8 18 3.5 mph 22" 24" 8.5 7.8 10.0 9.2 11.6 10.6 10.8 9.9 13.1 12.0 15.4 14.4 16.2 14.9 20.1 18.4 23.1 21.2

8004E 20 35.8 30.2

ES7-80 30 44.8 37.8

40 51.2 43.2

gpa = gallons per acre

tom = fluid ounces per minute

Band-granular formula: 27.7 34.7 39.6 25.2 23.1 21.6 19.8 31.5 28.9 27.0 24.7 36.0 33.0 30.9 28.3

psi = pounds per square inch mph= miles per hour

Calibration gauges are supplied with the Noble and Gandy granu-lar applicators. These gauges are useful in checking the accuracy of application rates.

The field procedure to use,

1. Adjust spout setting on applicator units to estimated output given by the manufacturer. Fill hoppers with granules. 2. Set tractor speed consistent with normal planting speed. 3. Operate over a measured distance of 900 ft. in a fitted field.

Collect the granules discharged in suitable containers at-tached beneath all the delivery openings (spouts).

4. Weigh the granules discharged by each spout individually and

adjust each spout to deliver the quantity given in item 6 below.

5. Band rates given in Table 6 were calculated as follows,

lb/ A granu I ar

=

.

43560.

X lb. granular used-band width in ft. X 6 (rows) X 900 ft. travel lb/ A active

=

lb/ A granular X 10%6. Band delivery rates for 10% granular materials.

7 Inch Band

22", 24" or any row spacing

Broadcast 900 Ft.

Rate 22" rows 24" rows Travel 396 Ft. Travel (a) lb.I Acre

Active lb. Per lb. Per Oz. Per Oz. Per

Ingredient Acre Acre Spout Spout

2.5 7.95 7.30 4.82 2.12 3.0 9.55 8.75 5.78 2.54 3.5 11.1 10.2 6.74 2.97 4.0 12.7 11.7 7.70 3.38 4.5 14.3 13.l 8.66 3.80 5.0 15.9 14.6 9.63 4.23

(a) 61.5 Arches= 396 Ft., 6 rows x 22 in. x 396 Ft. = 1/ 10 Acre

(b) For RoNeet 10% Granular Material Only

19 Madison Gauge (b) 3.65 4.30 5.00 5.60 6.30 7.00

Approximate Meter Settings for RONEET 10% G. ONLY 7" Band· 22" Rows

Lb. Per Acre 6 lb. 8 Lb. 10 Lb.

Gandy, 1 Box for 2 rows 11 15 17

J. Deere, 1 Box per row 1-25 1-27 1-29

Noble, 1 Box for 2 rows 6 8 10

Imperial, 1 Box for 2 rows 6 8 10

7. Test for accuracy and band rate delivery.

Always read and follow the instructions which the manufacturer has printed on the presticide label. This will give you further information on how to apply the chemical and on conditions which will affect results. This can save you money and help prevent crop damage.

Check the delivery rate of granular often. Changes in humidity and temperature change the rate of application. Do not change from chemical to chemical without calibration.

PLANTING

·

Great Western Hybrid Sugarbeet SeedGreat Western hybrid su~arbeet seed has proven itself in the

field in recent years. The high production level presently attained by

Great Western growers is due in large part to highly productive

vari-eties. The MONO-HY brand of Great Western hybrid seed was

intro-duced in 1971 as another step in achieving the ultimate in

produc-tivity.

A choice between MONO-HY and hybrid blend will be offered over

a large part of the Great Western territory in 1972 and it is expected

that MONO-HY varieties will be available to all growers in 1973. A

variety to be given the MONO-HY brand must be superior for the area

where it is to be grown.

SEED QUALITY is being emphasized by Great Western. The newly

improved seed processing plant at Longmont makes it possible to

achieve even higher standards of seed quality. MONO-HY seed will

have a minimum of 90% germination and 90% singles and it is

ex-pected that actually the germination and singles will be nearer 95%.

Seed sizing and plantability are being investigated by a seed scientist

at the Agricultural Research Center. Strict new standards have been

set.

SEED COLORING for MONO-HY seed is new in 1972. The brilliant

fluorescent red seed will aid the grower to find his seed when cali-brating his drill, and when checking for emergence.

BOXES for MONO-HY SEED, also new in 1972, will make seed handling easier and minimize damage to containers.

A DIFFERENTIAL PRICE for the various sizes of seed is also new

in 1972. For the grower desiring to plant larger seed, a progressively

lower price per pound, according to size and seeds per pound, will

reduce his cost compared to previous years.

Planting rates for growers planning selective stand reduction

with electronic thinners should not exceed 5 seeds per foot. With

good conditions, a 4 seeds per foot rate will give best results.

All Great Western seed has been treated with Maneb for

protec-tion against seedling disease.

As a reminder, best results from u5ing Great Western hybrid

seed will be obtained by: (I) giving the drill proper maintenance,

(2) calibrating the drill for the seed drop wanted, and (3) planting

at a reasonable rate of speed-3 MPH or slower. 21

PLANT POPULATION

To get highest yields, the trend in all major row crops is toward higher plant population. Our definition of 100 per cent harvested stand (26,136 beets per acre) is conservative compared with European standards. Yet our beet stands rarely exceed ED per cent and usually

fall below 75. In many years, only about two-thirds of our beet land is working to capacity. Can we afford one "lazy" acre out of three? That's what the question really comes down to.

A stand of 120 to 140 beets after thinning should give maximum sugar and yield. How can we increase our stands? Once thinned, the stand can never be increased, while some losses always occur be-tween thinning and harvest. Therefore, our beet population must be established by every operation that precedes thinning and the thin-ning operation itself.

Keep in mind:

1. Early preparation enables early planting.

2. Check your drill for correct plates and operating condition. 3. Protect your crop against losses from wind, crust, insects and

other adverse factors.

4. We recommend 4 to 5 seeds per foot when farming for

ma-chine thinnning. Present selective thinning mama-chines do satis-factory work on 5 seeds per foot or less. Plant for your soil and climate conditions. Up to 8 seeds per foot may be planted

in extreme cases.

The following chart will help you to determine the amount of

seed to obtain from the company.

SEEDS Per Ft. 8 6 5* 4 3

ESTIMATED POUNDS OF BEET SEED REQUIRED PER ACRE

MONO-HY SEED SIZE

Spacing No. 1 No.2

For 22 Inch Rows

1.5" 2.5 3.2 2.011 1.9 2.4 2.5"* 1.6* 2.0* 3.0" 1.2 1.6 4.011 .93 1.2 22 No.3 4.2 3.1 2.6* 2.1 1.6

For 28 or 30 Inch Rows 8 1.5" 1.9 2.4 3.2 6 2.0" 1.4 1.8 2.4 5* 2.5"* 1.2* 1.5* 2.0* 4 3.0" .93 1.2 1.6 3 4.0" .70 .90 1.2

Approx. No. of seeds

per lb. 77,000 60,000 46,000

*Maximum seeding r>te recommended for electronic thinners.

WARNING

IF YOU'RE GOING FASTER THAN A LAZY WALK

YOU ARE PLANTING TOO FAST, REDUCING YOUR STAND AND LOSING PART OF THE BENEFIT OF YOUR MONO-HY SEED.

SEED SPACING FOR SUGARBEET PLANTERS

Seed Spacing Sprockets Special

Seeds/ft. Inches Driver Driven Notes

- -I

John Deere 70 & 71

8 1.5 22 20 72 cell 6 2.0 9 11 72 cell 5* 2.5* 9 14 72 cell 4 3.0 11 20 72 cell 3 4.1 9 22 72 cell Milton (Gears) ~ 8 1.5 9 - 180 cell 6 2.0 10 - 120 cell 5* 2.5* 8 - 120 cell 4 3.0 7 - 120 cell 3 4.0 7 - 90 cell I.H.C. No. 295 8 1.6 20 11 82 cell 6 2.0 20 14 82 cell 5* 2.6* 20 18 82 cell

4 2.9 equal equal 82 cell

SEED SPACING FOR SUGARBEET PLANTERS {Continued)

Seed Spacing Sprockets

Seeds/ft. Inches Driver Driven

I.H.C. No. 185 (82 cell)

8 1.6 20 22 6 2.1 14 20 5* 2.6* 11 20 4 2.9 11 22 3 3.9 14 22 Dahlman 8 1.5 22 12 6 2.0 30 22 5* 2.6* 30 19 4 3.1 30 22 3 3.8 22 30

Allis-Chalmers-70 Series {18x7 tire)

8 1.5 20 8 6 2.0 13 7 5* 2.5* 15 10 4 3.0 10 8 3 4.0 14 15 Special Notes 10-20 gears 10-20 gears 10-20 gears 10-20 gears 12-40 gears 152 notch 152 notcn 100 notch 100 notch 152 notch 72 cell 72 cell 72 cell 72 cell 72 cell

"'

NSEED SPACING FOR SUGARBEET PLANTERS {Continued)

Seed Spacing Sprockets

Special

Seeds/ft. Inches Driver Driven Notes

r

Allis-Chalmers-SO Series {18x7 tire)

8 1.5 17 7 72 cell 6 2.1 18 10 72 cell 5* 2.5* 18 12 72 cell 4 3.1 17 14 72 cell 3 4.1 10 11 72 cell Dempster-402-44 8 1.6 10 7 7 1.8 10 8 5.2 2.3 equal equal 4.5* 2.7* 10 12 4 3.0 10 13 Winslow, Centra-Flo 8 1.4 38 A-17 48 cell 6 2.0 51 8-34 48 cell 5* 2.5* 42 A-17 24 cell 4 3.0 51 A-17 16 cell 3 4.0 51 8-34 24 cell

*For Best Results with Electronic Thinners, Plant No More Than 5 Seeds per Foot (2½" Seed Spacing).

( 0 N

RECOMMENDED PLANTER PLATES FOR G. W. MONOGERM SUGARBEET SEED

Seed Size No. 1 No.2 No.3

J. Deere 8132988 8140158 8133048

Cell size 8/64 9/64 10/64

Plate thickness .083 .083 .105

False ring N4523DB* N4523DB* N4523DB*

Floor plate AD-10193 AD-10193 AD-10193

Star wheel N2701DB N2701DB N2701DB

Millon** 8.5x6/64 10x6/64 llx7 /64

Cell size** 8.5x6/64 10x6/64 llx7 / 64

Downspout** P-44 P-44 P-44

Ej. Blade** P-43A P-43A P43-A

I.H.C. 295 463-426-Rl 463-427-Rl 463-428-Rl

Cell size 8/64 9/64 10/64

Plate thickness .080 .090 .100

Filler ring 621-978-R31 621-978-R31 None

Filler plate 464-256-R91 464-256-R91 464-256-R91

Knock-out 3616AA 3616AA 3616AA

I.H.C. 185 463-426-Rl 463-427-Rl 463-428-Rl

Cell size 8/64 9/64 10/64

Plate thickness .080 .090 .100

Filler ring 624-793-Rll 624-793-Rll None

Filler plate 464-256-Rl 464-256-Rl 464-256-Rl

Knocker 3616AA 3616AA 3616AA

...

RECOMMENDED PLANTER PLATES FOR G. W. MONOGERM SUGARBEET SEED (Con't)

Seed Size

No. 1

No.2

No.3

Dahlman OA A B

Cell size Belt Belt Belt

A-Chalmers 344412 344325 344326

Cell size 8/64 9/64 10/64

Plate thickness .085 .085 .105

Filler ring 327117 327117 327117

False ring special special special

Knocker Peg tooth Peg tooth Peg tooth

Dempster 101-3-0391 101-3-0392 101-3-0393 Cell size 8/64 9/64 10/64 Plate thickness .070 .080 .100 Pressure plate 101-3-0397 101-3-0397 101-3-0397 Retaining ring 101-3-0396 101-3-0396 101-3-0396 Knocker roller 101-3-0362 101-3-0362 101-3-0362 Centra-Flo 101547-6*** 101547-7*** 101547-9*** Inner retainer 101517-5 101517-5 101517-2 Outer retainer 100144-2 100144-2 100144-3 Diaphram 100112-2 100112-2 100112-3 *B27053 is interchangeable.

**New style metering wheels have drilled holes on the center face of the wheel-Ejector blade mounted outside of wheel. Designed to drill best between 3 & 4 miles per hour.

***Number of cells in seed ring (16, 24 or 48)

00

DRILL CHECK LIST FOR GOOD SEED DISTRIBUTION

CHECK YOUR DRILL! 1. Check the hopper, drive, and planter condition.

2. Check the seed cut-off point to see that the pawls or other divid-ers fit the seed plate properly so there will be no :hance of double cell fill.

3. Make sure the plate fits properly and if a filler plate is required,

be sure it is installed.

4. If the drill is equipped with a star gear, be sure it is positioned

exactly over the ejection point.

5. Be sure disc furrow openers are clean and free to turn.

6. Be sure depth bands are clean and scraper is properly adjusted. A rule of thumb for planting depth is: Early seeding-shallow planting,¾" deep. Later planting-I" to 1¼" deep.

7. Check seed ejection tube to be sure there are no restrictibns to

cause the seed to leave the tube in an erratic pattern.

8. Be sure the row spacing is correct and equal, and the marker is correctly set.

9. Be sure the drill is properly lubricated.

10. After planting each day, clean out seed cans or hoppers and

dis-card foreign material, if any.

11. Make use of your agriculturist for checking the cell size of your

drill plates, especially after you have planted 50 acres and ex-pect to plant more.

12. Last and most important, be sure the seed number and the drill

plate are correctly matched. It's a good idea to turn each drill press and drive wheel one revolution and count the number of seeds per foot, before starting to plant.

INSECT CONTROL

I. Sugarbeet root maggotA. Insecticides labeled for sugarbeet root maggot control Group 1 (more effective): Temik

Group 2 : Diazinon and Thimet

Group 3 (less effective) : Dasanit and Vapotox (Colorado only) (Continued)

Control of sugarbeet root maggot is often obtained from Dy-fonate and Di-Syston when they are used for wireworm and aphid-leafhopper control, respectively.

B. Suggested insecticides for maggot control At Planting : Diazinon or Temik Post-Emergence, Thimet

Granular formulations are safer to handle and persist longer in the soil than liquid spray formulations of the same insecti-cides.

C. Rates of application for various insecticides

At Planting*

Light Med. Heavy

District Soils Soils Soils

N. C. Colorado 1

l¼

l½

Montana-Wyomingl¼

l½

l¾

*Lb. active ingredient per acre in a 5-tr 7-inch band.

D. Suggested application methods

N. C. Colorado

Post-Emergence•

Light Med. Heavy

Soils ~oils Soils

l¼

l½

l¾

l½

l¾

21. Best maggot control can be expected from use of

recom-mended insecticide applied in a 5- to 7-inch band and in -corporated to a depth of about 2 inches by means of a

power incorporator just prior to planting.

2. Satisfactory maggot control can be obtained from an in-secticide applied in a 5- to 7-inch band and lightly incor-porated to a depth of 1-inch by means of a Russ-Ken soil incorporator immediately before planting.

3. Less consistent results can be expected from an insecti-cide applied in a 5- to 7-inch band either between the planter and press wheel or behind the press wheel, and lightly incorporated to about ½ inch with tine scratchers. 4. Satisfactory maggot control can also be obtained from a

timely post-emergence treatment. A recommended insecti-cide should be applied in a 5- to 7-inch band over the row when flies are first seen and the beets are at least in the two true-leaf stage. The insecticide is lightly incorporated to a depth of about ½ inch with tine scratchers, open drag chain, or other suitable devices.

Montana-Wyoming

Maggot infestation is particularly heavy in the Powell area and control is accordingly difficult. However, studies indi-cate that a reasonable maggot control can be expected from power incorporation or post-emergence application as mentioned above (1-0-1 and 1-0-4).

II. Pale-striped flea beetle larva

There is no insecticide specifically registered for control of the larval stage of this insect. However, several insecticides that are used for maggot and wireworm control are effective against this

insect. (Diazinon for maggot and Oyfonate for wireworm control).

An insecticide must be applied at planting time in a 5- to 7-inch band and incorporated to at least 2 inches deep, preferably with a power incorporator, just prior to planting. The method is exactly the same as that described under 1-0-1 for maggot control.

Unfortunately there is no simple yet accurate way of predicting flea beetle larva infestation. Past history of infestation and gen-eral area of infestation are well known by the local Agricultur-ists. Preventative measures in these potential areas are the best method available at the present time.

Ill. Webworms

A. Suggested insecticides and rates Oylox ... .1 to 1½ lb. Al/acre Sevin ... 1½ lb. Al/acre B. Suggested application method

As soon as small worms are noticed on beet plants, spray the infested area or field with a recommended insecticide using either a ground sprayer or by air.

IV. Other insect pests

For control measures against a specific insect pest, growers are advised to consult their local Agriculturist.

V. Toxicity of insecticides to sugarbeet seedlings All soil insecticides are potentially injurious to beet seedlings when they are placed in direct contact with seeds or in high concentration close to the seed furrow.

(Continued) 31

A. Relative toxicity of selected soil insecticides to sugarbeet

seedlings

Registration Status on Sugarbeets Less injurious: Temik ... (For root maggot control) Diazinon ... (For root maggot control) Vapotox.. .. .. (For root maggot control in

Colorado only)

More injurious: Dasanit ... (For root maggot control) Di-Syston .. (For aphid and leafhopper

con-trol)

Dyfonate ... (For wireworm control) Thi met ... (For root maggot control) B. Suggestions to avoid chemical injury to sugarbeets.

1. Calibrate application equipment accurately. 2. Use no more than the recommended dosage.

3. For band application, use a 5- to ?-inch band and not in a narrow band of 1- to 2-inches.

4. Thoroughly mix the insecticide with the soil. Power incor-poration results in less injury to beet seedlings than other incorporation methods.

5. Combinations of insecticides and herbicides may damage crop seedlings particularly under certain adverse growing conditions.

·

IRRIGATION

Timely irrigation is the key to growing an optimum sugarbeet crop. Irrigate up as soon as possible in the absence of natural mois-ture. Sugarbeet seed will "store well"' in a cool dry place but will not grow there.

Moisture is a must to activate herbicides and keep your crop

growing at the fastest possible rate.

A new service available to beet growers in part of Great Western territory is Irrigation scheduling. Optimum time and rate of irrigation application is furnished to participating growers. Electronic com-puters are used to calculate the best timing for your individual fields. Ask your Agriculturist if this service is available near your farm.

MECHANICAL THINNING

Modern sugarbeet production requires the use of both chemical weed control and mechanical stand adjustment in order to minimize the need for hand labor and maintain high sugar production per acre. In recent years many Great Western growers have successfully shifted completely away from hand labor for thinning. Following proper and timely applications of pre-emergence (and if necessary, post-emergence) herbicides, selective thinners such as the John Deere, Eversman and Monomat, can work in variable germination stands and leave better stands than with hand thinning.

Proper operation of selective thinners requires that a field have: Good weed control.

Smooth, clod free soil in the row.

Beet plants growing no closer than 2 inches apart. Planting of 5 or less seeds per foot.

Steering guide marks at planting help. Cultivation that prepares for the thinner.

Consider the use of a random blocker or thinner if your field has a uniform stand of well spaced beets. Spring-time weeders used judiciously to remove weeds weakened by herbicides, as well as eliminating germinating weed seed, are good tools to use in con-junction with machine blockers or thinners. This will reduce plant competition and speed up the growth of the crop.

We recommend that all mechanically-thinned stands of beets contain at least 120 and up to 140 hills per 100 Ft. of row. It has been found that maximum yields are obtained on these machine-thinned populations.

SET YOUR FIELDS UP FOR MACHINE THINNING